tailgate lock BMW 540i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 795 of 1002

Downloaded from www.Manualslib.com manuals search engine

400 Body-General

........................ General ........................... .40 0.2 Roof paddin~ 400-7

Body Assembly ................... .40 0.2

Body dimensions (in inches)

............ .40 0.2

Bodyshell

........................... 400-3

Exterior and aerodynamics

............. .40 0.3

Sport Wagon ...................... .40 0.4

Tailgate

............................ .40 0.5

Tailgate lock system

.................. .40 0.5

Rear wiper system ................... .40 0.6

Antenna and sound system ............ .40 0.6

Safety and Security Features ....... .40 0.7

Safety cage

......................... .40 0.7

Door locks and door handles

........... .40 0.7

.

........................... Seat belts 400-7

Airbags ............................ 400-8

Battery safety terminal (BST)

........... 400-9

Security

............................ 400-9

Interior Features ................... 400-9

............................. Seats 400-10

Instruments and controls .............. 400-10

Central body electronics

.............. 400-1 1

Heating and Air

Conditioning (IHKA)

............... 400-12

Page 799 of 1002

Downloaded from www.Manualslib.com manuals search engine

400-5

Body-General

Tailgate

The E39 Sporl Wagon tailgate is large with a low sill for easy

cargo loading. The tailgate opens to an angle of

88" mea-

sured from the rear roof pillar (D-pillar) and to a height of

2029

mm (79.8 in) measured from the ground to the upper edge of

the raised tailgate.

The rear window is bonded to a load bearing frame and can

be opened separately from the main tailgate. Tailgatesupport

gas springs are recessed into cavities in the roof.

Tailgate lock system

A mechanical tailgate lock cylinder is not used; the tailgate is

opened by the unlock pad above the license plate, the remote

tailgate switch located in the drivers kick panel, or via

FZV

(Iteyless entry) control.

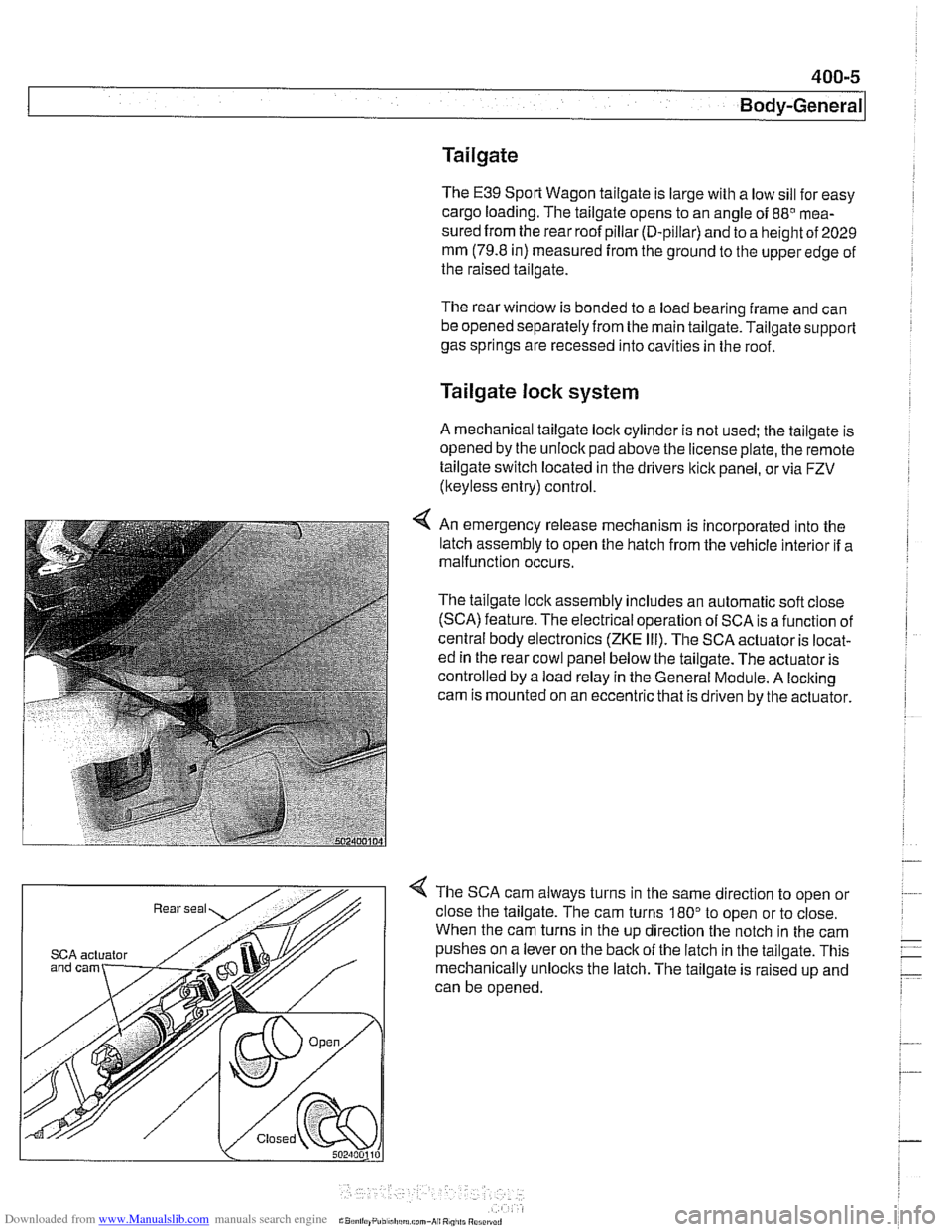

4 An emergency release mechanism is incorporated into the

latch assembly to open the hatch from the vehicle interior if a

malfunction occurs.

The tailgate lock assembly includes an automatic soft close

(SCA) feature. The electrical operation of SCA is a function of

central body electronics

(ZKE Ill). The SCA actuator is locat-

ed in the rear cowl panel below the tailgate. The actuator is

controlled by a load relay in the General Module. A locking

cam is mounted on an eccentric that is driven by the actuator.

4 The SCA cam always turns in the same direction to open or

close the tailgate. The cam turns

180" to open or to close.

When the cam turns in the up direction the notch in the cam

SCA actuator pushes on a lever on the back of the latch in the tailgate. This

mechanically unlocks the latch. The tailgate is raised up and

can be opened.

Page 842 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 2-1 4

l~runk Lid, Tailgate

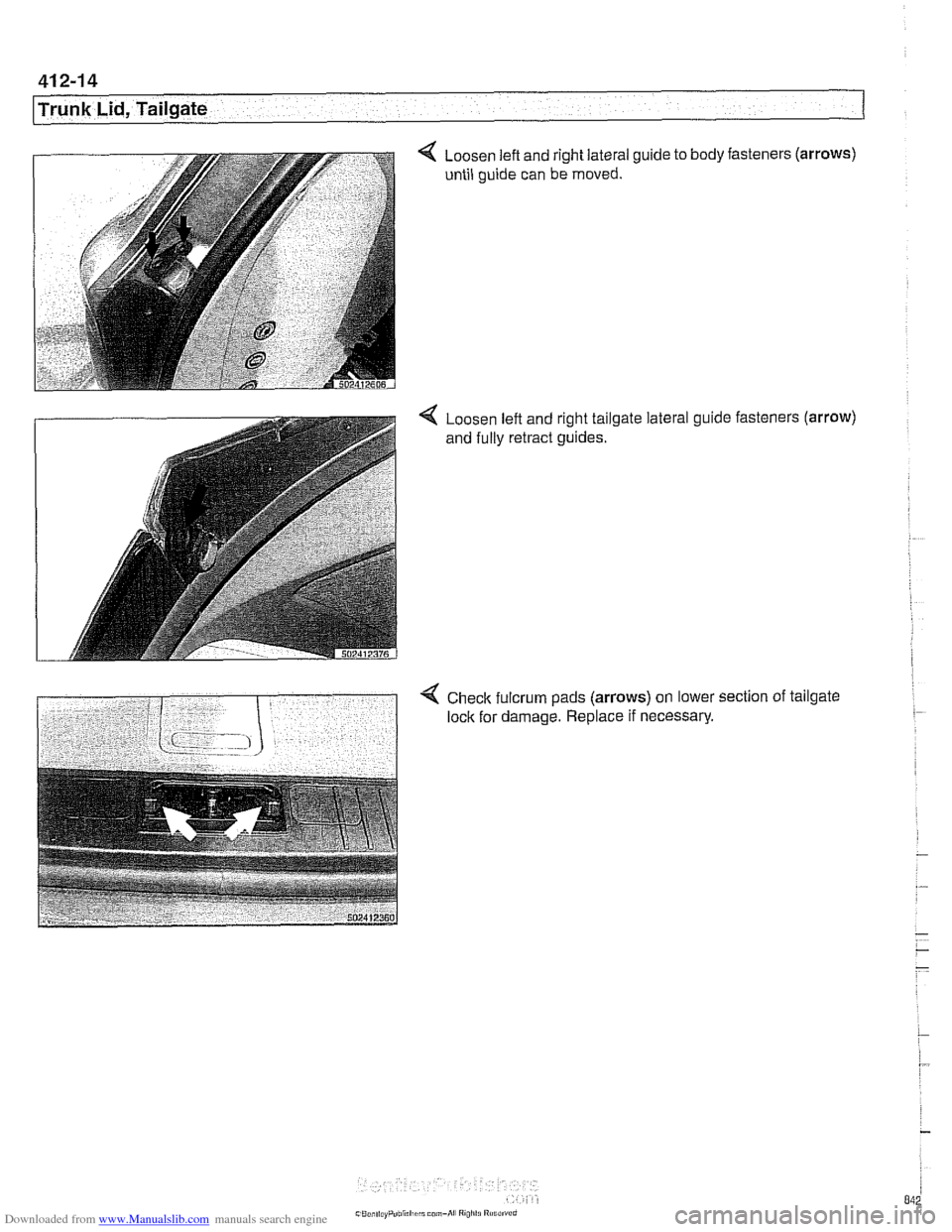

< Loosen left and right lateral guide to body fasteners (arrows)

until guide can be moved.

4 Loosen left and right tailgate lateral guide fasteners (arrow)

and fully retract guides.

Check fulcrum pads (arrows) on lower section of tailgate

lock for damage. Replace if necessary.

Page 843 of 1002

Downloaded from www.Manualslib.com manuals search engine

Trunk Lid, ~ail~atel

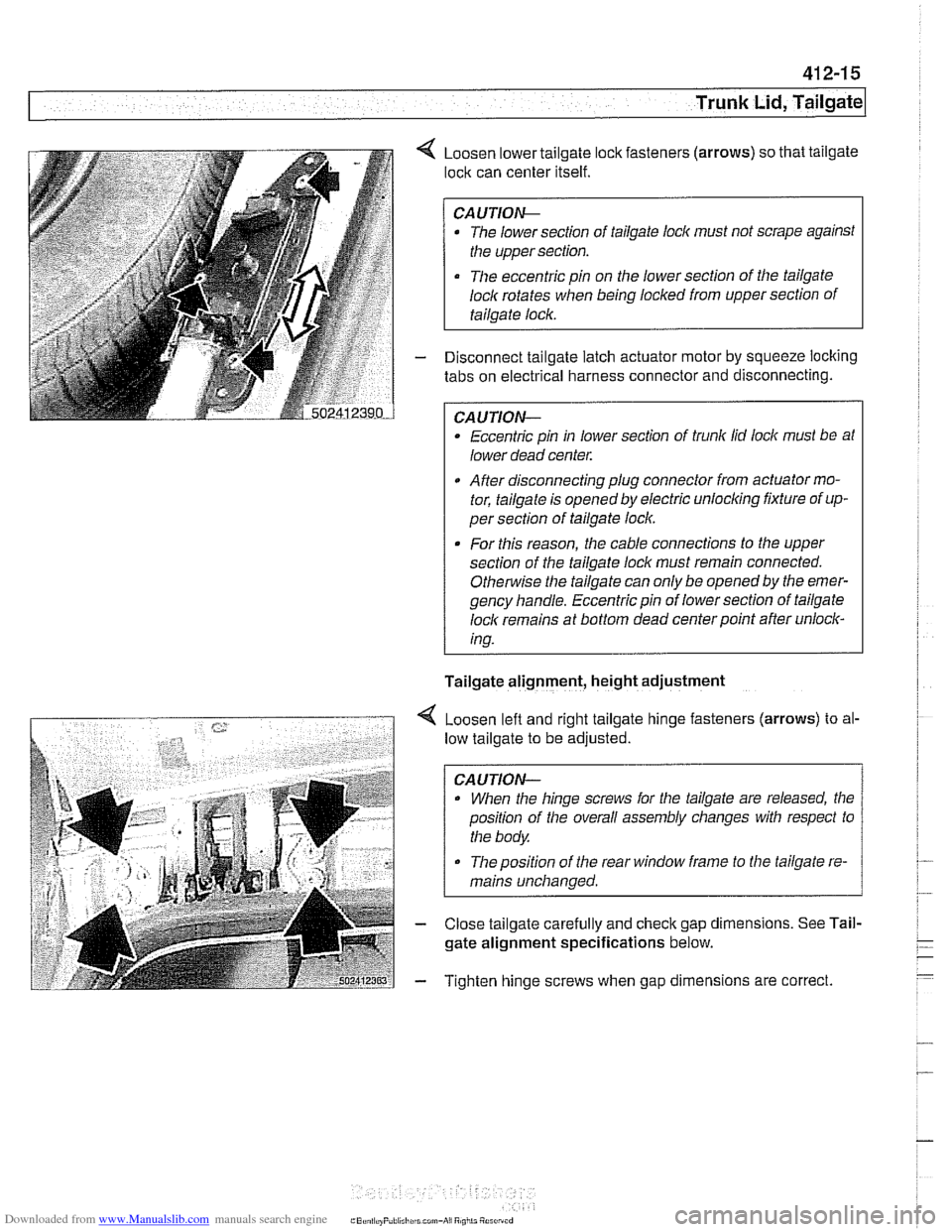

4 Loosen lower tailgate lock fasteners (arrows) so that tailgate

lock can center itself.

CAUTION-

The lower section of tailgate lock must not scrape against

the upper section.

The eccentric pin on the lower section of the tailgate

loclc rotates

when being locked from upper section of

tailgate lock.

- Disconnect tailgate latch actuator motor by squeeze locking

tabs on electrical harness connector and disconnecting.

CAUTION-

Eccentric pin in lower section of trunk lid lock must be at

lower dead center.

After disconnecting plug connector from actuator mo-

tor, tailgate is opened by electric

unloclcing fixture of up-

per section of tailgate loclc.

. For this reason, the cable connections to the upper

section of the tailgate loclc must remain connected.

Othe~tise the tailgate can only be opened by the emer-

gency handle. Eccentric pin of lower section of tailgate

loclc remains at bottom dead center point after unlock-

ing.

Tailgate alignment, height adjustment

4 Loosen left and right tailgate hinge fasteners (arrows) to al-

low tailgate to be adjusted.

CAUTION-

. When the hinge screws for the tailgate are released, the

position of the overall assembly changes with respect to

the body.

The position of the rear window frame to the tailgate re-

mains unchanged.

- Close tailgate carefully and check gap dimensions. See Tail-

gate alignment specifications below.

- Tighten hinge screws when gap dimensions are correct.

Page 848 of 1002

Downloaded from www.Manualslib.com manuals search engine

Trunk Lid, Tailgate

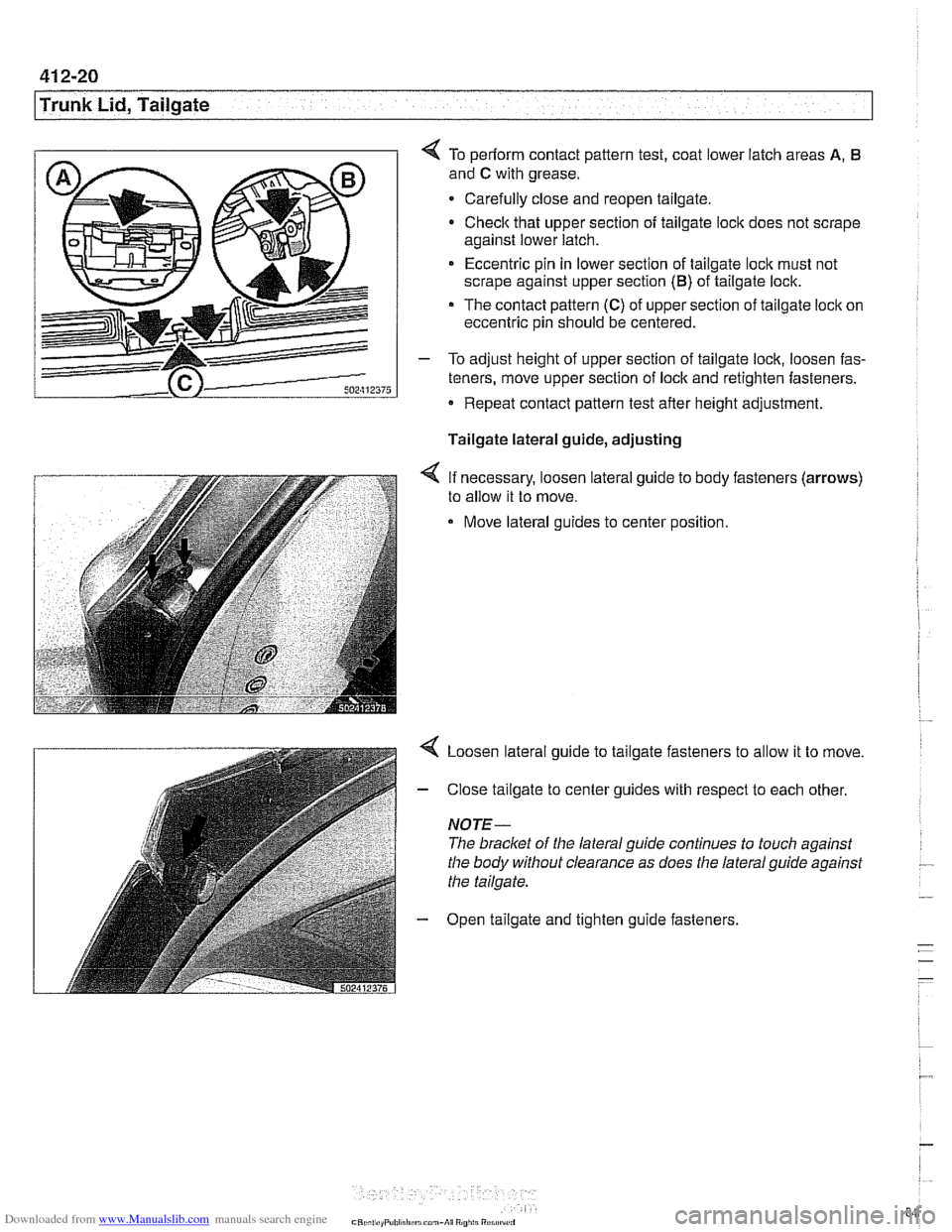

4 To periorm contact pattern test, coat lower latch areas A, 6

and C with grease.

Carefully close and reopen tailgate.

Check that upper section of tailgate lock does not scrape

against lower latch.

* Eccentric pin in lower section of tailgate loclc must not

scrape against upper section

(B) of tailgate lock.

The contact pattern (C) of upper section of tailgate lock on

eccentric pin should be centered.

- To adjust height of upper section of tailgate lock, loosen fas-

teners, move upper section of lock and retighten fasteners.

Repeat contact pattern test after height adjustment.

Tailgate lateral guide, adjusting

< If necessary, loosen lateral guide to body fasteners (arrows)

to allow it to move.

Move lateral guides to center position.

< Loosen lateral guide to tailgate fasteners to allow it to move.

- Close tailgate to center guides with respect to each other.

NOTE-

The bracket of the lateral guide continues to touch against

the body without clearance as does the lateral guide against

the tailgate.

- Open tailgate and tighten guide fasteners.

Page 849 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 2-21

Trunk Lid, ~ailaatel

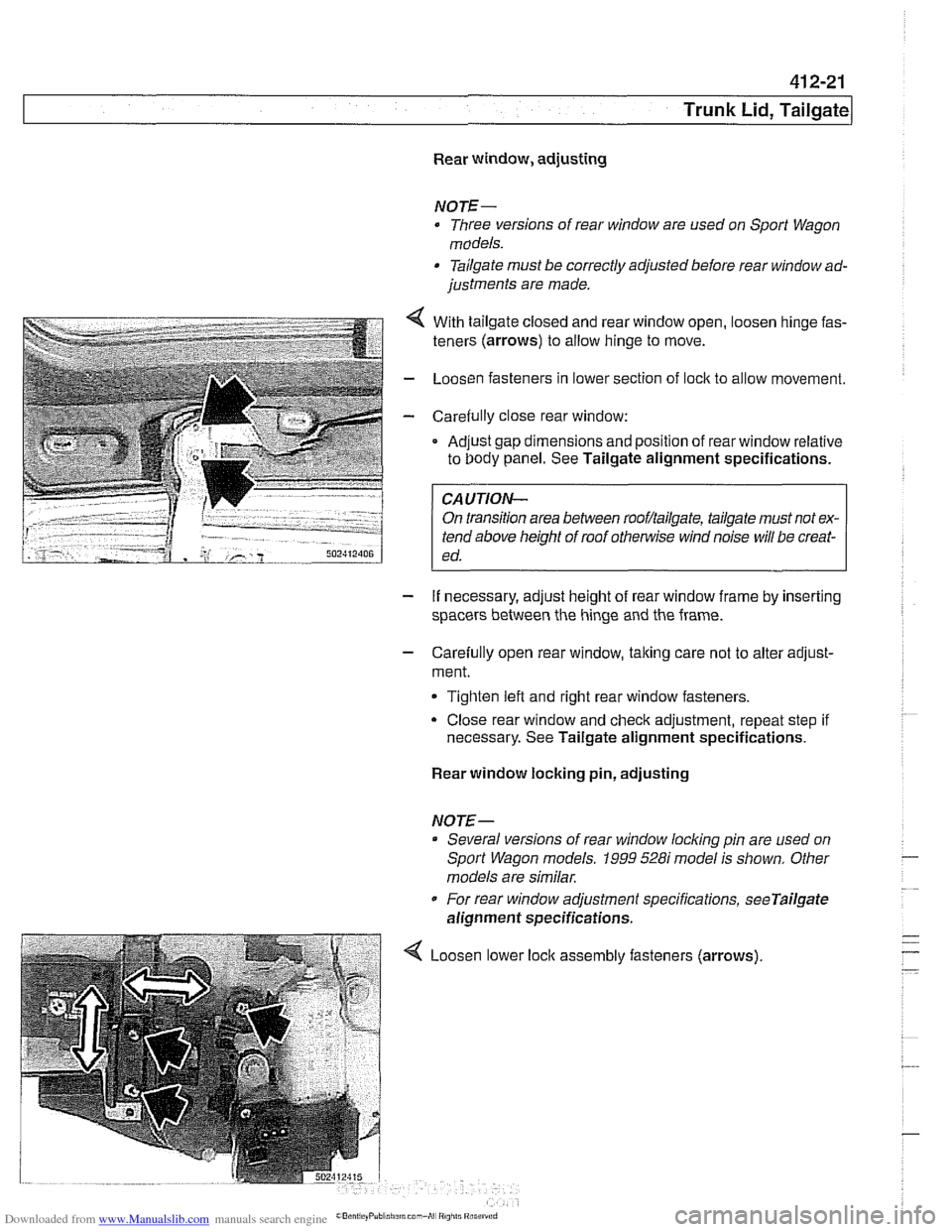

Rear window, adjusting

NOTE- Three versions of rear window are used on

Sport Wagon

models.

Tailgate must be correctly adjusted before rear window ad-

justments are made.

- . . . . . .. .. 4 With tailgate closeo ano rear window open, oosen ninge fas-

teners (arrows) to allow ninge to move.

- LoosL'n fasteners n lower section of ock to al ow movement.

- Care& ly c ose rear window:

Ad.~st gap dmensions and poston of rear window relative

to Oody panel. See Tailgate alignment specifications. .

FA-UTION- I

On transition area between rooflailgate, tailgate must not ex-

tend above height of roof

othe~lise wind noise will be creat-

ed.

- If necessary, adjust height of rear window frame by inserting

spacers between the hinge and the frame.

- Carefully open rear window, taking care not to alter adjust-

ment.

Tighten left and right rear window fasteners.

Close rear window and check adjustment, repeat step if

necessary. See Tailgate alignment specifications.

Rear window locking pin, adjusting

NOTE-- Several versions of rear window

locldng pin are used on

Sport Wagon models.

1999 528i model is shown. Other

models are similar.

For rear window adjustment specifications,

seeTailgate

alignment specifications.

Loosen lower assembly fasteners (arrows)

Page 850 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 2-22

1 Trunk Lid, Tailgate

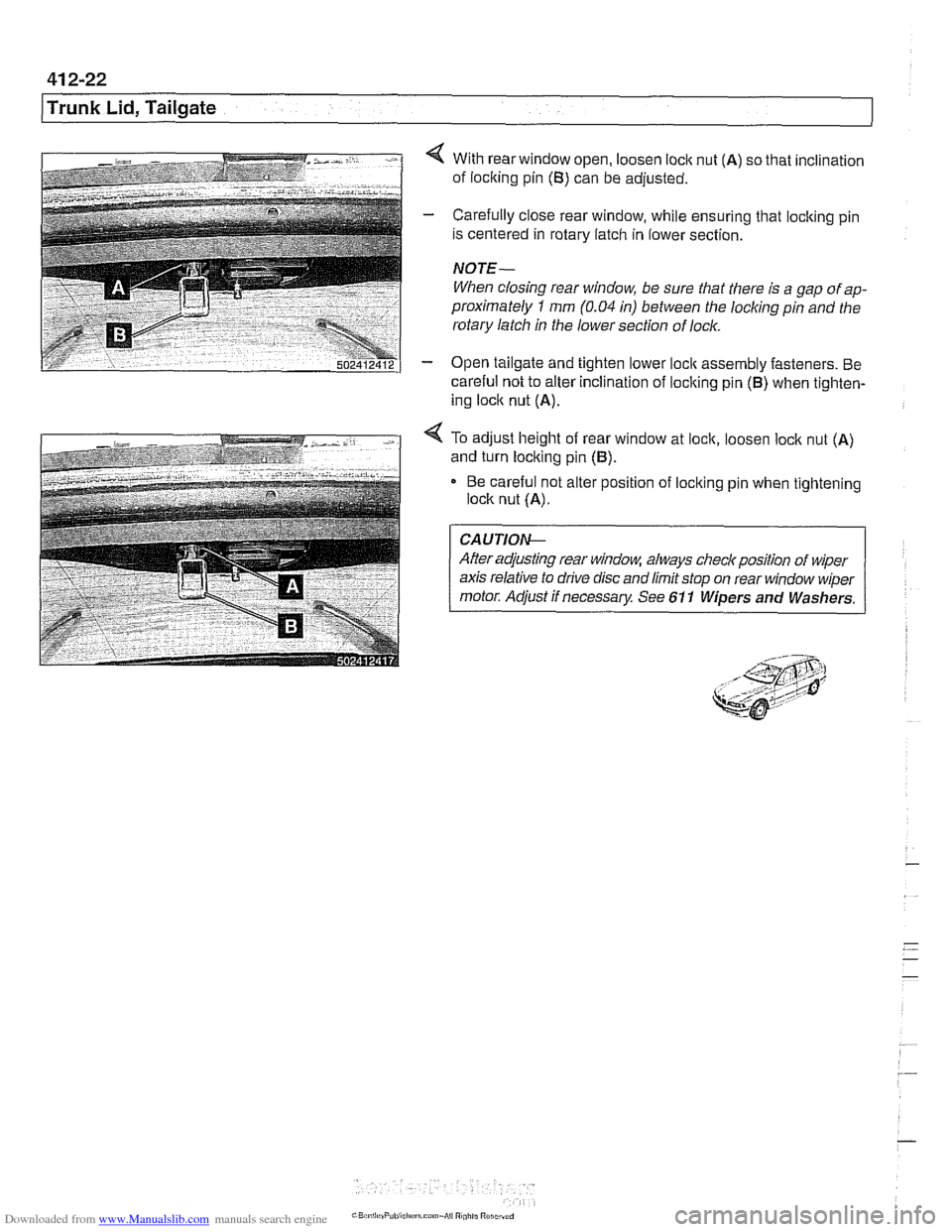

4 With rear window open, loosen loclc nut (A) so that inclination

of loclting pin

(B) can be adjusted.

- Carefully close rear window, while ensuring that locking pin

is centered in rotary latch in lower section.

NOTE-

When closing rear window, be sure that there is a gap of ap-

proximately

1 mm (0.04 in) between the locliing pin and the

rotary latch in the lower section of lock.

- Open tailgate and tighten lower loclc assembly fasteners. Be

careful not to alter inclination of loclting pin

(B) when tighten-

ing loclc nut

(A).

4 To adjust height of rear window at lock, loosen loclc nut (A)

and turn locking pin (B).

Be careful not alter position of loclting pin when tightening

lock nut

(A).

CA UTIOG

After adjusting rear window, always checlr position of wiper

axis relative to drive disc and limit stop on rear window wiper

motor. Adjust if necessary See 611 Wipers and Washers.

Page 895 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5 Central Locking and Anti-Theft

........................... General .51 5.2

Central Locking ................... .51 5.2

General Module

..................... .51 5.2

Central locking inputs and outputs

....... .51 5.3

Doorlocks

........................... 515-5

Trunklock

........................... 515-7

Remote entry (FZV)

.................. .51 5.7

Remote entry (FZV) inputs and outputs ... .51 5.8

Car Memory I Key Memory ............ .51 5.12

Trunk lid soft close (SCA)

............. .51 5.13

SCA subsystem

.................... .51 5.14

........ Tailgate and rear window locks

.51 5.14

Sport Wagon tailgate and rear

window

lock schematic ............... .51 5.15

Door Handles and Locks .......... .51 5.16

Door handle (outer), removing

and installing

....................... .51 5.16

Door latch, removing and installing

..... .51 5.17

Outer door lock cylinder, removing

and installing

....................... .51 5.18

Trunk Lock Assembly ............. 515-1 9

Trunk lock. removing and installing

...... 515-19

Trunk lock striker plate. removing

and installing

....................... 515-20

Tailgate lock. emergency release

....... 515-21

... Electronic Immobilization (EWS) 515-21

EWS variations

..................... 515-22

......... EWS control module. replacing 515-23

Transmitter

1 receiver module .......... 515-23

....................... Ring antenna 515-23

Anti-theft System (DWA) ........... 51 5-24

DWA LED Status

.................... 51 5-24

Tilt sensor

......................... 515-24

Interior protection .................... 51 5-25

Glass breakage sensors

.............. 515-26

Emergency disarming

................ 51 5-26

Page 896 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-2

/Central Locking and Anti-Theft

This section covers repair information for door, trunk and car-

go compartment locks, central locking, electronic

immob~liza-

tion (EWS) and anti-theft alarm (DWA).

€39 cars are equipped with sophisticated self-diagnostic elec-

trical systems. When experiencing malfunctions relating to

central locking. EWS or anti-theft systems, start the diagnosis

process using the

BMW service tester DIS, GT 1, MoDiC or

equivalent scan tool. An advanced diagnostic scan tool can

usually pinpoint electrical faults quickly and safely.

Additional electrical information can be found in:

610 Electrical Component Locations

ELE Electrical Wiring Diagrams

Central locking in E39 vehicles controls the door

locks, trunk

or tailgate lock and fuel filler flap lock. The control module for

the Central Body Electronics system (ZKE

Ill), lknown as the

General Module (GM

Ill), controls central locking.

ZKE

Ill manages the following central locking related func-

tions:

Central locking

* Keyless entry

Key memory

Power trunk release

Electric opening of tailgate

DWA alarm system

Diagnosis

General Module

4 The General Module (GM) (arrow) is responsible for the op-

eration of central body electronics. The GM is located behind

the glove compartment.

Based on input information, the GM uses internal transistors

to switch current flow (providing voltage or ground) through

circuits and actuators. Actuators are the final controlling de-

vices used by GM to operate or control various output func-

tions such as relays and motors.

The accompanying schematic, Central locking inputs and

outputs, illustrates the GM central locking system.

Page 898 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-4

I Central Locking and Anti-Theft

Driver's door lock

The

lock/unlock signals are sent as input to the door module

from two microswitches on the lockcylinder. The driver's door

module carries out the locking

/ unlocking functions of the

driver's door through its final stage control.

The signal to lock the remaining doors, trunk or tailgate and

fuel flap is sent over the P-Bus to the GM and the passenger

door module. Activation of the passengers door

loclt is carried

out by the passenger door module. The rear doors, trunlt or

tailgate and fuel flap are

locked by the f~nal stage in the GM.

When

locked from the outside, all doors are set to the double

lock position and the GM will not carry out any unlock com-

mands from the central

loclc button or remote trunk release

button.

Selective unlocking

When unlocking with the key or the remote transmitter, the

first unloclcrequestwill only unlock the driver'sdoor. A second

unlock request will unlock the remaining doors, trunk or tail-

gate and fuel flap.

Trunk locking

I

The vehicle can be locked/unlocked from the trunlc loclc cylin-

der. The GM locks the trunk or tailgate, rear doors and fuel fill-

er. The locking command is passed over the P-Bus to the

respective door modules to lock the driver's and passengers

doors.

Locking the trunk and removing the key in the

hor~zontal posi-

tion will set the valet lock and prevent opening of the trunlt

with the central locking system.

Central locking switch

-

< The central locking master control switch (arrow) is located

in the center console behind the shifter.

The central locking button will only single

loclt the doors

and trunk. The filler flap remains unloclted for refueling pur-

poses.

If a door is opened from inside while centrally locked, the

remaining doors remain locked.

The open door can be relocked, when closed, by manually

locking or pressing the central locking button twice. This

synchronizes the door

locks.