codes BMW M3 1995 E36 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 1995, Model line: M3, Model: BMW M3 1995 E36Pages: 759

Page 67 of 759

113

Cylinder

Head

Removal

and

Installation

GENERAL

.

...............

.

.

.

.

.

.......

113-1

CYLINDER

HEAD,

6-CYLINDER

.

.

.

.

.

.

.

113-10

Cylinder

head,

removing

(6-cylinder

engine)

..

113-10

CYLINDER

HEAD,

4-CYLINDER

..

.

...

.

.

113-1

Cylinder

head,

installing

(6-cylinder

engine)

...

113-15

Cylinder

head,

removing

(4-cylinder

engine)

...

113-1

E

Cylinder

head,

installing

(4-cylinder

engine)

...

113-6

GENERAL

CYLINDER

HEAD,

4-CYLINDER

The

information

given

inthis

repair

group

assumes

that

the

engine

is

installed

in

the

engine

bay

.

For

cylinder

head,

cam-

Cylinder

head,

removing

shaft,

and

valvetrain

disassembly

and

reconditioning

informa-

(4-cylinder

engine)

tion,

see116

Cylinder

Head

and

Valvetrain

.

For

ease

of

use

this

removal

procedure

is

broken

into

sub-

In

the

procedures

given

below,

engines

are

referred

to

by

sections,

as

follows

:

engine

code

.

If

necessary,

see100

Engine-General

for

en-

gine

code

and

application

information

.

NOTE-

If

a

head

gasket

problem

is

suspected,

acompression

test

will

usually

detectthe

fault

.

See

100

Engine-Gen-

eral

for

compression

testing

information

.

Special

BMW

service

tools

are

required

to

properly

remove

and

install

the

cylinder

head

on

both

the

4-cylinder

and

6-cyl-

inder

engines

.

The

special

tools

are

used

to

time

the

val-

vetrain

to

the

crankshaft

and

to

remove

the

Torx

(El

2)

head

bolts

.

Read

the

procedure

through

before

beginning

thejob

.

Cover

al¡

painted

surfaces

before

beginning

the

removal

procedure

.

As

an

aid

to

installation,

label

all

components,

wires,

and

hoses

before

removing

them

.

Do

not

reuse

gas-

kets,

O-rings

or

seals

during

reassembly

.

WARNING

-

Due

to

risk

of

personal

injury,

be

sure

the

engine

is

cold

before

beginning

the

removalprocedure

.

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

113-1

General

Coolingsystem,

draining

Cylinder

head

cover,

removing

Intake

manifold,

removing

Timing

chains,

uncoupling

Cylinder

head

assembly,

removing

WARNING

-

Allow

engine

to

cool

before

beginning

this

proce-

dure

.

General

1

.

Disconnect

negative

(-)

cable

from

battery

.

CAUTION

-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

"

Disconnecting

the

battery

may

erase

fault

codees)

stored

in

control

module

memory

.

Check

for

fault

codes

using

special

BMW

diagnostic

equipment

.

NOTE-

The

battery

is

mounted

in

the

luggage

compartment

behind

the

right

side

trim

panel

.

2

.

Working

underneath

vehicle,

remove

front

exhaust

pipe

from

exhaust

manifold

.

See

Fig

.

1

.

3

.

Disconnect

vacuum

hose

fitting

from

brake

booster

on

rear

bulkhead

.

Plug

opening

in

booster

and

hose

end

.

CYLINDER

HEAD,

4-CYLINDER

Page 76 of 759

113-10

CYLINDER

HEAD

REMOVAL

AND

INSTALLATION

Tightening

Torques

"

Coolant

drain

plug

to

cylinder

block

.

.

25

Nm

(18

ft-1b)

"

Intake

manifold

support

to

manifold

.

.

15

Nm

(11

ft-Ib)

"

Lower

intake

manifold

to

cylinder

head

.

..........

.

..

...

15

Nm

(11

ft-Ib)

"

Lower

intake

manifold

to

upper

manifold

..........

.

..

...

15

Nm

(11

ft-Ib)

"

Radiator

cooling

fan

to

coolant

pump

.

40

Nm

(30

ft-Ib)

"

Radiator

drain

screw

to

radiator

...

.

2

.5

Nm

(22

in-lb)

CYLINDER

HEAD,

6-CYLINDER

For

ease

of

use

this

procedure

is

broken

into

subsections,

as

follows

:

General

Coolingsystem,

draining

Cyiinder

head

cover,

removing

Intake

manifold,

removing

Timing

chains,

uncoupling

Cylinder

head

assembly,

removing

WARNING

-

Allow

the

engine

to

cool

before

beginning

this

pro-

cedure

.

General

1

.

Working

inside

luggage

compartment,

disconnect

neg-

ative

(-)

battery

cable

.

CAUTION-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-

tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

vi¡¡

.

"

Disconnecting

the

battery

may

erase

fault

code(s)

stored

in

control

module

memory

.

Check

for

fault

codes

using

special

BMW

diagnostic

equipment

2

.

Remove

front

exhaust

pipes

from

manifolds

.

Discard

nuts

.

3

.

Remove

air

filter

housing

complete

with

mass

air

flow

sensor

and

intake

air

ducting

.

Disconnect

vacuum

hos-

es

from

throttle

housing

.

4

.

On

M52

and

S52US

engines

:

Remove

secondary

air

injection

check-valve

from

front

of

engine

and

set

aside

.

CYLINDER

HEAD,

6-CYLINDER

Coolingsystem,

draining

5

.

Drain

engine

coolant

and

Rmove

coolant

hoses

from

thermostat

housing

.

Drain

engine

block

by

removing

block

drain

.

See

170

Radiator

and

Cooling

System

.

NOTE-

The

block

drain

is

on

the

exhaust

side

of

the

engine,

near

cylinder

no

.

5

.

6

.

Remove

radiator

cooling

fan

and

fan

shroud

.

See

170

Radiator

and

Cooling

System

.

NOTE-

The

radiator

cooling

fannut(32

mm

wrench)

has

left-

hand

threads

.

Cylinder

head,

removing

(6-cylinder

engine)

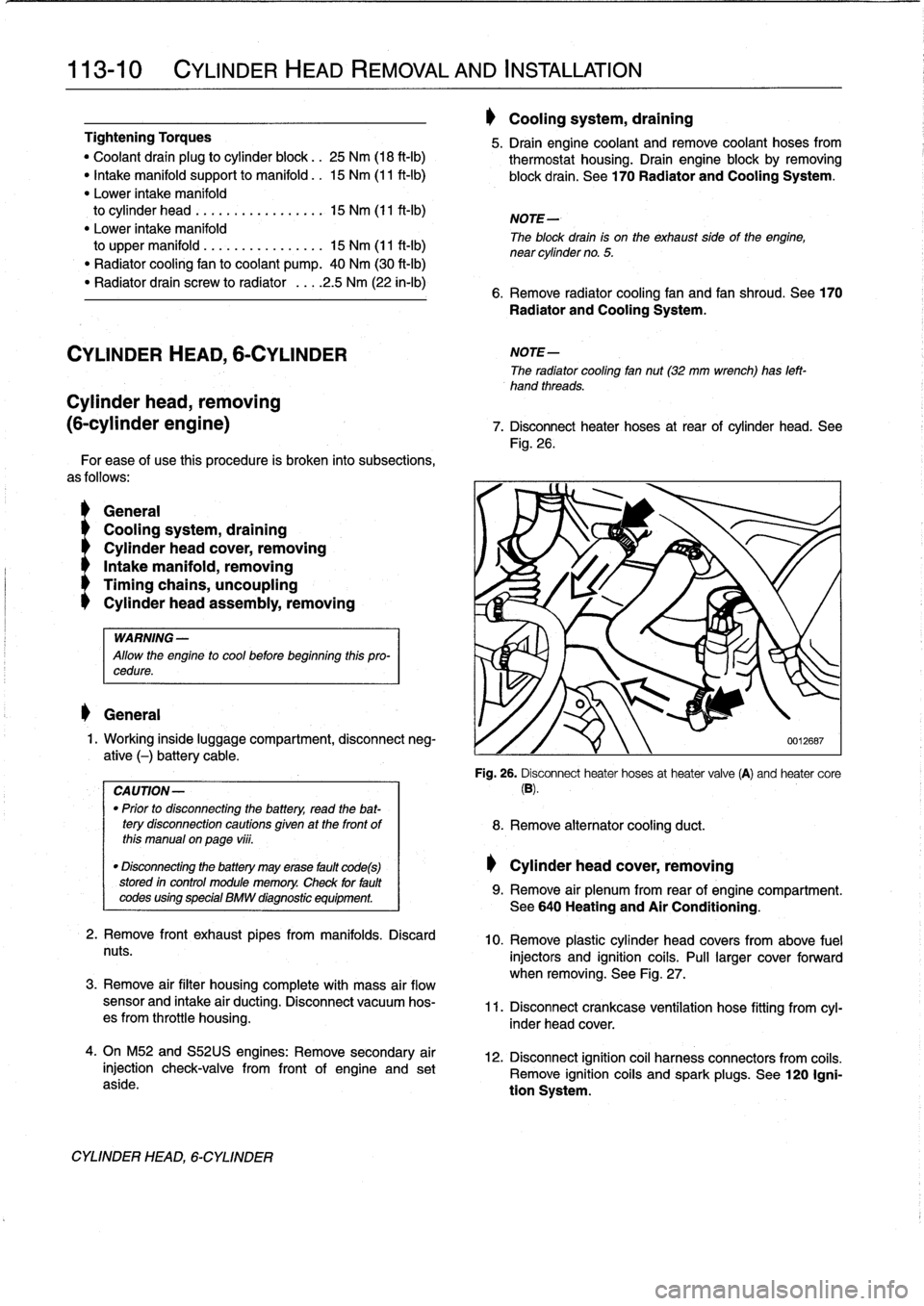

7

.

Disconnect

heater

hoses

at

rear

of

cylinder

head

.

See

Fig

.

26

.

'i

8

.

Remove

alternator

cooling

duct

.

Cylinder

head

cover,

removing

0012687

Fig

.

26

.

Disconnect

heater

hoses

at

heater

valve

(A)

and

heater

core

(B)

.

9

.

Remove

air

plenum

from

rear

of

engine

compartment

.

See640

Heating

and

Air

Conditioning

.

10

.

Remove

plastic

cylinder

head

covers

from

above

fuel

injectors

and

ignition

coils

.

Pull

larger

cover

forward

when

removing

.

See

Fig

.

27

.

11

.

Disconnect

crankcase

ventílation

hose

fitting

from

cyl-

inder

head

cover

.

12

.

Disconnect

ignition

coil

harness

connectors

from

coiis

.

Remove

ignition

coiis

and

spark

plugs

.

See

120

Igni-

tion

System

.

Page 103 of 759

Camshaft

timing

chains,

removing

(6-cylinder

engines)

1

.

Disconnect

negative

(-)

cable

from

battery

.

CA

UTION-

Disconnecting

the

battery

may

erase

fault

codes)

stored

in

control

module

memory

.

Check

for

fault

codes

using

special

BMW

diagnostic

equipment

.

2

.

Drain

engine

coolant

.

Drain

engine

block

by

removing

block

drain

.

Remove

radiator

cooling

fan

shroud

and

cooling

fan

.

See170

Radiator

and

Cooling

System

.

.

WARNING

-

Allow

the

engine

to

cool

before

openingor

draining

the

system

.

CAUTION-

Radiator

fan

has

left

hand

threads

.

NOTE-

The

block

drain

plug

is

located

on

the

exhaust

side

of

the

engine,

below

cylinder

no

.

4

.

3

.

Drain

engine

oíl

andremove

oil

pan

.

See

119

Lubrica-

tion

System

.

4

.

Remove

alternator

cooling

duct

.

5

.

Remove

two

large

coolant

hoses

from

thermostat

housing

.

Remove

engine

lifting

bracket

and

thermostat

housing

from

front

of

cylinder

head

.

6

.

Loosen

bolts

for

coolant

pump

pulley

.

Then

remove

drive

belts

for

alternator

andA/C

compressor

.

See

020

Maintenance

Program

.

Remove

coolant

pump

pulley

.

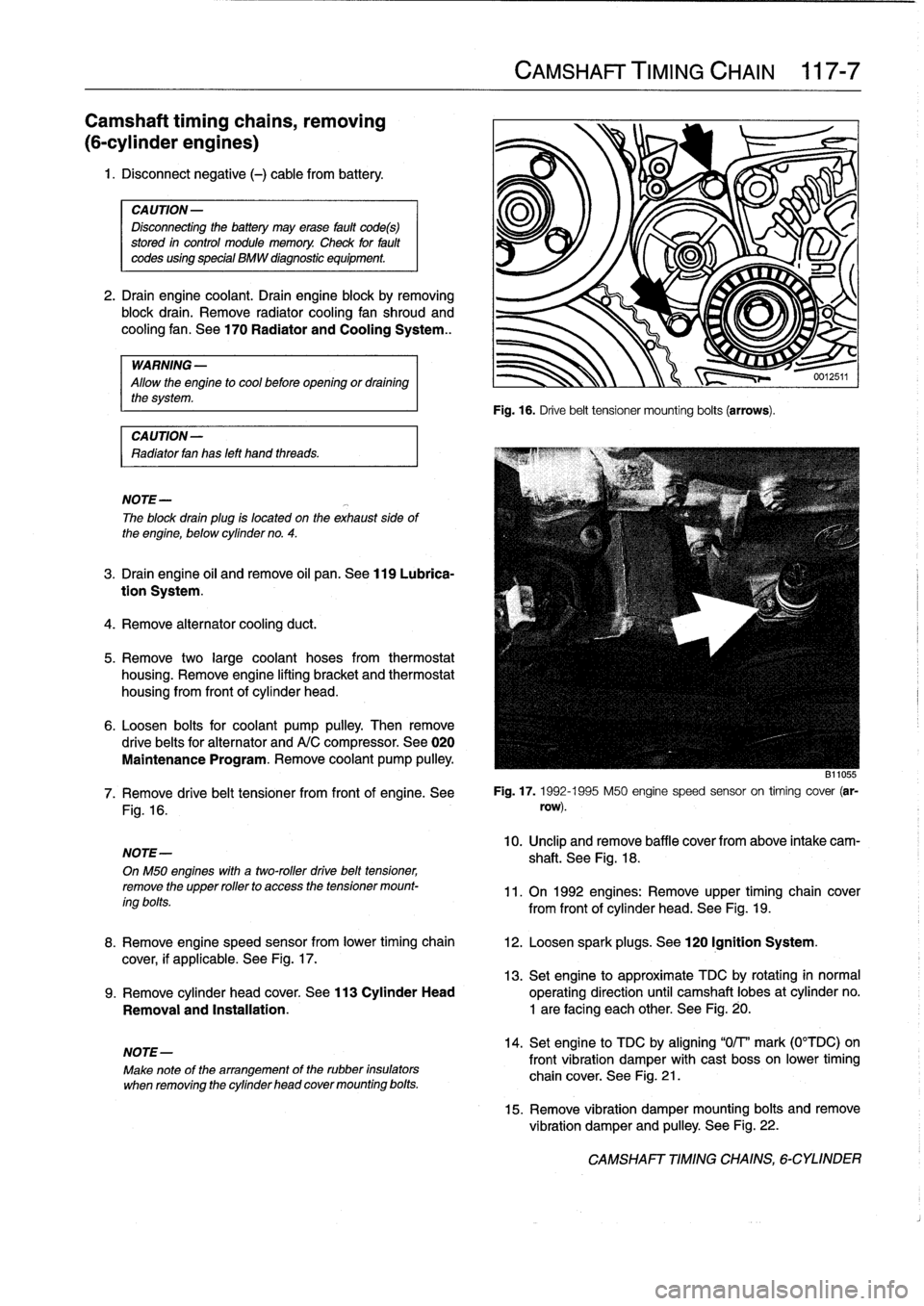

Fig

.

16

.

NOTE-

OnM50

engines

with

a

two-roller

drive

belt

tensioner,

remove

the

upper

rollerto

access

thetensioner

mount-

ing

bolts

.

NOTE-

Make

note

of

the

arrangement

of

the

rubber

insulators

when

removing

the

cylinder

head

cover

mounting

bolts

.

CAMSHAFT

TIMING

CHAIN

117-

7

Fig

.

16

.

Drive

belt

tensioner

mounting

bolts

(arrows)

.

B11055

7

.

Remove

drive

belt

tensioner

from

front

of

engine

.

See

Fig

.

17

.

1992-1995

M50

engine

speed

sensor

on

timing

cover

(ar-

row)

.

10

.

Unclip

andremove

baffle

cover

from

above

intake

cam-

shaft

.

See

Fig

.

18

.

11

.

On

1992

engines

:

Remove

upper

timing

chain

cover

from

front

of

cylinder

head

.

See

Fig

.

19

.

8

.

Remove

engine

speed

sensor

from

lower

timing

chain

12

.

Loosen

spark

plugs

.

See

120

Ignition

System

.

cover,

if

applicable

.

See

Fig

.

17

.

13

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

9

.

Remove

cylinder

head

cover

.

See

113

Cylinder

Head

operating

direction

until

camshaft

lobes

at

cylinder

no

.

Removal

and

Installatíon

.

1

are

facing

each

other

.

See

Fig

.

20

.

14

.

Set

engine

to

TDC

by

aligning

"0/T'

mark

(0°TDC)on

front

vibration

damper

with

cast

bosson

lower

timing

chain

cover

.

See

Fig

.

21

.

15

.

Remove

vibration

damper

mounting

bolts

and

remove

vibration

damper

and

pulley

.

See

Fig

.

22

.

CAMSHAFT

TIMING

CHAINS,

6-CYLINDER

Page 137 of 759

CHARGING

SYSTEM

TROUBLESHOOTING

.............

.

.

.

.

.121-2

Charging

System

Quick-Check

...

.

..

.

...

.

121-2

Static

current

draw,

checking

........

.

...

.

121-2

BATTERY

SERVICE

....................

121-3

Battery

Testing

.

.

.

.

.

.........

.

........

.

121-3

Hydrometer

Testing

.

...

.

.

.

...

.

.........

121-3

Battery

Open-Circuit

Voltage

Test

....

.

....

121-4

Battery

Load

Voltage

Test

.

.

.

.

.

.

.........

121-4

Battery

Charging

.

.

.

.

...

.

.

.

.

.

.

.

.........

121-4

ALTERNATOR

SERVICE

.

.

.

.

.

.

.....

.

...

121-4

Chargingsystem,checking

.

.

.

.

.

.........

121-4

Alternator,

removingand

installing

(4-cylinder

engine)

....

.

.

.

.

.

.

.

.........

121-5

Alternator,

removingand

installing

(6-cylinder

engine)

..

.

.

.

.

.

.

.

.

.

.........

121-6

GENERAL

The

charging

system

consists

of

a

belt-driven

alternator

with

integral

voltage

regulator

and

a

battery

mounted

in

the

luggage

compartment

.

Various

versions

of

alternators,

voltage

regulators,

starters,

and

batteries

are

used

in

the

E36

cars

.

It

is

important

to

re-

place

components

according

tothe

original

equipment

speci-

fication

.

Check

with

an

authorized

BMW

dealer

for

specific

application

and

parts

information

.

WARNING

-

"

Weargoggles,

rubbergloves,

and

a

rubberapron

when

working

around

batteries

and

battery

acid

(electrolyte)

.

"

Battery

acid

contains

sulfuric

acid

and

can

cause

skin

irritation

and

burning

.

ff

acid

is

spilled

onyour

skin

or

clothing,

flush

the

area

at

once

with

large

quantities

of

water

.

lf

electrolyte

gets

into

your

eyes,flush

them

with

largequantities

of

clean

wa-

terfor

several

minutes

and

call

a

physician

.

"

Batteries

that

are

being

charged

or

are

fully

charged

give

off

explosive

hydrogen

gas

.

Keep

sparks

and

open

flames

away

.

Do

not

smoke

.

BATTERY,

STARTER,

ALTERNATOR

121-1

121

Battery,

Starter,

Alternator

GENERAL

..

.

...

.

........

.

...

.

.

.

.

.

.

.

.

.

121-1

Voltage

regulator,

removing

and

ínstalling

.

.

.

121-6

Alternator

brushes,

inspecting

and

replacing

.121-7

STARTER

SERVICE

....

.

.

.

.

.

..........

.121-7

Starter

Troubleshootíng

121-7

15

..

.

.

.

.

.

........

.

.

.

Starter,

removing

and

installing

(4-cylinder

engine)

....

.

.

.

............

.

121-8

Starter,

removing

and

installing

(6-cylinder

engine

with

manual

transmission)

..

.

...........

.

...

121-8

Starter,

removing

and

installing

(6-cylinder

engine

with

automatic

transmission)

................

121-9

Solenoid

switch,

removingand

installing

....

121-10

TABLES

a

.

Battery,

Starter

and

Charging

System

Troubleshooting

............

.

.

.

.

:...

........

121-2

b

.

Specific

Gravity

of

Battery

Electrolyte

at

80°F

(27°C)

...............

.

.

..

..........

121-3

c

.

Open-Circuit

Voltage

and

Battery

Charge

........

121-4

d

.

Battery

Load

Test-Minimum

Voltage

.

..........

121-4

CAUTION

-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-tery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

"

Disconnecting

the

battery

cables

may

erase

fault

codes

stored

in

control

unit

memory

.

"

Always

disconnect

the

negative

()

battery

cable

first

and

reconnect

it

last

.

Cover

the

battery

post

with

an

insulating

material

whenever

the

cable

is

removed

.

"

After

reconnecting

the

battery,

the

power

window

motors

must

be

reinitialized

.

See

511

Door

Win-

dows

.

"

Never

reverse

the

battery

cables

.

Even

a

momen-

tary

wrong

connection

can

damage

the

alternatoror

other

electrical

components

.

"

Battery

cables

may

be

the

same

color

.

Label

ca-blebefore

removing

.

GENERAL

Page 150 of 759

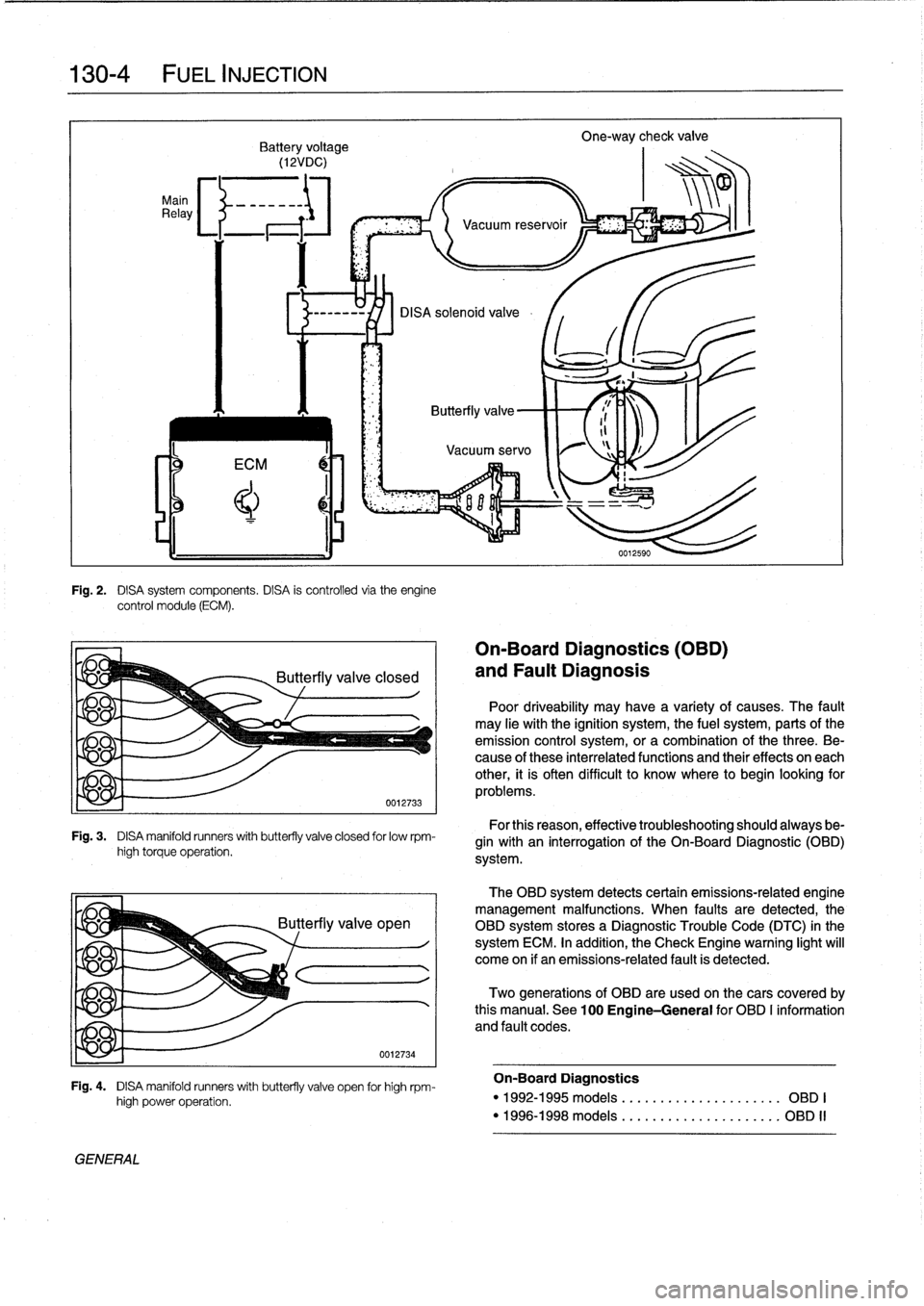

130-

4

FUEL

INJECTION

Main

Relay

Fig

.

2

.

DISA

system

components

.

DISA

is

controlled

via

theengine

control

module

(ECM)

.

Fig

.

3

.

DISA

manifold

runners

with

butterfly

valve

closed

for

lowrpm-

high

torque

operation

.

yje

q

GENERAL

high

power

operation

.

0012734

Fig

.

4

.

DISA

manifold

runners

with

butterfly

valve

open

for

high

rpm-

On-Board

Diagnostics

(OBD)

and

Fault

Diagnosis

Poor

driveability

may

have

a

variety

of

causes

.

The

fault

may

He

withthe

ignition

system,

the

fuel

system,

parts

ofthe

emission

control

system,

ora

combination

of

thethree

.

Be-

cause

of

these

interrelated

functions

and

their

effects

on

each

other,

it

is

often

difficult

to

know

where

to

begin

looking

for

problems

.

For

this

reason,

effective

troubleshooting

should

always

be-

gin

with

an

interrogation

of

the

On-Board

Diagnostic

(01313)

system

.

The

OBD

system

detects

certain

emissions-related

engine

management

malfunctions

.

When

faults

are

detected,the

OBD

system

storesa

Diagnostic

Trouble

Code

(DTC)

in

the

system

ECM

.

In

addition,

the

Check

Engine

warning

light

will

come

on

if

an

emissions-related

fault

is

detected

.

Two

generations

of

OBD

are

used

on

thecars

covered

by

this

manual

.

See

100

Engine-General

for

OBD

I

information

and

fault

codes

.

On-Board

Diagnostics

"

1992-1995models

....

.

...

...

.

...

......

OBD

I

"

1996-1998models

....

.

..

.

.

.

..

...

......

OBD

II

Page 152 of 759

130-

6

FUEL

INJECTION

Warnings

and

Cautions

For

personal

safety,

as

well

as

the

protection

of

sensitive

electronic

components,

the

following

warnings

and

cautions

should

be

adhered

to

when

working

on

the

engine

manage-

ment

system

.

GENERAL

WARNING

-

"

The

ignition

system

produces

high

voltages

that

can

be

fatal

.

Avoid

contact

with

exposed

termi-

nals

.

Use

extreme

caution

when

working

onacar

with

the

ignition

switched

on

or

the

engine

run-

ning

.

"

Do

not

touch

or

disconnect

any

high

voltage

ca-

bles

from

the

coils

or

spark

plugs

while

the

engine

is

running

or

beingcranked

by

the

starter

.

"

Connect

and

disconnect

the

DME

system

wiring

and

test

equipment

leads

only

when

the

ignition

is

switched

off

.

"

Gasoline

is

highly

flammable

and

fts

vaporsare

explosive

.

Do

not

smoke

or

work

on

a

car

near

heaters

or

other

fire

hazards

when

diagnosing

and

repalring

fuel

system

problems

.

Have

a

tire

extinguisher

avaílable

in

case

of

an

emergency

.

"

When

working

onan

open

fuel

system,

wear

suit-

able

hand

protection,

asprolonged

contact

wfth

fuel

can

cause

illnesses

and

skin

disorders

.

"

Renew

fuel

system

hoses,

clamps

and

O-rings

any

timethey

are

removed

.

"

Before

makingany

electrical

tests

that

require

the

engine

to

be

cranked

using

the

starter,

disable

the

ignition

system

as

described

in

120

Ignition

System

.

CAUTION-

"

Prior

to

disconnecting

the

battery,

read

the

bat-

tery

disconnectinn

cautions

given

at

the

front

of

this

manual

onpage

vifi

.

"

Do

not

connect

any

test

equipment

that

delivers

a

12-volt

power

supply

to

terminal

15

(+)

of

the

ig-

nitioncoil

.

The

current

flow

may

damage

the

ECM

.

In

general,

connect

test

equipment

only

as

speclfied

by

BMW,

this

manual,

or

the

equipment

maker

.

"

Only

use

a

digital

multlmeter

for

electrical

test

.

"

Only

use

an

LED

test

light

for

quick

tests

.

"

Disconnecting

the

battery

may

erase

fault

code(s)

stored

in

memory

.

Check

for

fault

codes

prior

to

disconnecting

the

battery

cables

.

ff

the

Check

Engine

light

ís

illuminated,

see100En-

gine-General

for

DME

fault

code

information

.

ff

any

other

system

faults

have

been

detected

(indi-

catedbyan

illuminated

warning

light),

see

an

au-

thorized

BMW

dealer

.

Additional

systems

with

self-diagnostic

capabilities

include,

ABS

(Anti-

lock

brakes),

SRS

(Airbags),

EML

and

ASC+T

and

AST

(Traction

Control)

.

"

Do

not

run

the

engine

wfth

any

of

the

spark

plug

wires

dlsconnected

.

Catalytic

converter

damage

may

result

.

"

Always

waitat

least

40

seconds

afterturning

off

the

ignition

before

removing

the

engine

control

module

(ECM)

connector

.

ff

the

connector

isre-

moved

before

this

time,

residual

power

in

the

sys-

tem

relay

may

damage

the

control

module

.

"

Cleanliness

is

essential

when

working

onan

open

fuel

system

.

Thoroughly

clean

fuel

line

con-

nections

and

surroundlng

areas

before

loosen-

ing

.

Avoid

moving

the

car

.

Only

fnstall

cleanparts

.

"

Fuel

system

cleaners

and

other

chemical

addi-

tives

other

than

those

specifically

recommended

by

BMW

may

damage

the

catalytic

converter,

the

oxygensensor

or

other

fuel

supply

components

.

Page 198 of 759

170-

4

RADIATOR

AND

COOLING

SYSTEM

A

quick

testat

the

coolant

temperature

gauge

sender

can

The

auxiliary

cooling

fan

comes

on

when

coolant

tempera

determine

if

the

gauge

is

functioning

correctly

.

ture

exceeds

a

predetermined

leve¡

or

whenever

the

air

condi-

tioning

is

on

.

A

dual-range

temperature

switch

for

cooling

fan

lf

the

gauge

needie

remains

at

the

rest

position

with

theen-

control

is

mounted

on

the

right

side

of

the

radiator

.

See

Fig

.

3

.

gine

warm,

remove

the

harness

connector

from

the

sender

and

jumper

the

correct

terminals

in

the

connector

to

simulate

a

high

engine

temperature

.

See

Table

a

.

Turn

the

ignition

on

.

If

the

gauge

needle

moves

upward,

the

sender

is

faulty

.

If

the

gauge

does

not

respond,

the

wiring

to

the

gauge

is

broken

(open

circuit)

or

the

gauge

itselfis

faulty

.

WARNING

-

1996

and

laten

models

are

OBD

11

compliant

.

Dis-

connecting

electrical

connectors

wíth

the

ignition

turned

on

may

set

fault

codes

in

the

ECM

.

It

is

rec-

ommended

that

you

leave

the

diagnosis

of

faults

in

the

coolant

temperature

sensorsystem

to

the

BMW

dealer

service

department

which

has

specialized

OBD

11

scan

tool

equipment

.

If

the

gauge

needle

reads

too

high

when

the

engine

is

cold,

remove

the

harness

connector

from

the

sender

.

Turn

the

igni-

tion

on

.

lf

the

gauge

needle

position

does

not

change,

the

wir-

ing

or

the

gauge

is

shorted

to

ground

.

If

the

gauge

needle

drops,

the

sender

is

faulty

and

should

be

replaced

.

When

re-

placing

a

faulty

coolant

temperature

sender,

the

gasket

ring

on

the

sender

should

also

be

replaced

.

Tightening

Torque

"

Temperature

gauge

sender

to

engine

18

Nm

(13

ft-Ib)

Cooling

fan,

testing

NOTE-

OnM44

engines

with

manual

transmission,

the

primary

electric

cooling

fan

is

mounted

on

the

engine

side

of

the

radiator

and

is

controlled

by

the

engine

control

module

(ECM)

.

Troubleshooting

thiscircuit

should

be

left

to

an

authorized

BMW

dealer

with

the

proper

diagnostic

equipment

An

otherwise

sound

cooling

system

may

still

overheat,

par-

ticularly

with

prolonged

idling,

due

to

a

failure

of

the

coolíng

fan(s)

.

The

belt-driven

cooling

fan

is

controlled

by

a

temperature

dependent

viscous

clutch

.

A

failed

fan

clutch

may

affect

air

flow

through

the

radiator

resulting

in

overheating

orpossibly

overcooling

.

Speed

Low

sp

High

s

With

the

engine

off,

check

thefan

clutch

by

spinning

thefan

.

eed

The

fan

should

spin

on

the

clutch

with

some

resistance

.

peed

Check

for

signs

of

leaking

fluid

from

the

clutch

.

If

thefan

free-

wheels

with

no

resistance,

cannot

be

tu

rned

by

hand,

or

there

are

signs

of

oil

leakage,

the

clutch

should

be

replaced

.

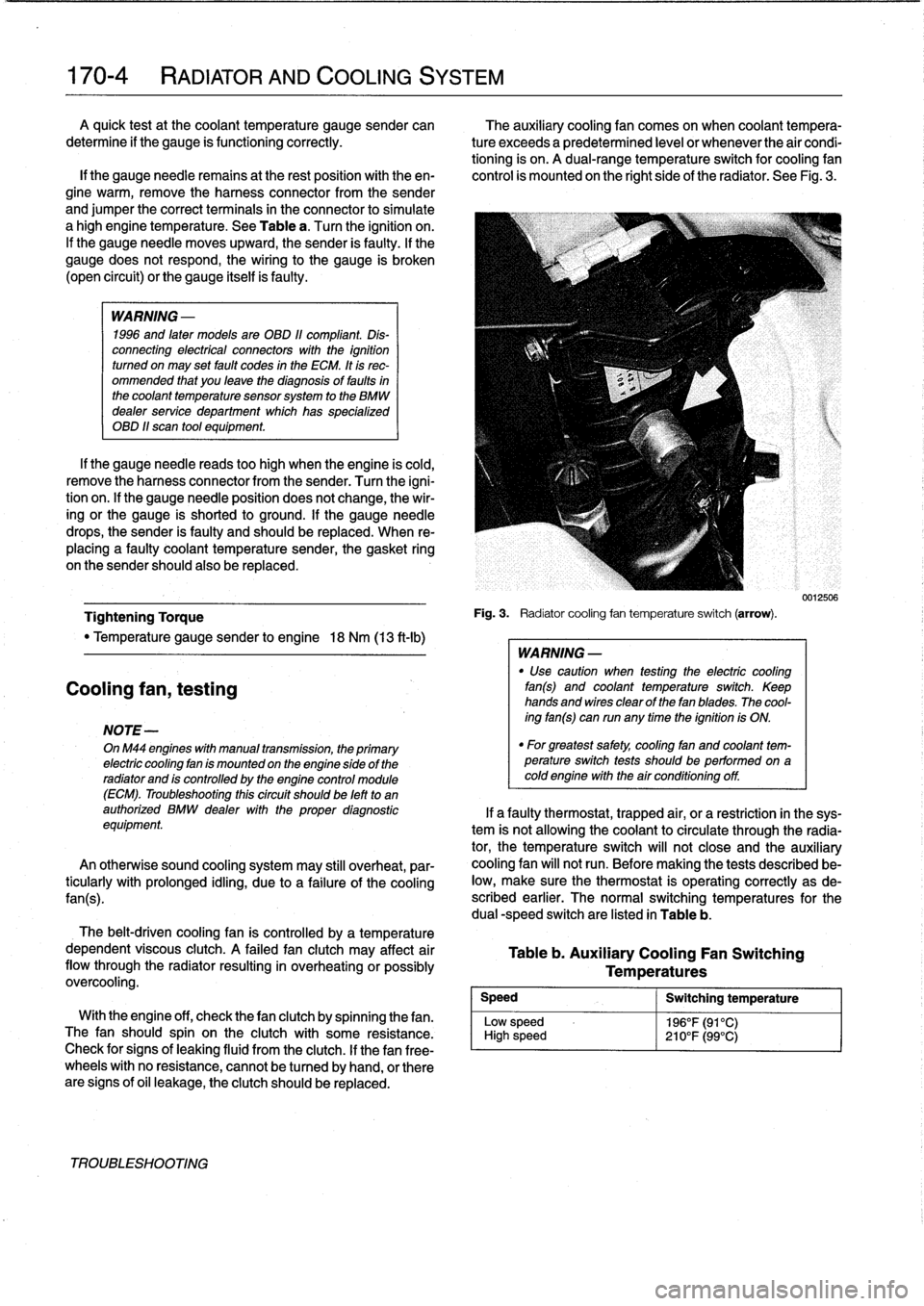

TROUBLESHOOTING

Fig

.

3

.

Radiatorcooling

fan

temperature

switch

(arrow)

.

WARNING

-

"

Use

caution

when

testing

the

electric

cooling

fan(s)

and

coolant

temperature

switch

.

Keep

hands

and

wires

clear

of

thefan

blades

.

The

cool-

ing

fan(s)

can

run

any

time

the

ignition

is

ON

.

"

For

greatest

safety,

coolíng

fan

and

coolant

tem-perature

switch

tests

shouldbe

performed

on

acoldengine

with

the

air

conditioning

off

.

Table

b

.

Auxiliary

Cooling

Fan

Switching

Temperatures

Switching

temperature

196°F(91°C)

210°F(99°C)

0012506

If

a

faulty

thermostat,

trapped

air,

or

a

restriction

in

the

sys-

tem

is

not

allowing

the

coolant

to

circulate

through

the

radia-

tor,

the

temperature

switch

will

not

close

and

the

auxiliary

cooling

fan

will

not

run

.

Before

making

the

tests

described

be-

low,

make

sure

the

thermostat

is

operating

correctly

as

de-

scribed

earlier

.

The

normal

switching

temperatures

for

the

dual

-speed

switch

are

listed

in

Table

b

.

Page 213 of 759

GENERAL

..

.

......

.

.

.

.....

.

...

.

.

.

.

.

.

.

.

200-1

Manual

Transmission

.

.

.....

.

.

.

.'

.

.

.

.

.

.

.

.

200-1

Automatic

Transmission

.........

.

.

.

.

.

.

.

.

200-1

Transmission

ID

Codes

..........

.

.

.

.

.

.

.

.

200-2

GENERAL

E36

models

areequipped

with

a

longitudinal

drivetrain

.

The

transmission

is

bolted

directly

to

the

rear

of

the

engine

.

A

driveshaft

connects

the

output

shaft

of

thetransmission

to

the

final

drive

.

The

final

drive

is

mounted

lo

the

rear

suspension

and

the

body

.

Individual

drive

axles

with

integrated

constant

velocity

joints

transfer

rotational

power

to

the

rear

wheels

.

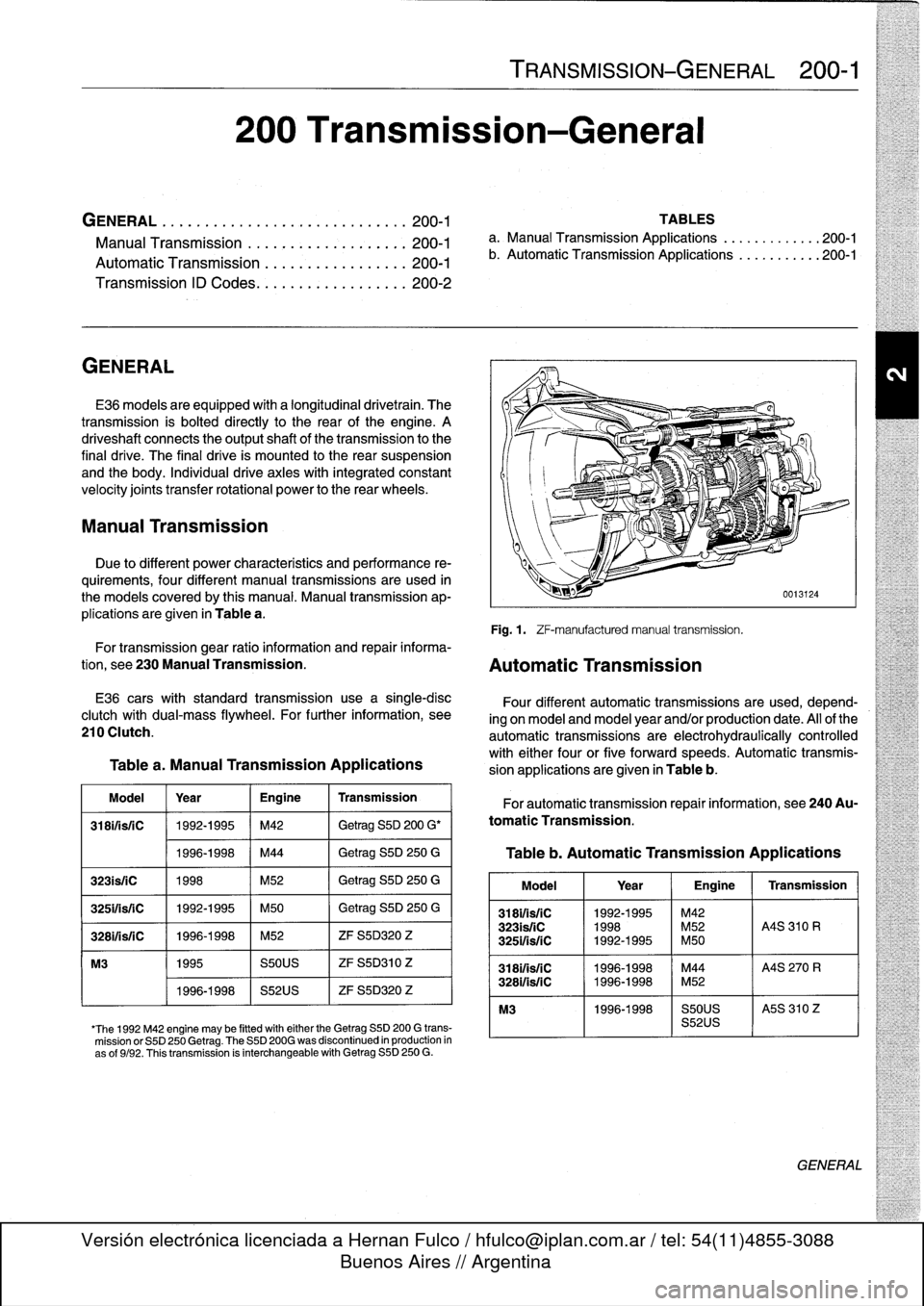

Manual

Transmission

Due

to

different

power

characteristics

and

performance

re-

quirements,

four

different

manual

transmissions

are

used

in

the

models

coveredby

this

manual

.

Manual

transmission

ap-

plications

are

given

in

Table

a

.

TRANSMISSION-GENERAL

200-1

200

Transmission-General

TABLES

a

.

Manual

Transmission

Applications

..

...........

200-1

b

.

Automatic

Transmission

Applications

...........

200-1

Fig

.

1

.

ZF-manufacturedmanual

transmission

.

For

transmission

gear

ratio

information

and

repair

informa-

tion,

see

230

Manual

Transmission

.

Automatic

Transmission

E36

carswith

standard

transmission

use

a

single-disc

clutch

with

dual-mass

flywheel

.

For

further

information,

see

210

Clutch

.

Table

a

.

Manual

Transmission

Applications

Model

Year

Engine

Transmission

318ifisfC

1992-1995

M42

Getrag

S5D

200

G'

1996-1998

M44

Getrag

S5D

250

G

323is/iC

1998

M52

Getrag

S5D

250

G

325ifsriC

1992-1995

M50

Getrag

S5D

250

G

3281/isfC

1996-1998

M52

ZF

S5D320

Z

M3

1995

S50US

ZF

S5D310

Z

1996-1998

S52US

ZF

S5D320

Z

'The

1992

M42

engine

may

be

fitted

witheither

the

Getrag

SSD

200

G

trans-

mission

or

S5D

250

Getrag

.

The

S5D

200G

was

discontinued

in

production

in

as

of

9/92

.

Thistransmission

is

interchangeable

with

Getrag

S5D

250

G

.

Four

different

automatic

transmissions

are

used,

depend-

ing

on

model

and

model

year

and/or

production

date

.

All

of

the

automatic

transmissions

are

electrohydraulically

controlled

with

either

four

or

five

forward

speeds

.

Automatic

transmis-

sion

applications

are

given

in

Table

b

.

For

automatic

transmission

repair

information,

see

240Au-

tomatic

Transmission

.

Table

b

.

Automatic

Transmission

Applications

Model

1

Year

1

Engine

1

Transmission

318i1is/1C

1992-1995

~

M42

323isfiC

1998

M52

A4S

310

R

3251/is/1C

1992-1995

M50

3181/isfC

11996-1998

M44

A4S

270

R

328i/is/1C

1996-1998

M52

M3

1996-1998

S50US

I

A5S

310

Z

S52US

GENERAL

Page 214 of 759

200-2

TRANSMISSION-GENERAL

Transmission

ID

Codes

On

both

manual

and

automatic

transmissions,

the

code

let-

ter

and

transmission

type

numbers

should

be

located

onan

ID

plate

attached

to

the

síde

of

thetransmission

.

Do

not

rely

on

numbers

cast

on

the

transmission

case

for

identification

.

In

addition,

thetransmission

lubricant

varies

between

trans-

missions

and

model

years

.

Fluid

application

information

should

be

clearly

marked

on

a

label

on

thetransmission

.

On

manual

transmissions,

either

ATF

(orange

label

reads

ATF-Oil!)

or

a

special

BMW

lubricant

(yellow

label

reads

MTF-

LT

1)

are

used

.

See

230Manual

Transmission

.

Automatic

transmissions

are

filled

with

either

Dexron

III

ATF

(black

trans

.

type

plate

reads

ATF-Oil!),

a

special

ffe-

time

oil

(green

trans

.

type

plate

reading

Life-Time

ó1)

.

See

240AutomaticTransmission

.

GENERAL

CAUTION-

lf

in

doubtas

to

the

typeof

fluid

installed

in

a

par-

ticular

transmission,

consult

and

authorized

BMW

dealer

service

department

for

the

latest

in

operat-

ing

fluids

.

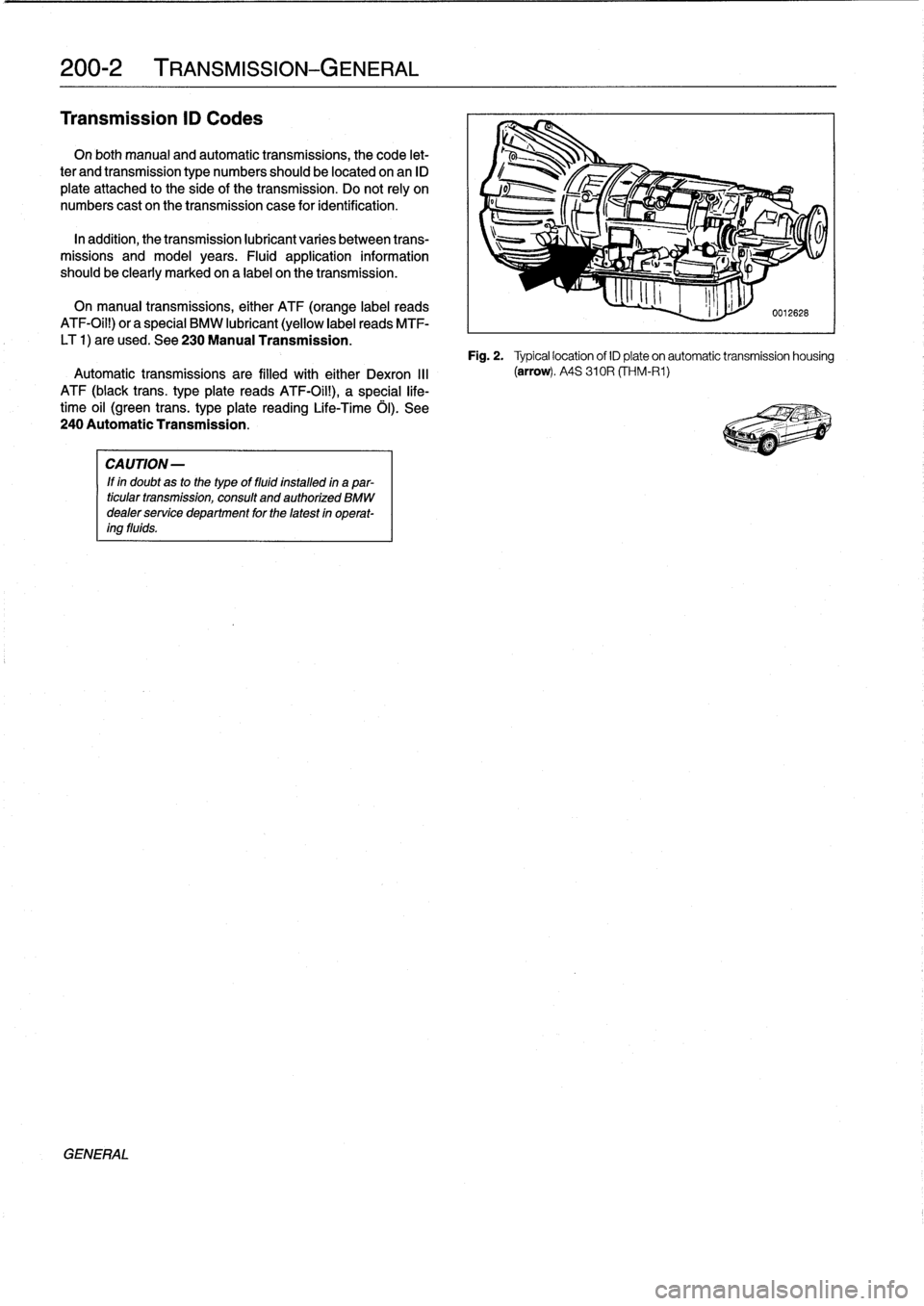

Fig

.

2

.

Typical

location

of

IDpíate

on

automatic

transmission

housing

(arrow)

.

A4S

310R

(THM-R1)

Page 229 of 759

AUTOMATIC

TRANSMISSION

240-1

240

Automatic

Transmission

GENERAL

.....

.

.

.

.

.

.

.

.

.

.

.

.

.

.........

.

240-1

TRANSMISSION

REMOVAL

AND

INSTALLATION

..................

.

.

.

.

.240-4

TRANSMISSION

SERVICE

.

.

.

.

.

.......

.

240-1

Transmission,

removing

and

installing

....

.

.

.240-4

ATF

leve¡,

checking

..

.

.

.

.

.

.

.

.

.

..........

240-1

ATF,

draining

and

filling

.

.

.

.

.

.

.

..........

240-2

TABLE

a

.

Automatic

Transmission

Gear

Ratios

.......

..

.

.

240-1

GENERAL

TRANSMISSION

SERVICE

lo

Automatic

transmissions

are

identified

by

code

letters

ATF

leve¡,

checking

foundon

a

data

plate

located

on

the

sideof

thetransmission

case,

behind

the

manual

valve

lever

.

See

200Transmis-

The

automatic

transmissions

installed

in

the

E36

models

sion-General

for

application

information

.

Forgear

ratio

spec-

are

normally

filled

with

Dexron

III

automatic

transmission

fluid

ifications,

see

Table

a

.

(ATF),

although

alternative

fluids

have

been

installed

from

the

factory,

depending

on

transmission

type

and

model

year

.

CAUTION-

Some

transmíssions

are

filled

with

a

special

BMW

"lifetime"

ATF

does

not

circulate

unless

the

engine

is

run-

automatic

transmission

fluid,

which

does

not

require

periodic

ning

.

When

towing

an

automafic

transmission

ve-

fluid

changes

.

hicle,

usea

flat-bed

truck

or

ralse

the

rear

wheels

off

the

ground

.

CAUTION-

Mixing

different

types

of

transmission

fluids

will

The

electronic

transmission

control

module

(TCM)

monitors

lead

to

transmission

failure

.

transmissionoperation

for

faults

and

alerts

the

driver

by

illumi-

nating

the

transmission

fault

indicator

on

the

instrument

pan-

el

.

On-board

diagnostic

codes

stored

in

the

TCM

mustbe

NOTE-

downloaded

and

interpreted

by

trained

technicians

using

spe-

The

transmission

lubricant

instafed

can

be

foundona

cial

BMW

diagnostic

equipment

.

type

plate

on

the

side

of

the

transmission

.

In

addition,

a

sticker

may

be

located

on

the

fluid

sump

indicatingthe

typeof

transmission

lubricant

used

.

Ifin

doubt,

con

NOTE-

sult

an

authorized

BMW

dealer

for

altemate

fluid

use

Internal

repairs

to

the

automatic

transmission

require

and

current

information

regardingtransmission

operat-

special

service

equipment

and

knowledge

.

If

it

is

deter-

ing

fluids

.

mined

thatinterna¡

service

is

required,

consult

en

au-

thorízedBMWdealerabouta

factoryreconditioned

unit

The

transmission

is

not

equipped

with

a

dipstick

.

Checking

or

a

transmission

rebuild

.

the

ATF

leve¡

requires

measuring

and

maintaining

a

specified

ATF

temperature

during

the

checking

procedure

.

The

check-

ing

temperature

is

not

fully

warm

orcold

(the

ATF

sump

should

be

approximately

warm

to

the

touch)

.

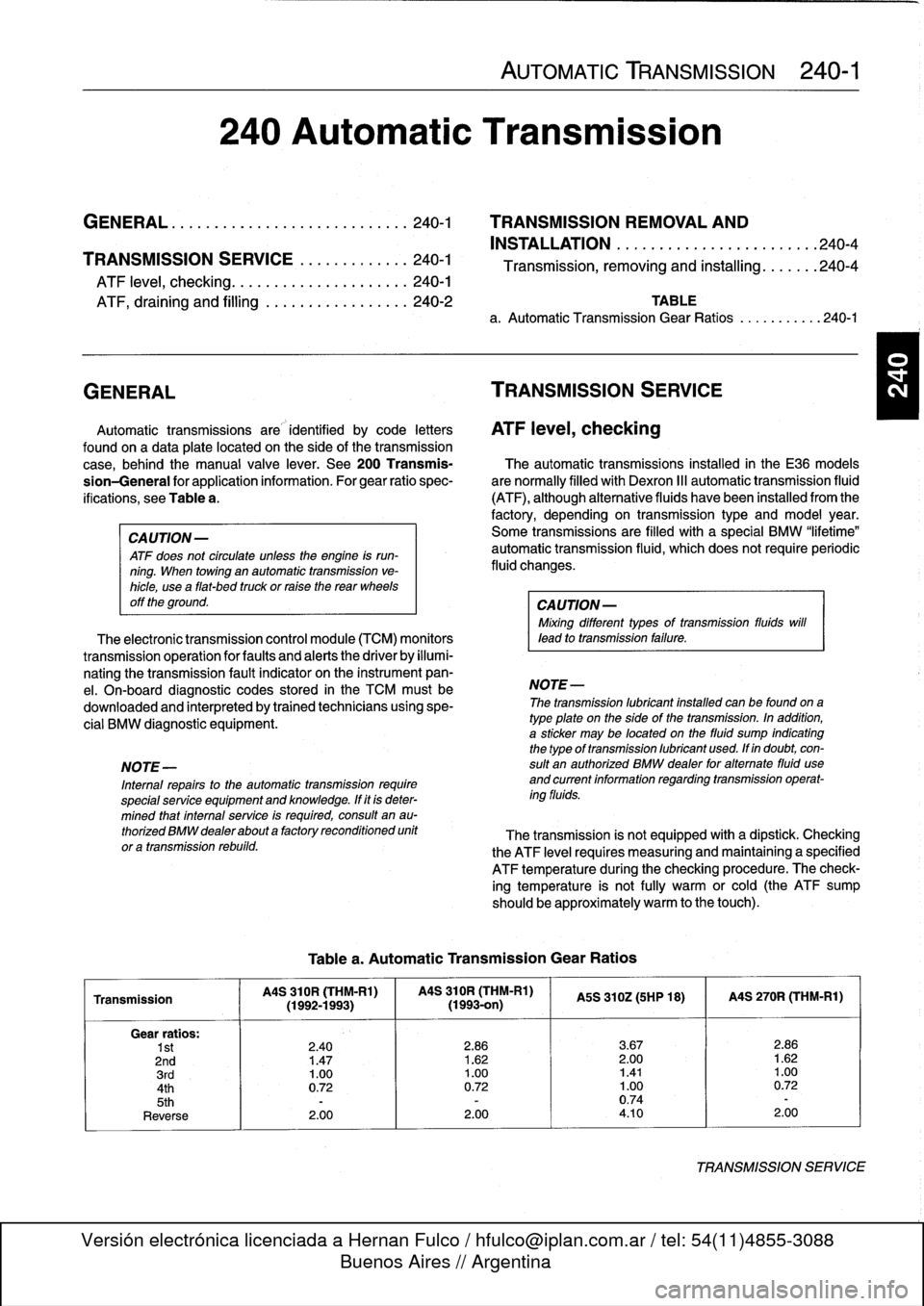

Table

a

.

Automatic

Transmission

Gear

Ratios

Transmission

MS

310R

(THM-R1)

MS

310R

(THM-Rl)

MS

310Z(5HP

18)

I

MS

270R

(THM-R1)

(1992-1993)(1993-on)

Gear

ratios

:

1st

2

.40

2

.86

3

.67

2

.86

2nd

1

.47

1

.62

2

.00

1

.62

3rd

1

.00

1

.00

1.41

1

.00

4th

0

.72

0

.72

1

.00

0

.72

5th

-

-

0

.74

-

Reverse

2

.00

2

.00

4

.10

2

.00

TRANSMISSIONSERVICE