manual transmission BMW 540i 2001 E39 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 540i, Model: BMW 540i 2001 E39Pages: 1002

Page 146 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .- --

Cylinder Head Removal and Installation

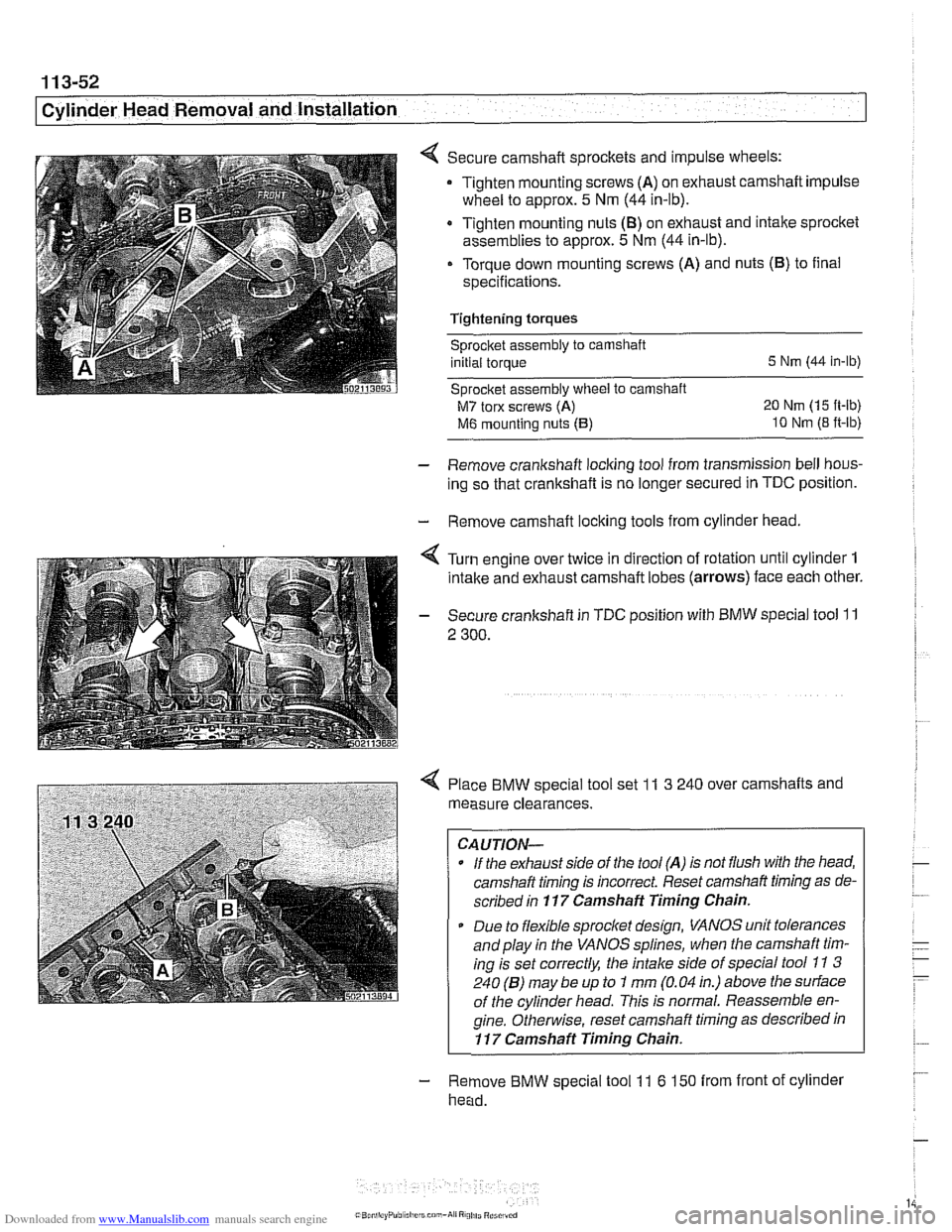

Secure camshaft sprockets and impulse wheels:

Tighten mounting screws

(A) on exhaust camshaft impulse

wheel to approx.

5 Nm (44 in-lb).

Tighten mounting nuts

(8) on exhaust and intake sprocket

assemblies to approx.

5 Nm (44 in-lb).

Torque down mounting screws (A) and nuts (B) to final

specifications.

Tightening torques

sprocket assembly to camshaft

initial torque

5 Nm (44 in-lb)

Sprocket assembly

wheel to camshaft

M7 torx screws (A) 20 Nm (15 ft-lb)

M6 mounting nuts (5) 10 Nm (8 ft-lb)

- Remove crankshaft locking tool from transmission bell hous-

ing so that crankshaft is no longer secured in

TDC position.

- Remove camshaft locking tools from cylinder head.

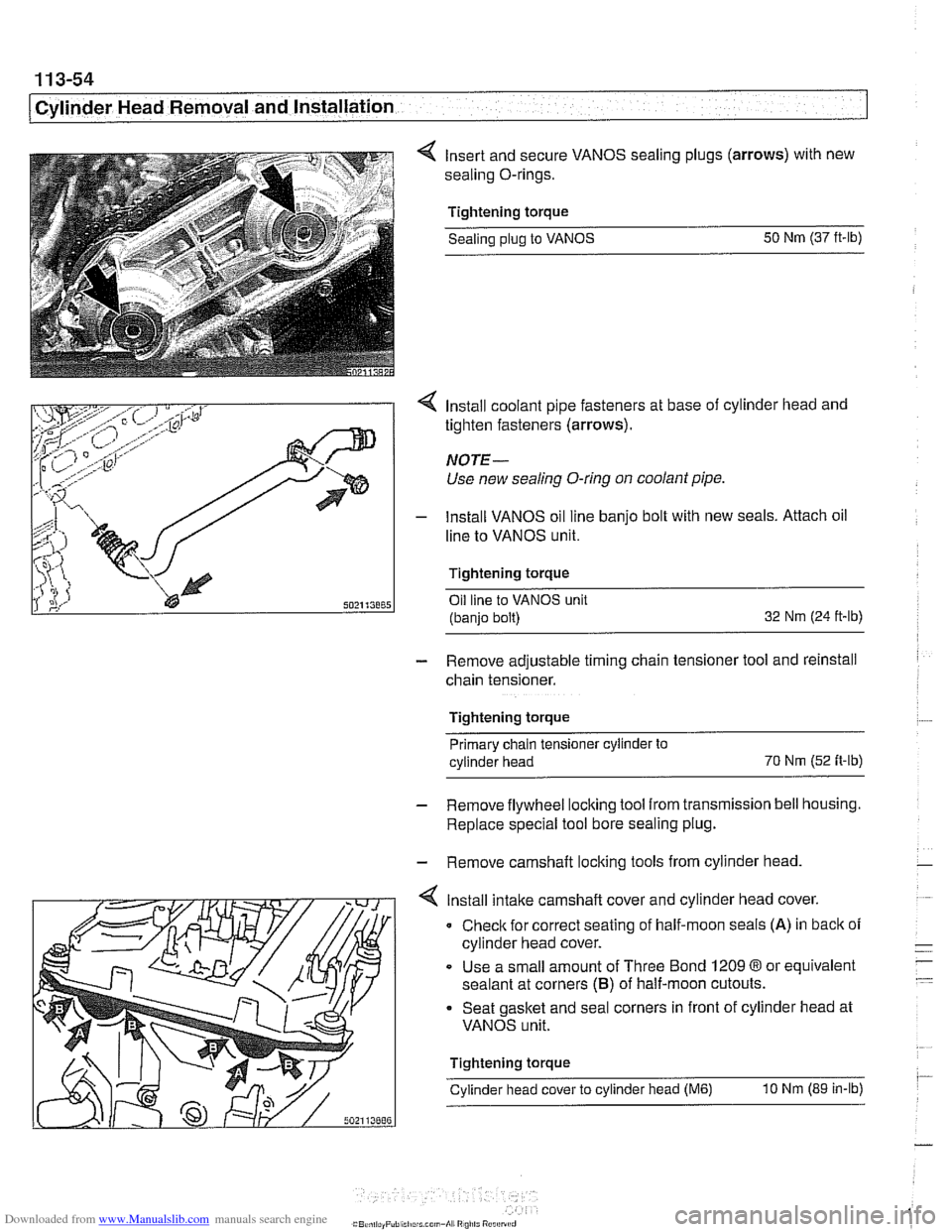

4 Turn engine over twice in direction of rotation until cylinder 1

intake and exhaust camshaft lobes (arrows) face each other.

- Secure crankshaft in TDC position with BMW special tool 11

2 300.

4 Place BMW special tool set 11 3 240 over camshafts and

measure clearances.

CAUTION-

- If the exhaust side of the tool (A) is not flush with tlie head,

camshaft timing is incorrect Reset camshaft timing as de-

scribed in

117 Camshaft Timing Chain.

* Due to flexible sprocket design, VANOS unit tolerances

and play in the VANOS splines, when the camshaft tim-

ing is set correctly, the intake side of special tool

11 3

240 (6) may be up to 1 mm (0.04 in.) above the surface

of the cylinder head. This is normal. Reassemble en-

gine.

Othe~lise, reset camshaft timing as described in

11 7 Camshaft Timing Chain.

- Remove BMW special tool 11 6 150 from front of cylinder

head.

Page 148 of 1002

Downloaded from www.Manualslib.com manuals search engine

. ." ".

[Cylinder Head Removal and Installation - .. - -1 -

4 Insert and secure VANOS sealing plugs (arrows) with new

sealing O-rings.

Tightening torque Sealing

plug to VANOS 50

Nm (37 ft-lb)

4 Install coolant pipe fasteners at base of cylinder head and

tighten fasteners (arrows).

NOTE-

Use new sealing O-ring on coolant pipe.

- lnstall VANOS oil line banjo bolt with new seals. Attach oil

line to VANOS unit.

Tightening torque Oil line to VANOS unit

(banjo bolt) 32

Nm (24 ft-ib)

- Remove adjustable timing chain tensioner tool and reinstall

chain tensioner.

Tightening torque Primary chain tensioner cylinder to

cylinder head 70

Nm

(52 fi-ib)

- Remove flywheel locking tool from transmission bell housing.

Replace special tool bore sealing plug.

- Remove camshaft locking tools from cylinder head

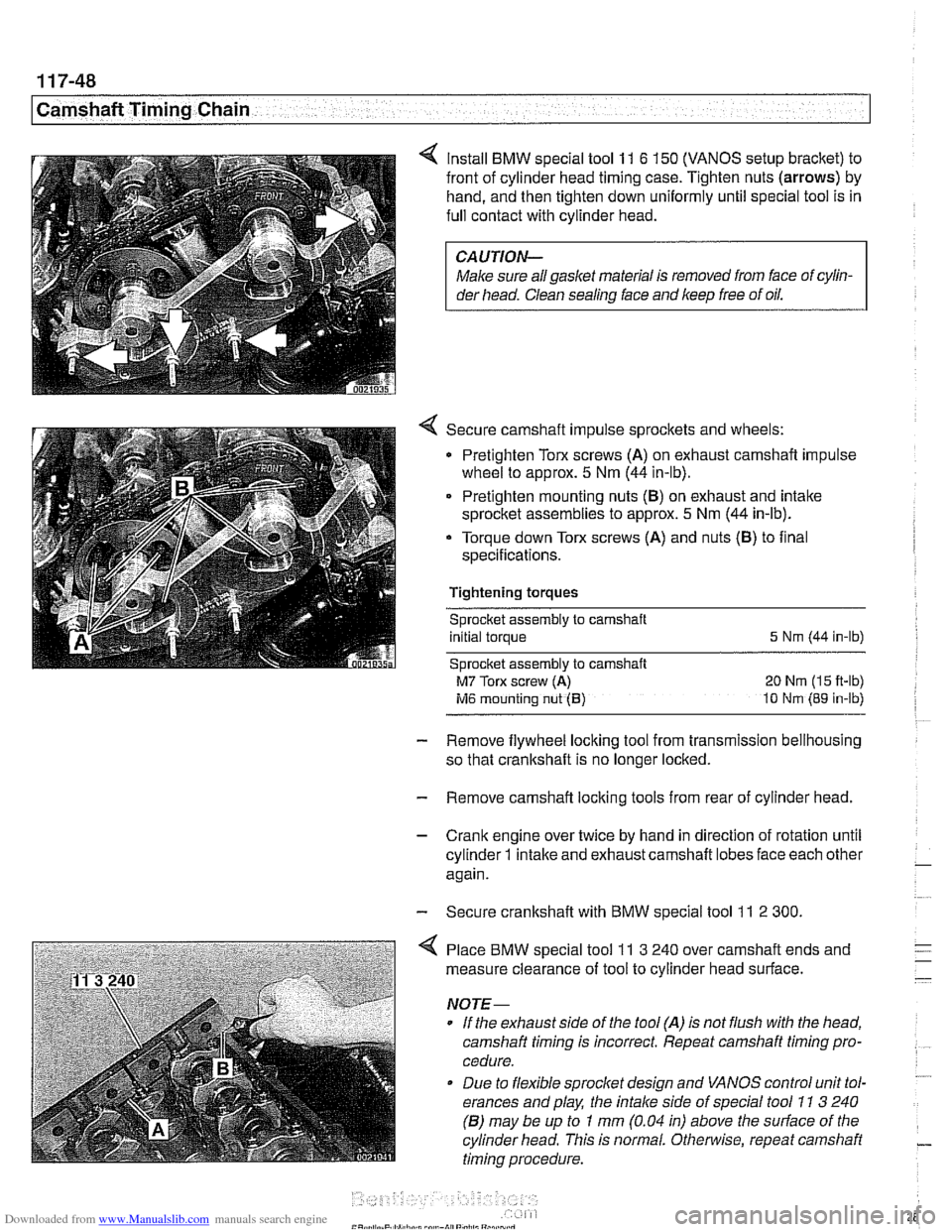

4 lnstall intake camshaft cover and cylinder head cover.

0 Check for correct seating of half-moon seals (A) in back of

cylinder head cover.

Use a small amount of Three Bond

1209 8 or equivalent

sealant at corners

(B) of half-moon cutouts.

Seat gasket and seal corners in front of cylinder head at

VANOS unit.

Tightening torque

Cylinder head cover to cylinder head

(M6) 10 Nm (89 in-lb)

Page 284 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

I Camshaft Timing Chain - --

Install BMW special tool 11 6 150 (VANOS setup bracket) to

front of cylinder head timing case. Tighten nuts

(arrows) by

hand, and then tighten down uniformly until special tool is in

full contact with cylinder head.

CAUTION-

Male sure all gasket material is removed from face of cylin-

der head. Clean

sealins face and keep free of oil.

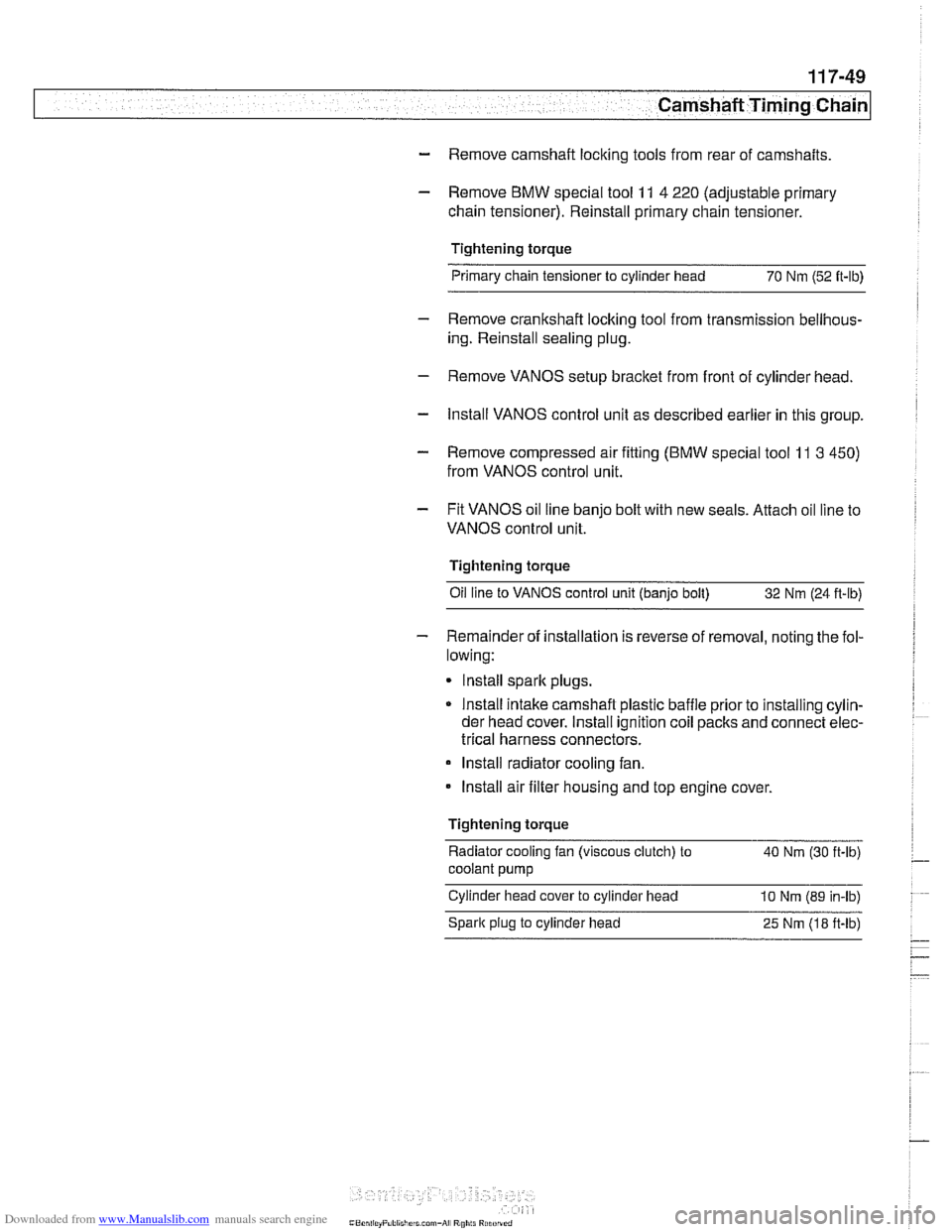

Secure camshaft impulse sprockets and wheels:

Pretighten Torx screws

(A) on exhaust camshaft impulse

wheel to approx.

5 Nm (44 in-lb).

Pretighten mounting nuts

(B) on exhaust and intake

sprocket assemblies to approx.

5 Nm (44 in-lb).

- Torque down Torx screws (A) and nuts (8) to flnal

specifications.

Tightening torques Sprocket assembly

to camshaft

initial torque

5 Nm (44 in-lb)

Sprocket assembly to camshaft

M7 Torx screw (A) 20 Nm (15 fl-lb)

ivl6 mounting nut (B) 10 tdm (89 in-lb)

- Remove flywheel locking tool from transmission bellhousing

so that crankshaft is no longer locked.

- Remove camshaft locking tools from rear of cylinder head.

- Crank engine over twice by hand in direction of rotation until

cylinder

1 intake and exhaust camshaft lobes face each other - again.

- Secure crankshaft with BMW special tool 11 2 300.

4 Place BMW special tool 11 3 240 over camshaft ends and

measure clearance of tool to cylinder head surface.

NOJE-

If the exhaust side of the tool (A) is not flush with the head,

camshaft timing

Is incorrect. Repeat camshaft timing pro-

cedure.

* Due to flexible sprocket design and VANOS control unit tol-

erances and play, the

intake side of special tool 11 3 240

(6) may be up to 1 mm (0.04 in) above the sudace of the

cylinder head. This is normal. Otherwise, repeat camshaft

timing procedure.

Page 285 of 1002

Downloaded from www.Manualslib.com manuals search engine

-- - -- - -- Camshaft Timing chain1

- Remove camshaft locking tools from rear of camshafts

- Remove BMW special tool 11 4 220 (adjustable primary

chain tensioner). Reinstall primary chain tensioner.

Tightening torque Primary chain tensioner to cylinder head

70

Nm (52 it-lb)

- Remove crankshaft locking tool from transmission bellhous-

ing. Reinstall sealing plug.

- Remove VANOS setup bracket from front of cylinder head

- lnstall VANOS control unit as described earlier in this group.

- Remove compressed air fitting (BMW special tool 11 3 450)

from VANOS control unit.

- Fit VANOS oil line banjo bolt with new seals. Attach oil line to

VANOS control unit.

Tightening torque

Oil line to VANOS control unit (banjo bolt) 32 Nm (24 H-lb)

- Remainder of installation is reverse of removal, noting the fol-

lowing:

lnstall spark plugs.

* lnstall intake camshaft plastic baffle prior to installing cylin-

der head cover. lnstall ignition coil packs and connect elec-

trical harness connectors.

Install radiator cooling fan.

- lnstall air filter housing and top engine cover.

Tightening torque Radiator cooling fan

(VISCOUS clutch) to 40 Nm (30 ft-lb)

coolant pump

Cyitnder head cover to cylinder head 10 Nm (89 in-lb)

Sparlc plug to cylinder head 25 Nm (18 ft-lb)

Page 291 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 7-55

Camshaft Timing Chain

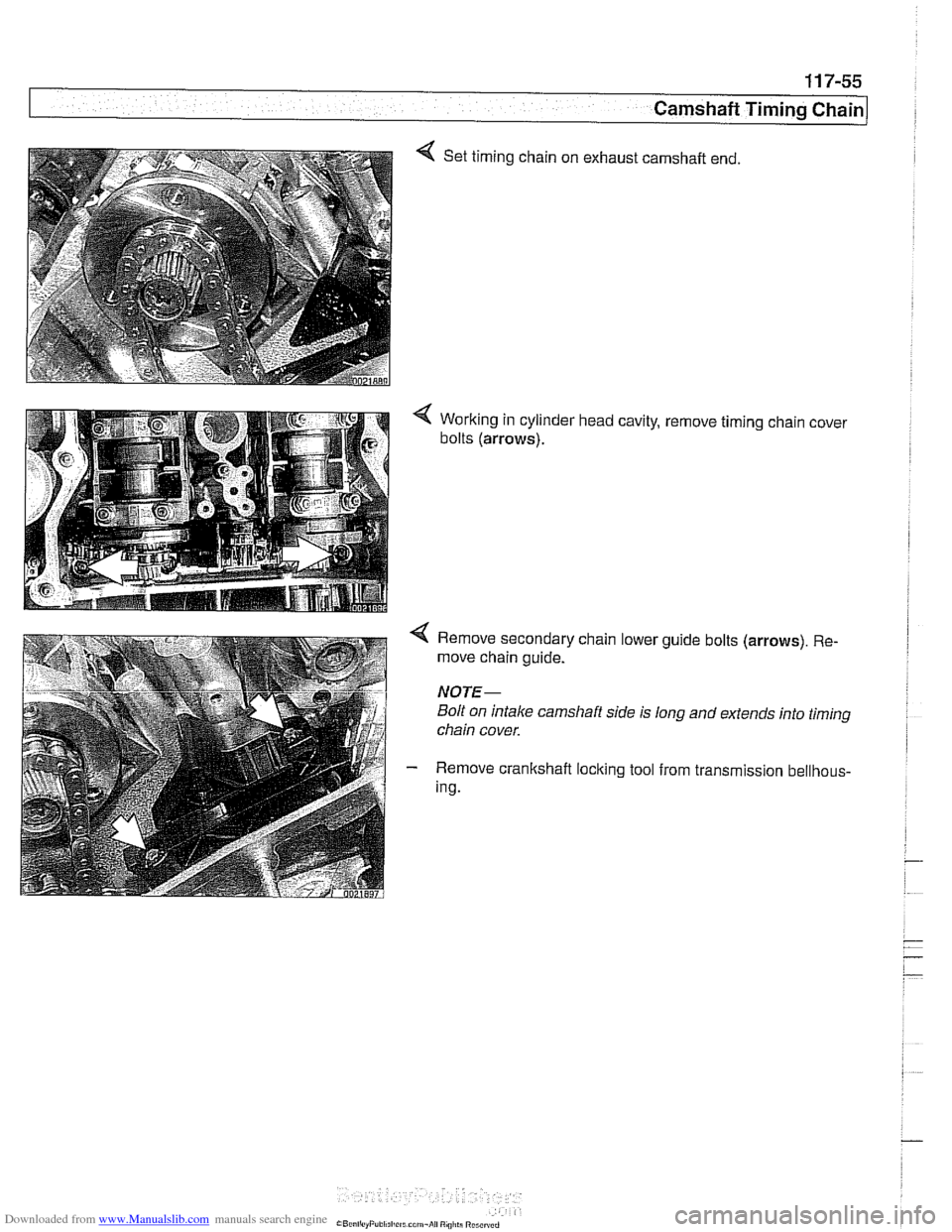

< Set timing chain on exhaust camshaft end

< Working in cylinder head cavity, remove timing chain cover

bolts

(arrows).

< Remove secondary chain lower guide bolts (arrows). Re-

move chain guide.

NOTE-

Bolt on intake camshaft side is long and extends into timing

chain cover.

- Remove crankshaft loclting tool from transmission bellhous-

ing.

Page 301 of 1002

Downloaded from www.Manualslib.com manuals search engine

Cp-- Camshaft -- Timing Chain

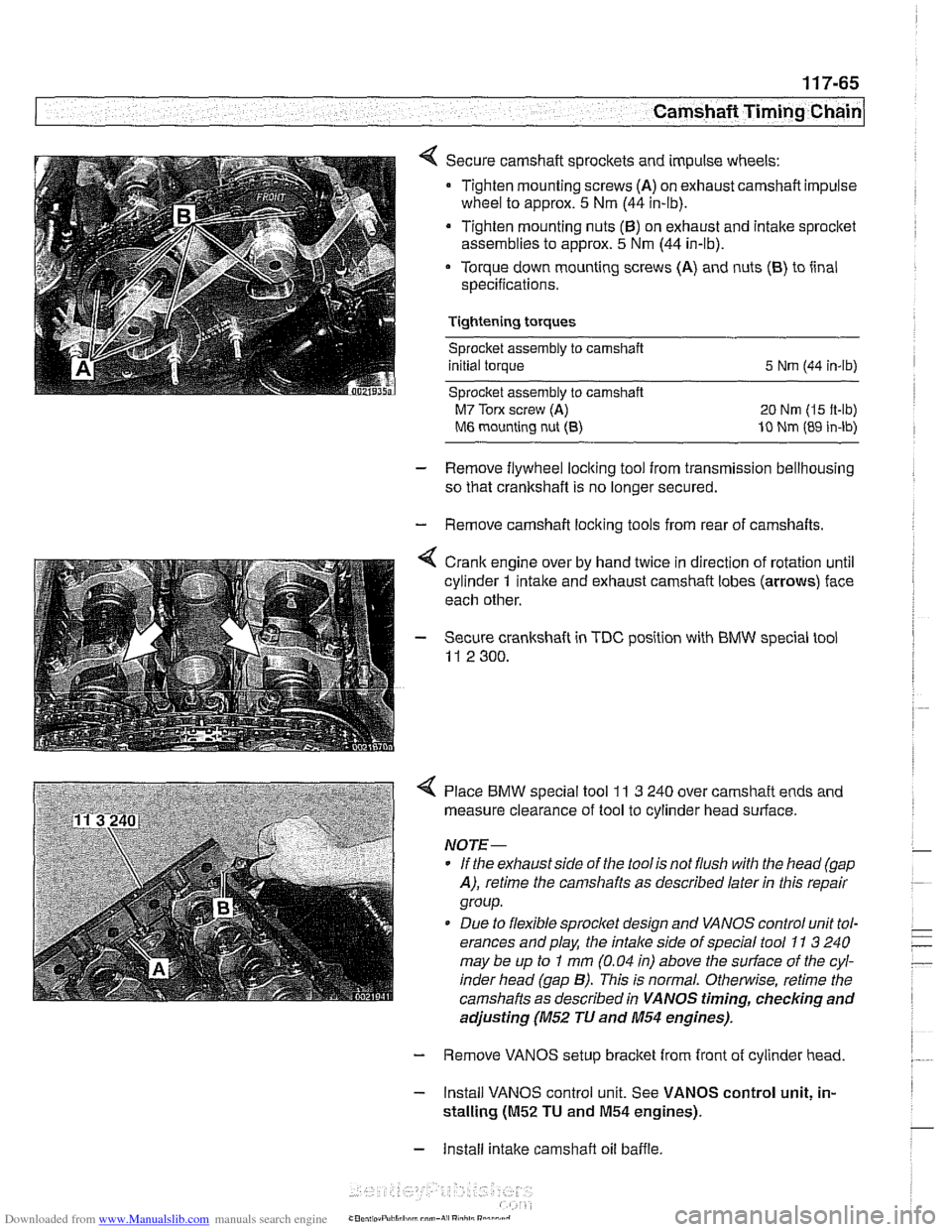

Secure camshaft sprockets and impulse wheels:

Tighten mounting screws

(A) on exhaust camshaft impulse

wheel to approx.

5 Nm (44 in-lb).

Tighten mounting nuts

(6) on exhaust and intake sprocket

assemblies to approx.

5 Nm (44 in-lb).

Torque down mounting screws (A) and nuts

(6) to iinal

specifications.

Tightening torques Sprocket assembly

to camshaft

initial torque

5 Nrn (44 in-lb)

Sprocket assembly to camshaft

M7 Torx screw (A) 20 Nm (I5 it-lb)

M6 mounting nut (8) 10 Nm (89 in-lb)

- Remove flywheel locking tool from transmission bellhousing

so that crankshaft is no longer secured.

- Remove camshaft loclting tools from rear of camshafts.

4 Crank engine over by hand twice in direction of rotation until

cylinder

1 intake and exhaust camshaft lobes (arrows) face

each other.

- Secure crankshaft in TDC position with BMW special tool

11 2 300.

4 Place BMW special tool 11 3 240 over camshaft ends and

measure clearance of tool to cylinder head surface.

NOTE-

* If the exhaust side of the tool is not flush with the head (gap

A), retime the camshafts as described laler in this repair

group.

Due to flexible sprocket design and VANOS control unit tol-

erances and play, the

intake side of special tool 71 3 240

may be up to

I mm (0.04 in) above the suriace of the cyl-

inder head (gap

B). This is normal. Otherwise, retime the

camshafts as described in

VANOS timing, checking and

adjusting (M52 TU and 11154 engines).

- Remove VANOS setup bracket from front of cylinder head

- Install VANOS control unit. See VANOS control unit, in-

stalling

(01152 TU and M54 engines).

- Install intake camshaft oil baffle

Page 318 of 1002

Downloaded from www.Manualslib.com manuals search engine

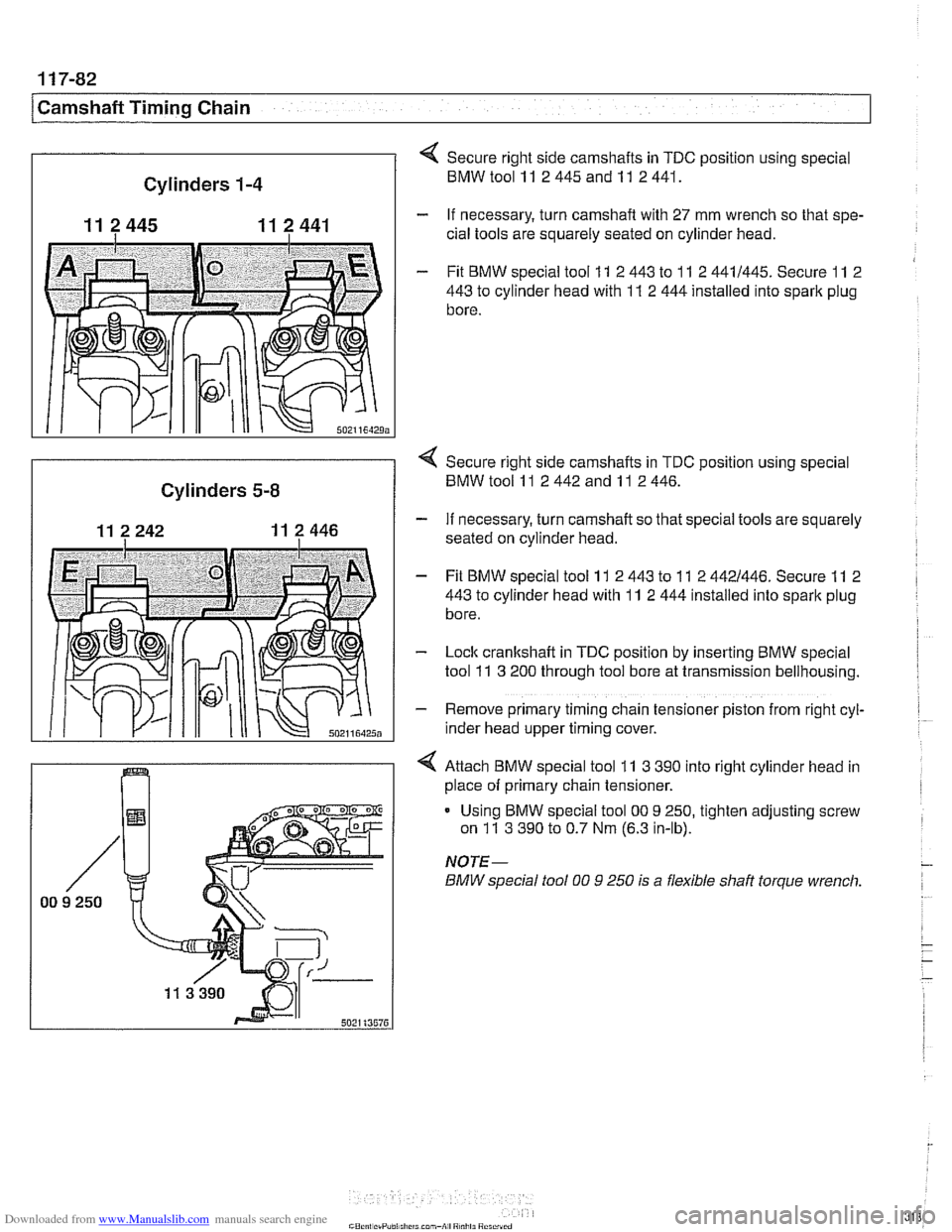

[camshaft Timina Chain Cylinders

1-4

11 2445 11 2 441

502116429;

Secure right side camshafts in TDC position using special

BMWtoolll 2445andll 2441.

- If necessary, turn camshaft with 27 mm wrench so that spe-

cial tools are squarely seated on cylinder head.

- Fit BMW special tool 11 2 443 to 11 2 4411445. Secure 11 2

443

to cylinder head with 11 2 444 installed into spark plug

bore.

I

< Secure right side camshafts in TDC position using special

Cylinders 5-8 BMW tool 11 2 442 and 11 2 446.

- If necessary, turn camshaft so that special tools are squarely

seated on cylinder head.

- Fit BMW special tool 11 2 443 to 11 2 4421446. Secure 11 2

443

to cylinder head with 11 2 444 installed into spark plug

bore.

- Lock cranltshaft in TDC position by inserting BMW special

tool

11 3 200 through tool bore at transmission bellhousing.

- Remove primary timing chain tensioner piston from right cyl-

~nder head upper timing cover.

4 Attach BMW special tool 11 3 390 into right cylinder head in

place of primary chain tensioner.

Using BMW special tool

00 9 250, tighten adjusting screw

on

11 3 390 to 0.7 Nm (6.3 in-lb).

NOTE-

BMW special fool 00 9 250 is a flexible shaft torque wrench.

Page 322 of 1002

Downloaded from www.Manualslib.com manuals search engine

11 9-2

Lubrication System

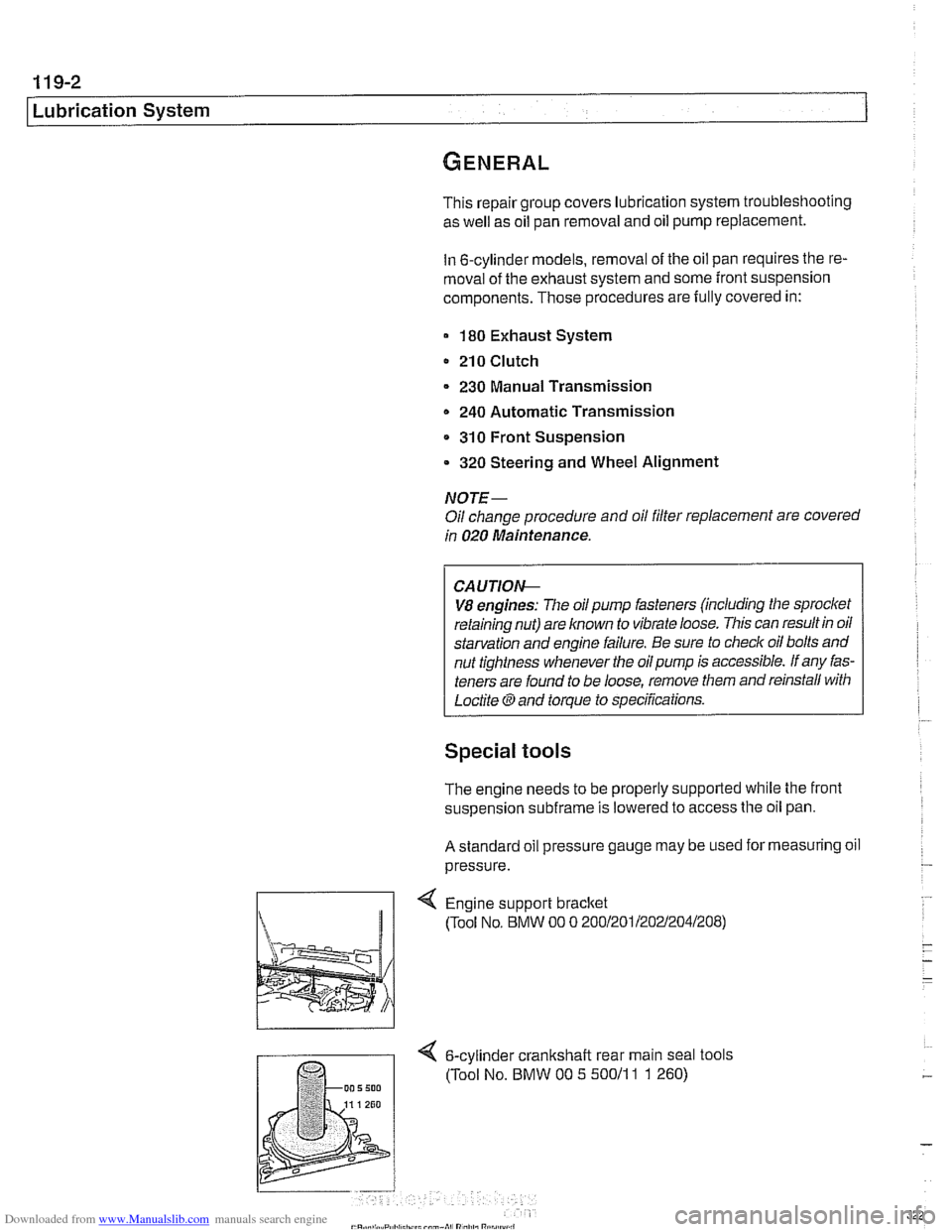

This repair group covers lubrication system troubleshooting

as well as oil pan removal and oil pump replacement.

In 6-cylinder models, removal of the oil pan requires the re-

moval of the exhaust system and some front suspension

components. Those procedures are fully covered in:

180 Exhaust System

210 Clutch

230 Manual Transmission

0 240 Automatic Transmission

310 Front Suspension

320 Steering and Wheel Alignment

NOTE-

Oil change procedure and oil filter replacement are covered

in

020 Maintenance.

CAUTIOG

V8 engines: The oil pump fasteners (including the sprocket

retaining nut) are known to vibrate loose. This can result in oil

starvation and engine failure. Be sure to check oil bolts and

nut tightness whenever the

oilpump is accessible. If any fas-

teners are found to be loose, remove them and reinstall with

Loctite

Band torque to specifications.

Special tools

The engine needs to be properly supported while the front

suspension

subframe is lowered to access the oil pan.

A standard oil pressure gauge may be used for measuring oil

pressure.

Engine support bracket

(Tool No, BMW 00 0 20012011202~2041208)

4 6-cylinder crankshalt rear main seal tools

(Tool No. BMW 00 5 50011

1 1 260)

Page 326 of 1002

Downloaded from www.Manualslib.com manuals search engine

Lubrication System

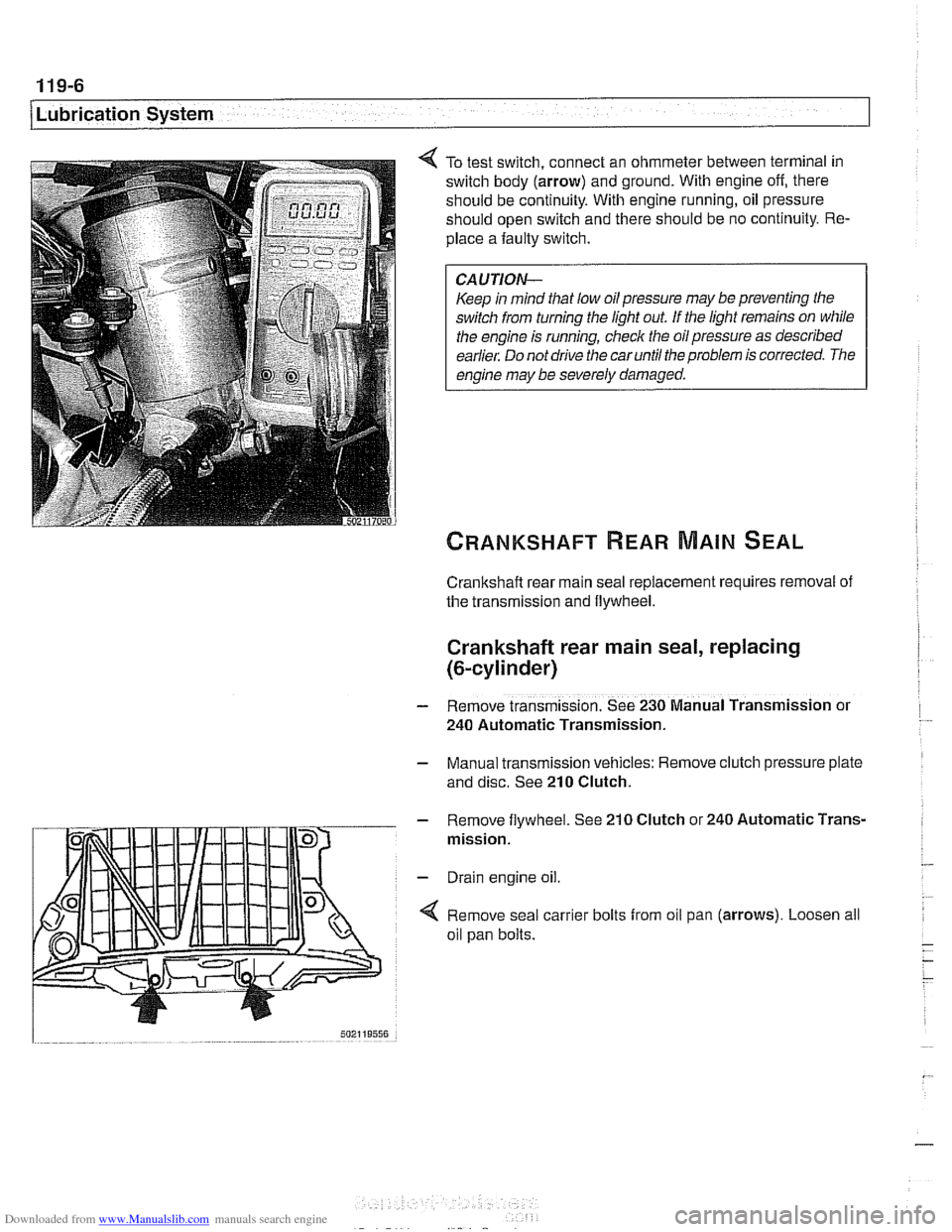

To test switch, connect an ohmmeter between terminal in

switch body (arrow) and ground. With engine off, there

should be continuity. With engine running, oil pressure

should open switch and there should be no continuity. Re-

place a faulty switch.

CAUTION-

Keep in mind that low oil pressure may be preventing the

switch from turning the light out

If the light remains on while

the engine is running, check the oil pressure as described

earlier. Do not drive the car until the problem is corrected. The

engine may be severely damaged.

Crankshaft rear main seal replacement requires removal of

the transmission and flywheel.

Crankshaft rear main seal, replacing

(&cylinder)

- Remove transmission. See 230 Manual Transmission or

240 Automatic Transmission.

- Manual transmission vehicles: Remove clutch pressure plate

and disc. See

210 Clutch.

- Remove flywheel. See 210 Clutch or 240 Automatic Trans-

mission.

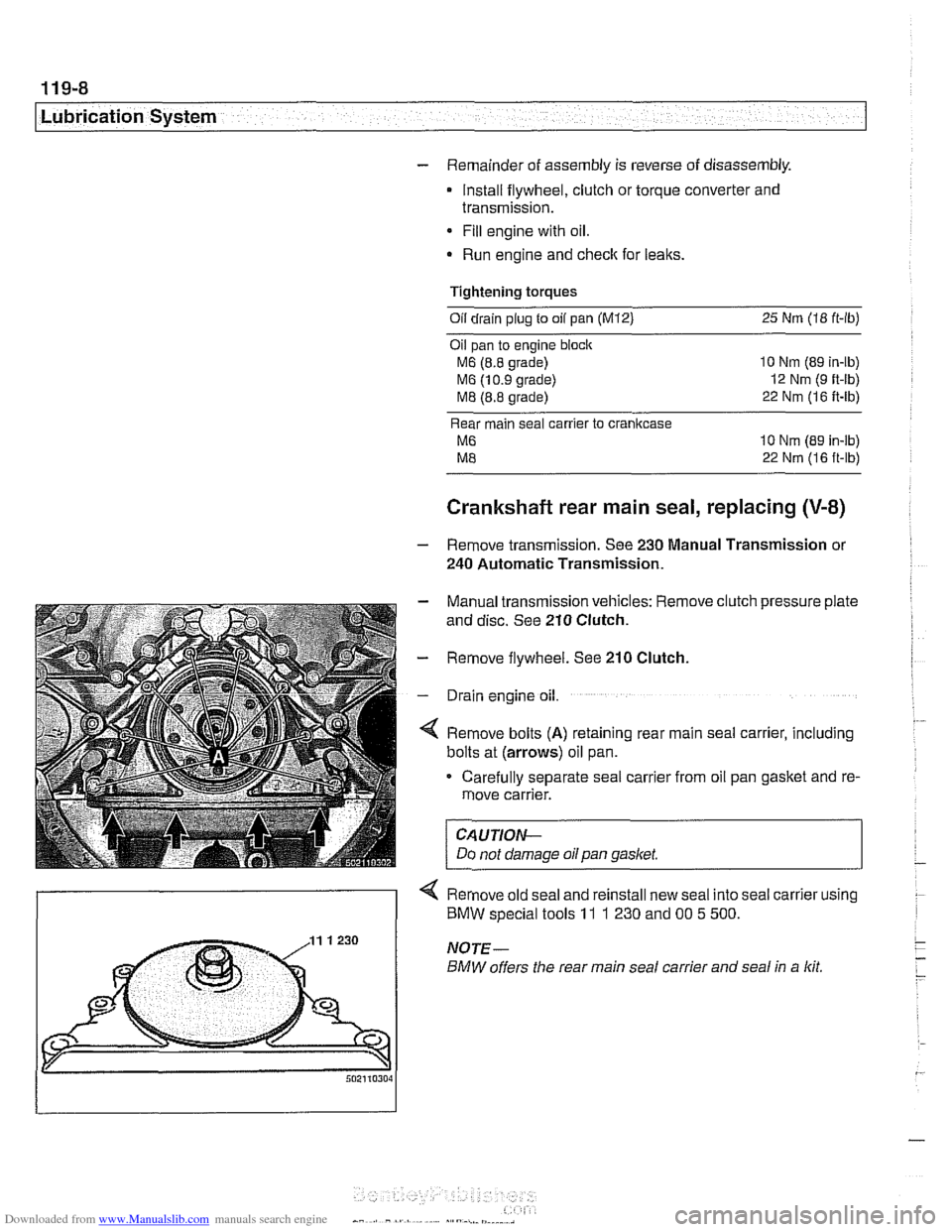

- Drain engine oil.

4 Remove seal carrier bolts from oil pan (arrows). Loosen all

oil pan bolts.

Page 328 of 1002

Downloaded from www.Manualslib.com manuals search engine

I Lubrication System -

- Remainder of assembly is reverse of disassembly.

Install flywheel, clutch or torque converter and

transmission.

Fill engine with oil.

- Run engine and check for leaks.

Tightening torques

Oil

drain plug fo oil pan (MI21 25 Nm (18 ft-lb)

Oil pan to engine

block

M6 (8.8 grade) 10 Nm (89 in-ib)

M6 (1 0.9 grade) 12 Nm (9 ft-lb)

M8 (8.8 grade) 22 Nm (1 6 it-lb)

Rear main seal carrier to crankcase

M6 10 Nm (89 in-lb)

ME 22 Nm (16 ft-lb)

Crankshaft rear main seal, replacing (V-8)

- Remove transmission. See 230 Manual Transmission or

240 Automatic Transmission.

- Manual transmission vehicles: Remove clutch pressure plate

and disc. See

210 Clutch.

- Remove flywheel. See 210 Clutch.

- Drain engine oil.

4 Remove bolts (A) retaining rear main seal carrier, including

bolts at (arrows) oil pan.

Carefully separate seal carrier from oil pan gasket and re-

move carrier.

CAUTION-

Do not damage oil pan gasket.

< Remove old seal and reinstall new seal into seal carrier using

) BMW special tools 11 1 230 and 00 5 500.