Belts BMW 540i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 3 of 1002

Downloaded from www.Manualslib.com manuals search engine

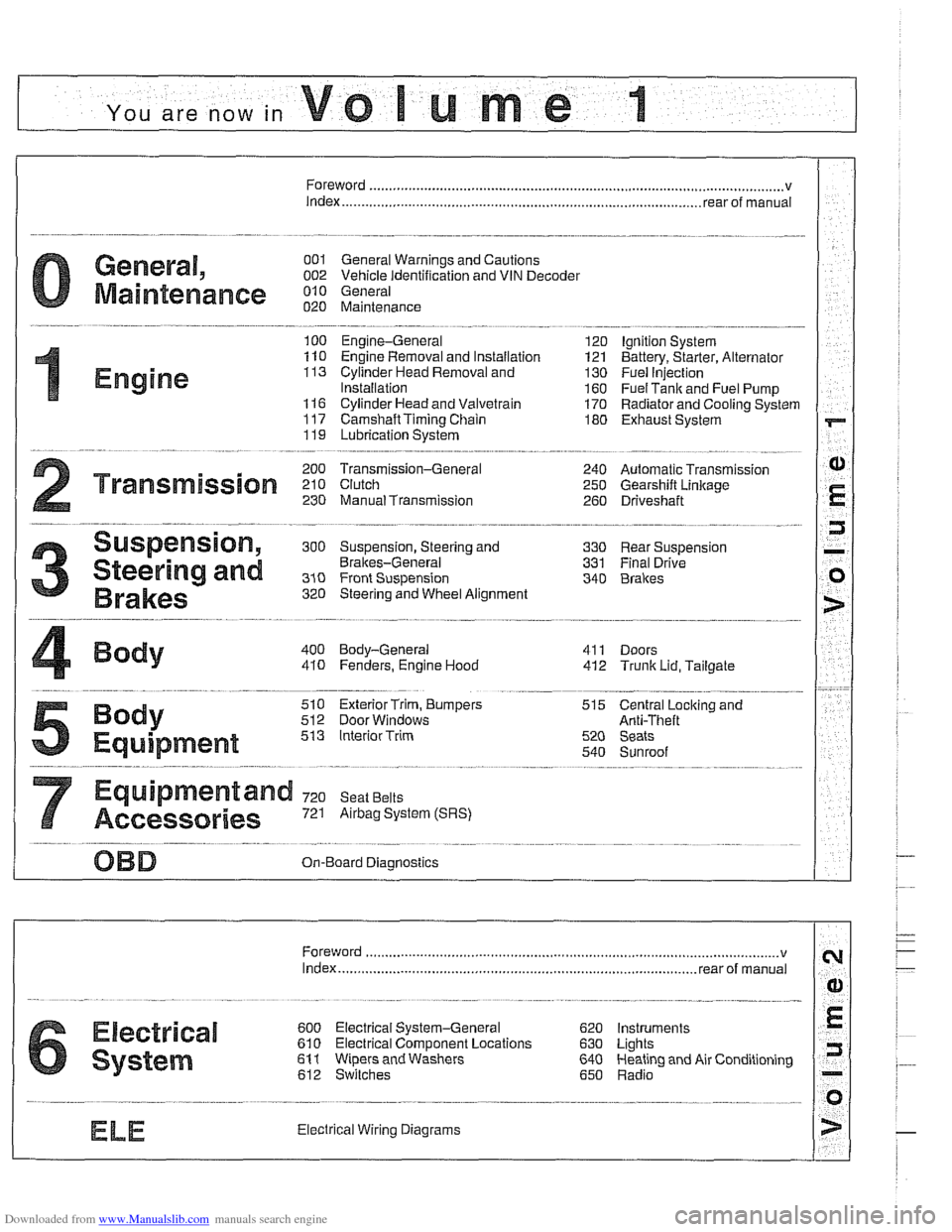

YOU are now in Volume I

I

Foreword ................... .. ........................................................................\

.......... v

Index

........................ .. ................................................................ rear of manual

General, 001 General Warnings and Cautions 002 Vehicle Identification and VIN Decoder

Maintenance OiO 020 Maintenance

Engine

100 Engine-General 110 Engine Removal and Installation

113 Cylinder Head Removal and

Installation

116 Cyiinder Head and Valvetrain 117 Camshaft Timing Chain

119 Lubrication System

200 Transmission-General

2 Transmission 210 clutch 230 ManualTransmission

I20 Ignition System

121 Battery, Starter, Alternator

130 Fuel Injection

160 Fuel Tank and Fuel Pump 170 Radiator and Cooling System

180 Exhaust System

240 Automatic Transmission

250 Gearshift Linkage 260 Driveshaft

Suspension, 300 Suspension, Steering and 330 Rear Suspension

Brakes-General 331 Final Drive

Steering and No Front Suspension 340 Brakes

320 Steering and Wheel Alignment

400 Body-General

410 Fenders, Engine Hood 411 Doors

412 Trunk Lid, Tailgate

510 Exterior Trim, Bumpers 512 Door Windows

Equipment 513 Interior Trim

7

Equipment and 720 seat Belts

Accessories 721 Airbag System (SRS)

OBD On-Board Diagnostics

. ............ ..

515 Central Lociting and

Anti-Theft

520 Seats 540 Sunroof

.................................................................... Foreword .............................. .. v

Index ................... .. ................................................................ rear of manual

Electrical

6 system

600 Electrical System-General 620 Instruments

610 Electrical Comoonent Locations 630 Liohts

611 wipers and washers 612 Switches eati in^ and Air Conditioning

Radio

. ........... ........ .........................

Electrical Wiring Diagrams

Page 9 of 1002

Downloaded from www.Manualslib.com manuals search engine

002 Vehicie identification and

VlN Decoder

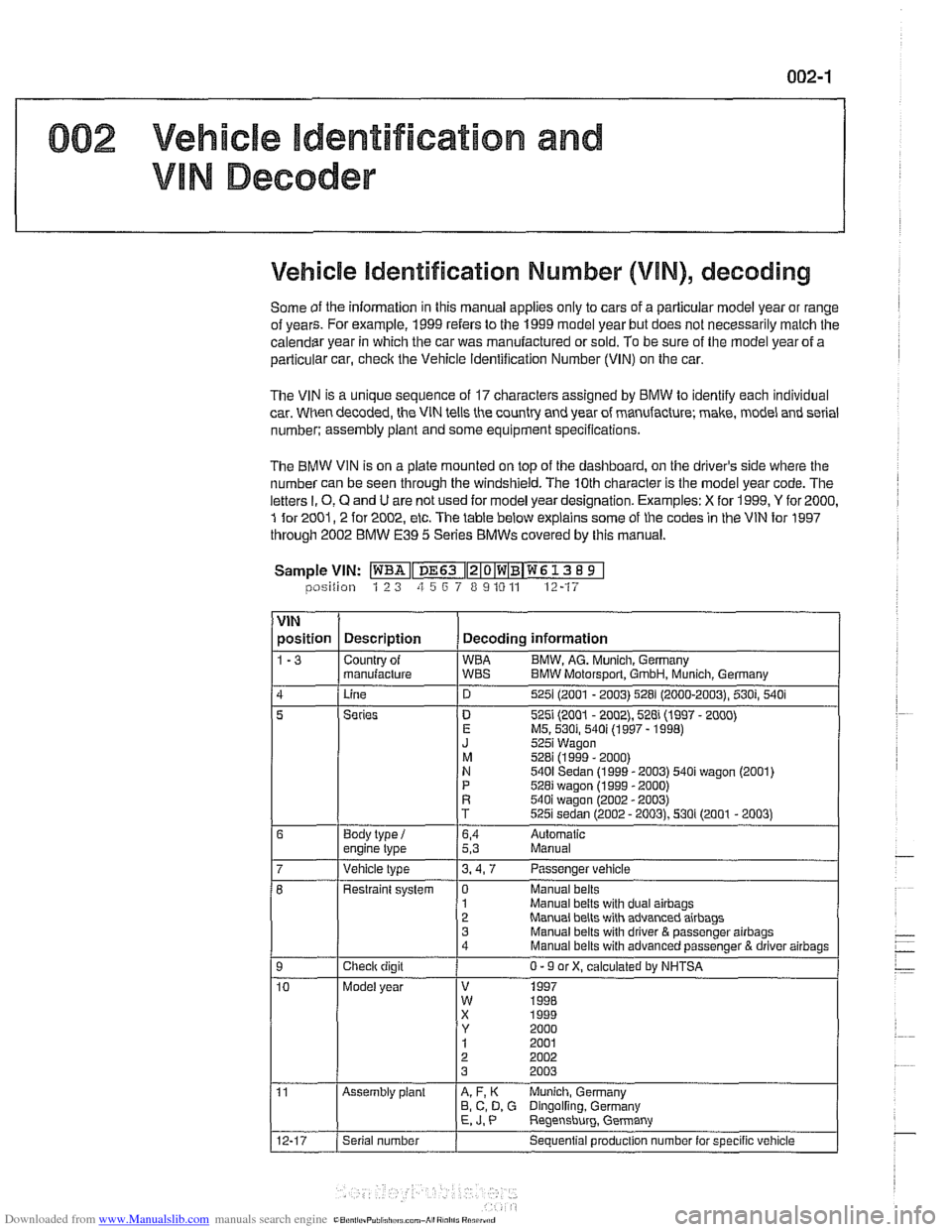

Vehicle identification Number (VIN), decoding

Some of the information in this manual applies only to cars of a parlicuiar model year or range

of vears. For

examole. 1999 refers to the 1999 model vear but does not necessarilv malch the

caiendsr year in which the car was manufactured or sold. To be sure of the model year of a

particular car,

checic the Vehicle ldentification Number (VIN) on the car.

The VIN is a unique sequence of 17 characters assigned by BMW lo identify each individual

car. When decoded, the VIN tells the country and year of manufacture; make, model and serial

number: assembly

plant and some equipment specifications.

The BMW VIN is on a plate mounted on top of the dashboard, on the driver's side where the

number can be seen through the windshield, The 10th character is the model year code. The

letters

I. 0, Q and U are not used for model year designation. Examples: X for 1999, Y for 2000,

1 for 2001,2 for 2002, etc. The table below explains some of the codes in the VIN for 1997

through 2002 BMW

E39 5 Series BMWs covered by this manual.

Sample

VIN: ~~Iz~o~w~B~w~ 13 8 9 1 lposition 1 2 3 zi 5 6 7 8 9 10 11 12-17

VIN

position Description Decoding information

1-3 Countrv of WBA B

I J 1 znan~+q ;BT BMW Molorsporl. Gmon, ~;nch Gerrn;!n,

Linc 525 (2UU1 - 2003) 528 (2000-2003. 530; 540 i

5

1

Manual belts with dual airbags Manual belts with advanced airbaos

Series

Body

type

i engine lype . ..

D 5251 (2001 - 2002), 528i (1997 - 2000) E MS. 530i, 540i (1997 - 1998) J 5251 Wagon

M 528i (1999 - 2000) N 5401 Sedan (1999 - 2003) 540i wagon (2001)

P 528i wagon (1999 - 2000) R 540i waaon 12002 - 20031

6,4 Aulomatic 5,3 Manual

Vehicle type 3.4.7 Passenger vehicle

Checlr digit

Model year Restraint

system

1 0 Manual belts

3 Manual belts wilh driver

& passenger airbags 4

Manual belts with advanced passenger B driver airbags

0 - 9 or X, calculated by NHTSA

V 1997 W 1RRR

Assembly plant A, F, K Munich, Germany

B, C, D, G Dingolfing. Germany E, J. P Reqensburq. Germany .

Serial number

Sequential produclion number lor specific vehicle

Page 14 of 1002

Downloaded from www.Manualslib.com manuals search engine

.

General

WARNING-

Never run the engine in tile work area unless it is well-ven-

tilated. The exhaust should be vented to the outside. Car-

bon monoxide (CO) in exhaust kills.

Remove all neckties,

scarfs, loose clothing, or jewelry

when working near a running engine or power tools.

Tuck in shirts. Tie long hair and secure it under a cap.

Severe injury can result from these things being

caugiit

in rotating parts.

Remove rings, watches, and bracelets. Aside from the

dangers of moving parts, metallic jewelry conducts

electricity and may cause shorts, sparks, burns, or

damage to the electricalsystem when accidentally con-

tacting the battery or other electrical terminals.

Disconnect the battery negative

(-) cable whenever

working on or near the fuel system or anything that is

electrically powered. Accidental electrical contact may

damage the electrical system or cause a fire.

Fuelis highly flammable. When working around fuel, do

not

smoke or work near heaters or other fire hazards.

Keep an approved fire extinguisher handy.

The fuel system is designed to retain pressure even

when the ignition is off When worlcing with the

fuelsys-

tem, loosen the fuel lines slowly to allow the residual

pressure to dissipate gradually. Take precautions to

avoid spraying fuel.

. Illuminate the worlc area adequately and safely Use a

portable safety light for worlcing inside or under the car.

A fluorescent type

light is best because it gives off less

heat. If using a light with a normal incandescent bulb,

use rough service bulbs to avoid

breakage. The hot fil-

ament of an accidentally broken bulb can ignite spilled

fuel or oil.

Keep sparks, lighted matches, and any open flame

away from the top of the battery. Hydrogen gas

emitted

by the battery is highly flammable. Any nearby source

of ignition may cause the battery to explode.

Never lay

tools or parts in the engine compartment or

on top of the battery. They may

fallinto confinedspaces

and be difficult to retrieve, become caught in belts or

other rotating parts when the engine is started, or

cause electrical shorts and damage to the electrical

system.

Page 33 of 1002

Downloaded from www.Manualslib.com manuals search engine

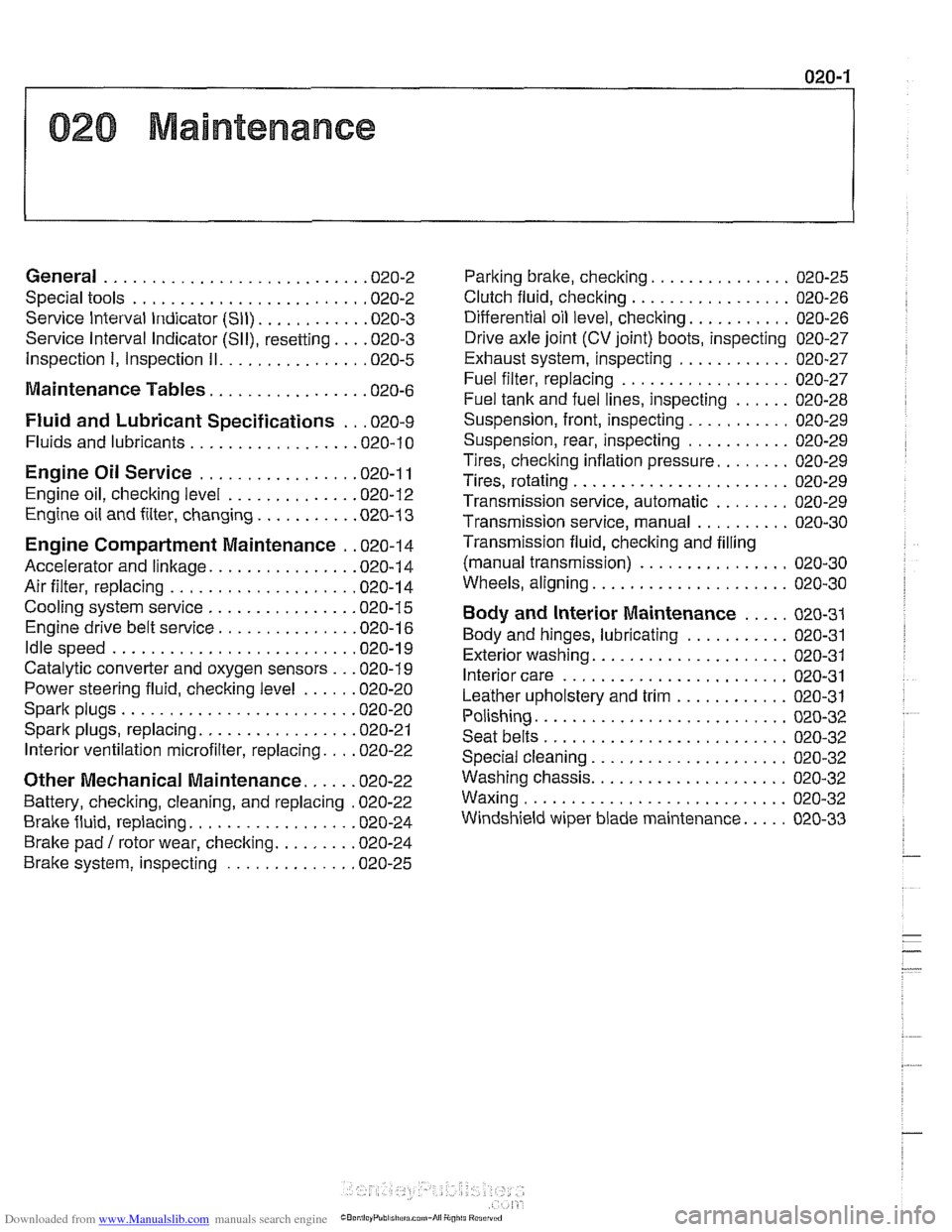

020 Maintenance

General ........................... .02 0.2

Special tools ........................ .02 0.2

Service Interval Indicator (Sll) ........... .02 0.3

Service Interval Indicator (Sll), resetting ... .02 0.3

Inspection I, Inspection 11 ............... .02 0.5

Maintenance Tables ................ .02 0.6

Fluid and Lubricant Specifications .. .02 0.9

Fluids and lubricants ................. .02 0.10

Engine Oil Service ................ .02 0.1 I

Engine oil. checking level ............. .02 0.12

Engine oil and filter. changing .......... .02 0-13

Engine Compartment Maintenance . .02 0.14

Accelerator and linkage ............... .02 0.14

Air filter. replacing ................... .02 0.1 4

Cooling system service ............... .02 0.15

Engine drive belt service .............. .02 0.16

Idlespeed .......................... 020-19

Catalytic converter and oxygen sensors .. .02 0.19

Power steering fluid, checking level ..... .02 0.20

Spark plugs ........................ .02 0.20

Spark plugs, replacing ................ .02 0.21

Interior ventilation microfilter, replacing ... .02 0.22

Other Mechanical Maintenance ..... .02 0.22

Battery, checking. cleaning. and replacing .02 0-22

Brake fluid. replacing ................. .02 0-24

Brake pad 1 rotor wear. checking ........ .02 0.24

Brake system, inspecting ............. .02 0.25

Parking brake. checking ............... 020-25

Clutch fluid. checking ................. 020-26

Differential oil level. checking ........... 020-26

Drive axle joint (CV joint) boots. inspecting 020-27

Exhaust system. inspecting ............ 020-27

Fuel filter. replacing .................. 020-27

Fuel tank and fuel lines. inspecting ...... 020-28

Suspension. front. inspecting ........... 020-29

Suspension. rear. inspecting ........... 020-29

Tires. checking inflation pressure ........ 020-29

Tires. rotating ....................... 020-29

Transmission service. automatic ........ 020-29

Transmission service. manual .......... 020-30

Transmission fluid. checking and filling

(manual transmission)

................ 020-30

Wheels. aligning ..................... 020-30

Body and Interior Maintenance ..... 020-31

Body and hinges. lubricating ........... 020-31

Exterior washing ..................... 020-31

Interior care ........................ 020-31

Leather upholstery and trim ............ 020-31

Polishing ........................... 020-32

Seat belts .......................... 020-32

Special cleaning ..................... 020-32

Washing chassis ..................... 020-32

Waxing ............................ 020-32

Windshield wiper blade maintenance ..... 020-33

Page 48 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-1 6

Maintenance

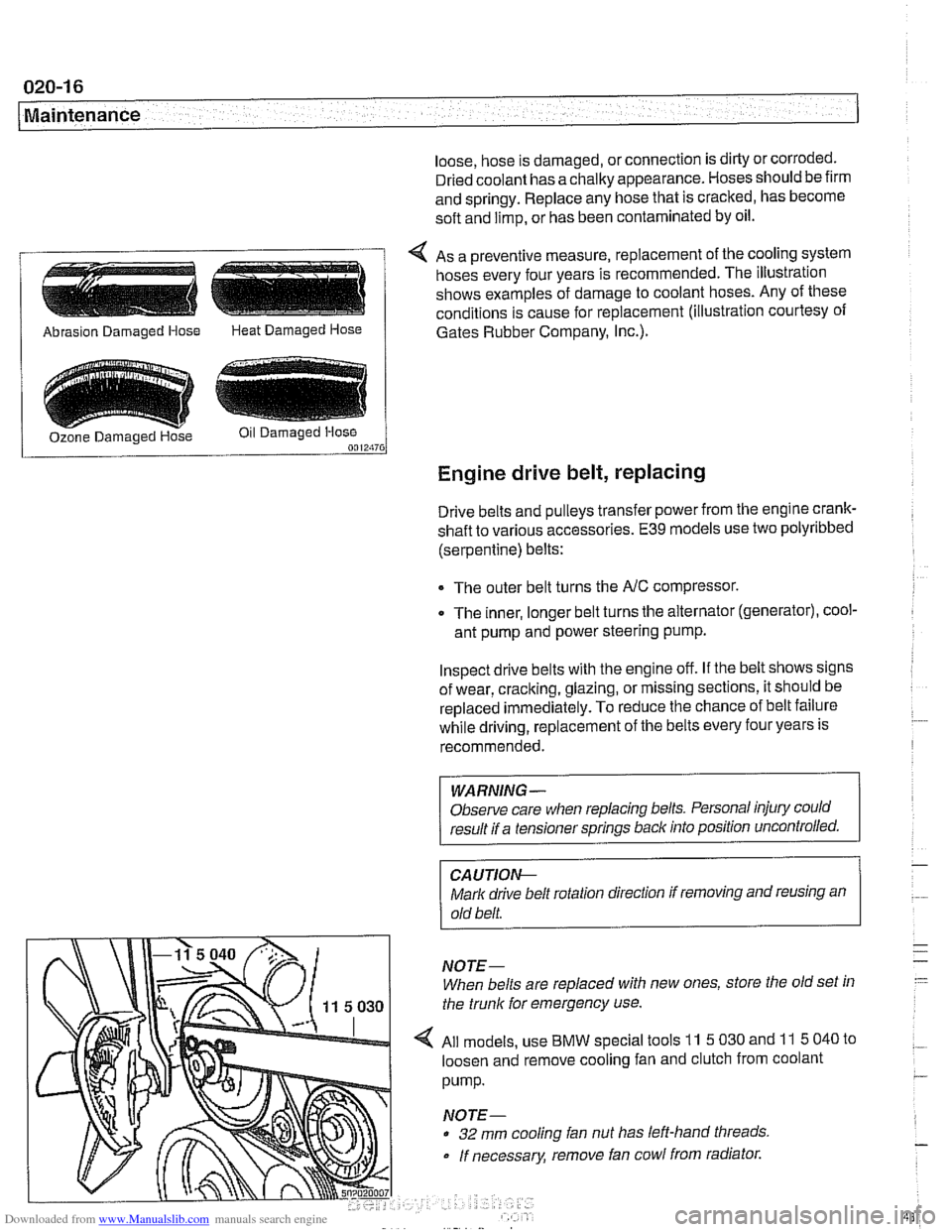

loose, hose is damaged, or connection is dirty or corroded.

Dried coolant has achalky appearance. Hoses should be firm

and springy. Replace any hose that is cracked, has become

soft and limp, or has been contaminated by oil.

4 As a preventive measure, replacement of the cooling system

hoses every four years is recommended. The illustration

shows examples of damage to coolant hoses. Any of these

conditions is cause for replacement (illustration courtesy of

/ Abrasion Damaged Hose Heat Damaged Hose 1 Gates Rubber Company, I~c.).

Engine drive belt, replacing

Drive belts and pulleys transfer power from the engine crank-

shaft to various accessories.

E39 models use two polyribbed

(serpentine) belts:

The outer belt turns the

NC compressor.

0 The inner, longer belt turns the alternator (generator), cool-

ant pump and power steering pump.

Inspect drive belts with the engine off. If the belt shows signs

of wear, cracking, glazing, or missing sections, it should be

replaced

immediately. To reduce the chance of belt failure

while driving, replacement of the belts every four years is

recommended.

WARNING -

Observe care when replacing belts. Personal injury could

result if a tensioner springs back into position uncontrolled.

CA UTIOI\C

Mark drive belt rotation direction if removing and reusing an

old belt.

NOTE-

When belts are replaced with new ones, store the old set in

the trunk for emergency use.

All models, use

BMW special tools 11 5 030 and 11 5 040 to

loosen and remove cooling fan and clutch from coolant

pump.

NOTE-

32 mm cooling fan nut has left-hand threads

If necessary, remove fan cowl from radiator.

Page 64 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-32

Maintenance

using a soft cloth. Regular use of a good quality leather condi-

tioner will reduce drying and cracking of the leather.

Polishing

Use paint polish only if the finish assumes a dull loolc afler

long service. Polish can be used to remove tar spots and tar-

nish, but

afleiwards a coat of waxshould be applied to protect

the clean finish. Do not use abrasive polish or cleaners on

aluminum trim or accessories.

Seat belts

Dirt and other abrasive particles will damage seat belt web-

bing. If it is necessary to clean seat belts, use a mild soap so-

lution. Bleach and other strong cleaning agents may weaken

the belt webbing and should be avoided.

WARNING-

Do not clean the seat belt webbing using dry cleaning or oth-

er chemicals. Allow wet belts to

dry before allowing them to

retract.

-

The condition of the belt webbing and the function of the re-

tractor mechanisms should be inspected. See

720 Seat Belts

for seat belt inspection information.

Speciai cieaning

Tarspots can be removed with a bug and tar remover. Never

use gasoline,

lterosene, nail polish remover, or other unsuit-

able solvents. Insect spots also respond to tar remover.

A bit

of baking soda dissolved in the wash water will facilitate their

removal. This method can also be used to remove tree sap

spots.

Washing chassis

Periodic washing of the underside of the car, especially in

winter, will help prevent accumulation of road salt and rust.

The best time to wash the underside is just afler the car has

been driven in wet conditions. Spray the chassis with a pow-

erful jet of water. Commercial or self-service carwashes may

not be bestforthis, as they may recycle the salt-contaminated

water.

Waxing

For a long-lasting, protective, and glossy finish, apply a hard

wax after the car has been washed and dried. Use carnauba

or synthetic based products. Waxing is not needed after

every washing. You can tell when waxing is required by

look-

Page 85 of 1002

Downloaded from www.Manualslib.com manuals search engine

Engine Removal and Installation

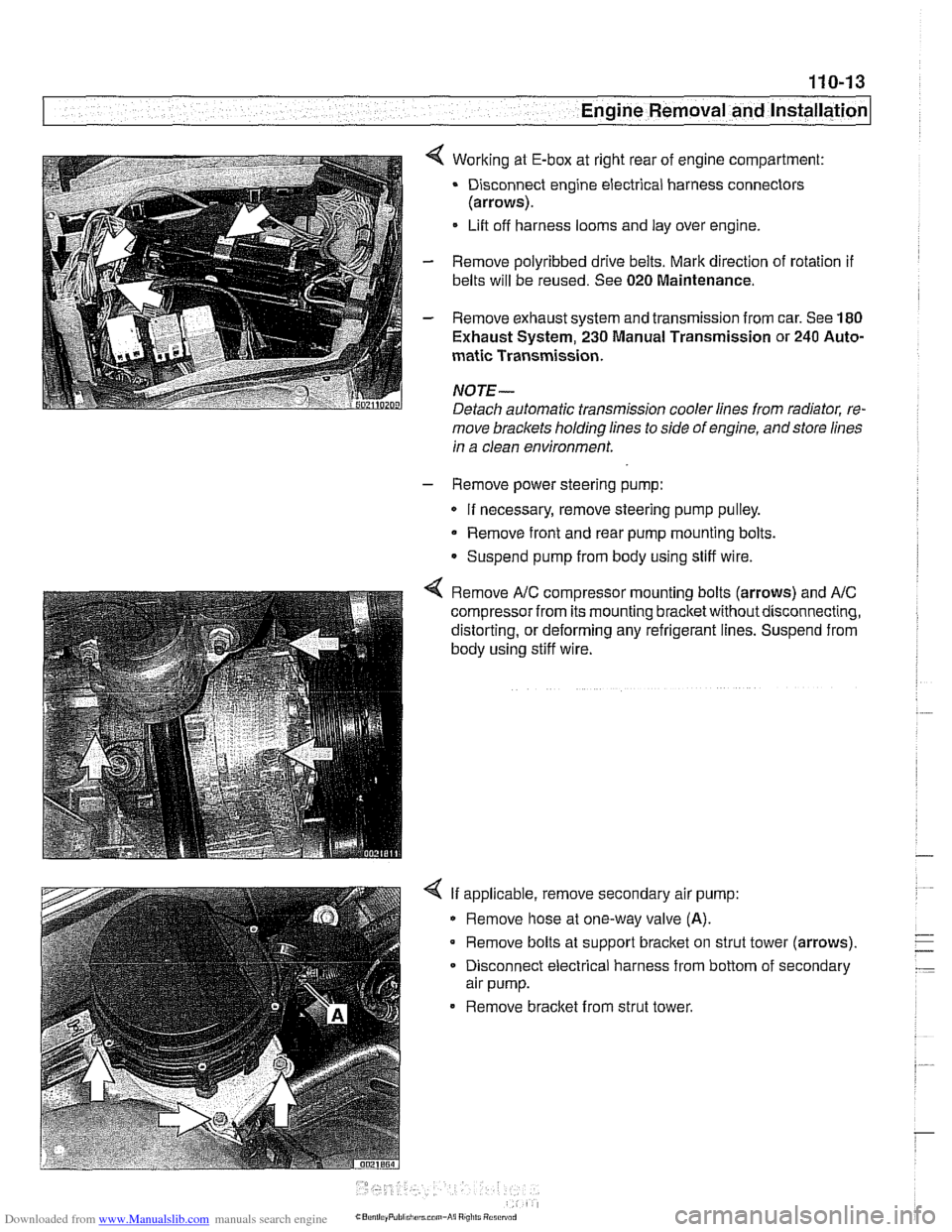

4 Working at E-box at right rear of engine compartment:

Disconnect engine electrical harness connectors

(arrows).

Lift off harness looms and lay over engine.

- Remove polyribbed drive belts. Mark direction of rotation if

belts will be reused. See 020 Maintenance.

- Remove exhaust system and transmission from car. See 180

Exhaust System, 230 Manual Transmission or 240 Auto-

matic Transmission.

NOJE-

Detach automatic transmission cooler lines from radiator, re-

move brackets holding lines to side of engine, andstore lines

in a clean environment.

- Remove power steering pump:

If necessary, remove steering pump pulley.

Remove front and rear pump mounting bolts.

Suspend pump from body using stiff wire.

4 Remove A/C compressor mounting bolts (arrows) and AIC

compressor from its mounting bracketwithoutdisconnecting,

distorting, or deforming any refrigerant lines. Suspend from

body using stiff wire.

4 If applicable, remove secondary air pump:

Remove hose at one-way valve

(A).

Remove bolts at support bracket on strut tower (arrows).

- Disconnect electrical harness from bottom of secondary

air pump.

Remove bracket from strut tower.

Page 87 of 1002

Downloaded from www.Manualslib.com manuals search engine

110-15

Engine Removal and lnstallation

- Installation is reverse of removal, noting the following:

Replace all gaskets. O-rings and seals.

Use new fuel injector seals

Check that engine drive belts properly engage pulley

grooves.

Inspect O-ring seal between mass air flow sensor and air

filter housing. To facilitate reassembly, coat seal with acid-

free grease.

Change engine oil and filter and

check all other fluid levels.

See

020 Maintenance.

Refill and bleed cooling system. See

170 Radiator and

Cooling System.

CAUTION--

When reattaching throttle assembly harness connectoc con-

nector is

fuNy tightened when arrows on connector and plug

line up.

Tightening torques

Coolant drain plug to cylinder block

25 Nm (18 ft-lb)

Engine mount to

subframe (M10) 45 Nm (33 ft-ib)

Exhaust manifold to cylinder head

M6 10 Nm (89 in-lb)

M7 or ME 20 Nm (15 ft-lb)

Intake manifold to cylinder head

M7 15 Nm (I 1 ft-lb)

ME 22 Nm (16 ft-lb)

Radiator cooling fan to coolant pump

40 Nm (30 ft-lb)

Radiator drain screw to radiator

2.5 Nm (22 in-lb)

Page 93 of 1002

Downloaded from www.Manualslib.com manuals search engine

--

-- Engine Removal and installation' -

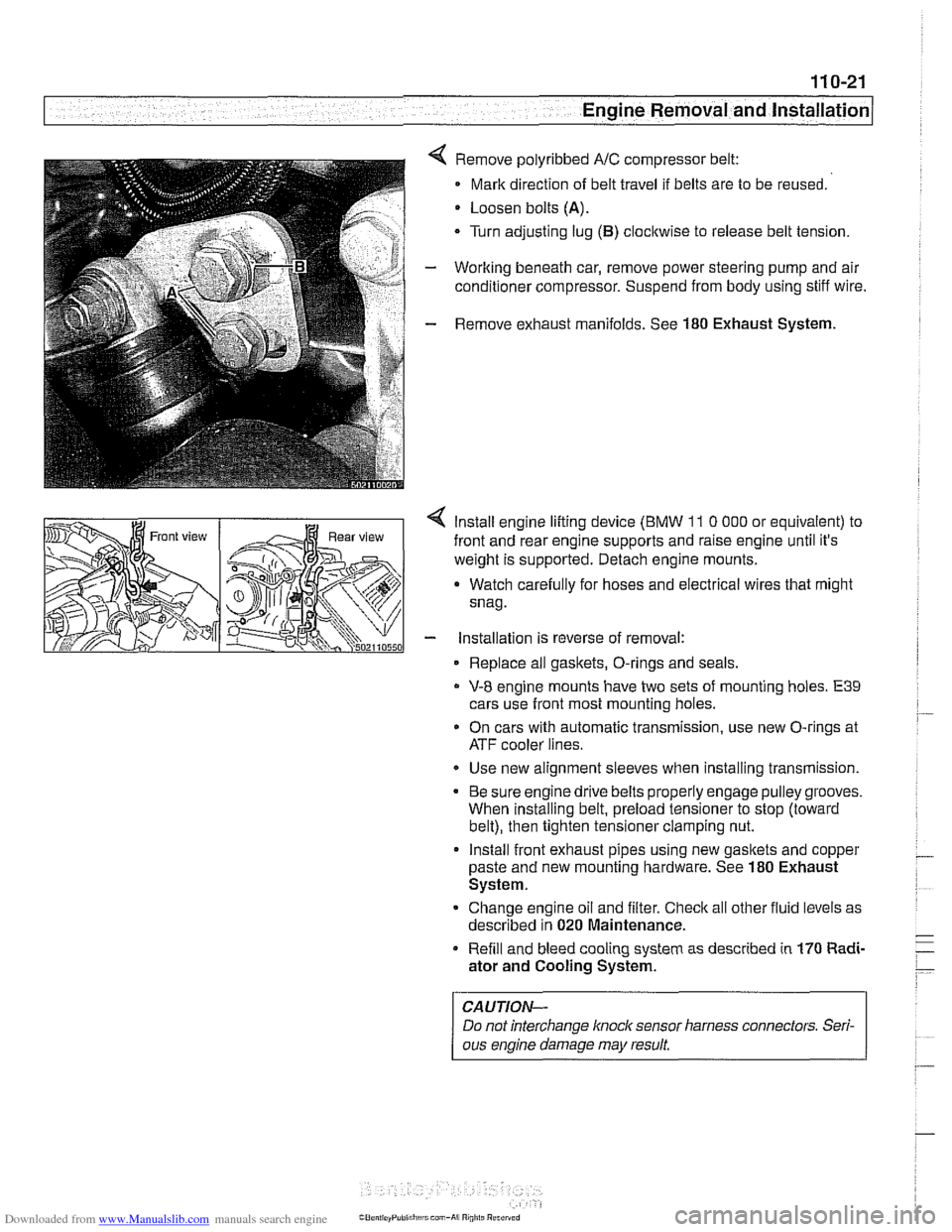

Remove polyribbed A/C compressor belt:

Mark direction of belt travel if belts are to be reused.

Loosen bolts

(A).

Turn adjusting lug (B) clocltwise to release belt tension.

Working beneath car, remove power steering pump and air

conditioner compressor. Suspend from body using stiff wire.

Remove exhaust manifolds. See

180 Exhaust System.

< lnstall engine lifting device (BMW 11 0 000 or equivalent) to

front and rear engine supports and raise engine until it's

weight is supported. Detach engine mounts.

a Watch carefully for hoses and electrical wires that might

snag.

- installation is reverse of removal:

Replace all gaskets, O-rings and seals.

V-8 engine mounts have two sets of mounting holes. E39

cars use front most mounting holes.

* On cars with automatic transmission, use new O-rings at

ATF cooler lines.

Use new alignment sleeves when installing transmission.

Be sure engine drive belts properly engage pulley grooves.

When installing belt, preload tensioner to stop (toward

belt), then tighten tensioner clamping nut.

lnstall front exhaust pipes using new gasltets and copper

paste and new mounting hardware. See

180 Exhaust

System.

Change engine oil and filter. Check all other fluid levels as

described in

020 Maintenance.

Refill and bleed cooling system as described in

170 Radi-

ator and Cooling System.

CAUTION-

Do not interchange knoclc sensor harness connectors. Seri-

ous engine damage may result

Page 124 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cylinder Head Removal and installation - - .- - - - -

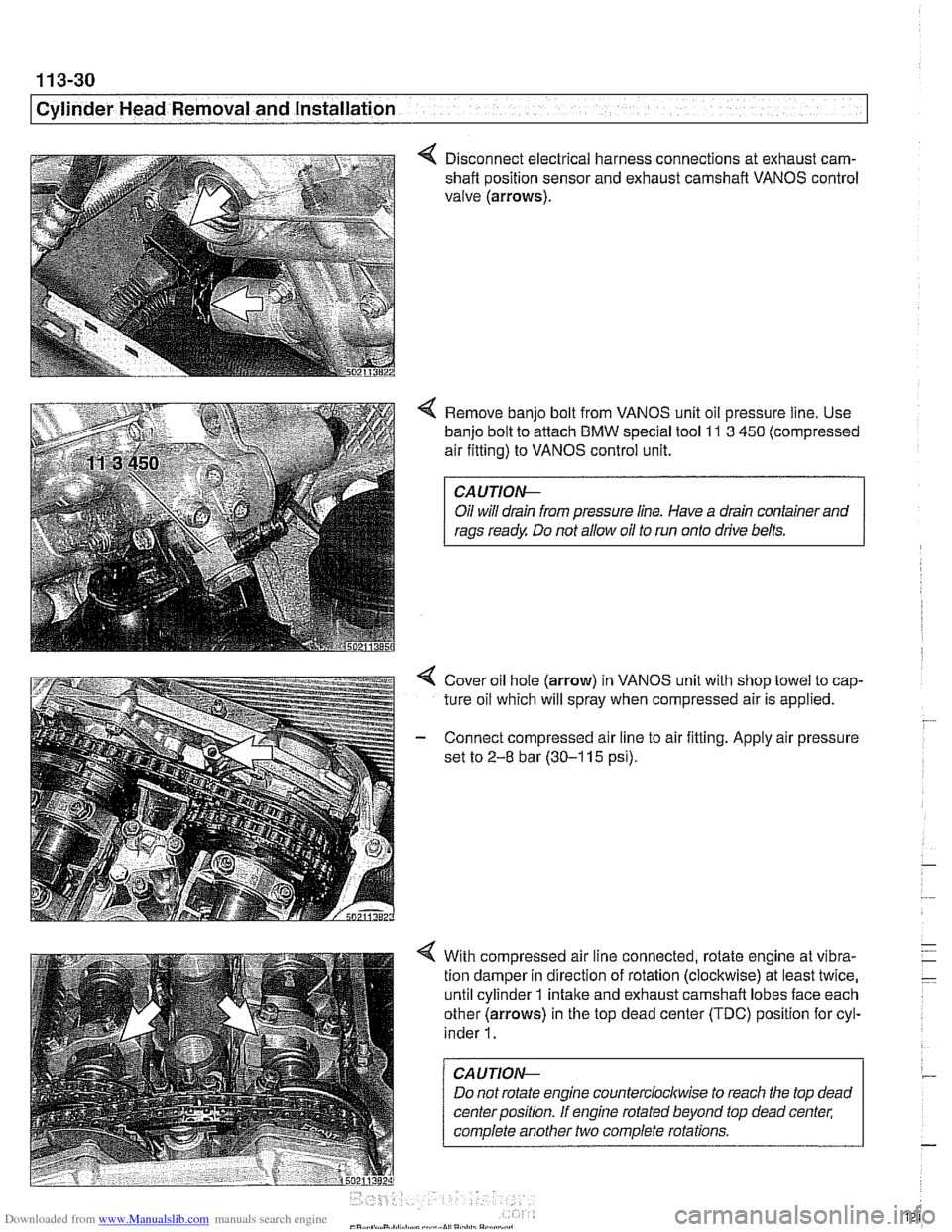

4 Disconnect electrical harness connections at exhaust cam-

shaft position sensor and exhaust camshaft VANOS control

valve (arrows).

4 Remove banjo bolt from VANOS unit oil pressure line. Use

banjo bolt to attach

BMW special tool 11 3 450 (compressed

air fitting) to VANOS control unit.

CAUTIOI\C

Oil will drain from pressure line. Have a drain container and

rags ready Do not allow oil to run onto drive belts.

4 Cover oil hole (arrow) in VANOS unit with shop towel to cap-

ture oil which will spray when compressed air is applied.

- Connect compressed air line to air fitting. Apply air pressure

set to

2-8 bar (30-1 15 psi).

4 With compressed air line connected, rotate engine at vibra-

tion damper in direction of rotation (clockwise) at least twice,

until cylinder 1 intake and exhaust camshaft lobes face each

other (arrows) in the top dead center (TDC) position for cyl-

inder

1.

CAUTION--

Do not rotate engine counterclocltwise to reach the top dead

center position. If engine rotated beyond top dead center;

complete another two complete rotations.