sport mode BMW 740IL 2001 E38 Level Control System Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 740IL, Model: BMW 740IL 2001 E38Pages: 57, PDF Size: 1.89 MB

Page 13 of 57

13

Level Control Systems

Air Suspension Systems (EHC)

Purpose of the System

Air Suspension systems were first introduced on the 1999 E39 Sportwagon. Since then

the E53 (X5) and E65/E66 (7Series) models were available with this new system. EHC are

available is two configurations, the Single Axle Air Suspension System and the Dual Axle

Air Suspension System. The Dual Axle (EHC II) system is only available on E53 X5 models

from the 2002 model year.

EHC systems can be found on the following vehicles:

E39 Sportwagon 528i, 525i and 540i from the 1999 Model Year (Single Axle)

E53 X5 3.0i and 4.4i from the 2000 Model Year (Single Axle)

E53 X5 4.6iS from 2002 (Single Axle)

E53 X5 3.0i and 4.4i from 2002 (Dual Axle EHC II)

E65/E66 from 2003 Model Year (Single Axle)

There are some functional changes with these systems. On EHC, the entire axle load is

borne by the air suspension. The underlying control philosophy of EHC is “Control only

when absolutely necessary”. This means that brief changes in the ride height are not com-

pensated (such as potholes). This avoids any unnecessary control operations.

The advantages of air suspension are as follows:

Control is independent of the vehicle engine

Single-wheel control is possible

Lateral locking is affected

A distinction is made between load and drive states

An inclined load is identified and corrected

However, an inclination is not compensated

Self diagnosis can be performed

Diagnosis with DISplus or GT-1 is possible

An automatic interruption of control takes place in case of cornering and wheel

changes.

Page 17 of 57

17

Level Control Systems

Air Springs

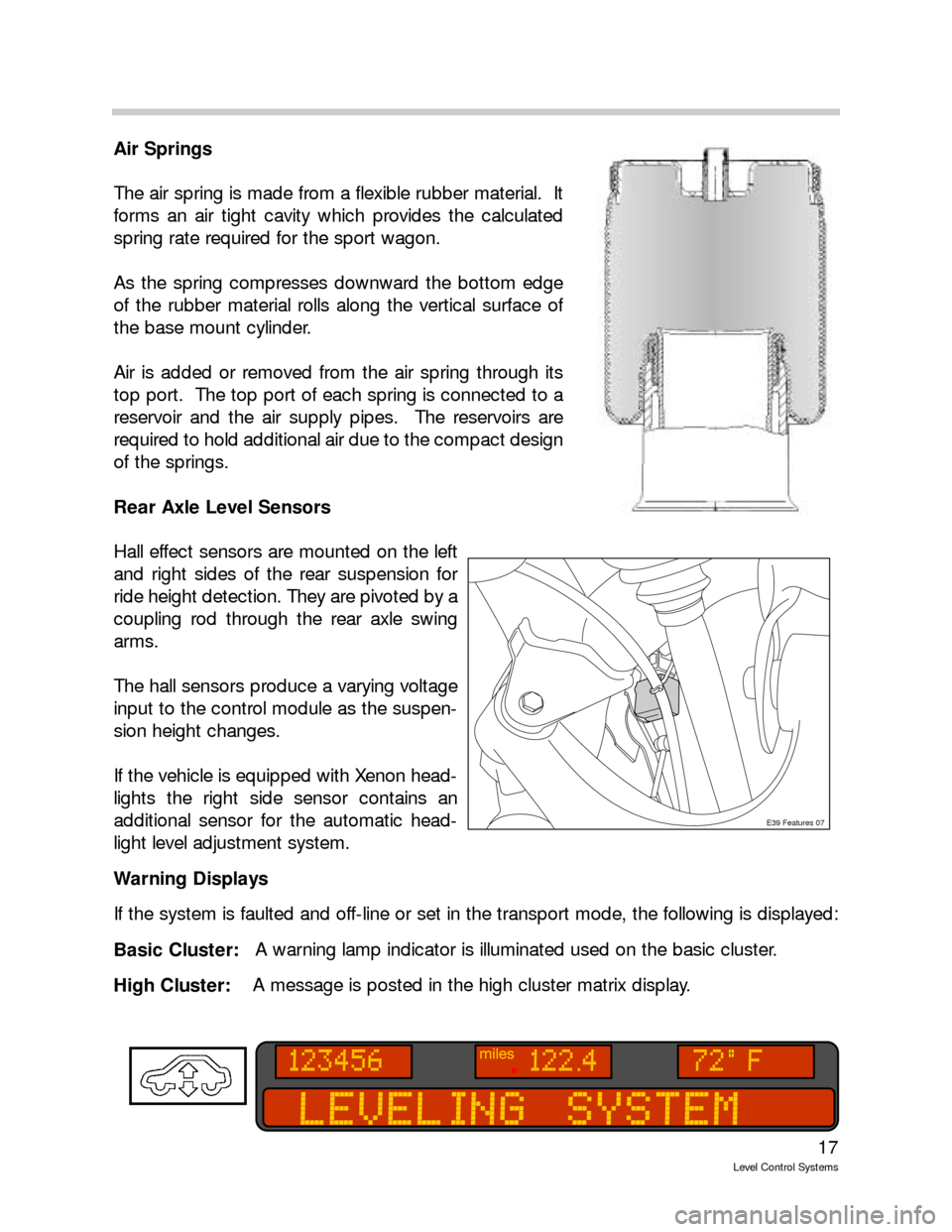

The air spring is made from a flexible rubber material. It

forms an air tight cavity which provides the calculated

spring rate required for the sport wagon.

As the spring compresses downward the bottom edge

of the rubber material rolls along the vertical surface of

the base mount cylinder.

Air is added or removed from the air spring through its

top port. The top port of each spring is connected to a

reservoir and the air supply pipes. The reservoirs are

required to hold additional air due to the compact design

of the springs.

Rear Axle Level Sensors

Hall effect sensors are mounted on the left

and right sides of the rear suspension for

ride height detection. They are pivoted by a

coupling rod through the rear axle swing

arms.

The hall sensors produce a varying voltage

input to the control module as the suspen-

sion height changes.

If the vehicle is equipped with Xenon head-

lights the right side sensor contains an

additional sensor for the automatic head-

light level adjustment system.

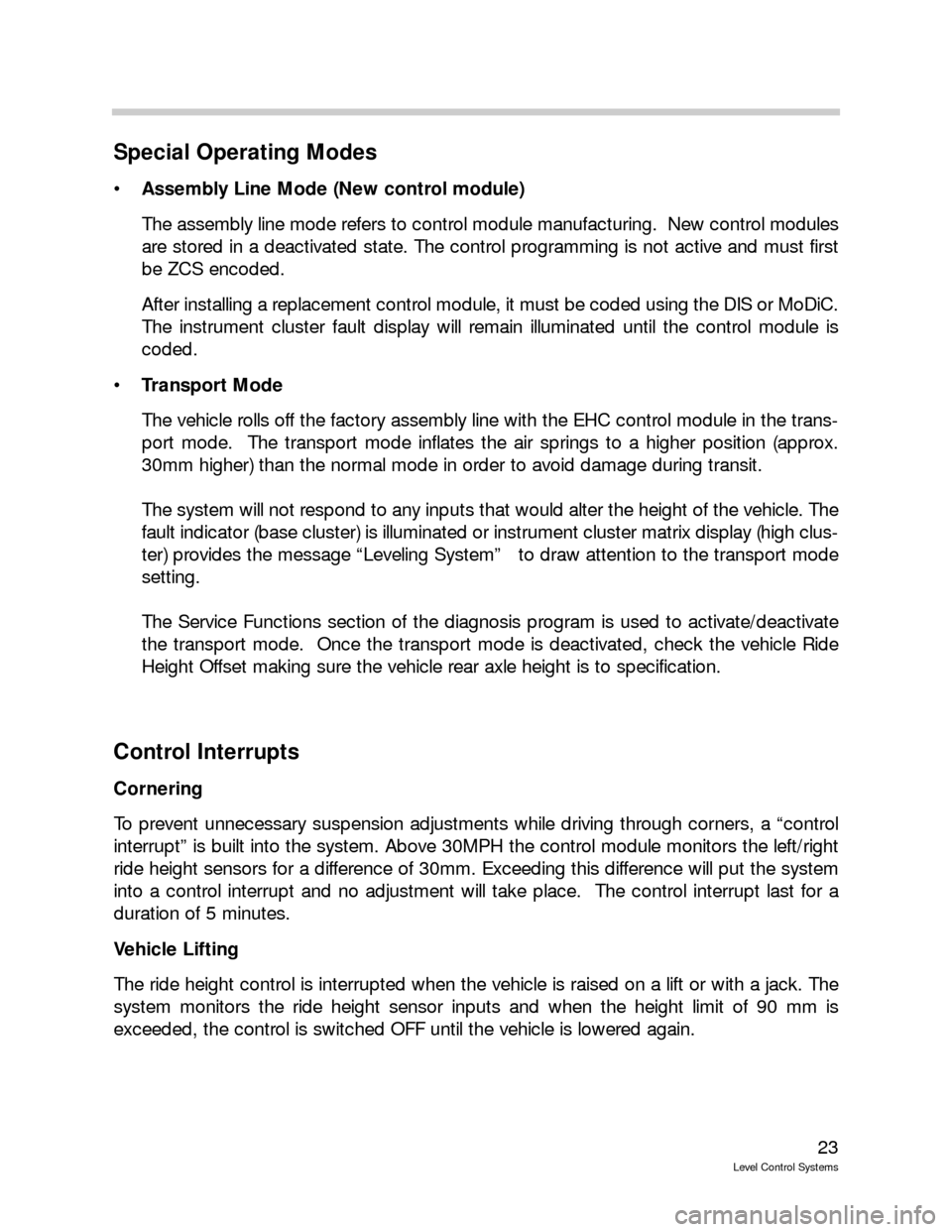

Warning Displays

If the system is faulted and off-line or set in the transport mode, the following is displayed:

Basic Cluster:A warning lamp indicator is illuminated used on the basic cluster.

High Cluster: A message is posted in the high cluster matrix display.

E39 Features 07

Page 21 of 57

21

Level Control Systems

EHC System Operation

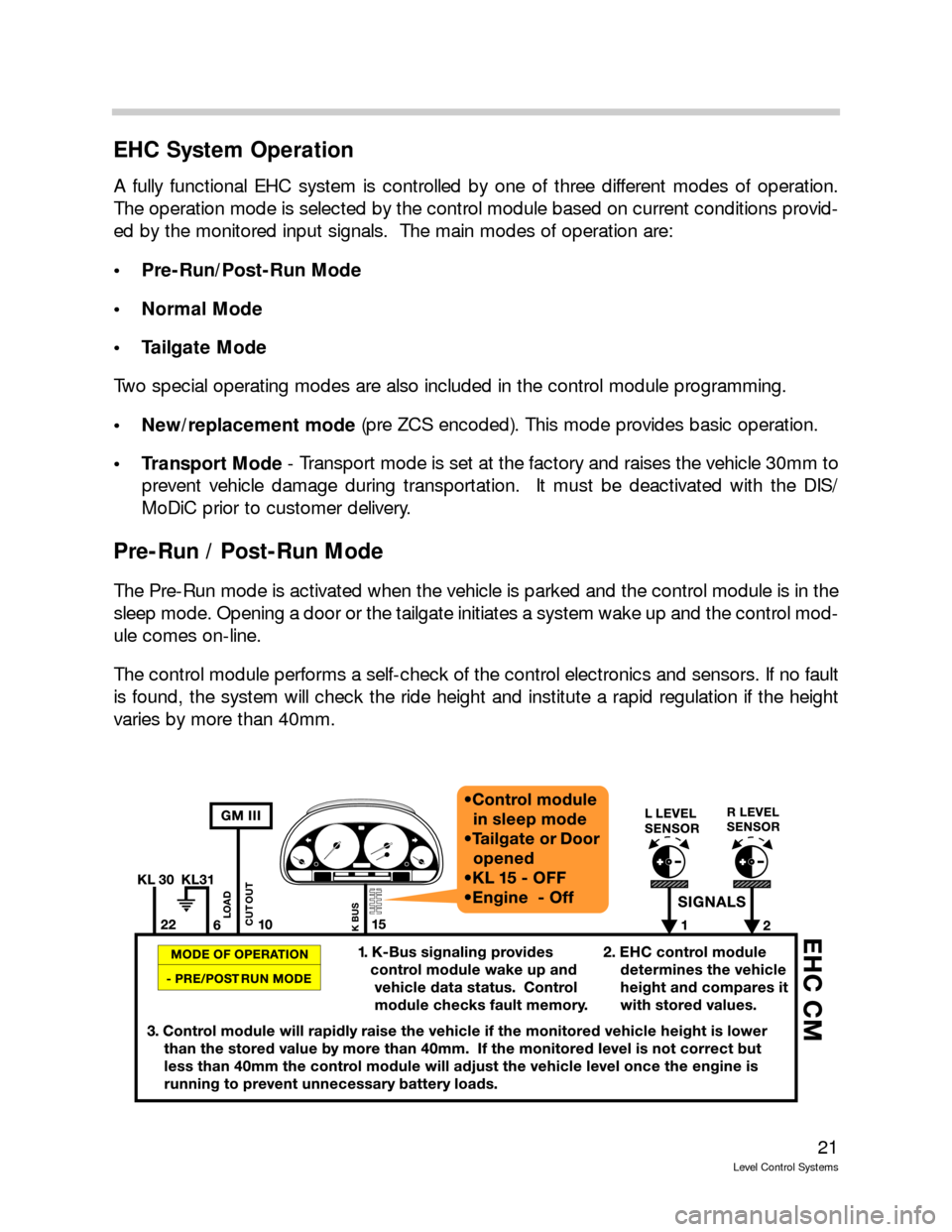

A fully functional EHC system is controlled by one of three different modes of operation.

The operation mode is selected by the control module based on current conditions provid-

ed by the monitored input signals. The main modes of operation are:

• Pre-Run/Post-Run Mode

Normal Mode

Tailgate Mode

Two special operating modes are also included in the control module programming.

New/replacement mode(pre ZCS encoded). This mode provides basic operation.

Transport Mode - Transport mode is set at the factory and raises the vehicle 30mm to

prevent vehicle damage during transportation. It must be deactivated with the DIS/

MoDiC prior to customer delivery.

Pre-Run / Post-Run Mode

The Pre-Run mode is activated when the vehicle is parked and the control module is in the

sleep mode. Opening a door or the tailgate initiates a system wake up and the control mod-

ule comes on-line.

The control module performs a self-check of the control electronics and sensors. If no fault

is found, the system will check the ride height and institute a rapid regulation if the height

varies by more than 40mm.

Page 23 of 57

23

Level Control Systems

Special Operating Modes

Assembly Line Mode (New control module)

The assembly line mode refers to control module manufacturing. New control modules

are stored in a deactivated state. The control programming is not active and must first

be ZCS encoded.

After installing a replacement control module, it must be coded using the DIS or MoDiC.

The instrument cluster fault display will remain illuminated until the control module is

coded.

Transport Mode

The vehicle rolls off the factory assembly line with the EHC control module in the trans-

port mode. The transport mode inflates the air springs to a higher position (approx.

30mm higher) than the normal mode in order to avoid damage during transit.

The system will not respond to any inputs that would alter the height of the vehicle. The

fault indicator (base cluster) is illuminated or instrument cluster matrix display (high clus-

ter) provides the message “Leveling System” to draw attention to the transport mode

setting.

The Service Functions section of the diagnosis program is used to activate/deactivate

the transport mode. Once the transport mode is deactivated, check the vehicle Ride

Height Offset making sure the vehicle rear axle height is to specification.

Control Interrupts

Cornering

To prevent unnecessary suspension adjustments while driving through corners, a “control

interrupt” is built into the system. Above 30MPH the control module monitors the left/right

ride height sensors for a difference of 30mm. Exceeding this difference will put the system

into a control interrupt and no adjustment will take place. The control interrupt last for a

duration of 5 minutes.

Vehicle Lifting

The ride height control is interrupted when the vehicle is raised on a lift or with a jack. The

system monitors the ride height sensor inputs and when the height limit of 90 mm is

exceeded, the control is switched OFF until the vehicle is lowered again.

Page 25 of 57

25

Level Control Systems

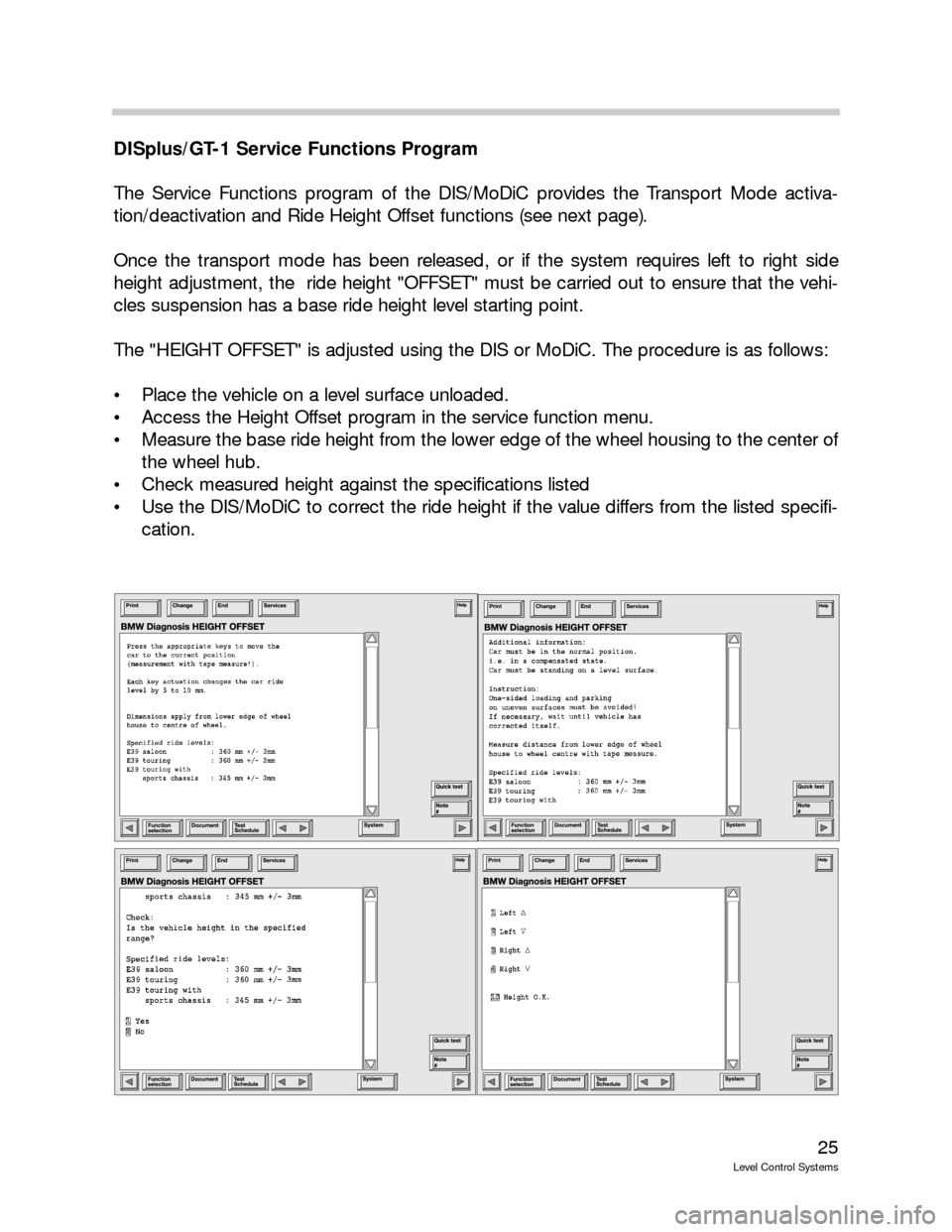

DISplus/GT-1 Service Functions Program

The Service Functions program of the DIS/MoDiC provides the Transport Mode activa-

tion/deactivation and Ride Height Offset functions (see next page).

Once the transport mode has been released, or if the system requires left to right side

height adjustment, the ride height "OFFSET" must be carried out to ensure that the vehi-

cles suspension has a base ride height level starting point.

The "HEIGHT OFFSET" is adjusted using the DIS or MoDiC. The procedure is as follows:

Place the vehicle on a level surface unloaded.

Access the Height Offset program in the service function menu.

Measure the base ride height from the lower edge of the wheel housing to the center of

the wheel hub.

Check measured height against the specifications listed

Use the DIS/MoDiC to correct the ride height if the value differs from the listed specifi-

cation.

Page 39 of 57

39

Level Control Systems

Workshop Hints

If a threshold level is exceeded on all 4 wheels when the vehicle is stationary, the control

unit assumes that the vehicle has been raised on a workshop platform.

There are three possible reset conditions for workshop platform recognition:

The original level values are undershot at all four wheels,

A selection is made by button,

A speed of >40 km/h is recognized for 3 s.

Vehicle jack

If the lowering speed at a wheel is too low during the lowering operation, the system

assumes that the wheel is jacked up. However, the downward velocity must be less than

a certain preprogrammed speed threshold. If the system detects a jacked wheel, it stores

the height of this wheel.

Car jack recognition is reset when the stored ride height is again undershot. When a trav-

elling speed of 40 km/h is maintained for at least 3 s, another control attempt is performed.

The car jack recognition can also be reset by button selection.

Please note that the system also controls ride height in diagnostic mode. For this reason,

Belt Mode must be activated before carrying out work on the system or before setting the

vehicle ride height.

Belt Mode:

Heights are fixed and are not compensated. If Belt Mode is set, the function LED is off. The

text message "ride-height control system inactive" appears in the instrument cluster.

Transport Mode:

The Transport Mode setting is for transportation purposes. When the ignition is turned on,

the message "ride-height control system inactive" appears. Heights are increased or

decreased depending on ignition key status, e.g. ride height is reduced when the vehicle is

lashed to a ship or train and raised when the "Engine on" signal is generated and when the

vehicle is transported on a transporter truck.

The correct ride height is set to ± 5 mm via "Activate components." The left and right ride

levels are set separately at the rear axle. The ride levels are then set at the front axle. The

left and right air springs are adjusted jointly for this purpose.

Following this, the new ride height for the front and rear axles is stored via the "Offset func-

tion."

Before replacing components, the system must be depressurized! This is done in the diag-

nostics via "control unit functions," "Component activation," "Pressure-relieve front axle/rear

axle." Repeat the activation procedure 6 times.

Page 46 of 57

46

Level Control Systems

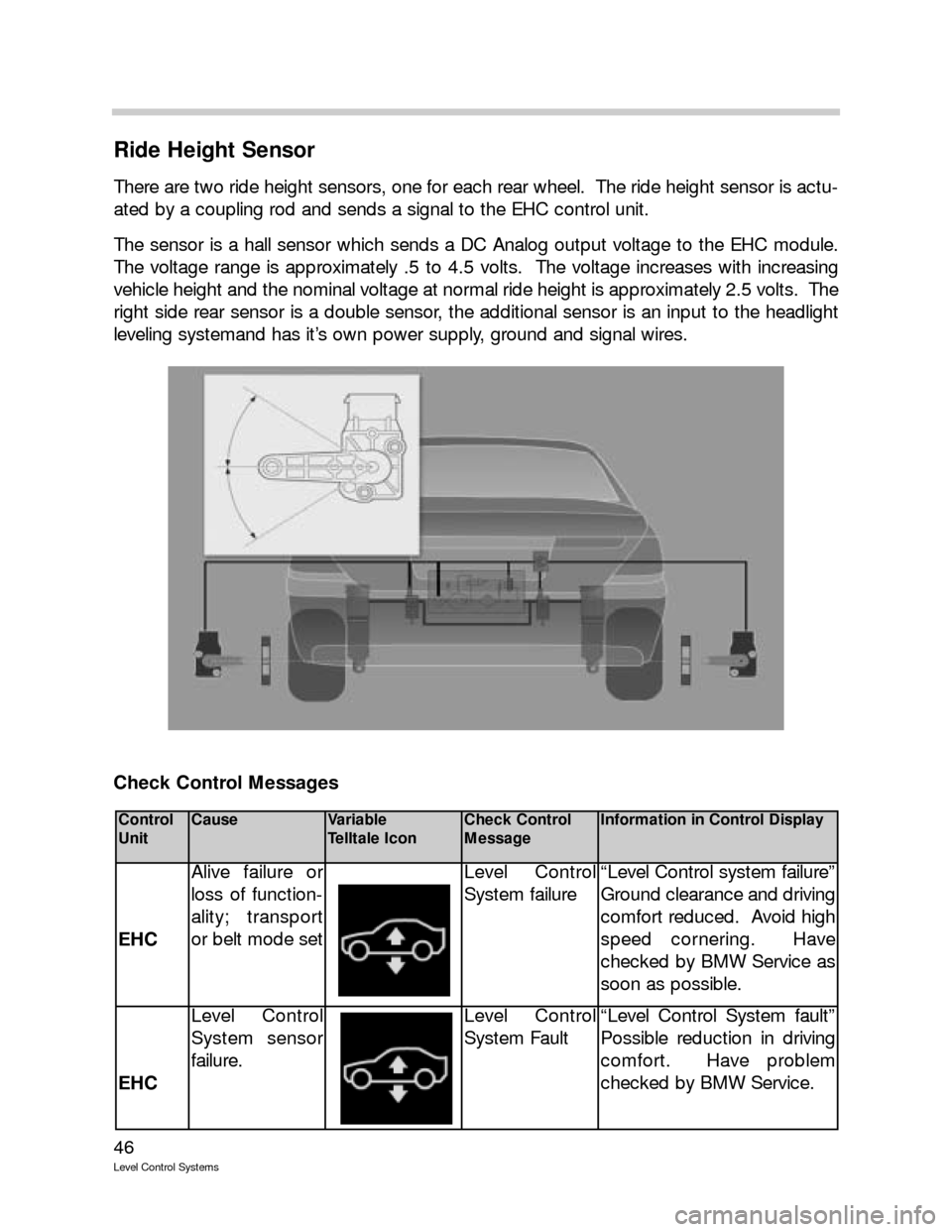

Ride Height Sensor

There are two ride height sensors, one for each rear wheel. The ride height sensor is actu-

ated by a coupling rod and sends a signal to the EHC control unit.

The sensor is a hall sensor which sends a DC Analog output voltage to the EHC module.

The voltage range is approximately .5 to 4.5 volts. The voltage increases with increasing

vehicle height and the nominal voltage at normal ride height is approximately 2.5 volts. The

right side rear sensor is a double sensor, the additional sensor is an input to the headlight

leveling systemand has it’s own power supply, ground and signal wires.

Check Control Messages

Control

UnitCauseVariable

Telltale IconCheck Control

MessageInformation in Control Display

EHC

Alive failure or

loss of function-

ality; transport

or belt mode setLevel Control

System failure“Level Control system failure”

Ground clearance and driving

comfort reduced. Avoid high

speed cornering. Have

checked by BMW Service as

soon as possible.

EHC

Level Control

System sensor

failure.Level Control

System Fault“Level Control System fault”

Possible reduction in driving

comfort. Have problem

checked by BMW Service.

Page 52 of 57

52

Level Control Systems

Lift

The Lift mode is used to prevent control operations when a wheel is changed or during

work on the vehicle while it is on a lifting platform.

This mode is recognized when the permitted rebound travel at one or more wheels is

exceeded. For the E65/E66 the limit is > 55mm.

A “jack” situation is also recognized when the ride level is stored and the lowering speed

drops below the value of 2 mm/s for 3 seconds.

If the vehicle has been raised slightly and the permitted rebound travel has not yet been

achieved, the control operation attempts to readjust the ride height. If the vehicle is not low-

ered, a car jack situation is recognized after a specific period of time and this ride height is

stored.

A reset is performed if the vehicle is again 10 mm below this stored ride height.

Transport

The Transport mode is set and cleared by means of a diagnosis activation. It serves to

increase the ground clearance in order to ensure a safe transportation of vehicles on trans-

porter trucks. The nominal height of the vehicle is raised in this mode by 30 mm.

When the Transport mode is activated, the air suspension symbol is indicated in the vari-

able telltale in the instrument cluster and a text message is output in the Check Control

Display.

Control operations do not take place in this mode because the vehicle mass does not

change during transportation.

Belt

The Belt mode is set for mounting on the belt in order to avoid control operations.

When the Belt mode is activated, the air suspension symbol is indicated in the variable tell-

tale in the instrument cluster and a text message is output in the Check Control display.

The Belt mode is cleared by means of a diagnostic activation only. The Belt mode can no

longer be set.

New control units are supplied with the Belt mode set.

Control operations are not performed, the safety concept only operates with limited effect.

The Belt Mode is also known as “Band Mode” or “Assembly Line Mode”.

Page 55 of 57

55

Level Control Systems

Workshop Hints

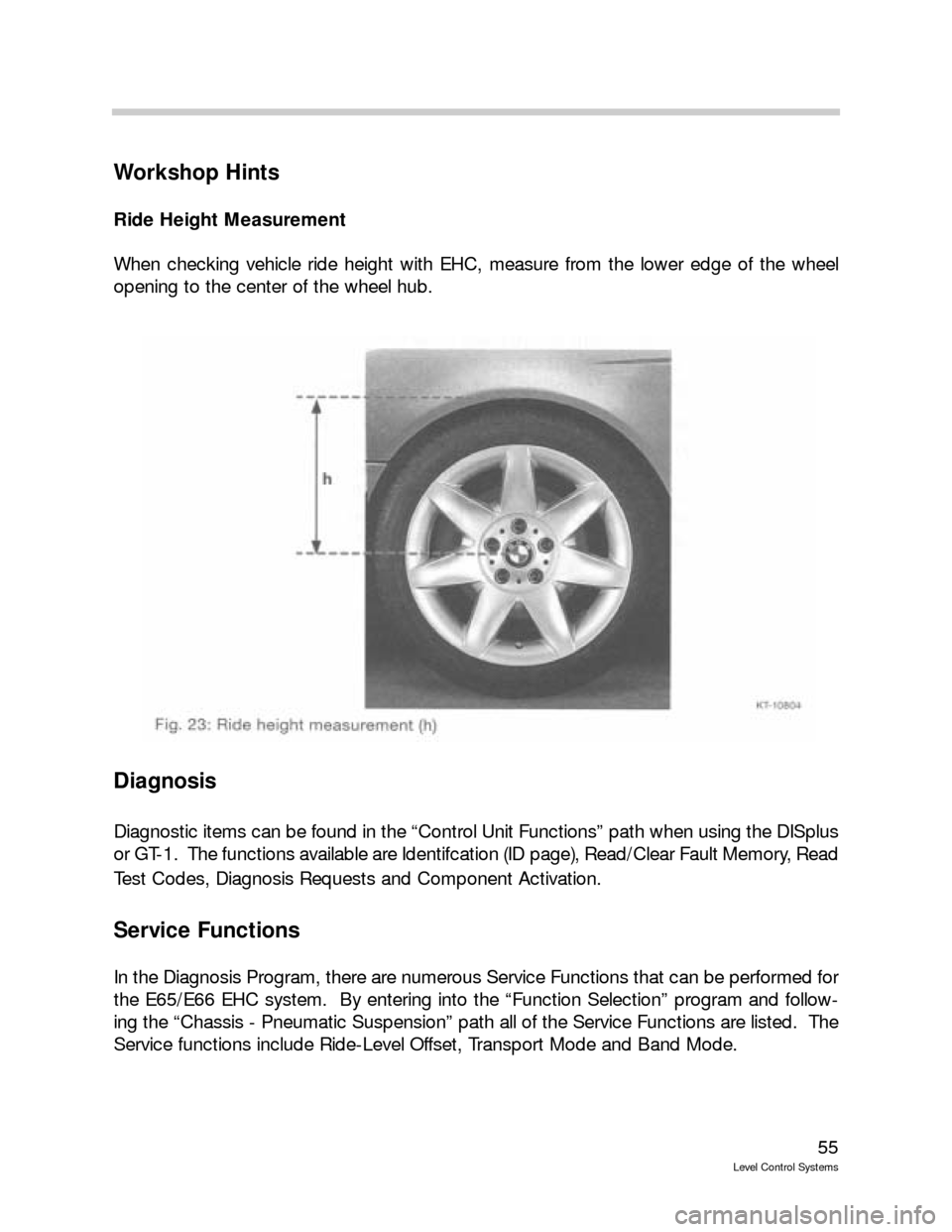

Ride Height Measurement

When checking vehicle ride height with EHC, measure from the lower edge of the wheel

opening to the center of the wheel hub.

Diagnosis

Diagnostic items can be found in the “Control Unit Functions” path when using the DISplus

or GT-1. The functions available are Identifcation (ID page), Read/Clear Fault Memory, Read

Test Codes, Diagnosis Requests and Component Activation.

Service Functions

In the Diagnosis Program, there are numerous Service Functions that can be performed for

the E65/E66 EHC system. By entering into the “Function Selection” program and follow-

ing the “Chassis - Pneumatic Suspension” path all of the Service Functions are listed. The

Service functions include Ride-Level Offset, Transport Mode and Band Mode.