trunk BMW 540i 2000 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2000, Model line: 540i, Model: BMW 540i 2000 E39Pages: 1002

Page 3 of 1002

Downloaded from www.Manualslib.com manuals search engine

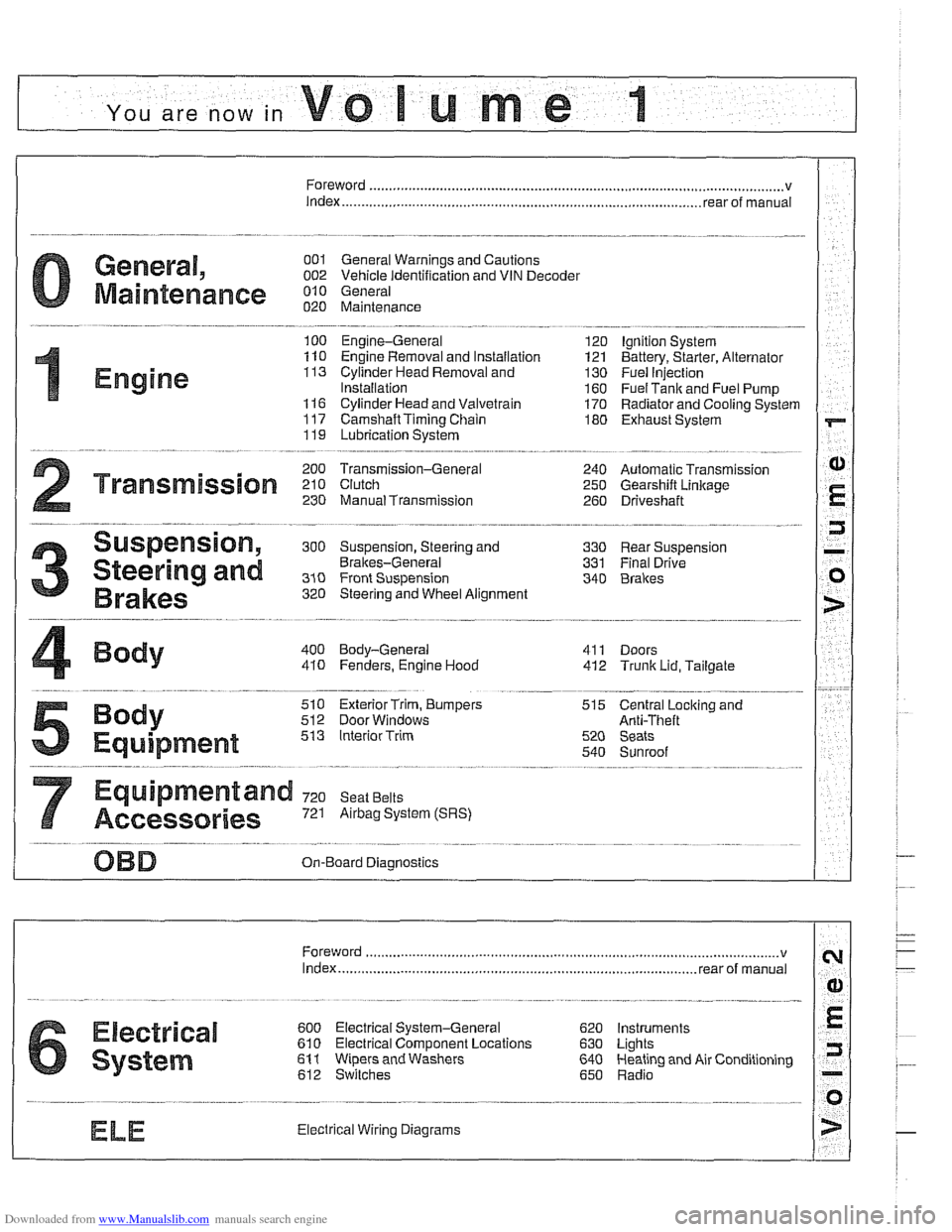

YOU are now in Volume I

I

Foreword ................... .. ........................................................................\

.......... v

Index

........................ .. ................................................................ rear of manual

General, 001 General Warnings and Cautions 002 Vehicle Identification and VIN Decoder

Maintenance OiO 020 Maintenance

Engine

100 Engine-General 110 Engine Removal and Installation

113 Cylinder Head Removal and

Installation

116 Cyiinder Head and Valvetrain 117 Camshaft Timing Chain

119 Lubrication System

200 Transmission-General

2 Transmission 210 clutch 230 ManualTransmission

I20 Ignition System

121 Battery, Starter, Alternator

130 Fuel Injection

160 Fuel Tank and Fuel Pump 170 Radiator and Cooling System

180 Exhaust System

240 Automatic Transmission

250 Gearshift Linkage 260 Driveshaft

Suspension, 300 Suspension, Steering and 330 Rear Suspension

Brakes-General 331 Final Drive

Steering and No Front Suspension 340 Brakes

320 Steering and Wheel Alignment

400 Body-General

410 Fenders, Engine Hood 411 Doors

412 Trunk Lid, Tailgate

510 Exterior Trim, Bumpers 512 Door Windows

Equipment 513 Interior Trim

7

Equipment and 720 seat Belts

Accessories 721 Airbag System (SRS)

OBD On-Board Diagnostics

. ............ ..

515 Central Lociting and

Anti-Theft

520 Seats 540 Sunroof

.................................................................... Foreword .............................. .. v

Index ................... .. ................................................................ rear of manual

Electrical

6 system

600 Electrical System-General 620 Instruments

610 Electrical Comoonent Locations 630 Liohts

611 wipers and washers 612 Switches eati in^ and Air Conditioning

Radio

. ........... ........ .........................

Electrical Wiring Diagrams

Page 28 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

General

BMW special tools

Many repairs covered in this manual call for the use of BMW

special tools. Many of the BMW special tools mentioned in

this manual are simply the best thing to use to do the job cor-

rectly. In these cases, the tool is identified with a

BMW parl

number. See your authorized BMW dealer parts department

for information on how to order special tools.

There are some jobs for which expensive special tools are es-

sential, and not a cost-effective purchase for a one time repair

by the do-it-yourself owner. This manual includes such re-

pairs for the benefit of those with the necessary experience

and access to tools. For the do-it-yourselfer, the need for spe-

cial tools is noted in the text, and whether or not BMW dealer

service is recommended.

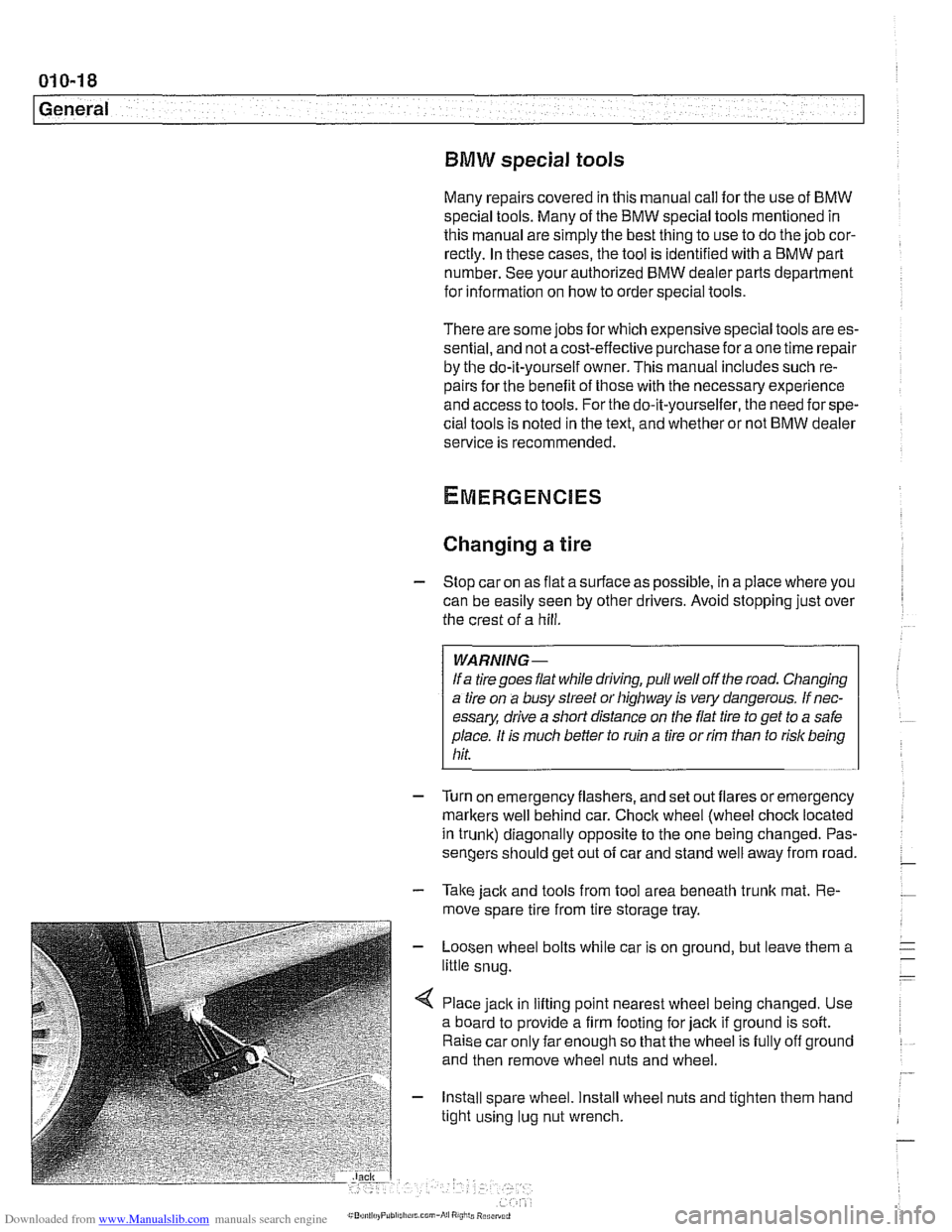

Changing a tire

- Stop car on as flat a surface as possible, in a place where you

can be easily seen by other drivers. Avoid stopping just over

the crest of a hill.

WARNING -

If a tire goes flat while driving, pull well off the road. Changing

a tire on a busy slreet or liigliway is very dangerous. If

nec-

essag drive a short distance on the flat tire to get to a safe

place. It is much better to ruin a tire or rim than to

risk being

hit.

-

- Turn on emergency flashers, and set out flares or emergency

markers well behind car.

Choclc wheel (wheel chock located

in trunk) diagonally opposite to the one being changed. Pas-

sengers should get out of car and stand well away from road.

- Take jaclc and tools from tool area beneath trunk mat. Re-

move spare tire from tire storage tray.

- Loosen wheel bolts while car is on ground, but leave them a

little snug.

< Place jack in lifting point nearest wheel being changed. Use

a board to provide a firm footing for jack if ground is soft.

Raise car only far enough so that the wheel is fully off ground

and then remove wheel nuts and wheel.

- Install spare wheel. Install wheel nuts and tighten them hand

tight using lug nut wrench.

Page 40 of 1002

Downloaded from www.Manualslib.com manuals search engine

--- -

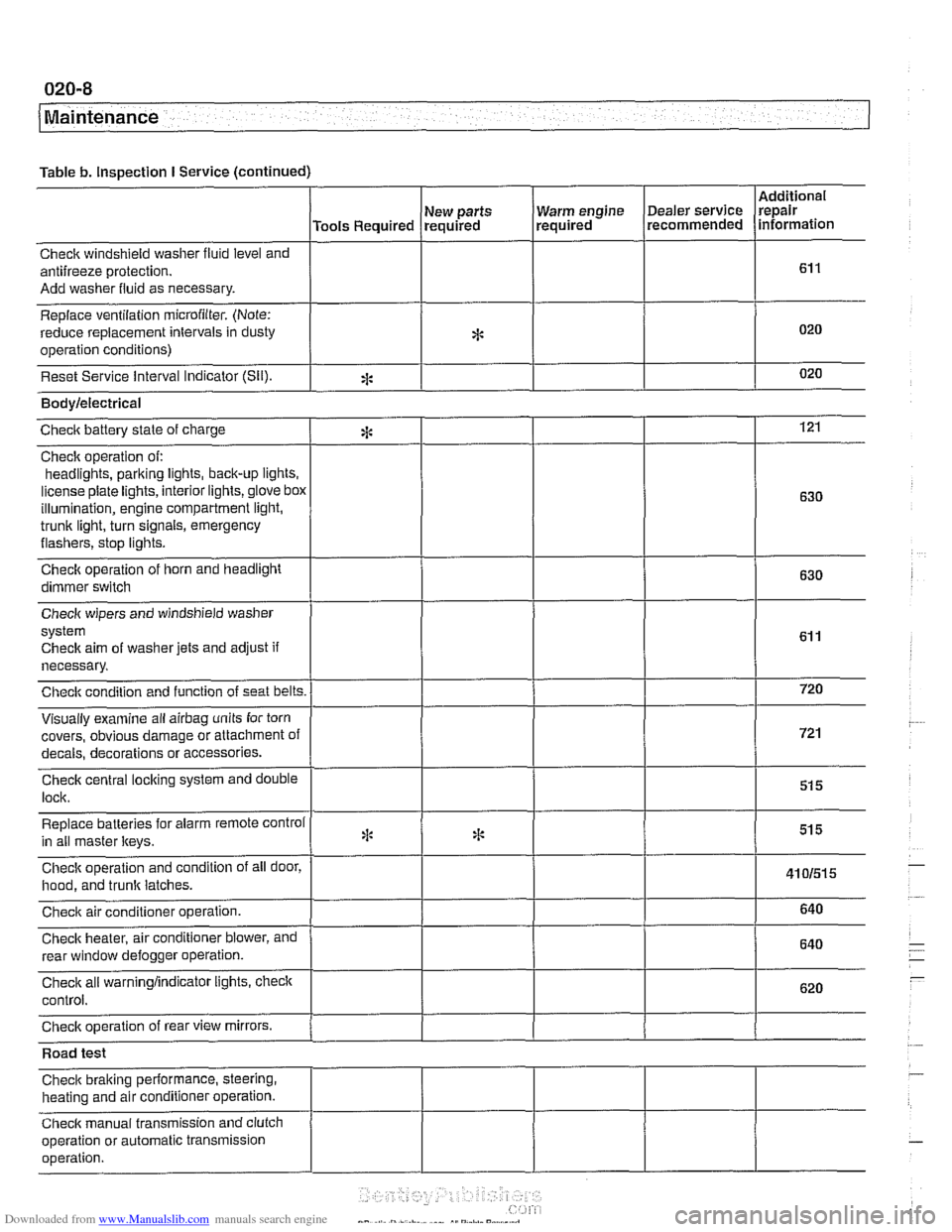

Maintenance

Table b. Inspection I Service (continued)

I I I I

Warm engine Dealer service

required recommended

Check windshield

washer fluid level and

antifreeze protection.

Add washer fluid as necessary.

Replace ventilation

microfilter. (Note:

reduce replacement intervals in dusty

operation conditions)

Reset Service interval Indicator

(Sil).

Additional

repair

information

Tools Required

*

eck aim of washer jets and adjust if

necessary.

covers, obvious damage or attachment o

s or accessories.

Road test

Check braking performance, steering,

heating and air conditioner operation.

Check manual transmission and clutch

operation or automatic transmission

operation. New

parts

required

*

Bodylelectrical

121

630

630

Checic battery state of charge

Check operation of:

headlights,

parking iights, back-up lights.

license plate lights, interior lights,

glove box

illumination, engine compartment light,

trunk light, turn signals, emergency

flashers, stop iights.

Check operation of horn and headlight

dimmer switch

:i:

Page 48 of 1002

Downloaded from www.Manualslib.com manuals search engine

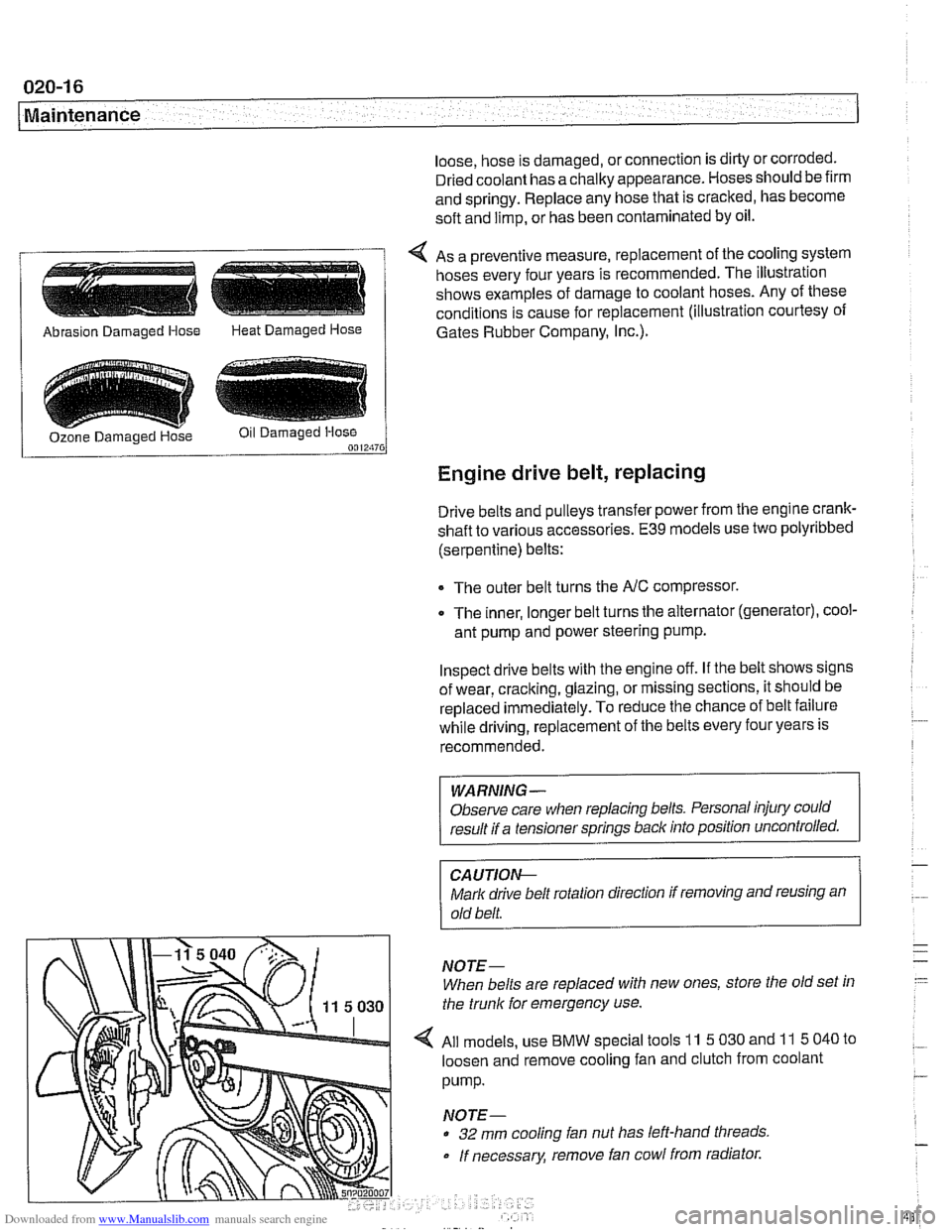

020-1 6

Maintenance

loose, hose is damaged, or connection is dirty or corroded.

Dried coolant has achalky appearance. Hoses should be firm

and springy. Replace any hose that is cracked, has become

soft and limp, or has been contaminated by oil.

4 As a preventive measure, replacement of the cooling system

hoses every four years is recommended. The illustration

shows examples of damage to coolant hoses. Any of these

conditions is cause for replacement (illustration courtesy of

/ Abrasion Damaged Hose Heat Damaged Hose 1 Gates Rubber Company, I~c.).

Engine drive belt, replacing

Drive belts and pulleys transfer power from the engine crank-

shaft to various accessories.

E39 models use two polyribbed

(serpentine) belts:

The outer belt turns the

NC compressor.

0 The inner, longer belt turns the alternator (generator), cool-

ant pump and power steering pump.

Inspect drive belts with the engine off. If the belt shows signs

of wear, cracking, glazing, or missing sections, it should be

replaced

immediately. To reduce the chance of belt failure

while driving, replacement of the belts every four years is

recommended.

WARNING -

Observe care when replacing belts. Personal injury could

result if a tensioner springs back into position uncontrolled.

CA UTIOI\C

Mark drive belt rotation direction if removing and reusing an

old belt.

NOTE-

When belts are replaced with new ones, store the old set in

the trunk for emergency use.

All models, use

BMW special tools 11 5 030 and 11 5 040 to

loosen and remove cooling fan and clutch from coolant

pump.

NOTE-

32 mm cooling fan nut has left-hand threads

If necessary, remove fan cowl from radiator.

Page 55 of 1002

Downloaded from www.Manualslib.com manuals search engine

Maintenance

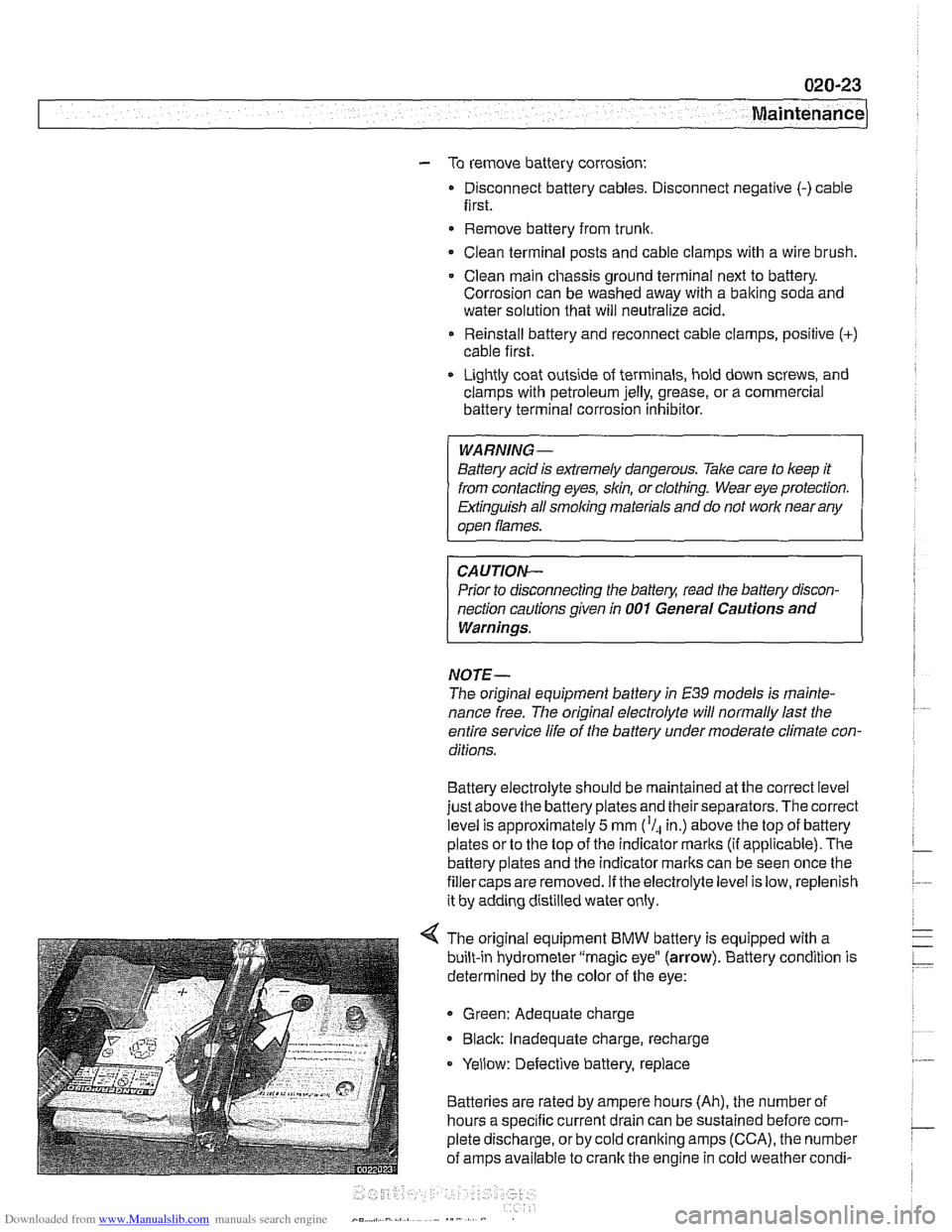

- To remove battery corrosion:

Disconnect battery cables. Disconnect negative (-)cable

first.

* Remove battery from trunk

Clean terminal posts and cable clamps with a wire brush.

Clean main chassis ground terminal next to battery.

Corrosion can be washed away with a

baking soda and

water solution that will neutralize acid.

Reinstall battery and reconnect cable clamps, positive

(+)

cable first.

Lightly coat outside of terminals, hold down screws, and

clamps with petroleum jelly, grease, or a commercial

battery terminal corrosion inhibitor.

WARNING

-

Battery acid is extremely dangerous. Take care to keep it

from contacting eyes, skin, or clothing. Wear eye protection.

Extinguish all

smolihg materials and do not work near any

oaen flames.

CAUTION-

Prior to disconnecting the batteg read the battery discon-

nection cautions given in

001 General Cautions and

Warnings.

NOTE-

The original equipment battery in E39 models is mainte-

nance free. The original electrolyte will normally last the

entire service life of the battery under moderate climate con-

ditions.

Battery electrolyte should be maintained at the correct level

just above the battery plates and theirseparators. The correct

level is approximately

5 mm ('14 in.) above the top of battery

plates or to the top of the indicator

marks (if applicable). The

battery plates and the indicator marks can be seen once the

fillercaps are removed.

if theelectrolyte level is low, replenish

it by adding distilled water only.

4 The original equipment BMW battery is equipped with a

built-in hydrometer "magic eye"

(arrow). Battery condition is

determined by the color of the eye:

Green: Adequate charge

* Black: Inadequate charge, recharge

Yellow: Defective battery, replace

Batteries are rated by ampere hours (Ah), the number of

hours a specific current drain can be sustained before com-

plete discharge, or by cold cranking amps (CCA), the number

of amps available to crank the engine in cold weather

condi-

Page 369 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

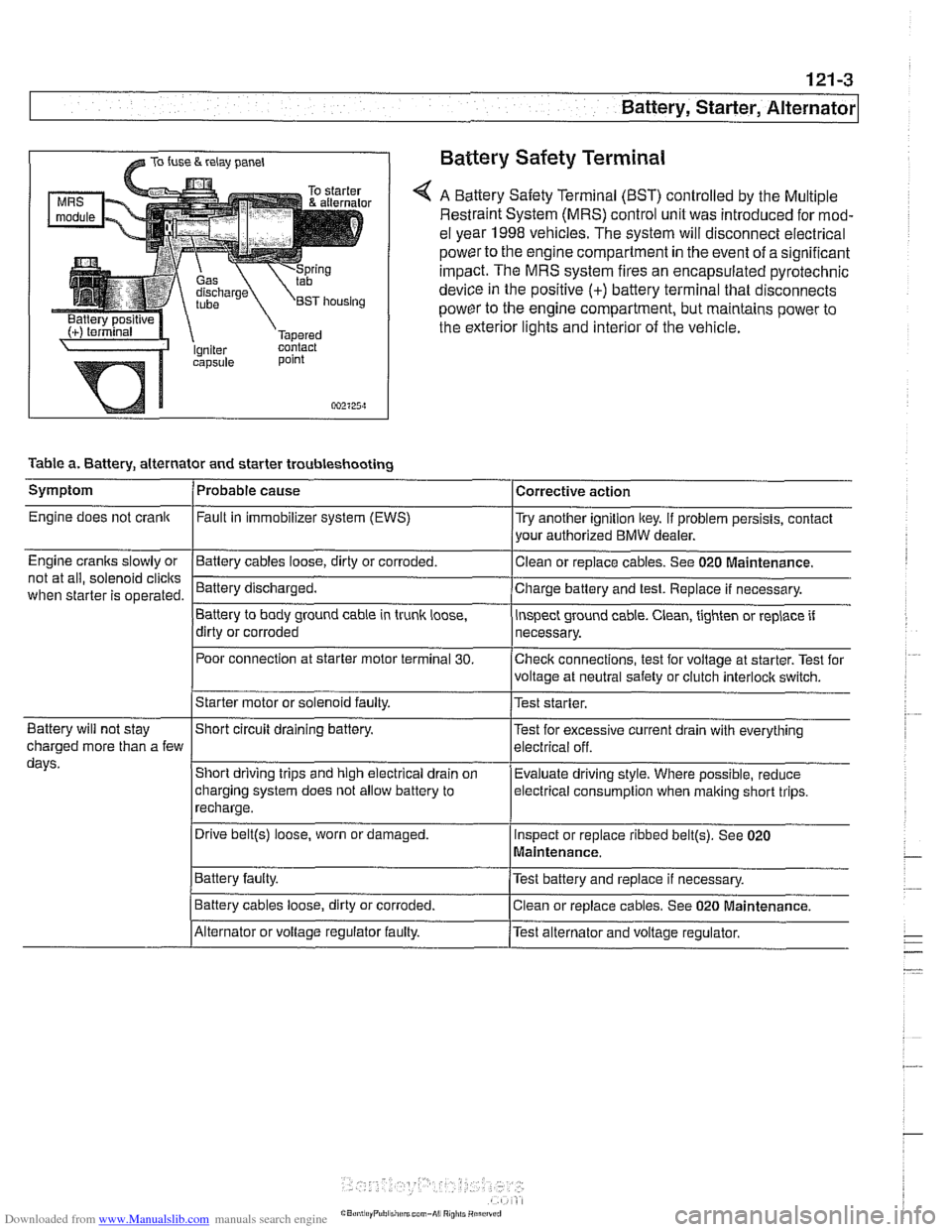

@ TO fuse & relay panel Battery Safety Terminal

A Battery Safety Terminal (BST) controlled by the Multiple

Restraint System (MRS) control unit was introduced for mod-

el year 1998

vehicles. The system will disconnect electrical

power to the engine compartment

in the event of a significant

impact. The MRS system fires an encapsulated pyrotechnic

device

in the positive (+) battery terminal that disconnects

power to the engine compartment, but maintains power to

the exterior lights and interior of the vehicle.

point

002125~1

Table a. Battery, alternator and starter troubleshooting

1-

/Starter motor or solenoid faulty. l~est starter.

Symptom

Engine does not crank

Engine cranks slowly or

not at all, solenoid

clicits

when starter is operated.

I I

Battery will not stay IShort circuit draining battery. l~est for excessive current drain with everything

Probable cause

Fault

in immobilizer system (EWS)

-Clean Battery cables loose, dirty or corroded.

Battery discharged.

Battery to body ground cable in trunk

loose,

dirty or corroded

Poor connection at starter motor terminal

30.

Corrective action

Try another ignition key. If problem persists, contact

your authorized BMW dealer.

or replace cables. See 020

~aintenance.

Charge battery and test. Replace if necessary.

inspect ground cable. Clean, tighten or replace if

necessary.

Checlc connections, test for voltage at starter. Test for

voltage at neutral safety or clutch

interloclc switch.

charged more than a few

days.

I~atter~ faulty. /Test battery and replace if necessary.

Short driving trips and high electrical drain

on

charging system does not allow battery to

recharge.

. I

I Battery cables loose, dirty or corroded. Iclean or replace cables. See 020 Maintenance.

Evaluate driving

style. Where possible, reduce

electrical

consumption when malting short trips.

Drive

belt@) loose, worn or damaged.

IAlternator or voltage regulator faulty. /Test alternator and voltage regulator.

Inspect

or replace ribbed

belt@). See 020

Maintenance.

Page 373 of 1002

Downloaded from www.Manualslib.com manuals search engine

Battery, Starter, ~lternatorl

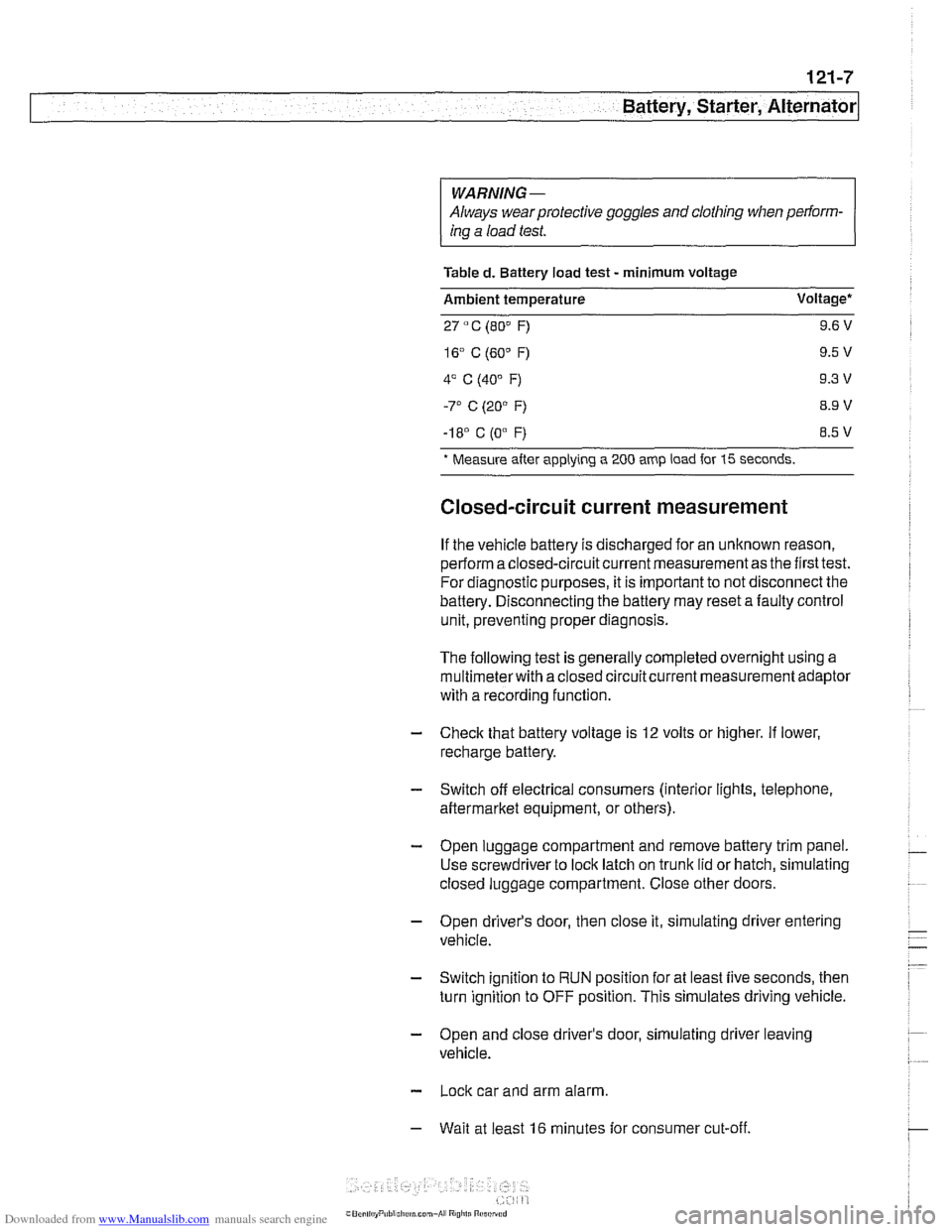

WARNING-

Always wear protective goggles and clothing when perform-

ing a load test.

Table

d. Battery load test - minimum voltage

Ambient temperature Voltage*

27

" C (80" F) 9.6 V

-I 8' C (0"

F) 8.5 V

* Measure

after applying a 200 amp load for 15 seconds.

Closed-circuit current measurement

If the vehicle battery is discharged for an unknown reason,

perform a closed-circuit current measurement as the first test.

For diagnostic purposes, it is important to not disconnect the

battery. Disconnecting the battery may reset a faulty control

unit, preventing proper diagnosis.

The following test is generally completed overnight using a

multimeterwith a closed circuitcurrent measurement adaptor

with a recording function

- Check that battery voltage is 12 volts or higher. If lower,

recharge battery.

- Switch off electrical consumers (interior lights, telephone,

aftermarket equipment, or others).

- Open luggage compartment and remove battery trim panel.

Use screwdriver to lock latch on trunk lid or hatch, simulating

closed luggage compartment. Close other doors.

- Open driver's door, then close it, simulating driver entering

vehicle.

- Switch ignition to RUN position for at least five seconds, then

turn ignition to OFF position. This simulates driving vehicle.

- Open and close driver's door, simulating driver leaving

vehicle.

- Lock car and arm alarm.

- Wait at least 16 minutes for consumer cut-off.

Page 375 of 1002

Downloaded from www.Manualslib.com manuals search engine

121-9

Battery, Starter, ~lternatorl

Battery charging

Discharged batteries can be recharged using a batterycharg-

er. Remove the battery from the trunk during charging.

Prolonged charging causes electrolyte evaporation to a level

that can damage the battery. It is best to use a low-current

charger

(6 amperes or less) to prevent battery damage

caused by overheating.

WARNING -

Hydrogen gas given off by the battery during charging is ex-

plosive. Do not smoke.

Keep open flames away from the top

ofthe batte~ and prevent electrical sparks by turning off the

battery charger before connecting or disconnecting it.

Battery electrolyte (sulfuric acid) can damage the car. If

electrolyte is spilled, clean the area with a solution

ofbak-

ing soda and water.

Always allow a frozen battery to thaw before attempting

to recharge it.

Always disconnect both battery cables and remove bat-

tery from vehicle during battery charging. Do not ex-

ceed

16.5 charging voltage at the battery

Battery safety terminal, replacing

If the battery safety terminal has been triggered, investigate

and correct the cause prior to replacement.

- Working in right side of luggage compartment, remove bat-

tery trim panel.

- Disconnect negative (-) battery terminal and cover with

insulator.

- Disconnect positive (+) cable from battery.

- Release positive (+) cable from cable brackets on luggage

compartment wall. Lay new repair cable parallel to positive

cable.

- Mark off length of new cable on old cable. Allow 10 cm

(2.5 in) of slack.

- Saw through old cable.

Do not use bolt cutters or similar tools to cut through cable.

A cable end that has been squashed

flat will not fit into the

Page 634 of 1002

Downloaded from www.Manualslib.com manuals search engine

300-1 4

I Susoension. Steerina and Brakes - General

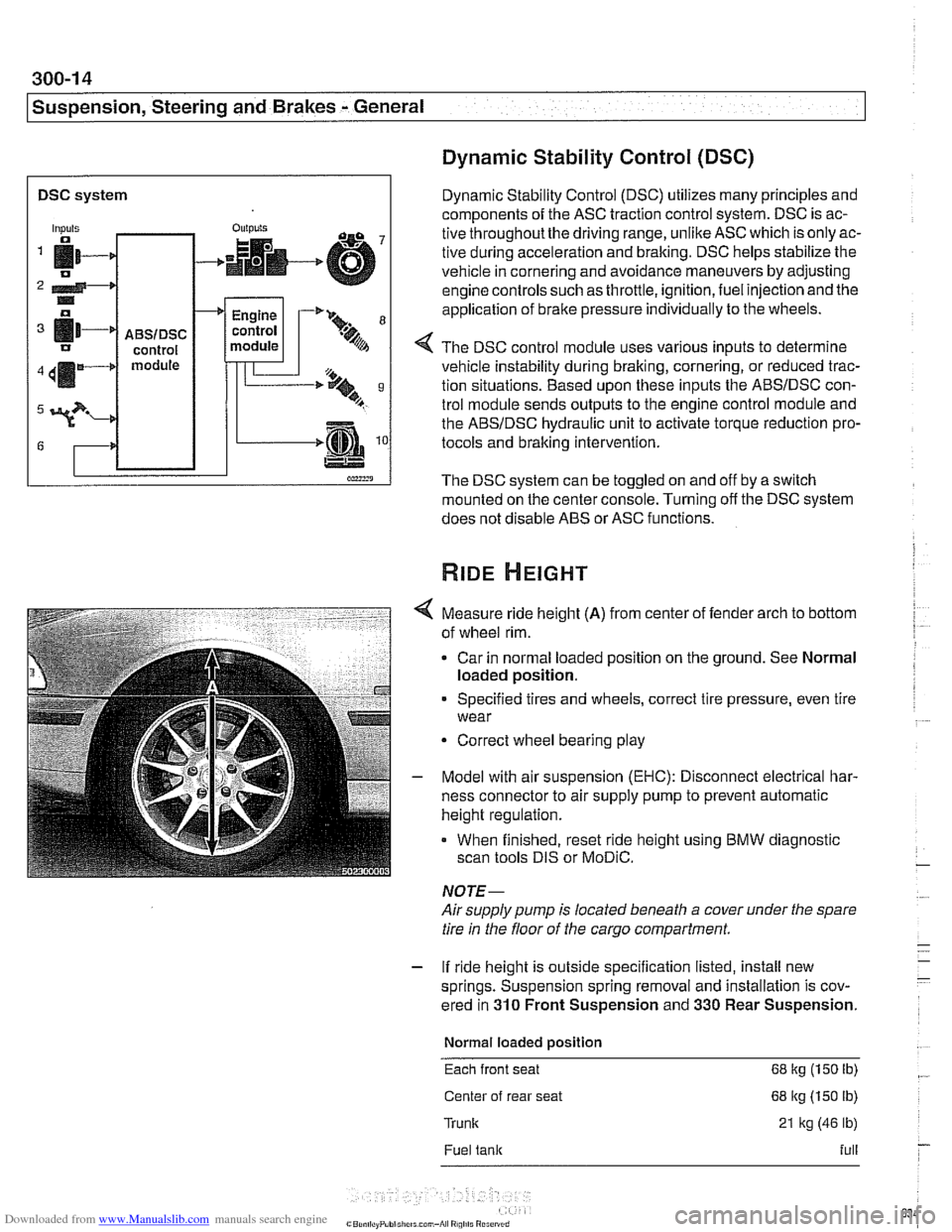

DSC system I

Dynamic Stability Control (DSC)

Dynamic Stability Control (DSC) utilizes many principles and

components of the ASC traction control system. DSC is ac-

tive throughoutthe driving range, unlike ASC which is only ac-

tive during acceleration and braking. DSC helps stabilize the

vehicle in cornering and avoidance maneuvers by adjusting

engine controls such as throttle, ignition, fuel injection and the

application of

brake pressure individually to the wheels.

Inputs

fi- 0

2 4-* .. o

[11-' IJ

411m4

3?-

G

4 The DSC control module uses various inputs to determine

vehicle instability during braking, cornering, or reduced trac-

tion situations. Based upon these inputs the ABSIDSC con-

trol module sends outputs to the engine control module and

the ABSIDSC hydraulic unit to activate torque reduction pro-

tocols and braking intervention.

-

ABSIDSC control module

OUI~YIS

4

The DSC system can be toggled on and off by a switch

mounted on the center console. Turning off the DSC system

does not disable ABS or ASC functions.

+

Measure ride height (A) from center of fender arch to bottom

of wheel rim.

Car in normal loaded position on the ground. See Normal

loaded position.

Engine

control

module

Specified tires and wheels, correct tire pressure, even tire

wear

-'* 9-

.%A

Correct wheel bearing play

T'== ..t, 9 B

-.m

Model with air suspension (EHC): Disconnect electrical har-

ness connector to air supply pump to prevent automatic

height regulation.

When finished, reset ride height using BMW diagnostic

scan tools DIS or

MoDiC.

NOTE-

Airsupply pump is located beneath a cover under the spare

tire in the floor of the cargo compartment.

- If ride height is outside specification listed, install new

springs. Suspension spring removal and installation is cov-

ered in

310 Front Suspension and 330 Rear Suspension.

Normal loaded position

Each front seat 68 kg (150 Ib)

Center of rear seat 68 kg (150 lb)

Trunk 21 kg (46 lb)

Fuel tank full

Page 701 of 1002

Downloaded from www.Manualslib.com manuals search engine

330-5

Rear Suspension

REAR STRUTS AND SPRINGS

(SEDAN MODELS)

Rear strut assembly, removing and

installing

Replace struts and coil springs in pairs only.

- Raise car and remove rear wheels.

WARNING -

Male sure the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands underneath struc-

tural chassis points. Do not place jack stands under

suspension parts.

- Remove rear parcel shelf:

Remove rear seat headrests by pulling straight up.

Remove both rear roof pillar (C-pillar) trim panels.

Unbolt rear seat

belt anchors. See 720 Seat Belts.

Models with fixed rear seat: Remove rear seat backrest.

See 520 Seats.

* Models with fold-down rear seat: Remove rear seat back-

rest side sections. See 520 Seats. Fold down backrest.

* Working inside trunk, remove roller blind mounting nuts

and bolts, if applicable. Also disconnect roller blind har-

ness connector at right edge of rear seat backrest.

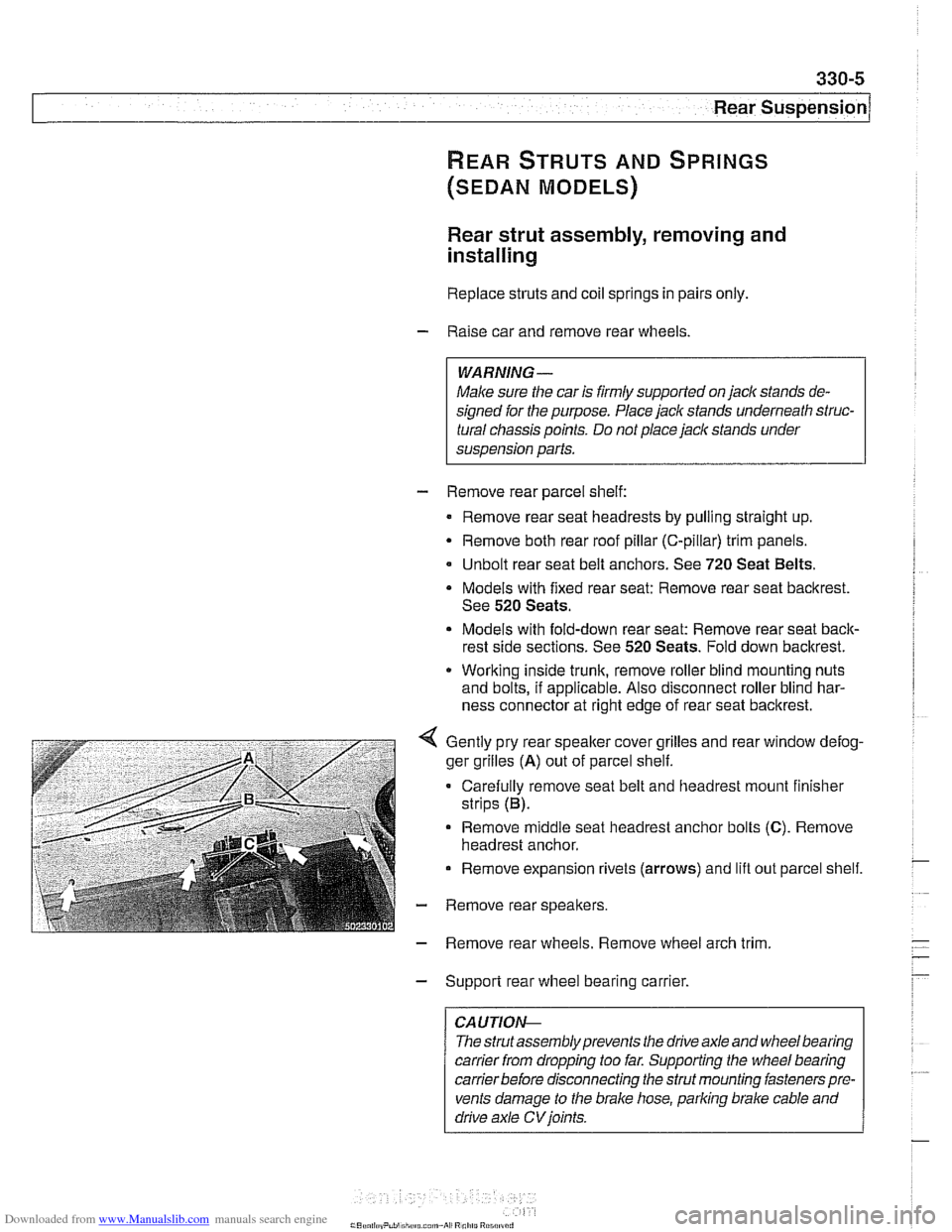

Gently pry rear speaker cover grilles and rear window defog-

ger grilles

(A) out of parcel shelf.

Carefully remove seat belt and headrest mount finisher

strips (B).

Remove

middle seat headrest anchor bolts (C). Remove

headrest anchor.

Remove expansion rivets (arrows) and lift out parcel shelf.

- Remove rear speakers.

- Remove rear wheels. Remove wheel arch trim

- Support rear wheel bearing carrier.

CAUTION-

The strutassembly prevents the drive axle and wheel bearing

carrier

from dropping too far. Supporting the wheel bearing

carrierbefore disconnecting the strut mounting fasteners pre-

vents damage to the brake hose, parking brake cable and

drive axle

CV joints.