stop start BMW 540i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 29 of 1002

Downloaded from www.Manualslib.com manuals search engine

General

Cars with discharged or dead batteries can be jump-started

using the good battery from another car. See owner's manual

for proper instruction on jump starting. When jump-starling

the engine, always note the following warnings.

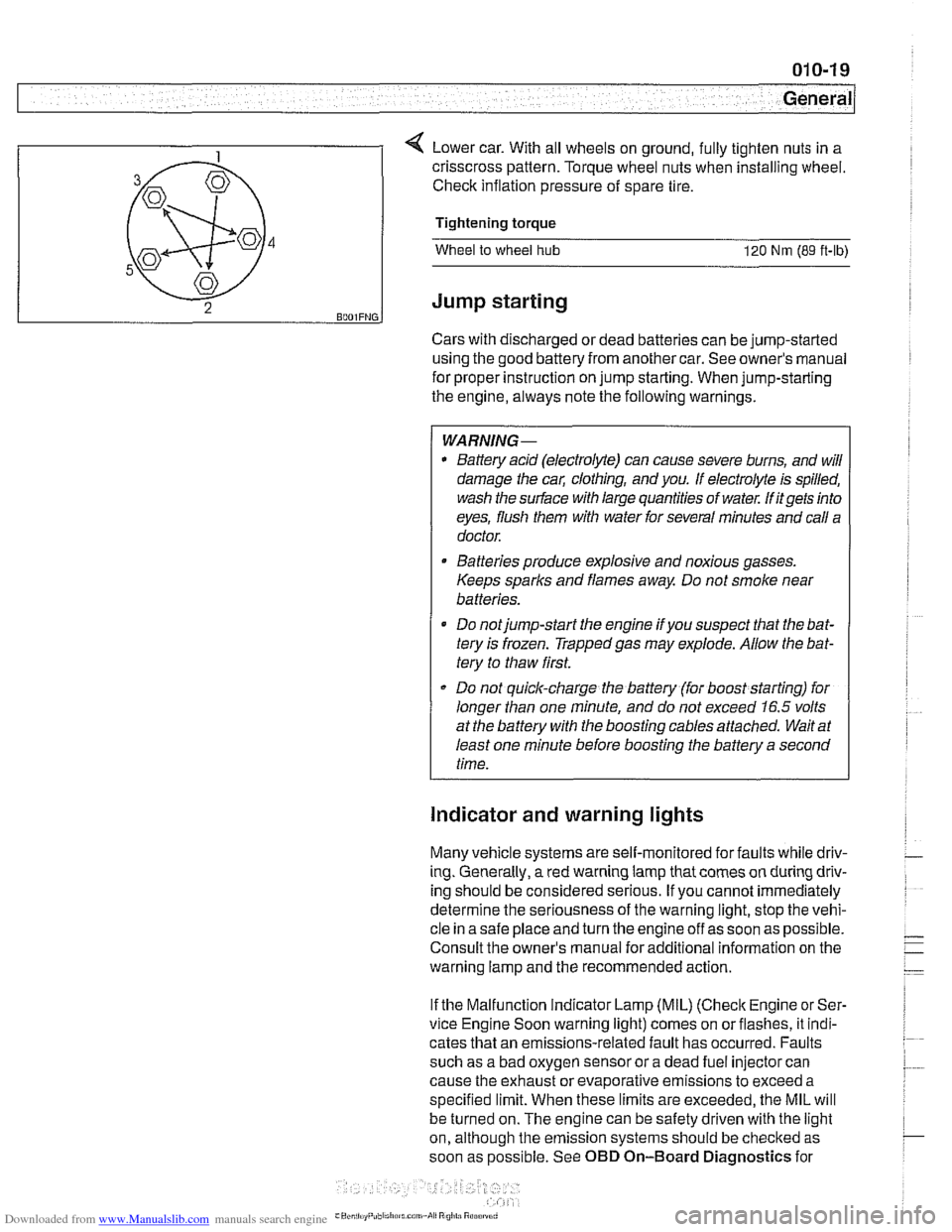

4 Lower car. With all wheels on ground, fully tighten nuts in a

WARNING-

* Battery acid (electrolyte) can cause severe burns, and will

damage the

cal; clothing, and you. If electrolyte is spilled,

wash the surface with large quantities of water.

M itgets into

eyes, flush them with water for several minutes and call a

doctor.

B4

5

43

2 BOOIFNG.

Batteries produce explosive and noxious gasses.

Keeps sparks and flames away. Do not smoke near

batteries.

Do notjump-start the engine

ifyou suspect that the bat-

tery is frozen. Trappedgas may explode. Allow the bat-

tery to thaw first.

Do not quick-charge the battery (for boost starting) for

longer than one minute, and do not exceed

16.5 volts

at the battery with the boosting cables attached. Wait at

least one minute before boosting the battery a second

time.

crisscross pattern.

Torque wheel nuts when installing wheel.

Check inflation pressure of spare tire.

Tightening torque

Wheel to wheel hub 120 Nm (89 ft-ib)

Jump starting

Indicator and warning lights

Many vehicle systems are self-monitored for faults while driv-

ing. Generally,

a red warning lamp that comes on during driv-

ing should be considered serious. If you cannot immediately

determine the seriousness of the warning light, stop the vehi-

cle in a safe place and turn the engine off as soon as possible.

Consult the owner's manual for additional information on the

warning lamp and the recommended action.

If the Malfunction Indicator Lamp (MIL)

(Check Engine or Ser-

vice Engine Soon warning light) comes on orflashes, it indi-

cates that an emissions-related fault has occurred. Faults

such as a bad oxygen sensor or a dead fuel injector can

cause the exhaust or evaporative emissions to exceed a

specified limit. When these limits are exceeded, the MIL will

be turned on. The engine can be safety driven with the light

on, although the emission systems should be

checked as

soon as possible. See OBD On-Board Diagnostics for

Page 46 of 1002

Downloaded from www.Manualslib.com manuals search engine

020-1 4

Maintenance

- When oil flow has diminished to an occasional drip, reinstall

drain plug with a new metal sealing washer and torque plug.

Tightening torque Engine oil drain plug to oil pan

25 Nrn (1.8 ft-lb)

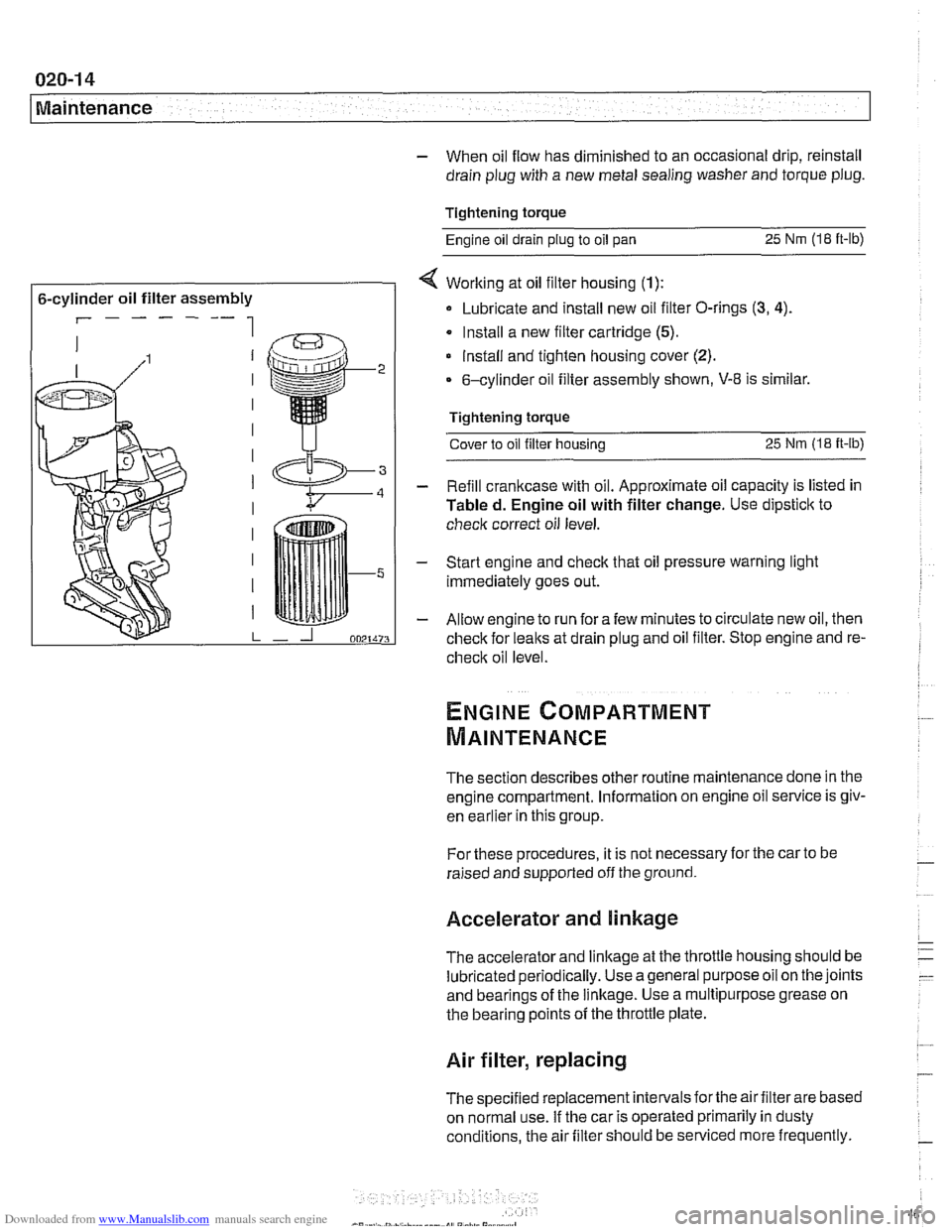

6-cylinder oil filter assembly

r------ 1

< Working at oil filter housing (1):

Lubricate and install new oil filter O-rings (3, 4).

Install a new filter cartridge (5).

lnstall and tighten housing cover (2).

6-cylinder oil filter assembly shown, V-8 is similar.

Tightening torque Cover to oil filter housing

25 Nm (1.8 it-lb)

- Refill crankcase with oil. Approximate oil capacity is listed in

Tabled. Engine oil with filter change. Use dipstick to

check correct oil level.

- Start engine and check that oil pressure warning light

immediately goes out.

- Allow engine to run fora few minutes to circulate new oil, then

check for leaks at drain plug and oil filter. Stop engine and re-

check oil level

The section describes other routine maintenance done in the

engine compartment. Information on engine oil service is

giv-

enkar~ier inthis group.

For these procedures, it is not necessary for the car to be

raised and supported off the ground.

Accelerator and linkage

The accelerator and linkage at the throttle housing should be

lubricated periodically. Use ageneral purposeoil on the joints

and bearings of the linkage. Use a multipurpose grease on

the bearing points of the throttle plate.

Air filter, replacing

The specified replacement intervals forthe air filter are based

on normal use. If the car is operated primarily in dusty

conditions, the air filter should be serviced more frequently.

Page 983 of 1002

![BMW 540i 2000 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

OBD-23

On-Board ~iagnostics]

I I

PI625 / 147 I Pedal Position Sensor Potentiometer Supply Channel 2 Electrical 1

Engine diagnostic troubl BMW 540i 2000 E39 Workshop Manual Downloaded from www.Manualslib.com manuals search engine

OBD-23

On-Board ~iagnostics]

I I

PI625 / 147 I Pedal Position Sensor Potentiometer Supply Channel 2 Electrical 1

Engine diagnostic troubl](/img/1/2822/w960_2822-982.png)

Downloaded from www.Manualslib.com manuals search engine

OBD-23

On-Board ~iagnostics]

I I

PI625 / 147 I Pedal Position Sensor Potentiometer Supply Channel 2 Electrical 1

Engine diagnostic trouble codes: M54 engine (continued)

P-code

BMW-FC Explanation

PI 604

PI604

PI619

PI620

PI624

PI632

PI633

PI634

P1 634

PI 634

PI 635

PI 636 50

51 123

123

146 i I

I

I Barometric Pressure Circuit Low

Control

Module Self-Test,

Speed Monitoring

Control Module Self-Test, Speed Monitoring

Map Cooling Thermostat Control Circuit Signal Low

Map Cooling Thermostat Control Circuit Signal High Pedal Position Sensor Potentiometer Supply Channel

1 Electrical (M52: Coolant Thermostat (Coolant

Temperature Below Thermostat Regulating Temperature))

115

115

115

135

136

115

109

PI639

PI675

PI694

P2088

P2089

P2090

P2091

I I

P2229 1197 I Barometric Pressure Circuit High

Throttle

Valve Adaptation Conditions Not Met

Throttle

Valve Adaptation Limp-Home Position Unknown

Throttle Valve Adaptation Spring Test Failed

Throttle

Valve Adaptation Spring Test Failed

Throttle

Valve Adaptation Spring Test Failed

Throttle Valve Adaptation Lower Mechanical Stop not Adapted

Throttle Valve Control Circuit

Throttle Valve Position Control, Control Deviation

PI 637

I I

P2270 1215 1 02 Sensor Signal Stuck Lean (Banic 1 Sensor 2)

PI 638 1160 I Throttle Valve Position Control Throttle Stucic Temporarily

162

161

135

136

21

21 19

19 Throttle

Valve Position Control Throttle

Stucic Permanently

Throttle Valve Actuator Start Test Re-Adaptation Required

Throttle Valve Actuator Start Test Spring Test and Limp-Home Position Failed

'A' Camshaft Position Actuator Control Circuit Low (Banlc 1)

'A' Camshaft Position Actuator Control Circuit High (Banlc 1)

'B' Camshaft Position Actuator Control Circuit Low (Bank 1)

'B' Camshaft Position Actuator Control Circuit High (Bank 1)

P2271

P2272

P2273

P3041

P3198 I I -

215

216

21 6

10481

10205 02

Sensor Signal Stucic Lean (Bank 1 Sensor 2)

02 Sensor Signal

Stuclc Lean (Bank 2 Sensor 2)

02 Sensor Signal Stuclc Lean (Bank 2 Sensor 2)

02 Sensor Lean and Rich Voltage Thresholds not Reached (Bank 2 Sensor 2)

Engine Coolant Temperature Gradient Too High

Engine Coolant Temperature Signal Stuck

P3199

P3238 1 10289 I Control Module Monitoring TPU Chip Defective

10207

Page 989 of 1002

Downloaded from www.Manualslib.com manuals search engine

On-Board ~ia~nosticsl

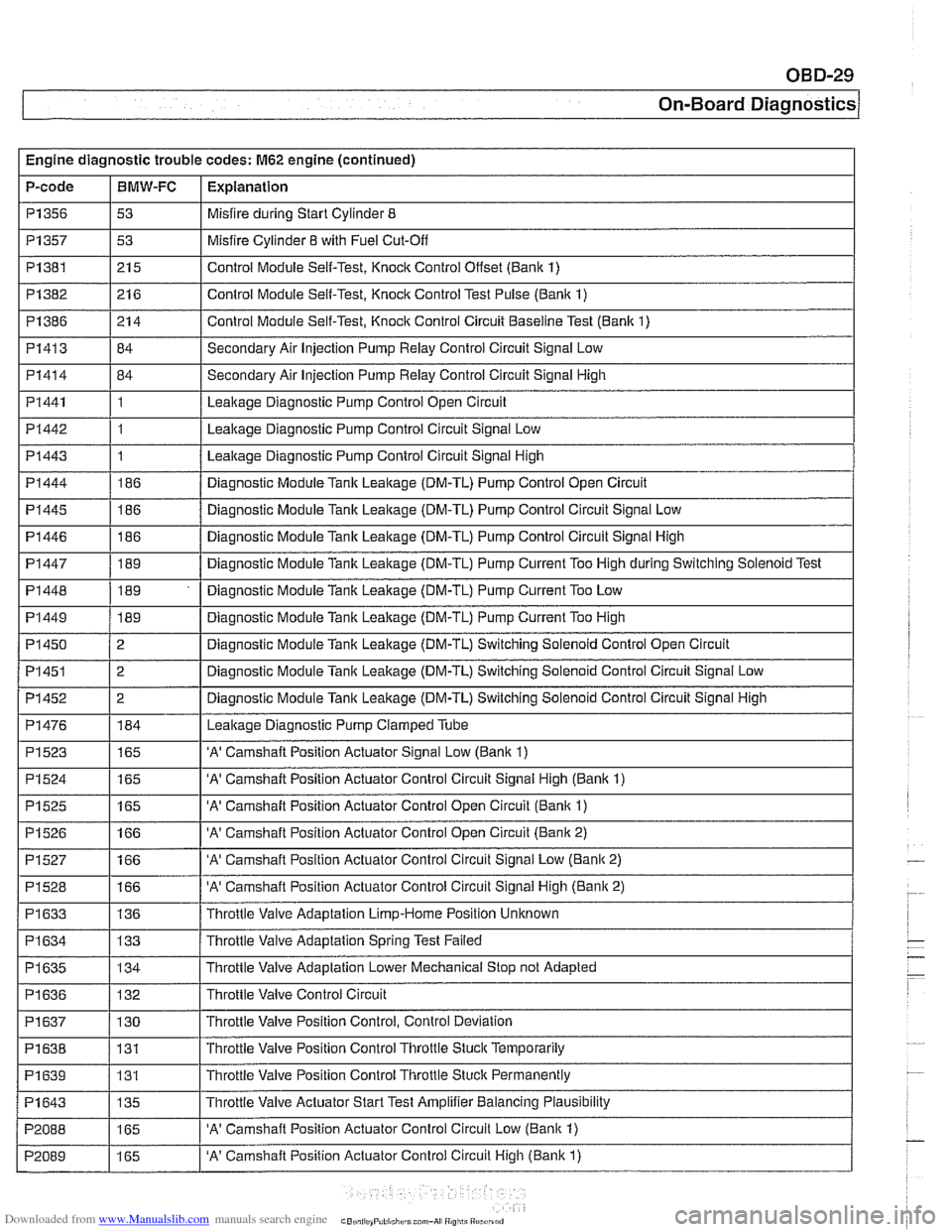

Engine diagnostic trouble codes: M62 engine (continued)

P-code

I I -

I I - -.

PI445 1186 / Diagnostic Module Tank Leakage (DM-TL) Pump Control Circuit Signal Low

PI357

PI382

PI386

PI413

PI414

PI441

PI442

PI443

PI444

P1356 1 53 I Misfire during Start Cylinder 8

BMW-FC

I P1523

I

I - -

1165 I 'A' Camshaft Position Actuator Signal Low (Banlc 1)

Explanation

P1381 1215 I Control Module Self-Test, Knock Control Onset (Bank 1)

53

21 6

21 4

84

84

1

1

1

186

PI 446

PI 447

PI 448

PI449

PI 450

PI451

PI452

PI476

Misfire Cylinder 8 with Fuel Cut-Off

Control Module Self-Test, Knock Control Test Pulse (Bank 1)

Control Module Self-Test, Knock Control Circuit Baseline Test (Bank 1)

Secondary Air Injection Pump Relay Control Circuit Signal Low

Secondary Air Injection Pump

Relay Control Circuit Signal High

Leakage Diagnostic Pump Control Open Circuit

Leakage Diagnostic Pump Control Circuit Signal Low

Leakage Diagnostic Pump Control Circuit Signal High

Diagnostic Module Tank Leakage (DM-TL) Pump Control Open Circuit

186

189

189

189

2

2

2

184

P1524

P1525

P1526

PI527

PI528

PI633

PI 634

PI 635

I I

PI 638 / 131 I Throttle Valve Position Control Throttle Stuck Temporarily

. -

Diagnostic Module Tank Leakage (DM-TL) Pump Control Circuit Signal High

Diagnostic Module

Tank Leakage (DM-TL) Pump Current Too High during Switching Solenoid Test

Diagnostic Module Tank Leakage (DM-TL) Pump Current Too Low

Diagnostic Module

Tank Leakage (DM-TL) Pump Current Too High

Diagnostic Module Tank Leakage (DM-TL) Switching Solenoid Control Open Circuit

Diagnostic Module

Tank Leakage (DM-TL) Switching Solenoid Control Circuit Signal Low

Diagnostic Module

Tank Leakage (DM-TL) Switching Solenoid Control Circuit Signal High

Leakaqe Diaqnostic Pump Clamped Tube

I I

165

165

166

166

166

136

133

134

'A' Camshaft Position Actuator Control Circuit Signal High (Banlc 1)

'A' Camshaft Position Actuator Control Open Circuit (Bank 1)

'A' Camshaft Position Actuator Control Open Circuit (Bank 2)

'A' Camshaft Position Actuator Control Circuit Signal Low (Bank 2)

'A' Camshaft Position Actuator Control Circuit Signal High (Bank 2)

Throttle Valve Adaptation Limp-Home Position Unknown

Throttle Valve Adaptation Spring Test Failed

Throttle Valve Adaptation Lower Mechanical Stop not Adapted

Throttle Valve Control Circuit

PI 636

PI639

P1643

P2088

P2089

PI 637 / 130 I Throttle Valve Position Control, Control Deviation

132

131

135

165

165 Throttle

Valve Position Control Thronle Stuck Permanently

Throttle Valve Actuator Start Test Amplifier Balancing Plausibility

'A' Camshaft Position Actuator Control Circuit Low (Banlc 1)

'A' Camshaft Position Actuator Control Circuit High (Bank 1)