ignition BMW 540I 2002 E39 Central Body Electronics ZKE Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2002, Model line: 540I, Model: BMW 540I 2002 E39Pages: 80, PDF Size: 4.14 MB

Page 43 of 80

All window operations signals are digital inputs to the door module and GM III.

• Comfort closing/opening of the windows from the driver’s lock cylinder. The remote key

provides opening only.

• When the ignition key is in accessory or “on” position press the switch to open or close

the windows. Window operation is possible with the ignition switched off until a front

door is opened or 16 minutes (maximum) has elapsed.

• Window load switching is through relays. The front window control relays are located in

the door modules, the rear window relays are in the GM III. The GM III monitors the cur-

rent draw for end limit position. The maximum run time for the window motors is limit-

ed to 6 seconds in the one-touch mode. This allows the motors to be switched off if the

end limit load sensing fails.

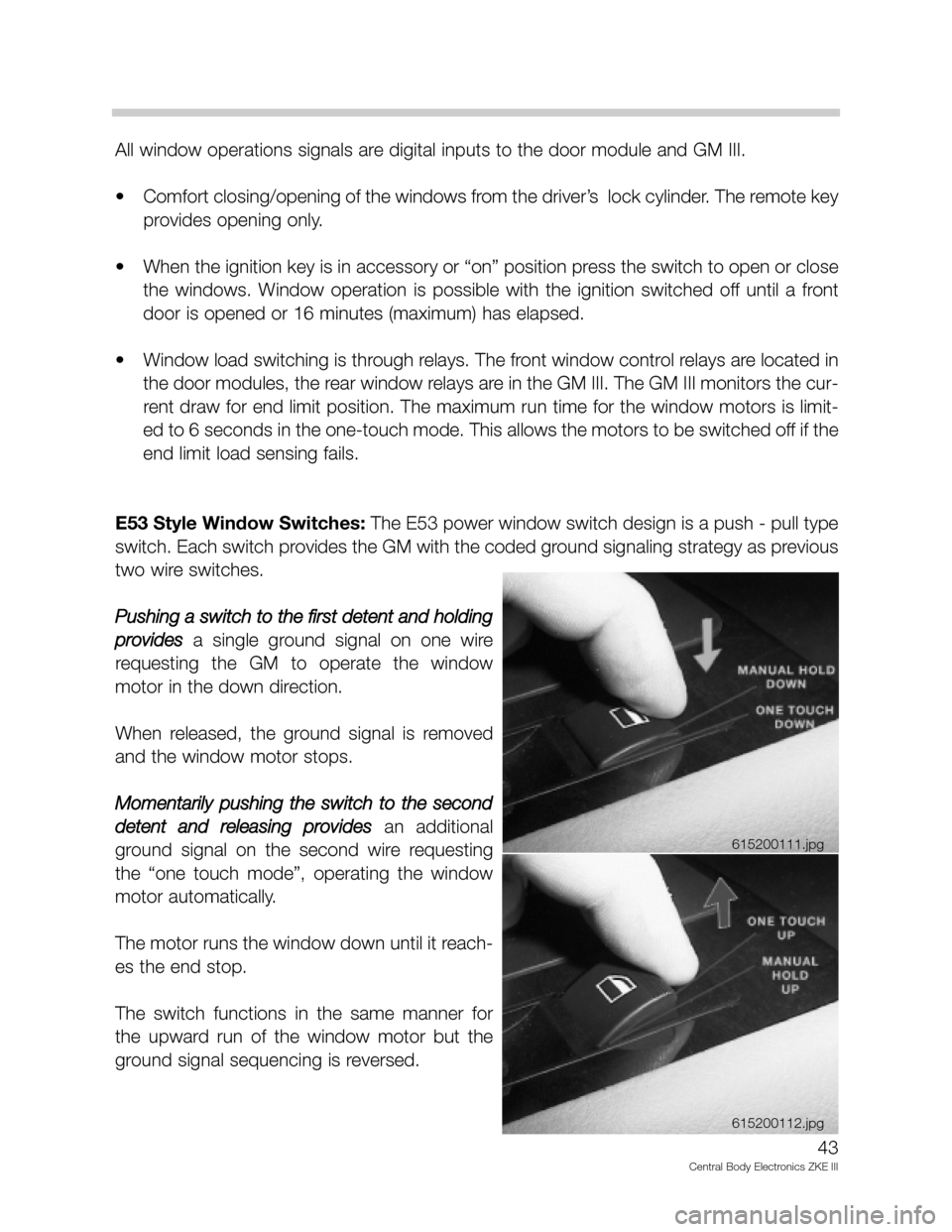

E53 Style Window Switches:The E53 power window switch design is a push - pull type

switch. Each switch provides the GM with the coded ground signaling strategy as previous

two wire switches.

Pushing a switch to the first detent and holding

provides

a single ground signal on one wire

requesting the GM to operate the window

motor in the down direction.

When released, the ground signal is removed

and the window motor stops.

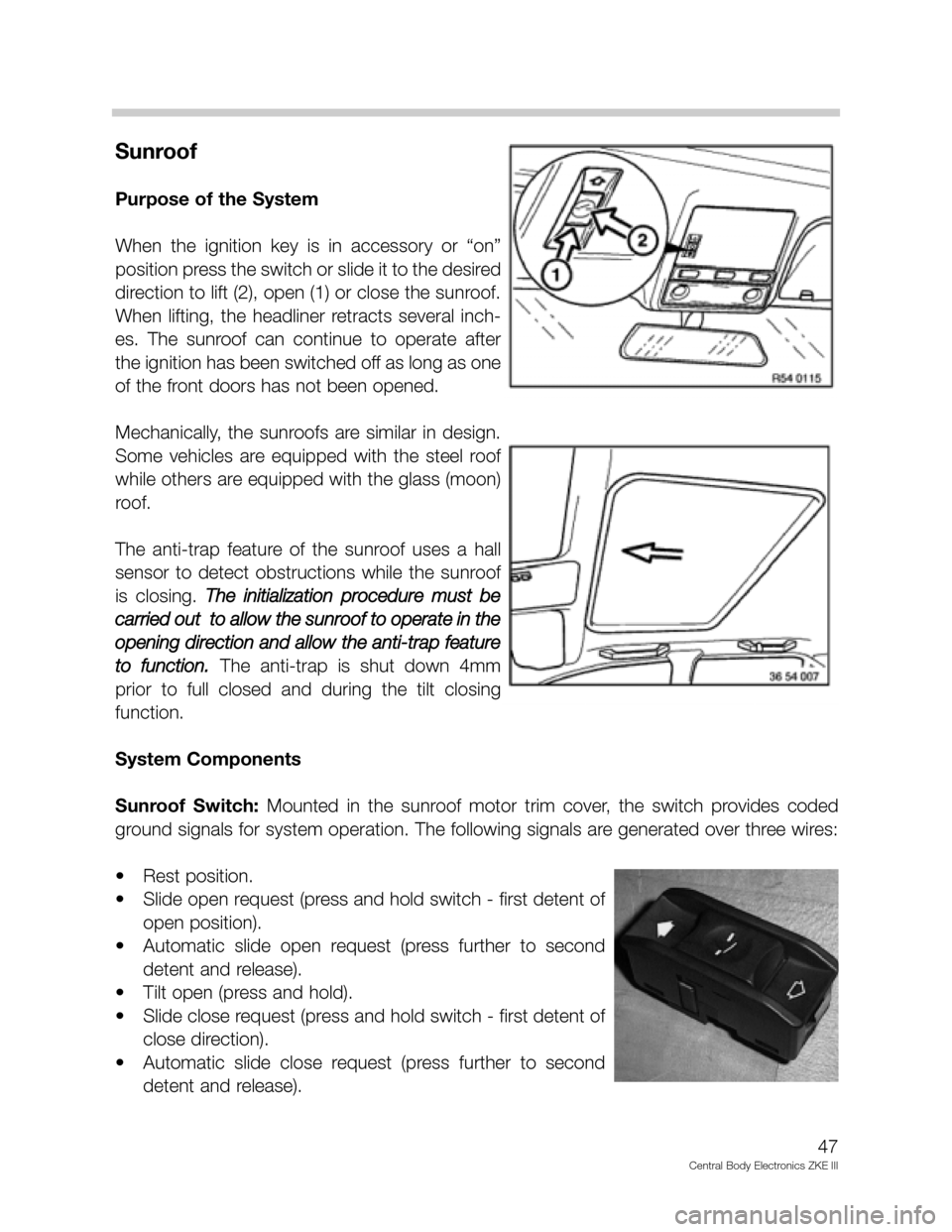

Momentarily pushing the switch to the second

detent and releasing provides

an additional

ground signal on the second wire requesting

the “one touch mode”, operating the window

motor automatically.

The motor runs the window down until it reach-

es the end stop.

The switch functions in the same manner for

the upward run of the window motor but the

ground signal sequencing is reversed.

43

Central Body Electronics ZKE III

615200111.jpg

615200112.jpg

Page 47 of 80

Sunroof

Purpose of the System

When the ignition key is in accessory or “on”

position press the switch or slide it to the desired

direction to lift (2), open (1) or close the sunroof.

When lifting, the headliner retracts several inch-

es. The sunroof can continue to operate after

the ignition has been switched off as long as one

of the front doors has not been opened.

Mechanically, the sunroofs are similar in design.

Some vehicles are equipped with the steel roof

while others are equipped with the glass (moon)

roof.

The anti-trap feature of the sunroof uses a hall

sensor to detect obstructions while the sunroof

is closing. The initialization procedure must be

carried out to allow the sunroof to operate in the

opening direction and allow the anti-trap feature

to function.

The anti-trap is shut down 4mm

prior to full closed and during the tilt closing

function.

System Components

Sunroof Switch:Mounted in the sunroof motor trim cover, the switch provides coded

ground signals for system operation. The following signals are generated over three wires:

• Rest position.

• Slide open request (press and hold switch - first detent of

open position).

• Automatic slide open request (press further to second

detent and release).

• Tilt open (press and hold).

• Slide close request (press and hold switch - first detent of

close direction).

• Automatic slide close request (press further to second

detent and release).

47

Central Body Electronics ZKE III

Page 51 of 80

Interior Lighting

Purpose of the System

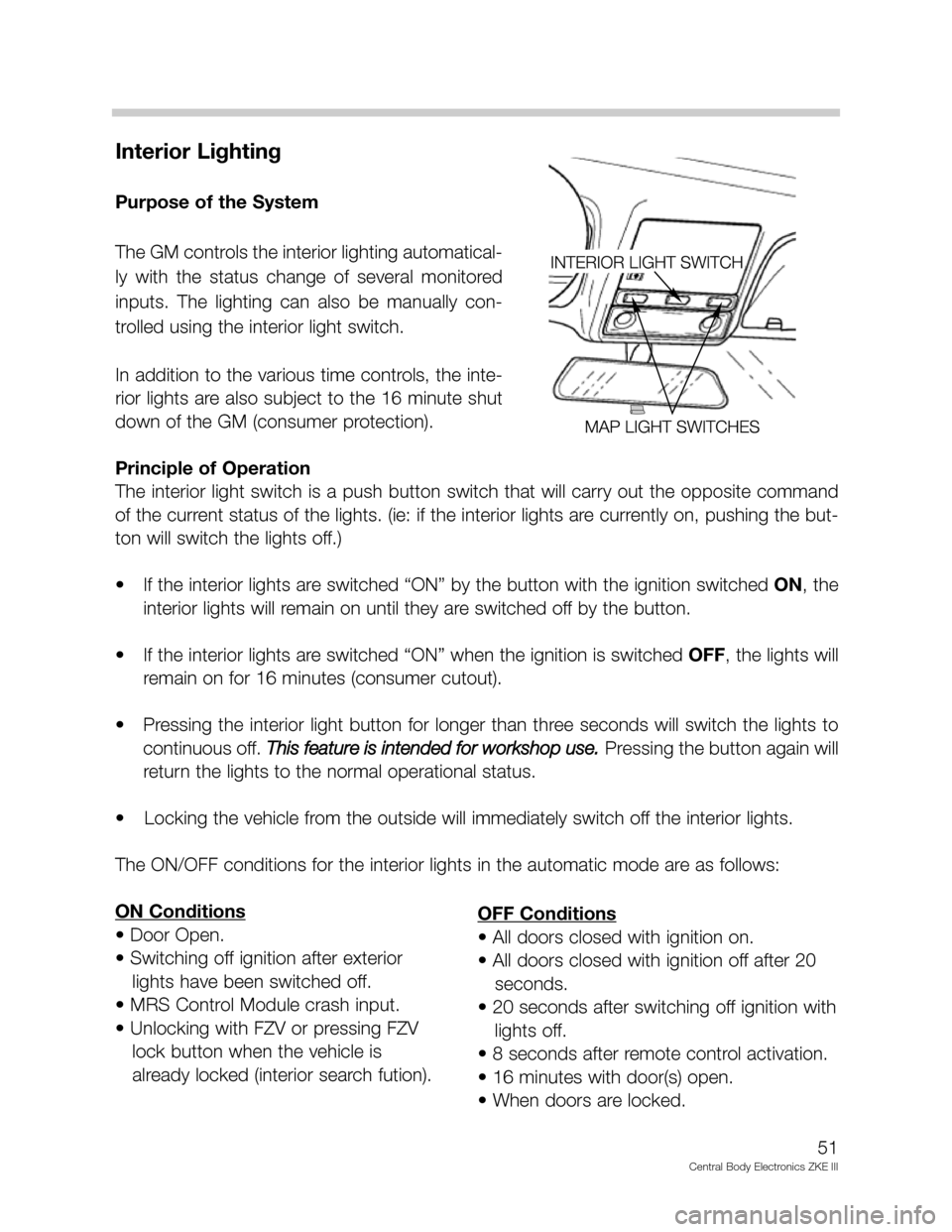

The GM controls the interior lighting automatical-

ly with the status change of several monitored

inputs. The lighting can also be manually con-

trolled using the interior light switch.

In addition to the various time controls, the inte-

rior lights are also subject to the 16 minute shut

down of the GM (consumer protection).

Principle of Operation

The interior light switch is a push button switch that will carry out the opposite command

of the current status of the lights. (ie: if the interior lights are currently on, pushing the but-

ton will switch the lights off.)

• If the interior lights are switched “ON” by the button with the ignition switched ON, the

interior lights will remain on until they are switched off by the button.

• If the interior lights are switched “ON” when the ignition is switched OFF, the lights will

remain on for 16 minutes (consumer cutout).

• Pressing the interior light button for longer than three seconds will switch the lights to

continuous off. This feature is intended for workshop use.

Pressing the button again will

return the lights to the normal operational status.

• Locking the vehicle from the outside will immediately switch off the interior lights.

The ON/OFF conditions for the interior lights in the automatic mode are as follows:

ON Conditions

• Door Open.

• Switching off ignition after exterior

lights have been switched off.

• MRS Control Module crash input.

• Unlocking with FZV or pressing FZV

lock button when the vehicle is

already locked (interior search fution).

51

Central Body Electronics ZKE III

OFF Conditions

• All doors closed with ignition on.

• All doors closed with ignition off after 20

seconds.

• 20 seconds after switching off ignition with

lights off.

• 8 seconds after remote control activation.

• 16 minutes with door(s) open.

• When doors are locked.

Page 54 of 80

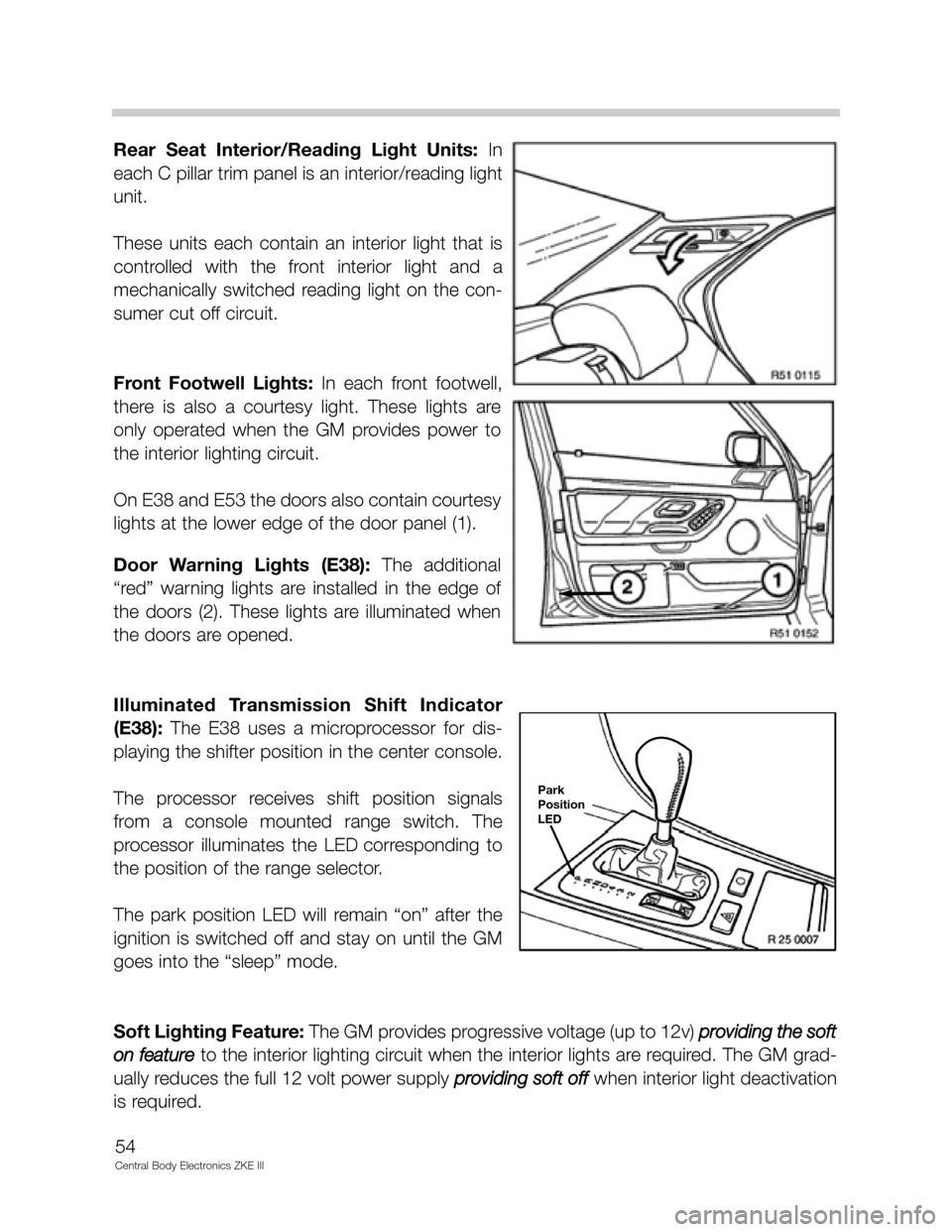

Rear Seat Interior/Reading Light Units: In

each C pillar trim panel is an interior/reading light

unit.

These units each contain an interior light that is

controlled with the front interior light and a

mechanically switched reading light on the con-

sumer cut off circuit.

Front Footwell Lights: In each front footwell,

there is also a courtesy light. These lights are

only operated when the GM provides power to

the interior lighting circuit.

On E38 and E53 the doors also contain courtesy

lights at the lower edge of the door panel (1).

Door Warning Lights (E38): The additional

“red” warning lights are installed in the edge of

the doors (2). These lights are illuminated when

the doors are opened.

Illuminated Transmission Shift Indicator

(E38): The E38 uses a microprocessor for dis-

playing the shifter position in the center console.

The processor receives shift position signals

from a console mounted range switch. The

processor illuminates the LED corresponding to

the position of the range selector.

The park position LED will remain “on” after the

ignition is switched off and stay on until the GM

goes into the “sleep” mode.

Soft Lighting Feature: The GM provides progressive voltage (up to 12v) providing the soft

on feature

to the interior lighting circuit when the interior lights are required. The GM grad-

ually reduces the full 12 volt power supply providing soft off

when interior light deactivation

is required.

54

Central Body Electronics ZKE III

Park

Position

LED

Page 59 of 80

59

Central Body Electronics ZKE III

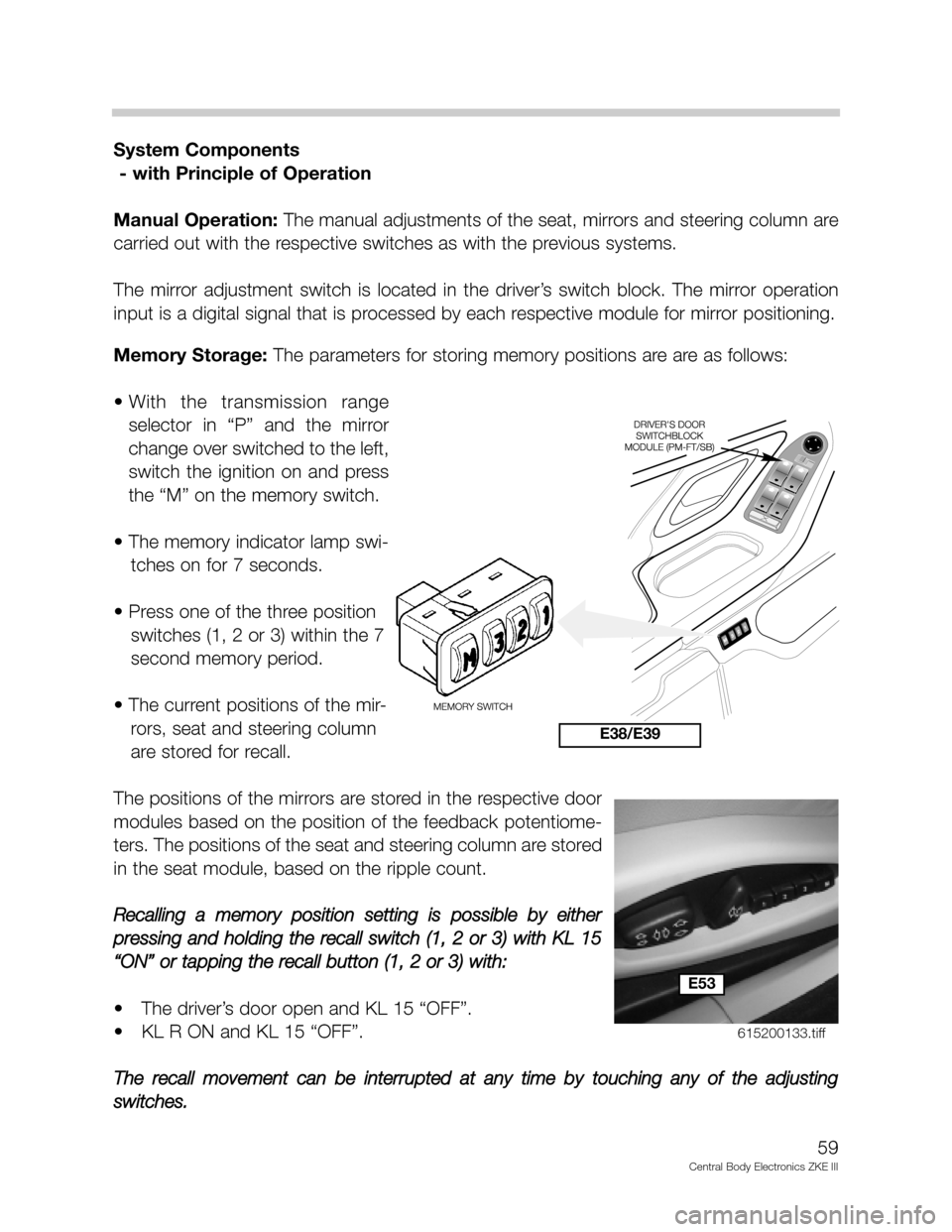

System Components

- with Principle of Operation

Manual Operation:The manual adjustments of the seat, mirrors and steering column are

carried out with the respective switches as with the previous systems.

The mirror adjustment switch is located in the driver’s switch block. The mirror operation

input is a digital signal that is processed by each respective module for mirror positioning.

Memory Storage: The parameters for storing memory positions are are as follows:

• With the transmission range

selector in “P” and the mirror

change over switched to the left,

switch the ignition on and press

the “M” on the memory switch.

• The memory indicator lamp swi-

tches on for 7 seconds.

• Press one of the three position

switches (1, 2 or 3) within the 7

second memory period.

• The current positions of the mir-

rors, seat and steering column

are stored for recall.

The positions of the mirrors are stored in the respective door

modules based on the position of the feedback potentiome-

ters. The positions of the seat and steering column are stored

in the seat module, based on the ripple count.

Recalling a memory position setting is possible by either

pressing and holding the recall switch (1, 2 or 3) with KL 15

“ON” or tapping the recall button (1, 2 or 3) with:

• The driver’s door open and KL 15 “OFF”.

• KL R ON and KL 15 “OFF”.

The recall movement can be interrupted at any time by touching any of the adjusting

switches.

E38/E39

E53

615200133.tiff

Page 63 of 80

Passenger’s Seat (without memory)

Principle of Operation

The passenger seat control switch is purely a mechanical switching module that activates

the passenger seat motors without position monitoring capabilities. Due to the limited op-

eration requirements, the passenger seat control switch is not equipped with on board

diagnostics.

The Passenger Seat control switch is equipped with an overload protection function. If

excessive amperage is drawn due to a defective motor or a switch is stuck driving a motor

to the end limit, the function activates opening the motor control circuit.

Passenger Seat Motors: Each motor is individually controlled by the Seat Control Switch.

Each position motor is connected to the seat position switch by a two wire circuit provid-

ing motor activation in both directions (no position recognition).

Passenger Seat Adjustment: Operation of the passenger seat is always possible regard-

less of the ignition key position. Moving a position switch operates a the motor control con-

tacts directly, the switch applies voltage and ground path directly to operate the motor.

Reversing the switch simply changes the motor polarity. More than one passenger seat

motor can be run simultaneously.

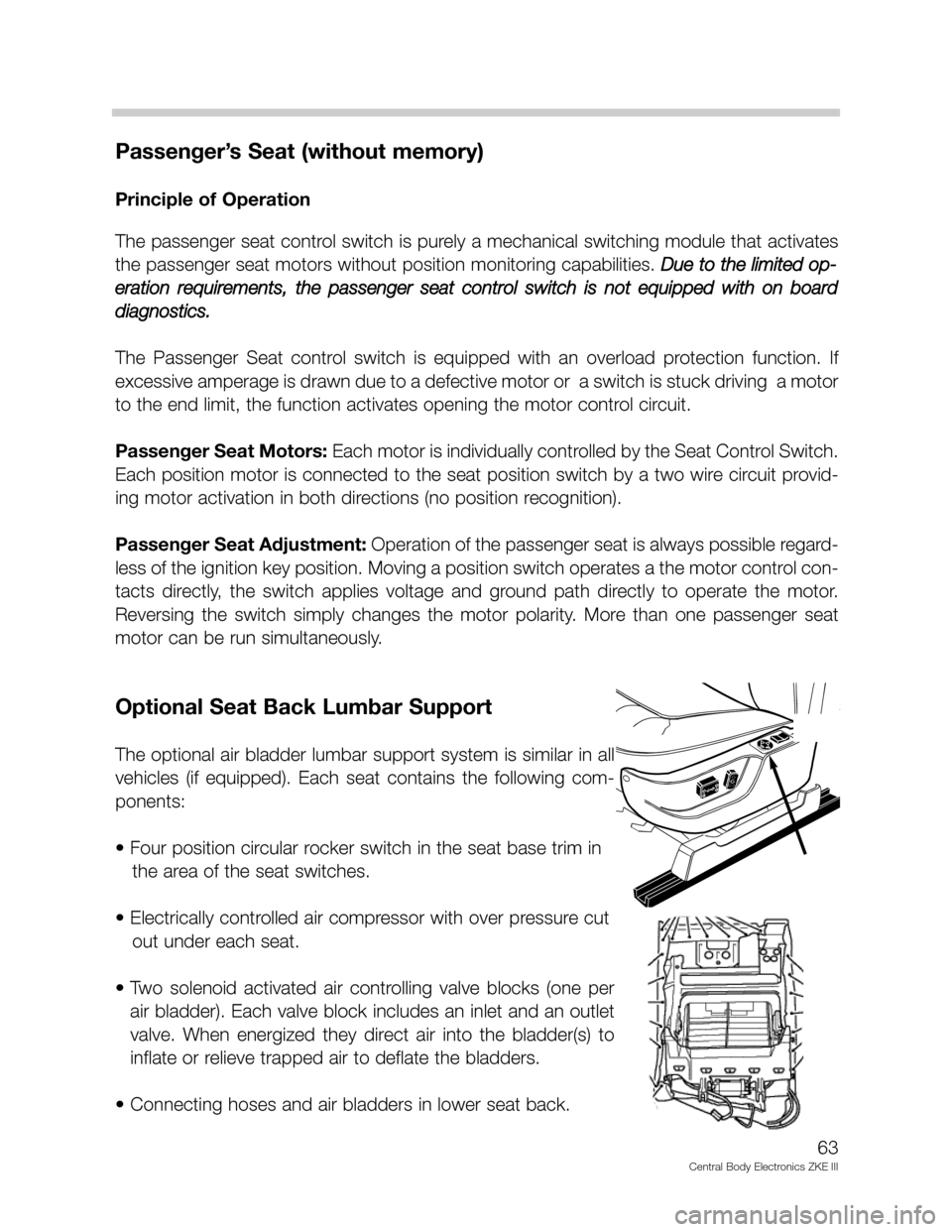

Optional Seat Back Lumbar Support

The optional air bladder lumbar support system is similar in all

vehicles (if equipped). Each seat contains the following com-

ponents:

• Four position circular rocker switch in the seat base trim in

the area of the seat switches.

• Electrically controlled air compressor with over pressure cut

out under each seat.

• Two solenoid activated air controlling valve blocks (one per

air bladder). Each valve block includes an inlet and an outlet

valve. When energized they direct air into the bladder(s) to

inflate or relieve trapped air to deflate the bladders.

• Connecting hoses and air bladders in lower seat back.

63

Central Body Electronics ZKE III

Page 65 of 80

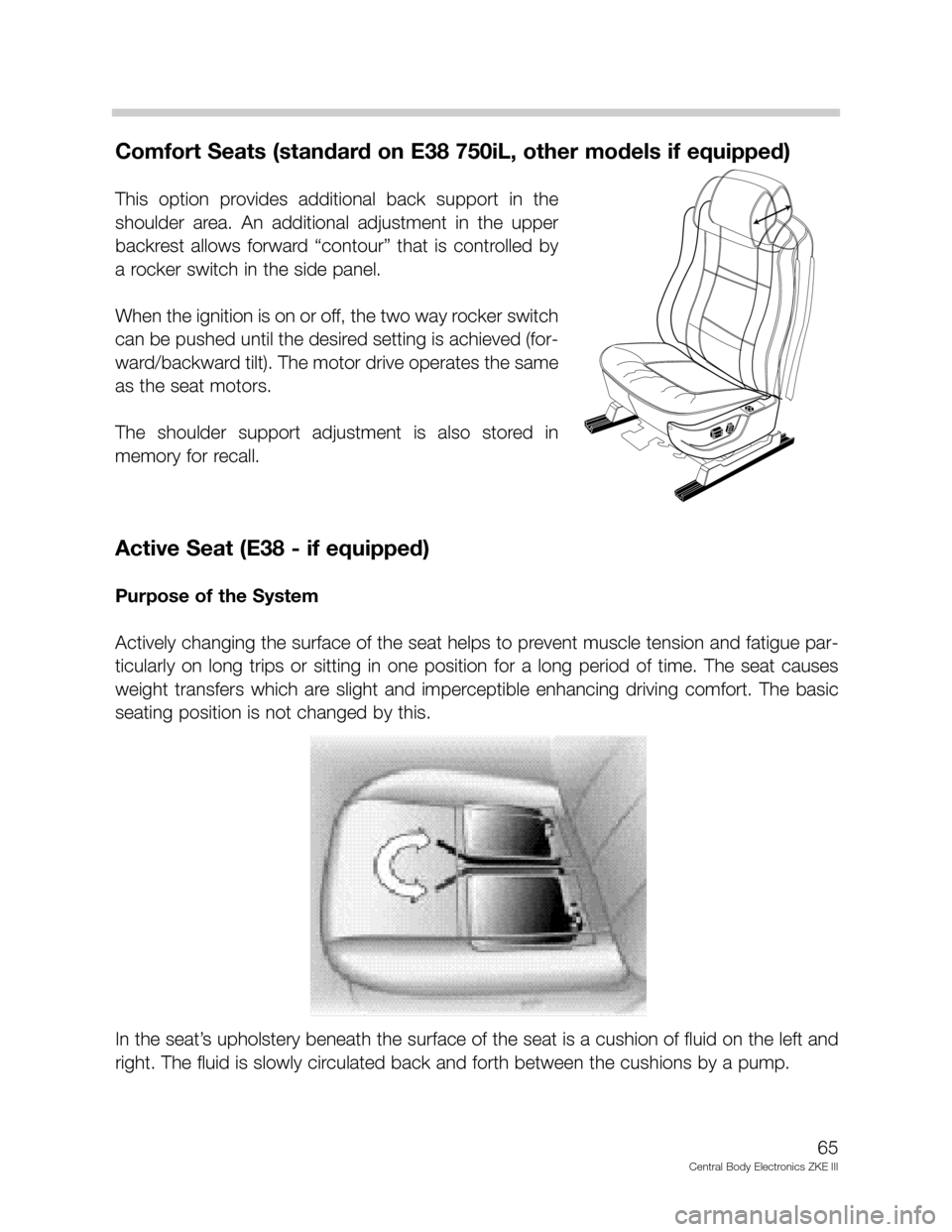

Comfort Seats (standard on E38 750iL, other models if equipped)

This option provides additional back support in the

shoulder area. An additional adjustment in the upper

backrest allows forward “contour” that is controlled by

a rocker switch in the side panel.

When the ignition is on or off, the two way rocker switch

can be pushed until the desired setting is achieved (for-

ward/backward tilt). The motor drive operates the same

as the seat motors.

The shoulder support adjustment is also stored in

memory for recall.

Active Seat (E38 - if equipped)

Purpose of the System

Actively changing the surface of the seat helps to prevent muscle tension and fatigue par-

ticularly on long trips or sitting in one position for a long period of time. The seat causes

weight transfers which are slight and imperceptible enhancing driving comfort. The basic

seating position is not changed by this.

In the seat’s upholstery beneath the surface of the seat is a cushion of fluid on the left and

right. The fluid is slowly circulated back and forth between the cushions by a pump.

65

Central Body Electronics ZKE III

Page 66 of 80

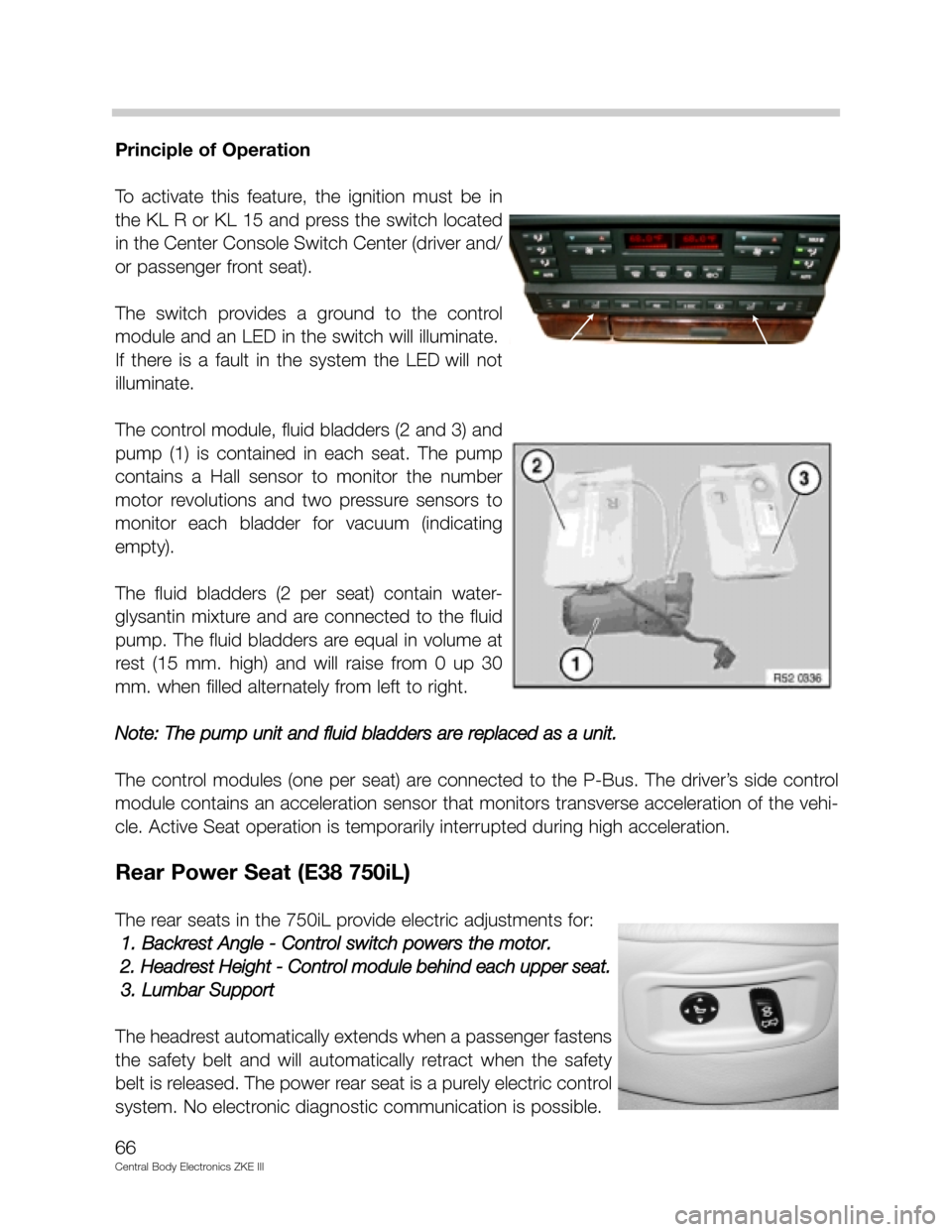

Principle of Operation

To activate this feature, the ignition must be in

the KL R or KL 15 and press the switch located

in the Center Console Switch Center (driver and/

or passenger front seat).

The switch provides a ground to the control

module and an LED in the switch will illuminate.

If there is a fault in the system the LED will not

illuminate.

The control module, fluid bladders (2 and 3) and

pump (1) is contained in each seat. The pump

contains a Hall sensor to monitor the number

motor revolutions and two pressure sensors to

monitor each bladder for vacuum (indicating

empty).

The fluid bladders (2 per seat) contain water-

glysantin mixture and are connected to the fluid

pump. The fluid bladders are equal in volume at

rest (15 mm. high) and will raise from 0 up 30

mm. when filled alternately from left to right.

Note: The pump unit and fluid bladders are replaced as a unit.

The control modules (one per seat) are connected to the P-Bus. The driver’s side control

module contains an acceleration sensor that monitors transverse acceleration of the vehi-

cle. Active Seat operation is temporarily interrupted during high acceleration.

Rear Power Seat (E38 750iL)

The rear seats in the 750iL provide electric adjustments for:

1. Backrest Angle - Control switch powers the motor.

2. Headrest Height - Control module behind each upper seat.

3. Lumbar Support

The headrest automatically extends when a passenger fastens

the safety belt and will automatically retract when the safety

belt is released. The power rear seat is a purely electric control

system. No electronic diagnostic communication is possible.

66

Central Body Electronics ZKE III

Page 67 of 80

67

Central Body Electronics ZKE III

Seat Heating Operation (from 99 MY)

Principle of Operation

The front seat heaters are adjustable through three ranges of

heating output temperature.

Pressing the respective seat heater button once provides

stage 1:

• All three LEDs illuminate and the heating elements are provided regulated output current

producing a seat temperature of 111

OF.

Pressing the button a second time provides stage 2:

• The top LED switches off and the heating elements are regulated to an output tempera-

ture of 102

OF.

Pressing the button a third time provides stage 3.

• The top and middle LEDs are off and the heating elements are regulated to an output tem-

perature of 95

OF.

The SZM monitors the seat heating element temperature via an NTC feedback signal to

regulate the output current which maintains the seat temperature.

Seat heating is switched off by pressing the button a fourth time,

pressing and holding the

button for more than 1 second or when the ignition is switched off.

System Components

Carbon Fiber Heating Pads:In each seat is a two

section heating pad wired in parallel. The heating pads

are resistors which when powered produce radiant

heat.

The seat base heating element also contains a temper-

ature sensor for feedback to provide the temperature

regulation output control.

KL31

KL15

TEMPERATURE

SENSOR

615200139.eps

Page 69 of 80

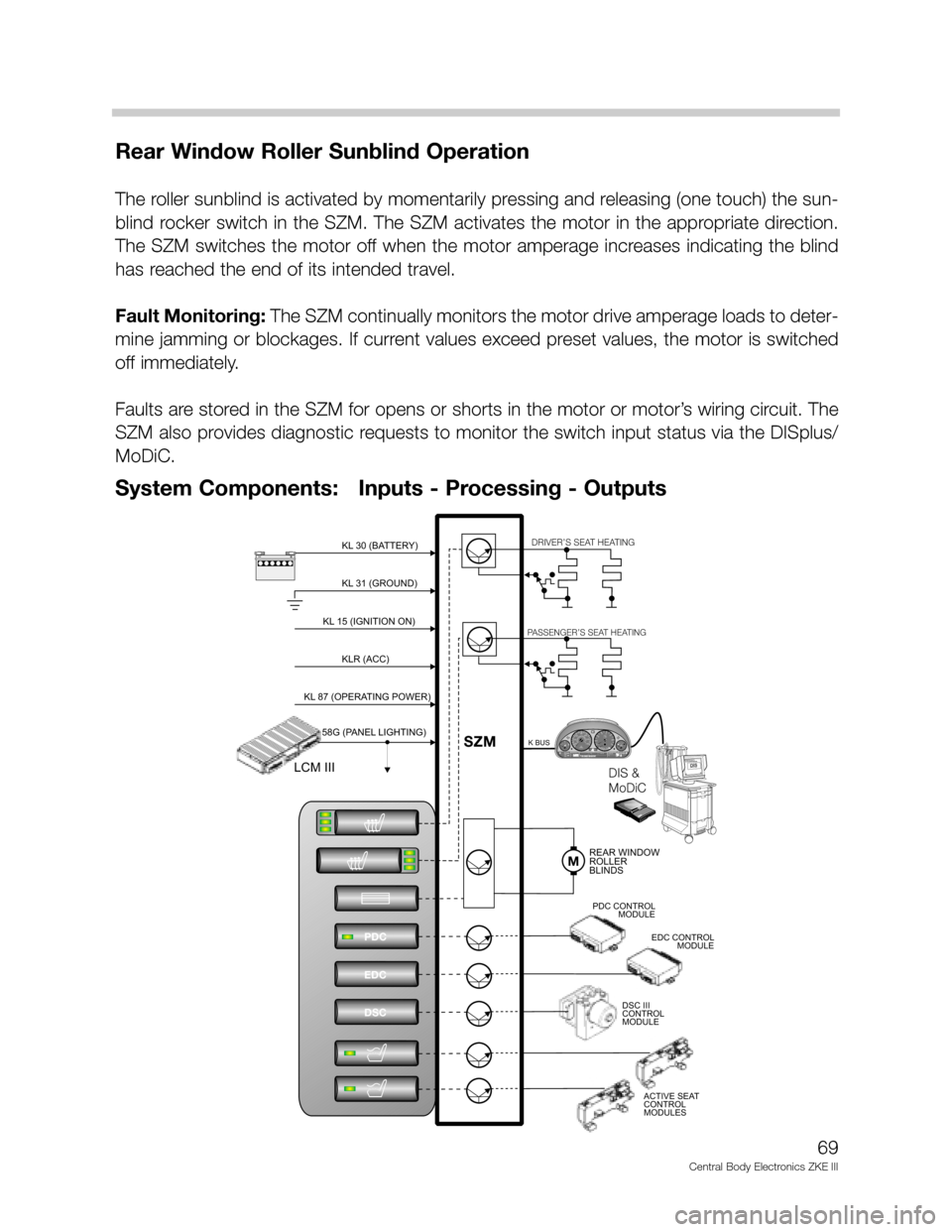

Rear Window Roller Sunblind Operation

The roller sunblind is activated by momentarily pressing and releasing (one touch) the sun-

blind rocker switch in the SZM. The SZM activates the motor in the appropriate direction.

The SZM switches the motor off when the motor amperage increases indicating the blind

has reached the end of its intended travel.

Fault Monitoring: The SZM continually monitors the motor drive amperage loads to deter-

mine jamming or blockages. If current values exceed preset values, the motor is switched

off immediately.

Faults are stored in the SZM for opens or shorts in the motor or motor’s wiring circuit. The

SZM also provides diagnostic requests to monitor the switch input status via the DISplus/

MoDiC.

69

Central Body Electronics ZKE III

KL 31 (GROUND)KL 31 (GROUND)

DIS

DIS

BMWDIS

B

M

WD

I

S

BMWDIS

BMW

DIS

D

ia

g

n

o

s

e

-

a

n

d

In

fo

r

m

a

ti

o

n

S

y

s

t

e

mDIS &

MoDiCDIS &

MoDiC

M

o

Di

C

0½

CHECK

ENGINE

CHECK

ENGINEOIL SERVICEOIL SERVICEINSPECTIONINSPECTIONP

1/min

x1000km/hELECTRONICMPH1

2020404060608080100180160140 1201002001202201402400234

5

6

7!!ABS20 DIGIT READOUT20 DIGIT READOUT

123456

prnd432

m

prnd432

m

122.4 +72.0 fo

+72.0 fomiles0

10

15 20 40

KL 30 (BATTERY)KL 30 (BATTERY)-+

KL 15 (IGNITION ON)KL 15 (IGNITION ON)

KLR (ACC)KLR (ACC)

KL 87 (OPERATING POWER)KL 87 (OPERATING POWER)

58G (PANEL LIGHTING)58G (PANEL LIGHTING)

LCM IIILCM III

PDC

EDC

DSC

MREAR WINDOW

ROLLER

BLINDSREAR WINDOW

ROLLER

BLINDS

DRIVER’S SEAT HEATINGDRIVER’S SEAT HEATING

PASSENGER’S SEAT HEATINGPASSENGER’S SEAT HEATING

K BUSK BUS

PDC CONTROL

MODULEPDC CONTROL

MODULE

EDC CONTROL

MODULEEDC CONTROL

MODULE

SZMSZM

DSC III

CONTROL

MODULEDSC III

CONTROL

MODULE

ACTIVE SEAT

CONTROL

MODULESACTIVE SEAT

CONTROL

MODULES

System Components: Inputs - Processing - Outputs