fuel filter BMW M3 1993 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1993, Model line: M3, Model: BMW M3 1993 E36Pages: 759

Page 185 of 759

160

Fuel

Tank

and

Fuel

Pump

GENERAL

.

.

.

.

.

.

...........

.

....

.

.

.

.

.

.

160-1

Operating

fuel

pump

for

tests

.

.

.

.

.

.

.......

.160-6

Fuel

Pump

Electrical

Tests

.

.

.

.

.

.

.

...

.

.

.

.

.

160-7

FUEL

TANK

AND

LINES

..

.

.

.

..........

160-2

Fuel

pump

electrical

circuit,

testing.

...

.

.

.

.

.

160-7

Fuel

tank,

draining

..

.

.

.

.

.

.

.

.

.

..........

160-2

Fuel

pump

power

consumption,

testing

.

.

.

.

.

.

160-7

Fuel

tank,

removing

and

installing

.........

160-3

Fuel

Delivery

Tests

....

.

.

.

...

.

.....

.

.

.

..

160-8

Fuel

Tank

Evaporative

Control

System

.....

160-4

Relieving

fuel

pressure

and

connecting

fuel

pressure

gauge

..

.

...........

.

.

.

..

160-8

FUEL

LEVEL

SENDERS

.

.

.

.

.

.......

.

.

.

160-4

System

pressure,

testing

.................

160-9

Fuel

level

senders,

testing

.

.

.

.

.

.......

.

.

.

160-5

Fuel

delivery

volume,

testing

.............

160-10

Fuel

leve¡

sender

and

fuel

pump

(right

side),

emoving

and

installing

.

.

.

.

.

.

160-5

TABLES

Fuel

leve¡

sender

(left

side),

a

.

FuelLeve¡

Sender

Resistances

...........

.

.

..

.160-5

removing

and

installing

.........

.

.

.

.

.

.

.

160-6

b

.

Fuel

Pump

Current

...

.................

..

...

160-8

c

.

Fuel

Pressure

Specifications

..............

.

..

160-10

FUEL

PUMP

.

.

.

................

.

.

.

.

.

.

.

160-6

d

.

Fuel

Pump

Delivery

Specifications

.........

.

..

160-10

Fuel

Pump

Fuse

and

Relay

.

.

.

....

.

.

.

.

.

.

.

160-6

GENERAL

This

repair

group

covers

service

information

specifically

for

The

cautions

and

warnings

on

this

page

should

beob

the

fuel

supply

system

.

Information

on

the

fue¡

injection

sys-

served

when

servicing

the

fuel

system

.

tem

is

covered

in

130

Fuel

Injection

.

NOTE-

Fue¡

filter

replacement

is

covered

in

020

Maintenance

Program

.

WARNING

-

"

The

fuel

system

is

designed

to

retain

pressure

even

when

the

ignition

isoff

.

When

working

with

the

fuel

system,

loosen

the

fuel

lines

slowly

toal-

low

residual

fuel

pressure

to

dissipate

gradually

.

Avoid

spraying

fuel

.

"

Before

beginning

any

work

on

the

fuel

system,

place

a

tire

extinguisher

in

the

vicinity

of

the

work

area

.

"

Fuel

is

highly

flammable

.

When

working

around

fuel,

do

not

disconnect

any

wires

that

could

cause

electrical

sparks

.

Do

not

smoke

or

work

near

heaters

or

other

tire

hazards

.

"

Always

unscrew

the

fuel

tank

cap

to

release

pres-

sure

in

the

tank

before

working

on

the

tank

or

fines

.

"

Do

not

use

a

work

light

near

any

fuel

.

Fuel

may

spray

onto

the

hot

bulb

causing

a

tire

.

"

Make

sure

the

work

area

is

properly

ventifated

.

FUEL

TANK

AND

FUEL

PUMP

160-1

CAUTION-

"

Prior

to

disconnecting

the

battery,

read

the

bat-tery

disconnection

cautions

given

at

the

front

of

this

manual

onpage

viü

.

"

Before

making

any

electrical

tests

with

the

ignition

tumed

on,

disable

the

ignition

system

as

de-

scribed

in

120

Ignition

System

.

Be

sure

the

bat-tery

is

disconnected

when

replacing

components

.

"

To

prevent

damage

to

the

ignition

system

or

the

electronic

fuel

system

components,

including

the

control

unit,

aiways

connect

and

disconnect

wires

and

test

equipment

with

the

ignition

off

.

"

Cleanliness

is

essential

when

working

with

the

fuel

system

.

Thoroughly

clean

the

fuel

fine

unionsbefore

disconnecting

any

of

the

fines

.

"

Use

only

clean

tools

.

Keep

removed

parts

clean

and

sealed

or

covered

with

a

clean,

lint-free

cloth,

especially

if

completion

of

the

repair

is

delayed

.

"

Do

not

move

the

car

while

the

fuel

system

is

open

.

"

Avoid

using

high

pressure

compressed

air

to

blow

out

fines

and

componente

.

High

pressure

can

rupture

infernal

seals

and

gaskets

.

"

Always

replace

seals

and

O-rings

.

GENERAL

Page 192 of 759

160-

8

FUEL

TANK

AND

FUEL

PUMP

UU131

tst5

Fig

.

11

.

Voltage

supply

to

fuel

pump

harness

(black)

connector

being

checked

(arrow)

.

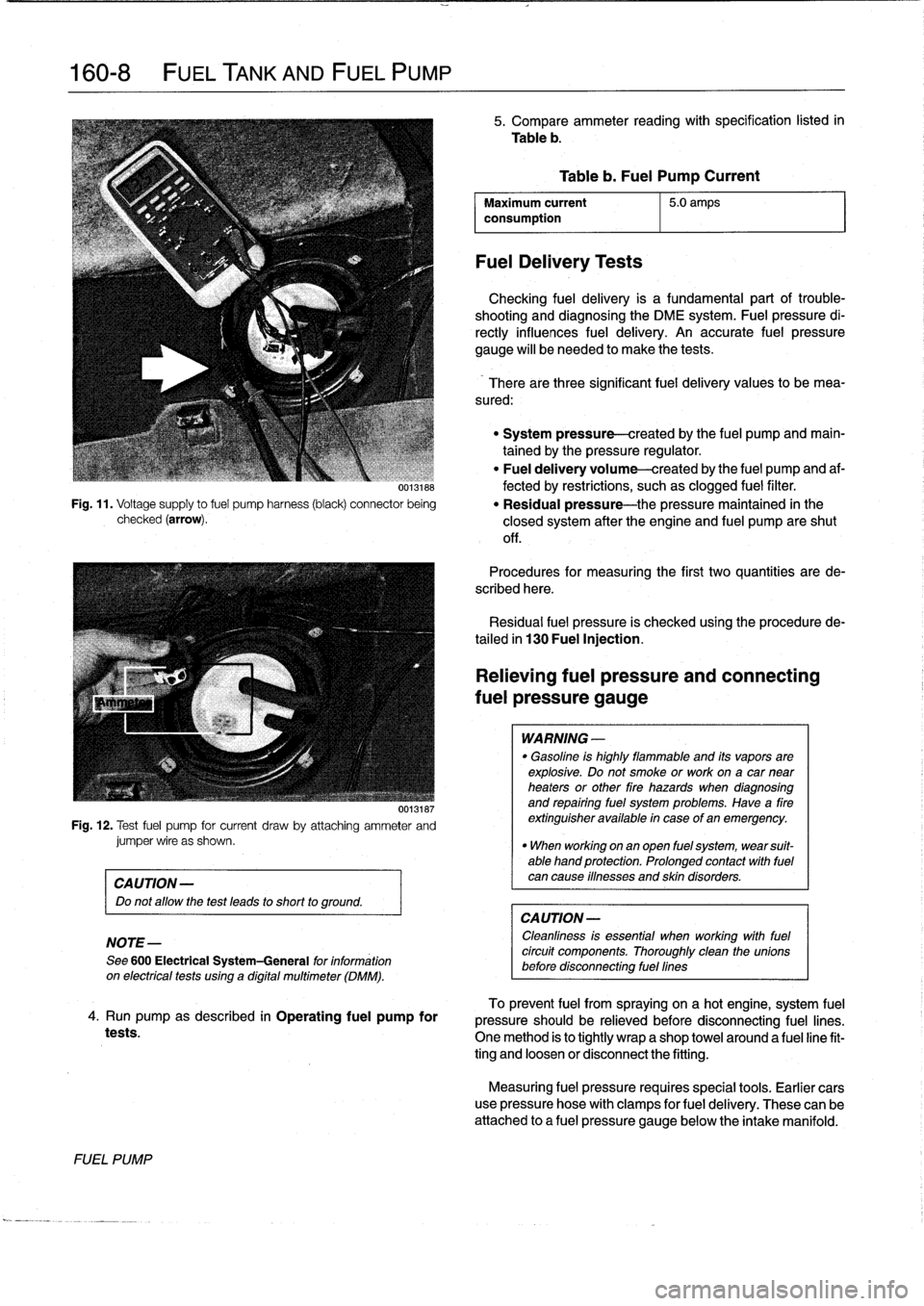

00131ts7

Fig

.

12

.

Test

fuel

pump

for

current

draw

by

attadhing

ammeter

andjumper

wire

as

shown

.

CAUTION-

Do

not

allow

the

test

leads

to

short

to

ground

.

NOTE-

See

600

Electrical

System-General

for

information

on

electricaltests

using

a

digital

multimeter

(DMM)

.

4

.

Run

pump

as

described

in

Operating

fuel

pump

for

tests

.

FUEL

PUMP

5

.

Compare

ammeter

reading

with

specification

listed

in

Table

b

.

Maximum

current

5

.0

amps

consumption

FuelDelivery

Tests

Table

b

.

Fuel

Pump

Current

Checking

fuel

delivery

is

a

fundamental

part

of

trouble-

shooting

and

diagnosing

the

DME

system

.

Fuelpressure

di-

rectly

influences

fuel

delivery

.

An

accurate

fuel

pressure

gauge

will

be

needed

to

make

the

tests

.

There

arethree

significant

fuel

delivery

values

to

bemea-

sured

:

"

System

pressure-created

by

the

fuel

pump

and

main-

tained

by

the

pressure

regulator

.

"

Fuel

delivery

volume-created

by

the

fuel

pump

and

af-

fected

by

restrictions,

suchas

clogged

fuel

filter

.

"

Residual

pressure-the

pressure

maintained

in

the

closed

system

after

the

engine

and

fuel

pump

areshut

off

.

Procedures

for

measuring

the

first

two

quantities

arede-

scribed

here

.

Residual

fuel

pressure

is

checked

using

the

procedurede-

tailed

in

130

Fuel

Injection

.

Relieving

fuel

pressure

and

connecting

fuel

pressure

gauge

WARNING

-

"

Gasoline

is

highly

flammable

and

its

vaporsare

explosive

.

Do

not

smoke

or

work

ona

car

near

heaters

or

other

fire

hazards

when

diagnosing

and

repairing

fuel

system

problems

.

Have

a

fire

extinguisher

available

in

case

of

an

emergency

.

"

When

working

onan

open

fuel

system,

wear

suit-

able

hand

protection

.

Prolonged

contact

with

fuel

can

cause

iflnesses

and

skin

disorders

.

CA

UTION-

Cleanliness

is

essential

when

working

withfuel

circuit

components

.

Thoroughly

clean

the

unionsbefore

disconnecting

fuel

fines

To

prevent

fuel

from

spraying

on

a

hotengine,

system

fuel

pressure

should

be

relieved

before

disconnecting

fuel

lines

.

One

method

is

to

tightly

wrap

a

shop

towel

around

a

fuel

line

fit-

ting

and

loosen

or

disconnect

the

fitting

.

Measuring

fuel

pressure

requires

special

tools

.

Earlier

cars

use

pressure

hose

with

clamps

for

fuel

delivery

.

These

can

be

attached

to

a

fuel

pressure

gauge

below

the

intake

manifold

.

Page 194 of 759

160-

1

0

FUEL

TANK

AND

FUEL

PUMP

3

.

Operate

fuel

pump

as

described

earlier

under

Operat-

ing

fuel

pump

for

tests

.

Check

that

fuel

pressure

cor-

responds

to

specifications

listed

in

Table

c

.

"

If

system

pressure

is

low,

repeat

test

whilegradually

pinching

off

return

hose

.

Pressure

should

rise

rapidly

.

If

not,fuel

pump

is

most

likely

faulty

.

"

If

system

pressure

is

too

high,

check

return

line

from

pressure

regulator

to

tank

.

Check

for

kinks

in

hose

.

Blow

compressed

air

through

line

to

check

for

block-

ages

.

If

no

faulty

canbe

found,

pressure

regulator

is

most

likely

faulty

.

See

130

Fuel

Injection

for

testing

and

replacementprocedures

.

Table

c

.

Fuel

Pressure

Specifications

Engine

1

Fuel

pressure

4-cylinder

M42/M44

3

.0

:e

0

.06

bar(43

.5

±0

.9

psi)

6-cylinder

M50/S50US

3

.0

:j-

0

.06bar(43

.5

t0

.9

psi)

M52/S52US

3

.5

t

0

.06

bar

(51

t0

.9psi)

CA

UTION-

Do

not

use

compressed

air

above

40

psi

to

blow

out

fines

or

components

.

Interna¡

damage

to

com-

ponents

may

result

.

4

.

When

finished,

disconnect

pressure

gauge

.

FUEL

PUMP

Fuel

delivery

volume,

testing

1

.

Disconnect

return

line

from

fuel

rail

in

engine

compart-

ment

.

2

.

Connect

a

length

of

hose

to

fitting

on

fuel

rail

and

place

open

end

of

hose

in

a

suitable

container

for

catching

fuel

(2-quart

capacity)

.

3

.

Run

fuel

pump

for

exactly

30

seconds

as

described

earlier

under

Operating

fuel

pump

for

tests

and

mea-

sure

fuel

collected

.

Refer

to

Table

d

.

WARNING-

Table

d

.

Fuel

Pump

Delivery

Specifications

Fuel

under

pressure

is

present

duringthe

test

.

Use

I

Engine

Delivery

rate

(30

seconds

@

12V)

hose

clamps

at

all

connections

.

4-cylinder

M42/M44

0

.875

fter

(0

.93

qt)

6-cylinder

M50/S50US

0

.875

fter(0

.93

qt)

M52/S52US

~

1

.12

liter

(1

.16

qt)

4

.

When

finished

testing,

reconnect

fuel

line

.

Tighten

all

hose

clamps

.

NOTE-

It

is

common

practice

to

replace

the

fuel

filter

any

time

the

fuel

pump

unit

is

replaced

.

Page 447 of 759

GENERAL

E36

cars

are

equipped

with

integrated

automatic

heating

and

air

conditioning

systems

.

Many

of

the

procedures

given

in

this

repair

group

require

that

the

A/C

refrigerant

charge

be

evacuated

using

specialized

equipment

.

See

A/C

System

Warningsand

Cautions

later

in

this

repair

group

.

HEATER

AND

CONTROLS

Blower

motor,

removing

and

installing

NOTE-

On

6-cylinder

cars,

the

plastic

top

enginecover

and

fuel

rail

covermustbe

removed

.

The

fuel

injectorhamess

re-

taining

screws

must

be

removed

and

the

harness

set

aside

.

The

engine

control

module

(ECM)

cover

must

be

removed,

the

control

unit

connectors

unplugged

and

the

harness

pulled

out

of

the

way

.

See

130

Fuel

Injection

.

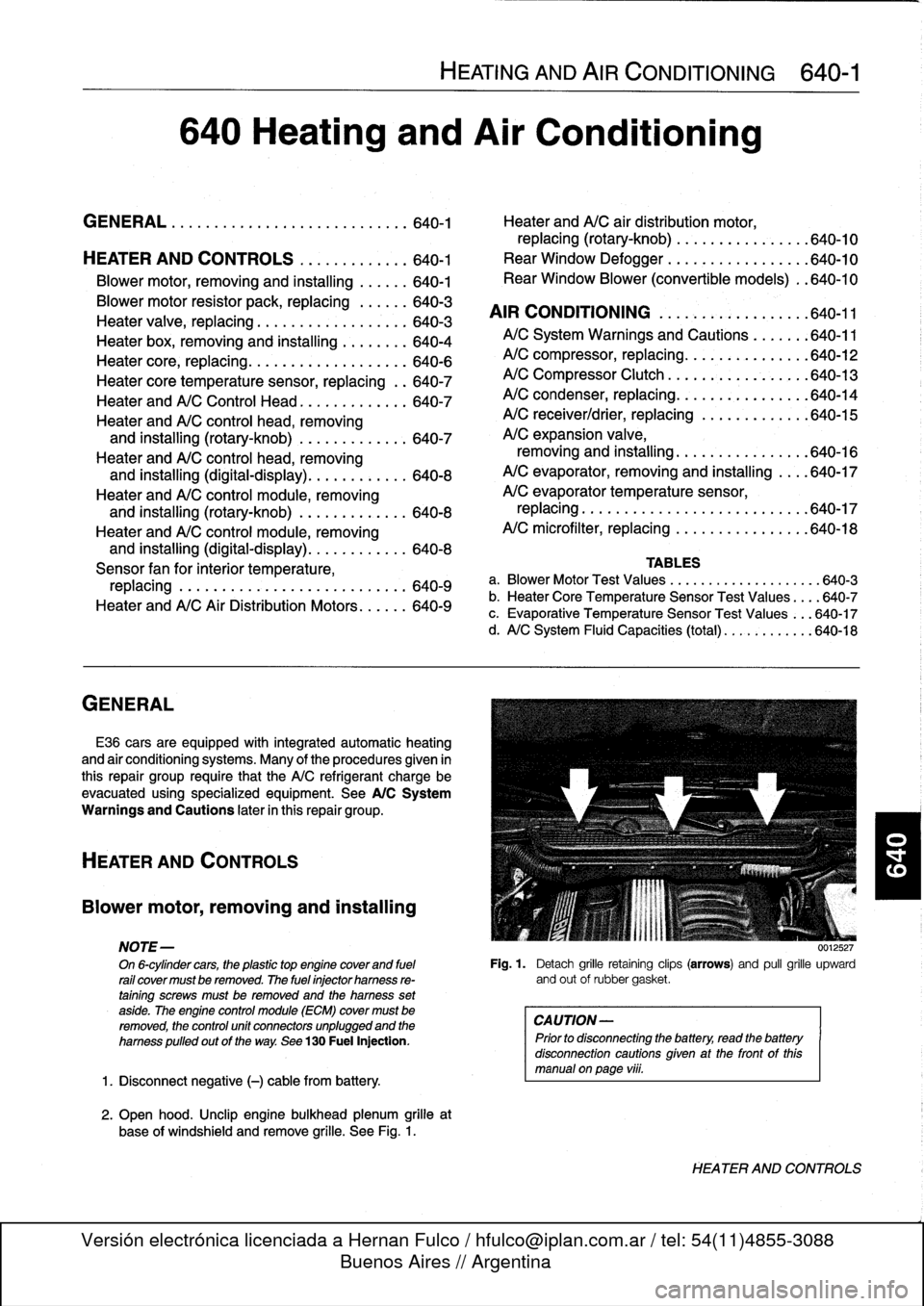

1

.

Disconnect

negative

(-)

cable

from

battery

.

2

.

Open

hood

.

Unclip

engine

bulkhead

plenum

grille

at

base

of

windshíeld

and

remove

grille

.

See

Fig

.

1

.

HEATING

AND

AIR

CONDITIONING

640-1

640

Heating

and

Air

Conditioning

GENERAL

.

...

.

....

.

.

.

.

.

.

.

.

.

.......

.

.

.

640-1

Heater

andA/C

air

distribution

motor,

replacing(rotary-knob)

.

.

...

.

.

.

.......

.

640-10

HEATER

AND

CONTROLS

.

.....

.

.

.

.

.

.

.640-1

Rear

Window

Defogger

.

.

.

.

.

.

.

.

.

.

...

.

.

.

640-10

Blower

motor,

removing

and

installing

.

.

.

.

.

.

640-1

Rear

Window

Blower

(convertible

models)

.

.640-10

Blowermotor

resistor

pack,

replacing

.

.

.

.

.

.

640-3

AIR

CONDITIONING

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-11

Heater

valve,

replacing

...........

.

.

.

.

.

.

.

640-3

Heater

box,

removing

and

installing

.

.

.

.

.

.

.

.

640-4

A/CSystem

Warnings

and

Cautions

.

.

.

.

.

.

:640-11

Heater

core,

replacing

.....

.

.

:

....

.

.

.

.

.

.

.

640-6

A/C

compressor,

replacing

.

.

::.

:

:

.

.

.

.

.

.

.

.640-12

Heater

core

temperature

sensor,

replacing

.

.

640-7

A/C

Compressor

Clutch

.

.

.

.

.

.

.

:

.

.

.

.

.

.

.

.

.

640-13

Heater

andA/C

Control

Head

.

.

....

.

.....

.

640-7

A/C

condenser,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-14

Heater

andA/C

control

head,

removing

A/C

receiver/drier,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.

640-15

and

installing

(rotary-knob)

.

.

....

.

......

640-7

A/C

expansion

valve,

Heater

andA/C

control

head,

removing

removing

and

installing

...

.

.....

.

.

.

.

.

.

.

640-16

and

installing

(digital-display)

.

.....

.

.....

640-8

A/C

evaporator,

removing

and

installing

.

.

..

640-17

Heater

andA/C

control

module,removing

A/C

evaporator

temperature

sensor,

and

installing

(rotary-knob)

.

.

...

.

.

.

.

.

.

.

.

640-8

replacing

.

.

.

.

.

.

..............

.

.

.

.

.

..

640-17

Heater

andA/C

control

module,removing

A/C

microfilter,

replacing

......

.

....

.

.

.

..

640-18

and

installing

(digital-display)

.

...

.

.

.

.

.

...

640-8

Sensor

fan

for

interior

temperature,

TABLES

replacing

.

.

.

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

640-9

a

.

Blower

Motor

Test

Values

.........

...

.

.

......

640-3

Heater

andA/C

AirDistribution

Motors

.

.

.

.

.

.

640-9

b

.

Heater

Core

Temperature

Sensor

Test

Values

...

.640-7

c

.

Evaporative

Temperature

Sensor

Test

Values

...

640-17

d

.

A/C

System

Fluid

Capacities

(total)

..

..........

640-18

0012527

Fig

.

1

.

Detach

grille

retaining

clips

(arrows)

and

pull

grille

upward

and

out

of

rubbergasket

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautionsgiven

at

the

front

of

this

manual

onpage

viii

.

HEATER

AND

CONTROLS

Page 523 of 759

LEFT

-

LEFT

I

I

-

RIGHT

-

RIGHT

I

(

)

TAIL

(

)

TAIL

I

I

(

)

TAIL

(

)

TAIL

I

-

LIGHT

-

LIGHT

I

I

LIGHT

-

LIGHT

I

I

II

I

II

I

I

_

I

(

)

BACK-

LEFTUP

(

^

)

BRAKE

I

I

(

^

)

BACK

FIGHT

UP

(

_

)

BRAKE

LIGHT

LIGHT

LIGHT

LIGHT

I

I

II

I

I

______________J

______________J

64882

-

7993

ONLY

ELECTRICAL

WIRING

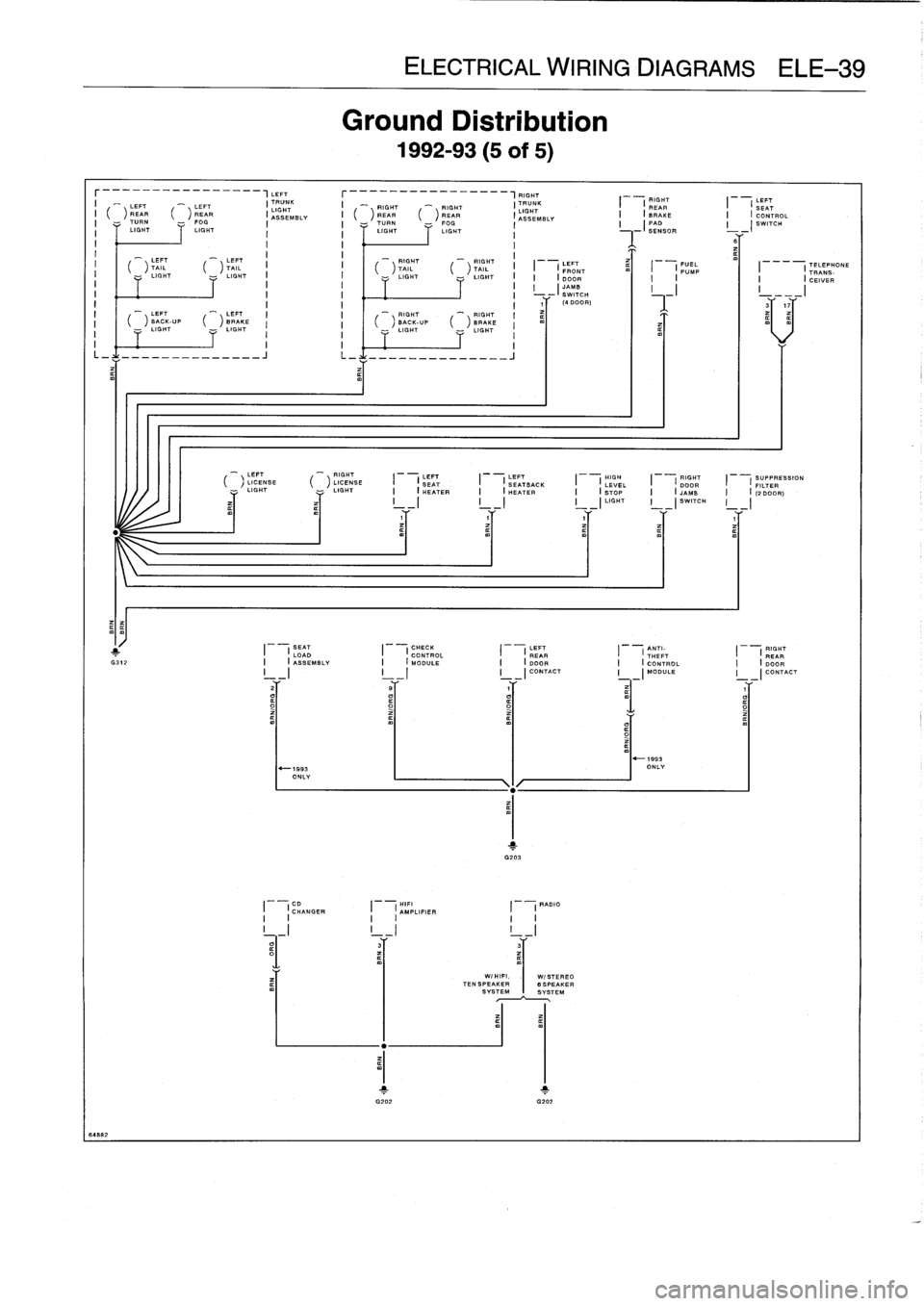

DIAGRAMSELE-39

Ground

Distribution

1992-93

(5

of

5)

,LEFT

rFIGHT

I

_

_

LEFT

"~LEFT

(TRUNK

I

TRUNK

I

RIGHT

LEFT

I

G

LIGHT

REAR

REAR

RIGHT

~'

RIGHT

I

I

REAR

I

(SEAT(ASSEMBLY

I

(

)

REAR

(

)

BEAR_

(ASSEMBLY

I

(BRAKE

I

(CONTROL

I

-

TURN

FOG

I

I

TURN

FOG

I

I

(

PAD

I

(

SWITCH

LIGHT

LIGHT

i

i

LIGHT

LIGHT

i

SENSOR

B

()

LEFT

LICENSE

(

)

LICENSE

I

(

SEAT

I

I

SEATBACK

I

(

LEVEL

I

(

DOOR

I

I

FILTER

ESSION

LIGHT

LIGHT

I

(

HEATER

I

l

HEATER

I

V

(

STOP

I

v

(

JAMB

I

v

I

(2DOOR)

I

I

I

__I

I

_

(

LIGHT

I

-(SWITCH

I__I

Y

Y

SEAT

I

CHECK

LEFT

ANTI-

RIGHT

(

I

LOAD

CONTROL

REAR

I

(

THEFT

I

I

REAR

G312

I

I(

ASSEMBLY

I

(

MODULE

I

(

DOOR

I

(

CONTROL

I

(

DOOR

I

-

I

I

_

I

I

_I

CONTACT

I

_I

MODULE

I

_I

CONTACT

CD

HIFI

RADIO

I

(

CHANGER

I

(

AMPLIFIER

i

II

I

I

I

I

I

WIHIFI

.

I

WISTEREO

TENSPEAKER

BSPEAKER

SYSTEMSYSTEM

I

LEFT

FUEL

TELEPHONE

(

FRONT

I

(

PUMP

I---

I

TRANS-

DOOR

I

I

I

I

CEIVER

I

(JAMB

I

I

I

SWITCH

,Y

(4DOOR

I

=

Y

~~Y

Page 527 of 759

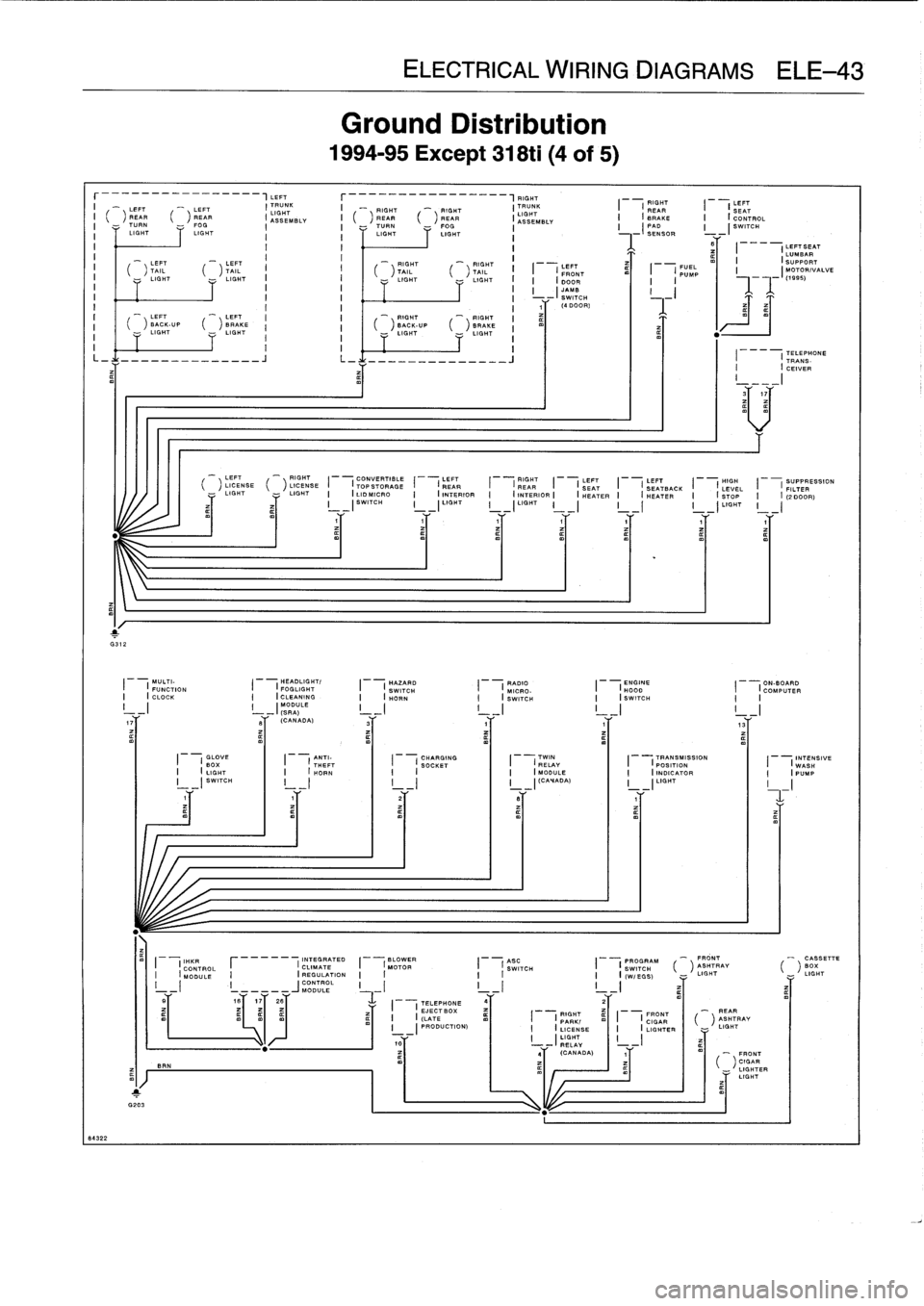

ELECTRICAL

WIRING

DIAGRAMSELE-43

r----------_-__--,LEFT

r---__-------~_--,FIGHT

I

-

RIGHT

LIT

LEFT

"-

LEFT

I

IGHT

K

I

_

RIGHT

'

RIGHT

I

'TRUNK

SEMBLY

I

(

REAR

I

(

SEAT

I

(

)

REAR

(

)

REAR

I

gSSEMBLV

I

(

)

REAR

(

)REAR

I

I

(

BRAKE

I

(

CONTROL

AS

I

-

TURN

-

FOG

I

I

-

TURN

-

FOG

I

I

(

PAD

I

-(

SWITCH

I

LIGHT

LIGHT

I

I

LIGHT

LIGHT

I

SENSOR

I

I

I

I

B

LEFT

SEAT

I

(LUMBAR

I

-

LEFT

-

LEFT

_RIGHT

RIGHT

I

I

(

)

TAIL

(

)

SUPPO

TAIL

I

I

(

)

TAIL

(

)

TAIL

I

I

(

LEFT

I

,

FUEL

I

I

MO70RRVALVE

LIGHT

-

LIGHT

i

i

LIGHT

-~

LIGHT

i

I

I

DRM9T

I

(

PUMP

(I9SB)

I

I

I

I

I

v

I

SWITCH

I

T

T

(4

DOOR)

84322

1

G312

_

LEFT

'

LEFT

>

BACK-UP

(

)

BRAKE

LIGHT

LIGHT

G203

Ground

Distribution

1994-95

Except

318ti

(4

of

5)

'

RIGHT

"'

RIGHT

(

)

BACK-UP

(

>

BRAKE

LIGHT

,,

LIGHT

L_1--------------

J

L-1

--------------

i

I

_I

_I

_I

MODU

(SRA)

LE

I

_I

I

_I

I

_I

I

_I

17T

SY

(CANADA,

3T

Y

IaY

,

1

TELEPHONE

I

---

I

TRANS-CEIVER

I

._I

3T

,

7Y

_LEFT

-

RIGHT

_

CONVERTIBLE

LEFT

_RIGHT

_

LEFT

_

LEFT

_

HIGH

SUPPRESSION

(

)

LICENSE

(

)

LICENSE

I

I

TOPSTORAGE

I

(

REAR

I

(

REAR

I

(

SEAT

I

I

SEATBAIK

I

(

LEVEL

I

(

FILTER

LIGHT

LIGHT

I

I

LID

MICRO

I

(

INTERIOR

I

ANTERIOR

(

Y

(

HEATER

I

Y

(

HEATER

I

v

.

(

STOP

I

v

I

(2

DOOR)

I

I

SWITCH

I

I

LIGHT

I

_

I

LIGHT

_-

I

I

-

I

I

_

I

LIGHT

I-I

Y

YY

MULTI-

HEADLIGHT/

HAZARD

RADIO

ENGINE

ON-BOARD

I

(

FUNCTION

I

I

FOGLIGHT

I

(

SWITCH

I

(

MICRO-

I

I

H000

I

(

COMPUTER

I

I

CLOCK

I

I

CLEANING

I

(

HORN

I

(

SWITCH

I

(

SWITCH

I

I

GLOVE

ANTI-

CHARGING

TWIN

TRANSMISSION

INTENSIVE

I

(

BOX

I

(

THEFT

I

(

SOCKET

I

(

RELAY

I

(

POSITION

I

(

WASH

I

(

LIGHT

I

(

HORN

I

I

I

(

MODULE

I

(

INDICATOR

I

(

PUMP

I

_

(

SWITCH

I

_

I

I

-I

L-1

(CANADA)

I

-(LIGHT_

_

I

I

IT

IT

21'

ST

,Y

IHKR

INTEGRATED

BLOWER

ABC

OGRAM

-

FRONT

-

CASSETTE

CONTROL

I

r

-

CLIMATE

I

(MOTOR

II

I

:PR

ASHTRAY

BOX

SWITCH

SW

I

TCH

(

MODULE

I

(

REGULATION

I

i

I

I

I

(W/EGS)

LIGHT

LIGHT

I

i

-----JMODULE

L

I

I

I

I

I

`7'

I

1617

26

I

(TELEPHONE

4

"I

4

_

4

EJECTBOX

RIGHT

FRONT

REAR

I

(

(LATE

I

(

PARK(

I

(

CIGAR

(

)

ASHTRAY

-(

PRODUCTION)

I

(

LICENSE

I

(

LIGHTER

-

LIGHT

I

I

LIGHT

-

I

RELAY

4

(CANADA)

1

FRONT

BRN

(

^

)

CIGAR

LIGHTER

LIGHT

Page 533 of 759

TELEPHONE

CONVERTIBLE

RIGHT

REAR

CENTRAL

RIGHT

DRIVERS

___

I

I

_

__

_

_

___

_7RAN5-

I

I

TOpSTORAGE

I

I

BRAKEPAD

I

(

LOCKING

(

)LICENSE

I

II

I

CEIVER

I

LID

MICRO

I

I

SENSOR

I

(

SWITCH

LIGHT

SEAT

[-

,

RIGHT

-(

(1996)

I

(

__

I

I

I

_I__

I

(

SWATCH

SWITCH

31'

17Y

LUGGAGE

COMPARTMENT

TELEPHONECONNECTOR

(1997)

DRIVERS

1

-

1

FUEL

I

IJAMB

I

I

IPUMP

I

_I

SWITCH

I

I

_I

F__

f

____

_

_-_---

------

1997WITH

m

I

ALL

CONVERTIBLE

OTHERS

CONVERTIBLE

LEFT

I

I

REAR

I

I

TOP

I

I

REAR

WINDOW

I

(CONTROL

i

(INTERIOR

I

(BLOWER

-

I

MODULE_

I

-

I

LIGHT

I

-I

SWITCH

Y

V

1

SUPPRESSION

RIGHT

LEFT

-

LEFT

I

I

RAR

I

I

(

FILTER

I

(

REAR

~

i

h

)

TAIL

(

)

TAIL

I

(

REAR

I

(

WINDOW

I

I

(2

DOOR)

I

(

I

LIGHT

LIGHT

(

INTERIOR

m

I

(

BLOWER

LIGHT

I

I

LIGHT

INTERIOR

-

-I

1

2

_

(

HARD

1

2

I

DRIVERS

LEFT

I

-

LEFT

^'

LEFT

I(

SEAT

m

I

(

REAR

BACK-UP

BRAKE(CONNECTOR(

I

I

DRIGHT

Z

EFOGGEfl

I

(REAR

I

(

HEATER

I

(

INTERIOR

I

-

LIGHT

-

LIGHT

II

_I

I

I

I

(DOOR

I

_

I

I

-

(

LIGHT

I

I

I

m

I

y,

-I

(1

BR~1

cT

1

2

L_

I

IT-PD

ml

-

iCONNECTOR1

I

I

1

G312

0312

(CONVERTIBLE)

MULTI-

HEADLIGHT/

HAZARD

RADIO

ENGINE

TRANSMISSION

I

(

FUNCTION

I

I

FOGLIGHT

I

I

I

I

FINAL

B

LOWER

I

I

CLOCK

I

(

CLEANING

SWITCH

SWITCH

I

(

SHOWIODTC

I

(

INDICATOR

I

I

I

I

I

I

I

(

I

(

H

I

(

I

(

STAGE

MOTOR

UNIT

III

I

I

I

MO

1996)

LE

_

_

_

_

__

_

I_

_

I

I

I

_

_(1996)

I

I

I

(

LIGHT

I

-I

I

I

17

g~

(CANADA)

gY

17

1T

tY

Gy

I

I

~j

AUTOMATIC

I

(CLIMATE

CENTER

I

(CONTROL

GLOVE

SERVOTRONIC

CHARGING

ON-BOARD

INTENSIVE

-

I

MODULE

I

(

BOX

I

(

CONTROL

I

(

SOCKET

CONSOLE

m

I

(COMPUTER

m

I

IWgSH

I

_

I

(LIGHT

mI

I

(

MODULE

mI

I

I

MI

TELEPHONE

II

(()

II

I

1996

PUMP

1997

W/IHKA

InOR

ALL1996

_-__41,

_

-F_---_-0-9-_----f--f----0--0_----_f-f--_----___-----

I

-

(

(1997)

I

-(

(1997)

I

_

I

AS

C

FRONT

I

I

SWITCH

I

I

CIGAR

I

I

I

I

LIGHTER

I

_I

_I

I

_I

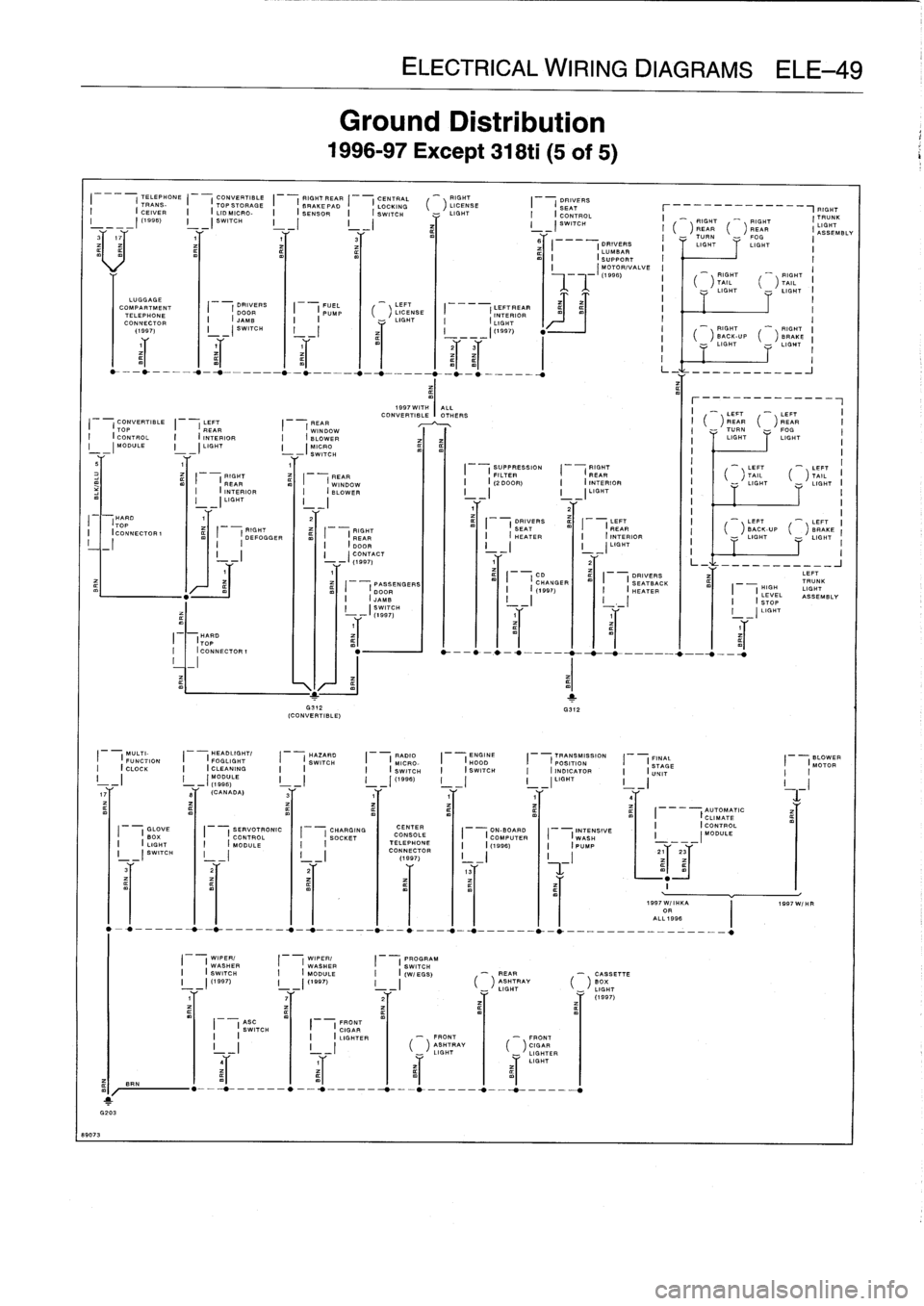

Ground

Distribution

1996-97

Except

318ti

(5

of

5)

-

LEFT

LICENSE

-

LIGHT

ELECTRICAL

WIRING

DIAGRAMS

ELE-49

I

DRIVERS

LEFT

PASSENGERS

I

OHANGER

I

ISEATBACK

HIGH

TRUNK

I

(

DOOR

I

(

(1997)

I

(

HEATER

I

I

LIGHT

I

i

I

I

I

II

I

LEVEL

JAMB

ASSEMBLY

I

SWITCH

I

I

LIGHT

WIPER/

WIPER/

PROGRAM

I

(

WASHER

I

(

WASHER

I

(

SWITCH

I

(

SWITCH

I

(

MODULE

I

I

(W/EGS)

-

FIGHT

"'

RIGHT

ITRUNK

REARTURN

-

~FOGR

iASSEMBLY

~I

I

I

DRIVERS

I

LIGHT

LIGHT

LUMBAR

II

(SUPPORT

I

II

MOTOR/VALVE

I

_

I

\

(1996)

i

-~

RIGHT

~--'

T

A

IL

I

\

FRONT

-,

FRONT

LGGAF

HTAY

I

-'LIGHTER

LIGHT

-

REAR

-

CASSETTE

_

LIGHT

RAY

6

GHT

Y

Y

(1997)

mI

SRN

1

G203

69073

-

RIGHT

RIGHT

BACK-UP

(

)

BRAKE

LIGHT

-

LIGHT

L_-~

-

___________J

r

-

Y

I

(

)

REAR

(

)

REAR

I

-

TURN

FOG

I

LIGHTLIGHT

I

Page 537 of 759

RIGHT

FUEL

RIGHTREAR

CENTRAL

LEFTREAR

DRIVER'S

---

(

FEAR

I

(

PUMP

I

I

BRAKE

PAD

I

(

LOCKING

I---

(

INTERIOR

I---

(

SEAT

INTERIOR

(

I

I

(

SENSOR

I

(

SWITCH

I

(

LIGHT

I

(

LUMBAR

(

LIGHT

I

I

I

I

I_

_

_

I

_

_

I

I

(

SUPPORT

v

o

I

~

~

eT

,T

,T

3/~

MOTORIVALVE

LUGGAGE

COMPARTMENT

TELEPHONE

CONNECTOR

I

I

DRIVER'S

DOOR

I

(JAMB

I

_I

SWITCH

I

-

LEFT

-

LEFT

CONVERTIBLE

LEFT

FEAR

CONVE

WIT

R

H

TIBLE

OT

A

HLEL

RS

_

_

CD

I

(

)

FEAR

(

)

REAR

I

(

TOP

I

FEAR

I

(

WINDOW

I

(CHANGER

I

T

TURN

--

FOG

I

CONTROL

I

(

INTERIOR

I

(

BLOWER

I

I

LIGHT

LIGHT

I

(

MODULE

I(

LIGHT

I

I

WORD

m

m

_

_

SW

-

H

I

I

-

LEFT

_

LEFT

I1

REAR

CONVERTIBLE

RIGHT_

_

_

_

_

_

I

(

)

TAIL

(

)

TAIL

II

I

(

DEFOGGER

I

I

TOP

STORAGE

I

(REAR

I

-

LIGHT

-

LIGHT

I

I

I

v

(LID

MICRO

I

v

(INTERIOR

I

I

SWITCH

I

_(

LIGHT

I

I

-

-

-

I

I1

1

2

I

-

LEFT

UP

-

LEFT

HARD

RIGHT

PASSENGER'S

FILTER

SID

.

DRIVER'

ACK-

BRAKE

S

I

(

(

I

I

(

TOP

I

(

REAR

I

(

DOOR

I

(

m

I

I

EATBACK

I

LIGHT

LIGHT

II

ICONNECTORI

I

I

(INTERIOR(

ml

I

IJgMB

I

I(2DOOR)

HI

(EATER

I

I

I_

I

I

I

(

LIGHT

I

I

I

_(

SWITCH

I

_I

I

I

-I

I

L_1

---J

10441

5

(HARD

TOP

ICONNECTOR1

_1

MULTI-

HAZARD

ENGINE

TRANSMISSION

FINAL

AUTOMATIC

BLOWER

(

FUNCTION

I

(

SWITCH

I

(

HOOD

I

(

POSITION

(

STAGE

I

(

CLIMATE

I

(

MOTOR

(

CLOCK

I

I

I

(

SWITCH

I

(

INDICATOR

I

(

UNIT

I

(

CONTROL

I

I

mI

/

1

G203

BRN

GLOVE

I

CHARGING

BIGHT

I

'

SOCKET

I-_I

I

_I

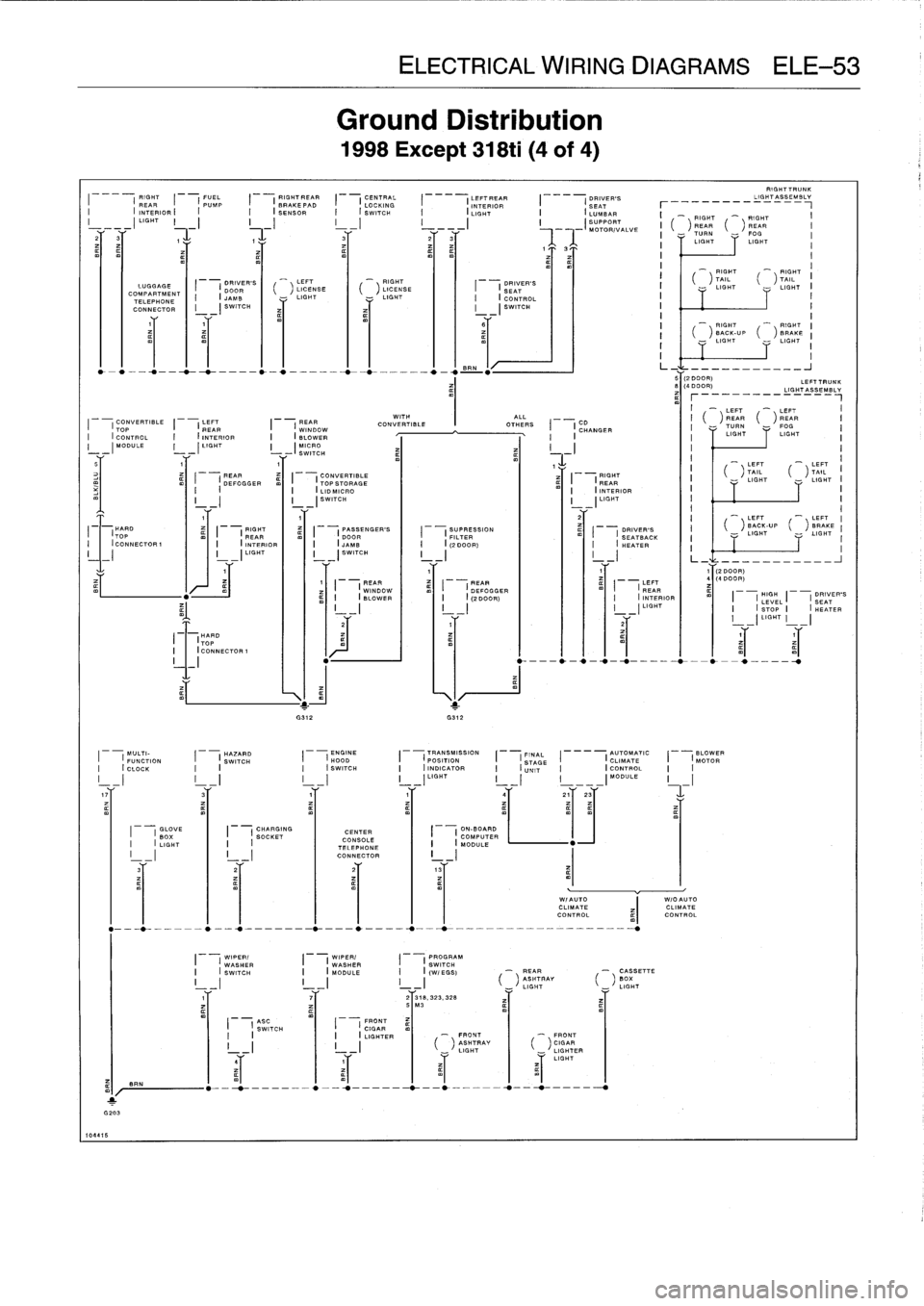

Ground

Distribution

1998Except

318ti

(4

of

4)

LEFT

-

RIGHT

LICENSE

(

)

LICENSE

LIGHT

-

LIGHT

1

FEAR

PEAR

I

I

WINDOW

I

I

DEFOGGER

I

I

BLOWER

I

I

(2

DOOR)

~%___'j

__\I/

G312

G312

CENTER

CONSOLE

TELEPHONE

CONNECTOR

I

I

WIPER/

I

(

WIPER/

I

(

PROGRAMWASHER

WASHER

SWITCH

I

(SWITCH

I

(

MODULE

I

I(WIEGS)

-

REAR

-

CASSETTE

II

II

II

('T

RAV

(B

_

__

LIGH_'IGHT

71

521

318,

323,

328

v3

ELECTRICAL

WIRING

DIAGRAMS

ELE-53

I

I

DRIVER'S

SEAT

I

(CONTROL

_I

SWITCH

ASO

FRONT

I

I

SWITCH

I

I

CIGAR

I

I

I

(

LIGHTER

-

FRONT

FRONT

ASHTRAY

CGAR

L

GHT

LIGHTER

LIGHT

I-

LEFT

FEAR

I

INTERIOR

I

-

I

LIGHT

RIGHTTRUNK

-_------_IGH-T_SSE=BL=

I

-

RIGHT

"~

RIGHT

I

(

)

REAR

(

)REAR

I

TURN

FOG

I

LIGHTLIGHT

RIGHT

~'

gIGHT

I

TAIL

(

)

TAIL

LIGHT

-

LIGHT

I

I

_

RIGHT

-

RIGHT

(

)

BACK-UP

(

)BRAKE

I

I

LIGHT

I

I

I

L_

___J

"T2

DEEP)

LEFTTRUNK

LIGHT

_

__

_

_

_

_

__

¢~

LIGHTASSEMBLV

a

r__

(2

DOOR)

(4

DOOR)

I

I

1

I

HIGH

DRIVER'S

I

LEVEL

1

SEAT

I

I

STOP

I

HEATER

I

-)

LIGHT

I

-

I

Page 540 of 759

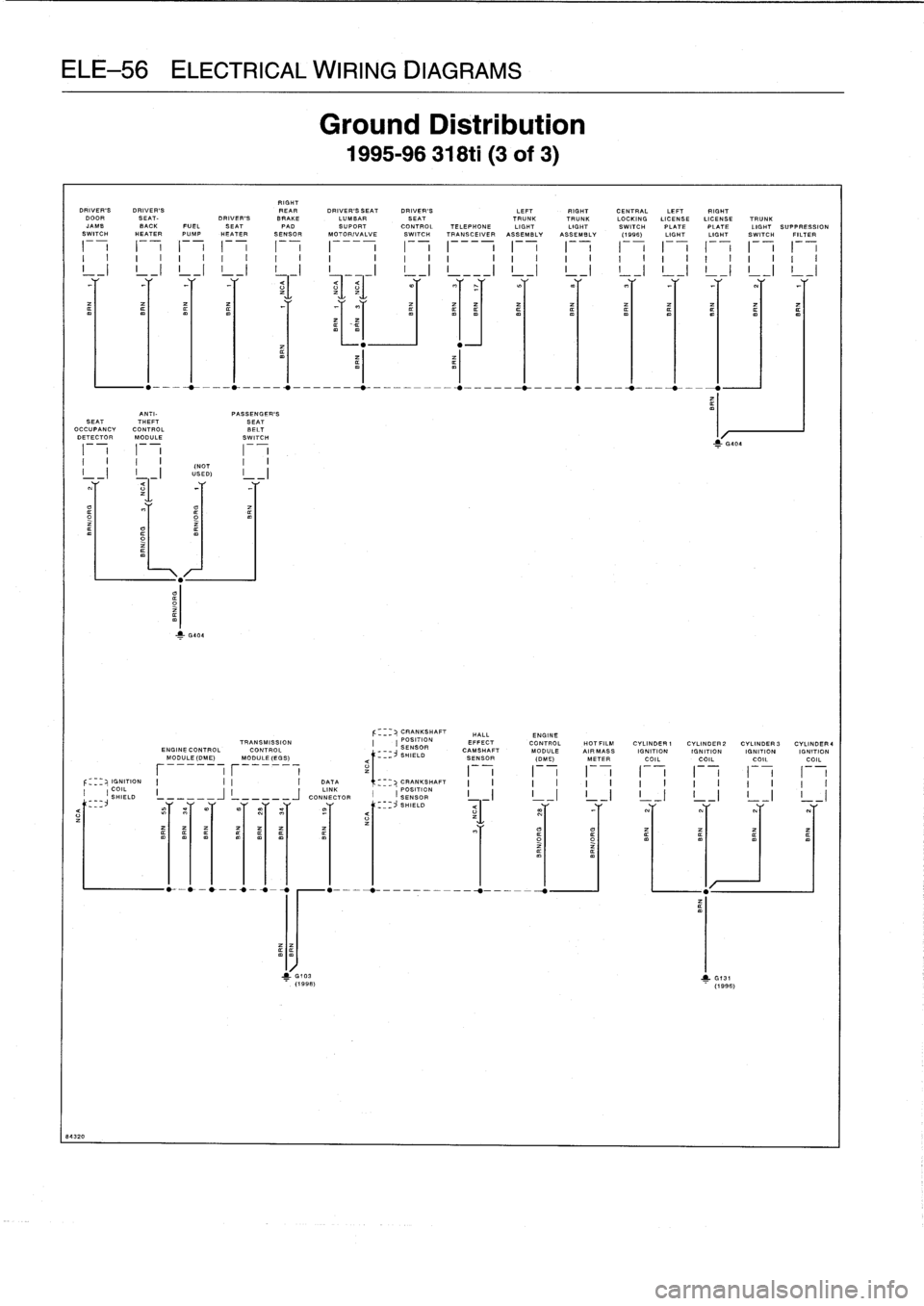

ELE-56

ELECTRICAL

WIRING

DIAGRAMS

ANTI-

PASSENGER'S

SEAT

THEFT

SEAT

OCCUPANCY

CONTROL

BELT

DETECTOR

MODULE

SWITCH

84320

RIGHT

DRIVER'S

DRIVER'S

REAR

DRIVER'S

SEAT

DRIVER'S

LEFT

RIGHT

CENTRAL

LEFT

RIGHT

DOOR

SEAT-

DRIVER'S

BRAKE

LUMBAR

SEAT

TRUNKTRUNK

LOCKINGLICENSE

LICENSE

TRUNK

JAMB

BACK

FUEL

SEAT

PAD

SUPORT

CONTROL

TELEPHONE

LIGHT

LIGHT

SWITCH

PLATEPLATE

LIGHT

SUPPRESSION

SWITCH

HEATER

PUMP

HEATER

SENSOR

MOTOR/VALVE

SWITCH

TRANSCEIVER

ASSEMBLY

ASSEMBLY

(1995)

LIGHT

LIGHT

SWITCH

FILTER

F

-

1

--,

1

-

7

I

_-

I

F

-

F

-,

1

-

7F

-

F

-

F

-

I

--,

1

--,

1

-

7

I

I

I

~

I

I

I

I

,

I

,

I

~

I

I

I

I

I

I

I

,

I

,

I

I

I

I

I

I

I

L

-I

L

-I

I

I

L

-I

L

-I

L

-I

L

-I

!

_I

L

-I

L

-I

(NOT

USED)

1

G404

1

G103

(1998)

Ground

Distribution

1995-96

318ti

(3

of

3)

Z

G404

CRANKSHAFT

HALL

ENGINE

TRANSMISSION

POSITION

EFFECT

CONTROL

HOTFILM

CYLINDER

1

CYLINDER2

CYLINDER

3

CYLINDER4

ENGINECONTROL

CONTROL

SENSOR

CAMSHAFT

MODULE

AIR

MASS

IGNITION

IGNITION

IGNITION

IGNITION

MODULE(DME)

MODULE(EGS)

-

j

SHIELD

SENSOR

,~

(DME)

METER

COILCOIL

COILCOIL

----

r

I

I

-

I

I

i

I

i

IGNITION

I

I

I

DATA

CRANKSHAFT

I

COIL

LINK

POSITION

I

IIII

I,

SHIELDL

CONNECTOR

SHIELD

SENSOR

I

I

I

III

I

III

I

II

I

__

_Y

_TY

SE

mY

Y

~Y

=Y

<___

_

~-

1"

=(

Y

T

Y

Y

1

G131

(1996)

Page 543 of 759

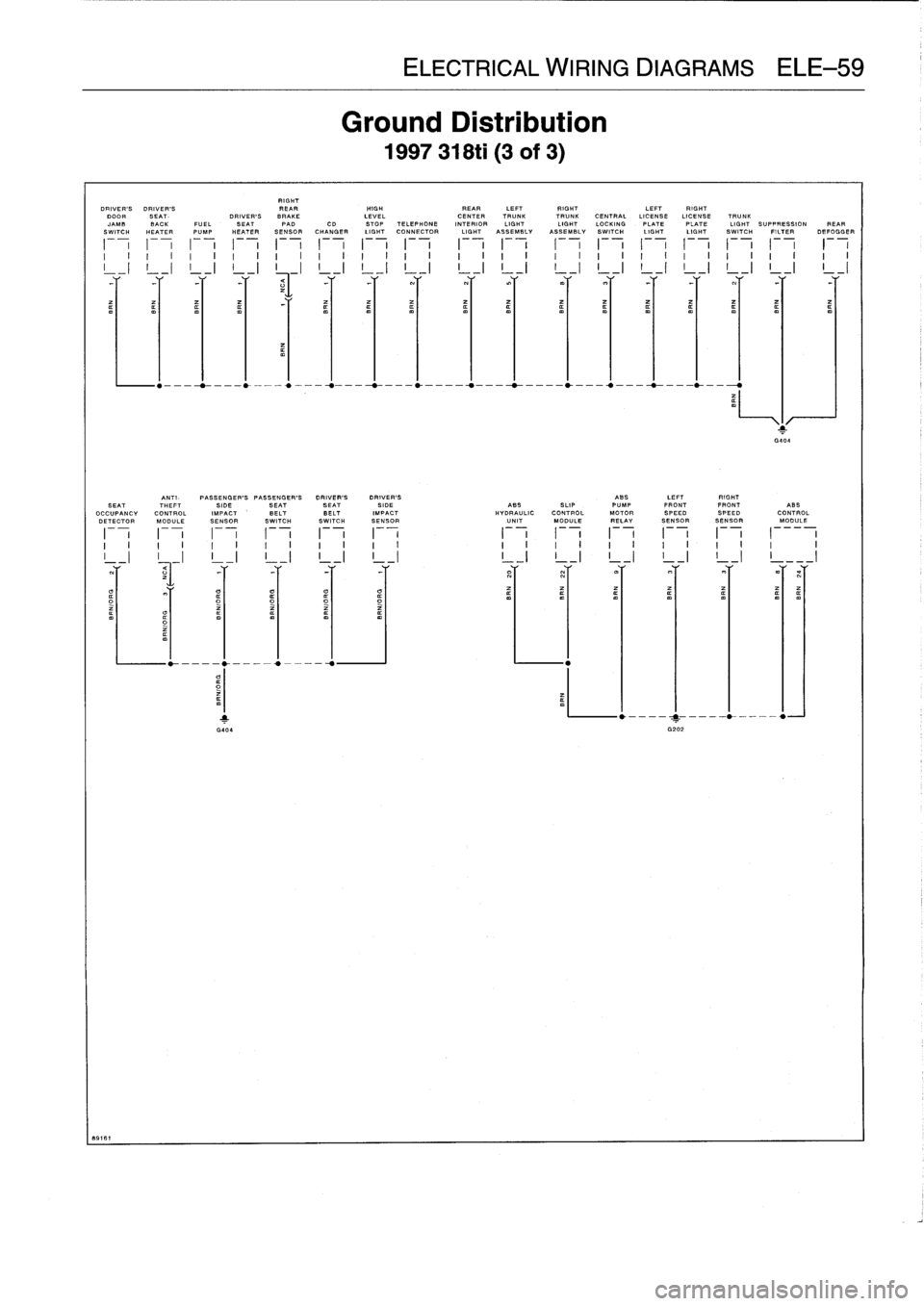

RIGHT

DRIVER'S

DRIVER'S

REAR

HIGH

REAR

LEFT

RIGHT

LEFT

RIGHT

DOOR

SEAT-

DRIVER'S

BRAKE

LEVEL

CENTERTRUNK

TRUNK

CENTRAL

LICENSELICENSE

TRUNK

JAMB

BACK

FUEL

SEAT

PAD

CD

STOP

TELEPHONE

INTERIOR

LIGHT

LIGHT

LOCKING

PLATEPLATE

LIGHT

SUPPRESSION

REAR

SWITCHHEATER

PUMP

HEATER

SENSOR

CHANGER

LIGHT

CONNECTOR

LIGHT

ASSEMBLYASSEMBLY

SWITCH

LIGHTLIGHT

SWITCH

FILTER

DEFOGGER

I

--,

I

i

F-

I

I

_-

I

1

-

7

1

-

7

F

-

,

I

--

,

F

-,

1

--,

I

1

--,

1

-

7

I

-

i

I

-

i

I

i

I

i

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

II

!

_I

!

_I

!

_I

I

_I

!

_I

!

_I

L-1

L-1

L

-I

L

-I

L-1

L-1

L-1

L-1

!

_I

L-1

Y

Y

-T

r

-r

-T

Y

Y

Y

rY

-T-T

r

Y

=r

ANTI-

PASSENGER'SPASSENGER'S

DRIVER'S

DRIVER'S

ASS

LEFT

RIGHT

SEAT

THEFT

SIDE

SEAT

SEAT

SIDE

A

BS

SLIP

PUMP

FRONT

FRONT

ASSOCCUPANCY

CONTROL

IMPACT

I

BELT

BELT

IMPACT

HYDRAULIC

CONTROL

MOTOR

SPEED

SPEED

CONTROL

DETECTOR

MODULESENSOR

SWITCH

SWITCH

SENSOR

UNIT

MODULE

RELAY

SENSOR

SENSORMODULE

F

-,

I

I

I

I

F

-

I

F-

I

F

-

II

I

I

I

I

I

1

I

I

I

I

II

_I

Y

=1

-T-T

Y

=f

ELECTRICAL

WIRING

DIAGRAMS

ELE-59

Ground

Distribution

1997

318ti

(3of

3)

IIII

F

-,

F

-,

F

-,

I

II

I

I

I

I

I

I

I

I

I

I

I