Throttle Position Sensor BMW M3 1995 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1995, Model line: M3, Model: BMW M3 1995 E36Pages: 759

Page 180 of 759

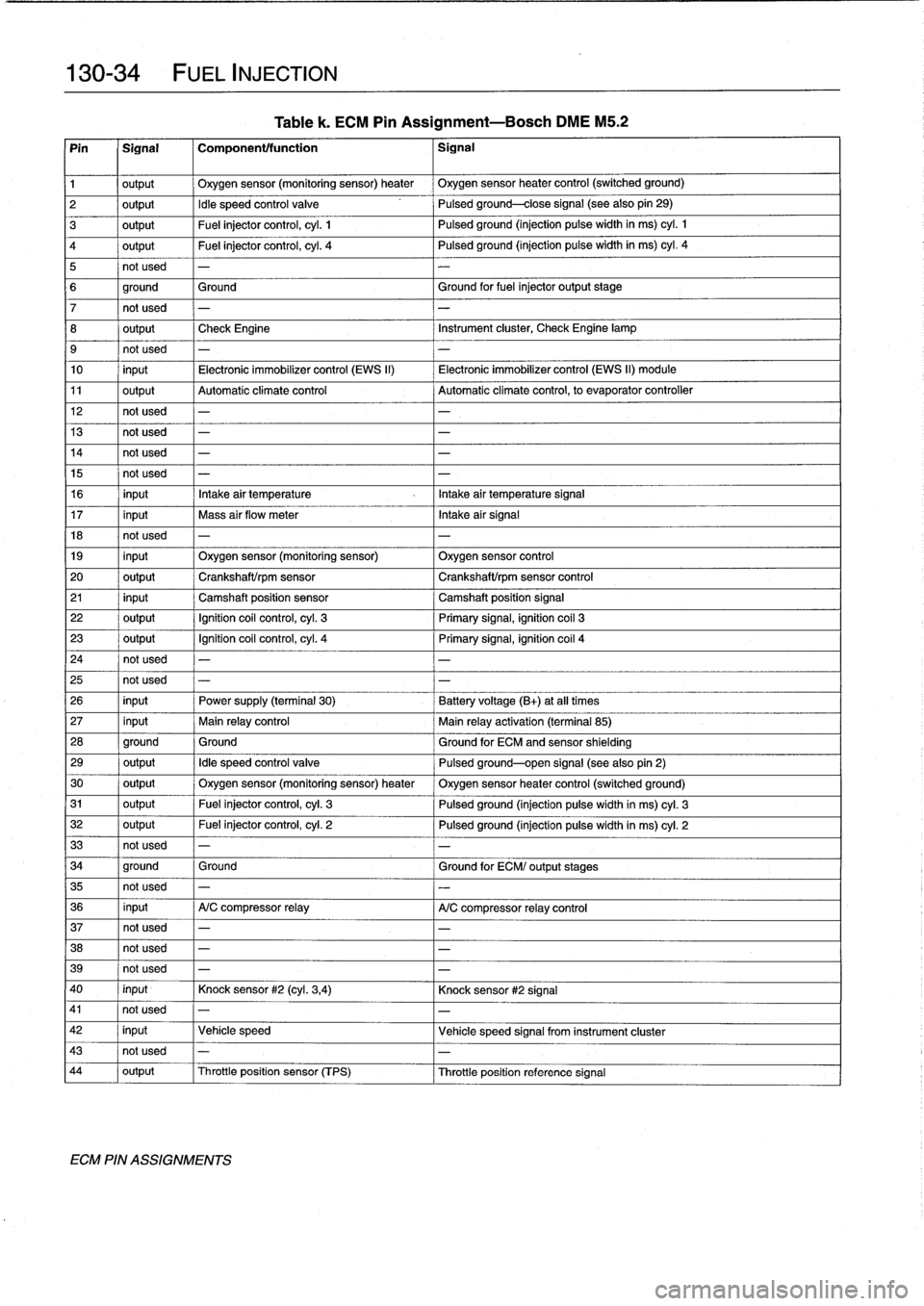

130-

34

FUEL

INJECTION

Pin

i

Signal

1

Component/function

1

Signal

1

output

Oxygen

sensor

(monitoring

sensor)heater

Oxygen

sensor

heater

control

(switched

ground)

2

output

Idle

speed

control

valve

Pulsed

ground-close

signal

(see

also

pin

29)

3

output

Fuel

injector

control,

cyl

.

1

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

1

4

output

Fuel

injector

control,

cyl

.

4

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

4

5

not

used

-

-

6

ground

Ground

Ground

for

fuel

injector

output

stage

7

not

used

-

8

1

output

1

Check

Engine

1

Instrument

cluster,

Check

Engine

lamp

9

not

used

-

-

10

input

Electronic

immobilizer

control

(EWS

II)

Electronic

immobilizer

control

(EWS

II)

module

11

output

Automatic

climate

control

Automatic

climate

control,

to

evaporator

controlier

12

not

used

-

-

13

not

used

-

-

14

not

used

-

-

15

not

used

-

-

16

input

Intake

air

temperature

Intake

air

temperature

Signal

17

input

Mass

air

flow

meter

Intake

air

signal

18

not

used

-

-

19

input

Oxygen

sensor

(monitoring

sensor)

Oxygen

sensor

control

20

output

Crankshaft/rpm

sensor

Crankshaft/rpm

sensor

control

21

input

Camshaft

position

sensor

Camshaft

position

signal

22

output

Ignition

coil

control,

cyl

.

3

Primary

signal,

ignitioncoil

3

23

output

Ignition

coil

control,

cyl

.

4

Primary

signal,

ignitioncoil

4

24

not

used

-

-

25

not

used

-

-

26

input

Power

supply

(terminal

30)

Battery

voltage

(B+)

at

al¡

times

27

input

Main

relay

control

Main

relay

activation

(terminal

85)

28

ground

Ground

Ground

for

ECM

and

sensor

shielding

29

output

Idle

speed

control

valve

Pulsed

ground-open

signal

(seealsopin

2)

30

output

Oxygen

sensor

(monitoring

sensor)

heater

Oxygen

sensor

heater

control

(switched

ground)

31

output

Fuel

injectorcontrol,

cyl

.

3

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

3

32

output

Fuel

injector

control,

cyl

.

2

Pulsed

ground

(injection

pulsewidth

in

ms)

cyl

.

2

33

I

not

used

40

input

Knock

sensor

#2

(cyl

.

3,4)

Knock

sensor

#2

signal

41

not

used

-

-

42

input

Vehicle

speed

Vehicle

speed

signal

from

instrument

cluster

43

not

used

-

-

44

output

Throttleposition

sensor

(TPS)

Throttleposition

reference

signal

ECM

PIN

ASSIGNMENTS

Table

k

.

ECM

Pin

Assignment-Bosch

DME

M5

.2

34

ground

Ground

Ground

for

ECM/

output

stages

35

not

used

-

-

36

input

A/C

compressor

relay

A/C

compressor

relay

control

37

not

used

-

-

38

not

used

-

-

39

not

used

-

-

Page 181 of 759

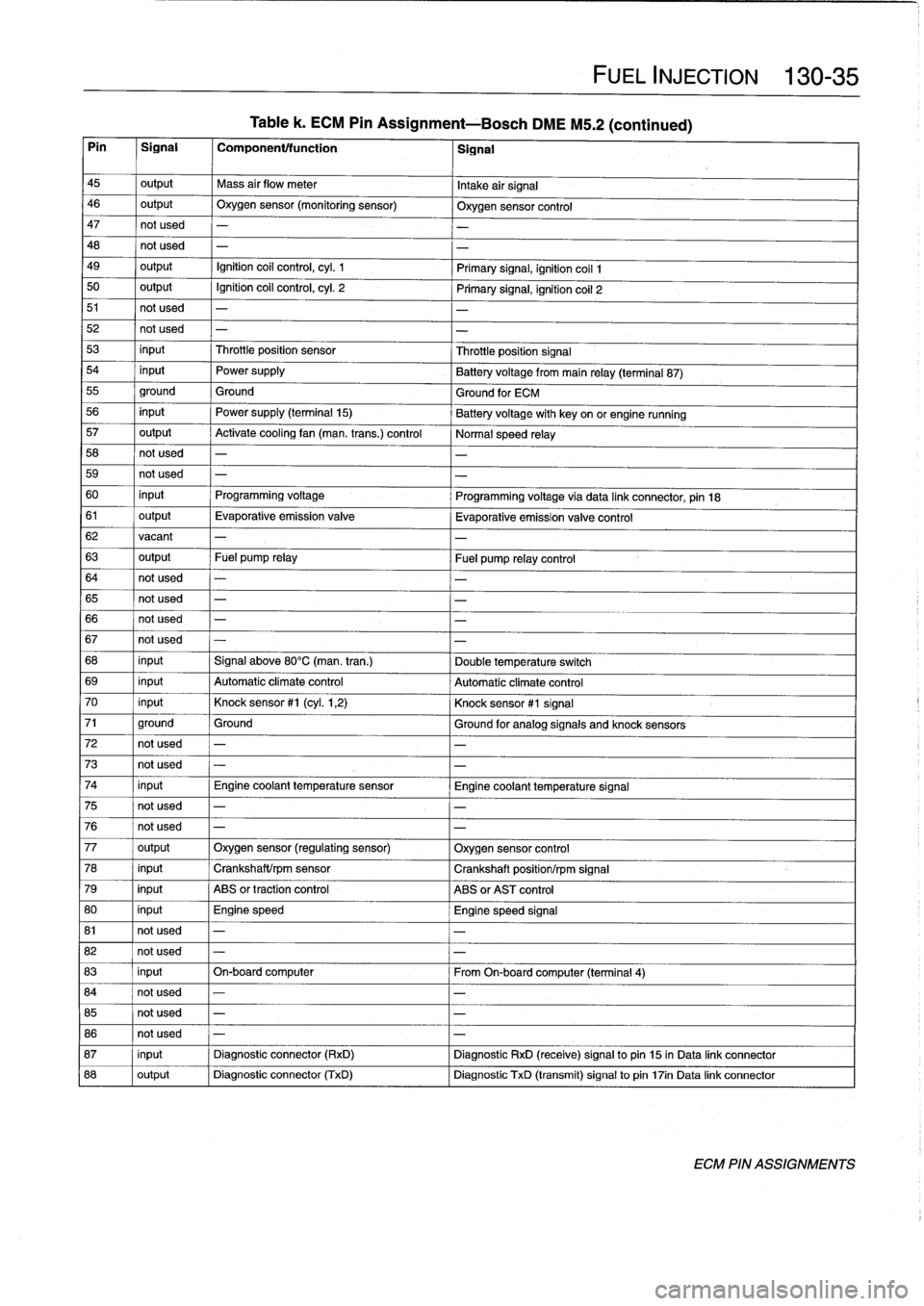

Table

k

.

ECM

Pin

Assignment-Bosch

DME

M5

.2

(continued)

Pin

I

Signal

1

Componentltunction

1

Signal

45

I

output

I

Mass

air

flow

meter

I

Intake

airSignal

46

output

Oxygen

sensor

(monitoring

sensor)

Oxygen

sensor

control

47

not

used

-

48

not

used

-

49

output

Ignition

coil

control,

cyl

.

1

Primary

signal,

ignition

coil

1

50

output

Ignition

coil

control,

cyl

.

2

Primary

signal,

ignition

coil

2

51

not

used

-

52

not

used

-

53

input

Throttleposition

sensor

Throttleposition

Signal

54

input

Power

supply

Batteryvoltage

from

main

relay

(terminal

87)

55

ground

Ground

Ground

for

ECM

56

input

Power

supply

(terminal

15)

Battery

voltage

with

key

on

or

engine

running

57

output

Activate

cooling

fan

(man

.

trans

.)

control

Normal

speed

relay

58

not

used

-

-

59

not

used

-

-

60

input

Programming

voltage

Programming

voltage

via

data

link

connector,

pin

18

61

output

Evaporative

emissionvalve

Evaporative

emission

valve

control

62

vacant

-

-

63

output

Fuel

pump

relay

Fuel

pump

relay

control

64

not

used

-

65

not

used

-

-

66

not

used

-

-

67

not

used

-

-

68

input

Signal

above

80°C(man

.

tran

.)

Double

temperature

switch

69

input

Automatic

climate

control

Automatíc

climate

control

70

input

Knock

sensor

#1

(cyl

.

1,2)

Knock

sensor

#1

Signal

71

ground

Ground

Ground

for

analog

signals

and

knock

sensors

72

not

used

-

-

73

not

used

-

-

74

input

Engine

coolant

temperature

sensor

Engine

coolant

temperatura

Signal

75

not

used

-

-

76

not

used

-

-

77

output

Oxygen

sensor

(regulating

sensor)

Oxygen

sensor

control

78

input

Crankshaft/rpm

sensor

Crankshaft

position/rpmSignal

79

input

ABS

or

traction

control

ABS

or

AST

control

80

input

Engine

speed

Engine

speed

Signal

81

not

used

-

-

82

not

used

-

-

FUEL

INJECTION

130-

3

5

83

input

On-board

computar

From

On-boardcomputer

(terminal

4)

84

not

used

-

-

85

not

used

-

-

86

not

used

-

-

87

input

Diagnostic

connector

(RxD)

Diagnostic

RxD

(receive)signal

to

pin

15

in

Data

link

connector

88

output

I

Diagnostic

connector

(TxD)

Diagnostic

TxD

(transmit)

signal

to

pin

17in

Data

link

connector

ECM

PIN

ASSIGNMENTS

Page 182 of 759

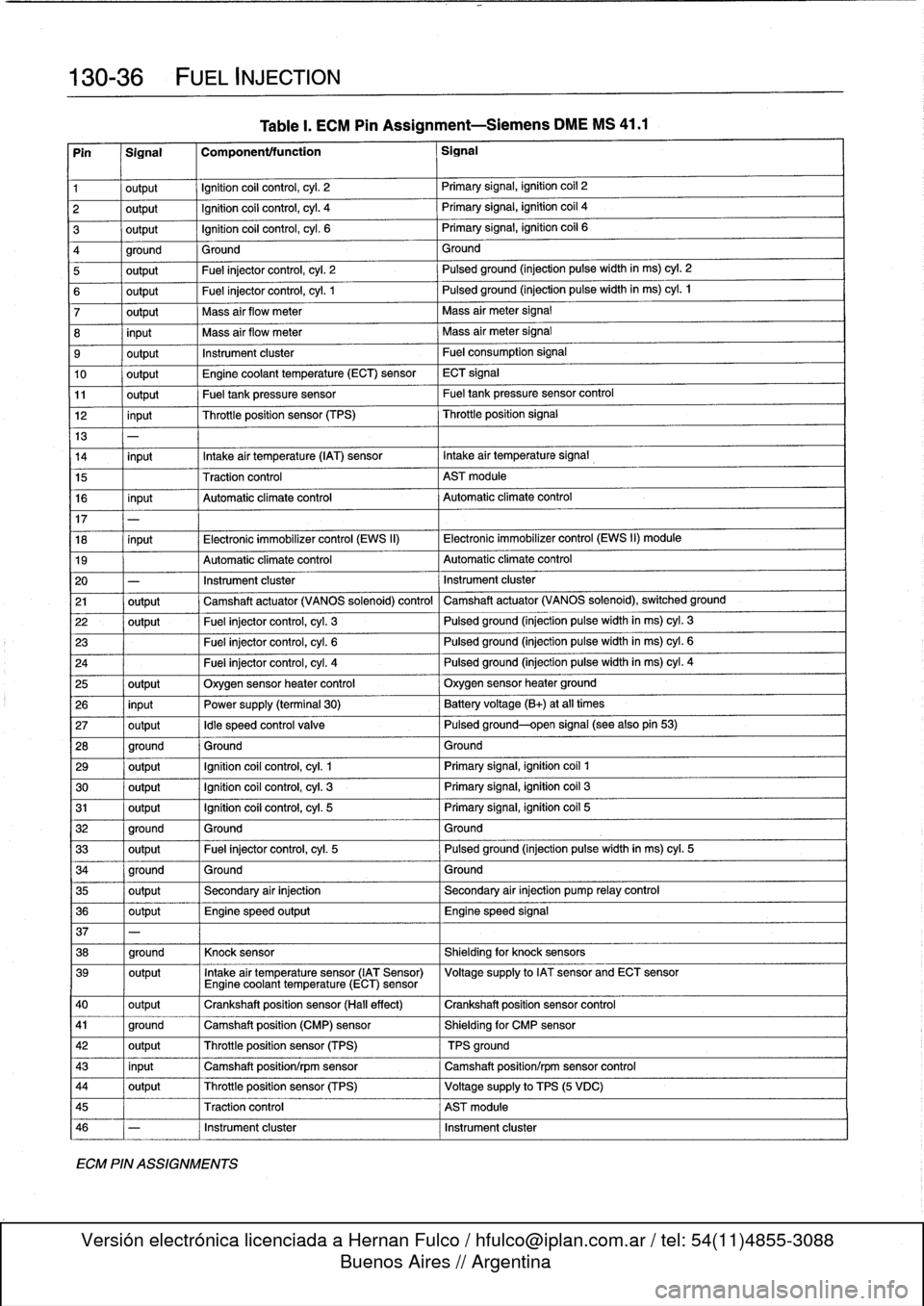

130-

3

6

FUEL

INJECTION

Pin

1

Signal

1

Componentffunction

1

Signal

1

output

Ignition

coil

control,

cyl

.

2

Primary

signal,

ignition

coil

2

2

output

Ignition

coil

control,

cyl

.

4

Primary

signal,

ignitioncoil

4

3

output

Ignition

coil

control,

cyl

.

6

Primary

signal,

ignition

coil

6

4

ground

Ground

Ground

5

output

Fuel

injectorcontrol,

cyl

.

2

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

2

6

output

Fuel

injectorcontrol,

cyl

.

1

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

1

7

output

Mass

air

flow

meter

Mass

air

meter

signal

8

input

Mass

air

flow

meter

Mass

air

meter

signal

9

output

Instrument

cluster

Fuel

consumption

signal

10

output

Engine

coolant

temperature

(ECT)

sensor

ECT

signal

11

output

Fueltankpressure

sensor

Fueltankpressure

sensor

control

12

input

Throttleposition

sensor

(TPS)

Throttleposition

signal

13

-

14

input

Intake

air

temperature

(IAT)

sensor

Intake

air

temperature

signal

15

Traction

control

AST

module

16

input

Automatic

climate

control

Automatic

climate

control

17

18

input

Electronic

immobilizer

control

(EWS

II)

Electronic

immobilizer

control

(EWS

II)

module

19

Automatic

climate

control

Automatic

climate

control

20

-

Instrument

cluster

Instrument

cluster

21

output

Camshaft

actuator

(VANOS

solenoid)

control

Camshaft

actuator

(VANOS

solenoid),

switched

ground

22

output

Fuel

injectorcontrol,

cyl

.

3

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

3

23

Fuel

injectorcontrol,

cyl

.

6

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

6

24

Fuel

injectorcontrol,

cyl

.

4

Pulsed

ground

(injection

pulse

width

in

ms)

cyl

.

4

25

output

Oxygen

sensor

heater

control

Oxygen

sensor

heater

ground

26

input

Power

supply

(terminal

30)

Battery

voltage(B+)

at

all

times

27

output

Idle

speed

control

valve

Pulsed

ground-open

signal

(see

also

pin

53)

28

ground

Ground

Ground

29

output

Ignition

coil

control,

cyl

.

1

Primary

signal,

ignition

coíl

1

30

output

Ignition

coil

control,

cyl

.

3

Primary

signal,

ignition

coil

3

31

output

Ignition

coil

control,

cyl

.

5

Primary

signal,

ignition

coil

5

32

ground

Ground

Ground

33

output

Fuel

injector

control,

cyl

.

5

Pulsedground

(injection

pulsewidth

in

ms)

cyl

.

5

34

ground

Ground

Ground

35

output

Secondary

air

injection

Secondary

air

injection

pump

relay

control

36

output

Engine

speed

output

Engine

speed

signal

37

-

38

ground

Knock

sensor

Shielding

for

knock

sensors

39

output

Intake

air

temperature

sensor

(IAT

Sensor)

Voltagesupply

to

IAT

sensor

and

ECT

sensorEngine

coolant

temperature

(ECT)

sensor

40

output

Crankshaft

position

sensor

(Hall

effect)

Crankshaft

position

sensor

control

41

ground

Camshaft

position

(CMP)

sensor

Shielding

for

CMP

sensor

42

output

Throttle

position

sensor

(TPS)

TPS

ground

43

input

Camshaft

position/rpm

sensor

Camshaft

position/rpm

sensor

control

44

output

Throttle

position

sensor

(TPS)

Voltagesupply

to

TPS

(5

VDC)

45

Traction

control

AST

module

46

-

Instrument

cluster

Instrument

cluster

ECM

PIN

ASSIGNMENTS

Table

I.

ECM

Pin

Assignment-Siemens

DME

MS

41

.1

Page 232 of 759

240-

4

AUTOMATIC

TRANSMISSION

TRANSMISSION

REMOVALAND

INSTALLATION

Removal

and

installation

of

thetransmission

is

best

accom-

plished

on

a

lift

using

a

transmission

jack

.

Use

caution

and

safe

workshop

practices

when

working

beneath

car

and

low-

ering

transmission

.

WARNING

-

To

lift

the

vehicle

safely,

see010

Fundamentals

for

the

Do-it-Yourself

Owner

.

CAUTION-

"

Be

sure

the

vehicle

is

properly

supported

.

The

removal

of

the

transmission

may

upset

the

bal-

ance

of

the

vehicle

on

a

lift

.

"

Tilting

the

engine

to

remove

the

transmission

can

lead

to

damage

to

various

components

due

to

lack

of

clearance

.

-On

carswith

AST

remove

throttle

body

.

-Remove

brake

fluid

reservoir

if

necessary

.

Torx-head

bolts

are

used

to

mount

thetransmission

to

the

bellhousing

.

Be

sure

to

have

appropriate

tools

on

hand

before

starting

thejob

.

2

.

Install

engine

support

across

engine

bay

.

Raise

and

safely

support

vehicle

.

See

Fig

.

6

.

WARNING

-

"

When

raising

thecar

using

a

floor

jack

or

a

hy-

draulic

lift,

carefully

position

the

jack

pad

to

pre-

vent

damaging

the

car

body

.

A

suitable

liner

(wood,

rubber,

etc

.)

should

be

placed

between

the

jack

and

the

car

to

prevent

body

damage

.

"

Watch

the

jack

closely

.

Make

sure

it

stays

stable

and

does

not

shift

or

tilt

.

As

the

car

is

raised,

the

car

may

roll

slightty

and

the

jack

may

shift

.

CAUTION-

Removal

of

transmission

will

cause

engine

to

tip

unlessengine

support

is

used

.

TRANSMISSION

REMOVAL

AND

INSTALLATION

Fig

.

6

.

Engine

support

equipment

used

to

support

engine

from

above

before

removing

transmission

.

3

.

Raise

vehicle

to

gain

access

to

underside

of

car

.

4

.

Drain

ATF

from

transmission

as

described

earlier

.

5

.

Disconnect

oxygen

sensor

harness

.

Remove

exhaust

system,

and

exhaust

heat

shield

.

See

180

Exhaust

System

.

Transmission,

removing

and

installing

6

.

Remove

driveshaft

.

See

260

Driveshaft

.

1

.

Disconnect

negative

(-)

cable

from

battery

.

7

.

With

selector

lever

in

Park,

disconnect

shift

selector

le-

ver

cable

from

lever

and

remove

cable

bracket

.

Hold

CA

UTION-

linkage

clamping

bolt

stationary

when

loosening

Prior

to

disconnectiog

the

battery,

read

the

battery

clamping

nut

.

See

Fig

.

7

.

disconnection

cautions

given

at

the

front

of

this

manual

on

page

vi¡¡

.

Fig

.

7

.

Selector

lever

cable

clamping

nut

(A)

.

Loosen

cable

clamping

nut

(B)

and

remove

cable

from

bracket

.

Always

counterholdclamping

bolt

when

loosening

nut

.

Page 252 of 759

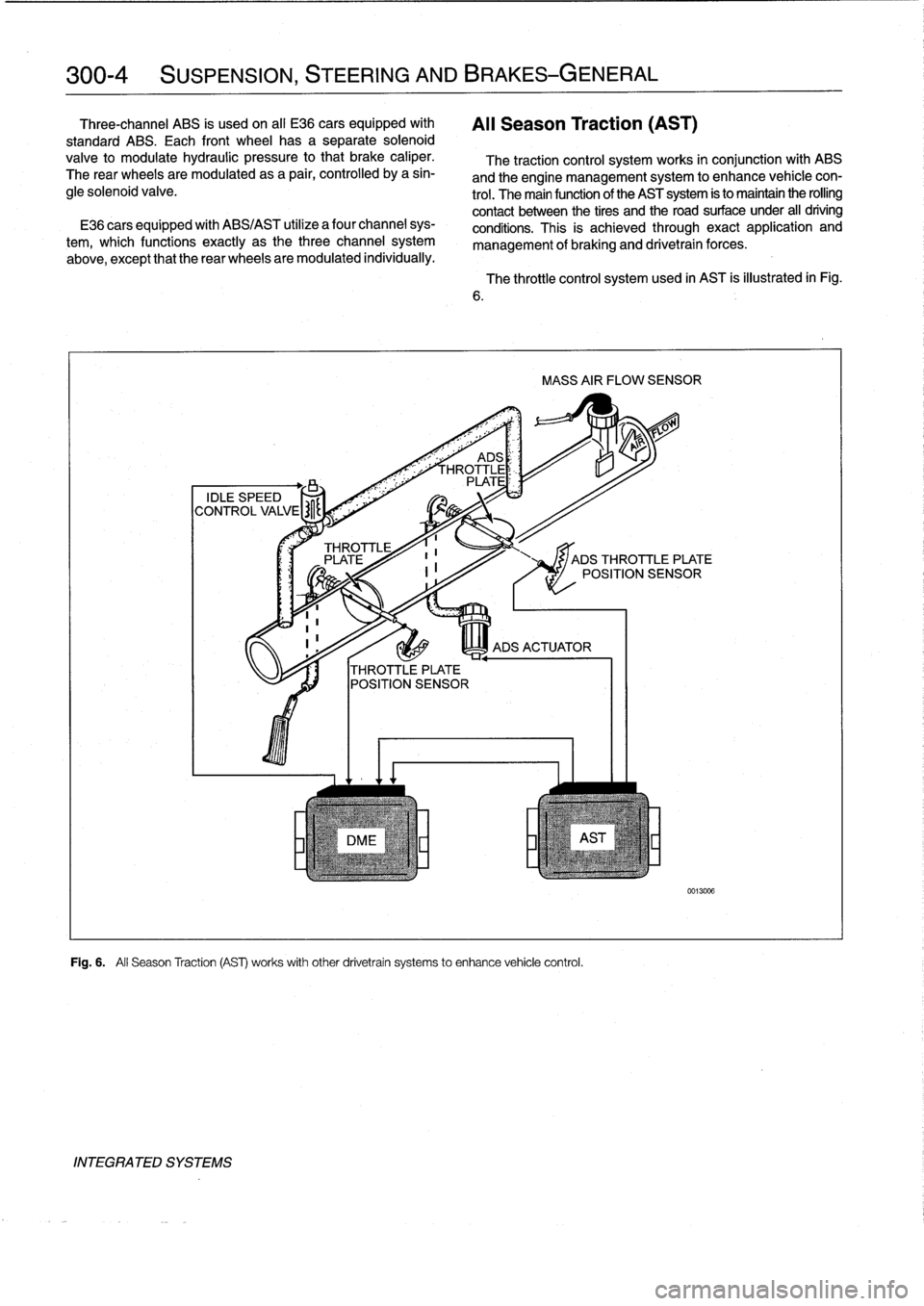

300-4

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

Three-channel

ABS

ís

used

on

al[

E36

cars

equipped

with

Al¡

Season

Traction

(AST)

standard

ABS

.

Each

front

wheelhas

a

separate

solenoid

valve

to

modulate

hydraulic

pressure

to

that

brake

caliper

.

The

traction

control

system

works

in

conjunction

with

ABS

The

rear

wheels

are

modulated

asa

pair,

controlled

by

a

sin-

and

the

engine

management

system

to

enhance

vehicle

con

gle

solenoid

valve

.

trol

.

The

main

function

of

the

AST

system

is

to

maintain

the

rolling

contact

between

the

tires

and

the

road

surface

under

al¡

driving

E36

cars

equipped

with

ABS/AST

utilize

a

four

channel

sys-

conditions

.

This

is

achieved

through

exact

application

and

tem,

which

functionsexactly

as

the

three

channelsystem

management

of

braking

and

drivetrain

forces

.

above,except

that

the

rear

wheels

are

modulated

individually

.

IDLE

SPEED

CONTROL

VALVE

HROTTLE

PLATE

6

.

Í

III

i

ADS

ACTU

AT

OR

THROTTLE

PLATE

POSITION

SENSOR

DME

Fig

.

6

.

All

Season

Traction

(AS)

works

withother

drivetrain

systems

to

enhance

vehicle

control

.

INTEGRATED

SYSTEMS

The

throttle

control

system

used

in

AST

is

illustrated

in

Fig

.

MASS

AIR

FLOW

SENSOR

JADS

THROTTLE

PLATE

POSITION

SENSOR

0013006

Page 254 of 759

300-6

SUSPENSION,

STEERING

AND

BRAKES-GENERAL

BATTE

RY

KL

30

ECM

MAIN

C~

RELAY

KL

15

DSC

SWITCH

LF1

;1~lZZ~

nSLn

l'

z

sJ

WHEEL

RF

c_

.

LR

r_

.

>

RR

ELECTRONIC

BRAKE

LIGHT

SWITCH

SPEED

SENSORS

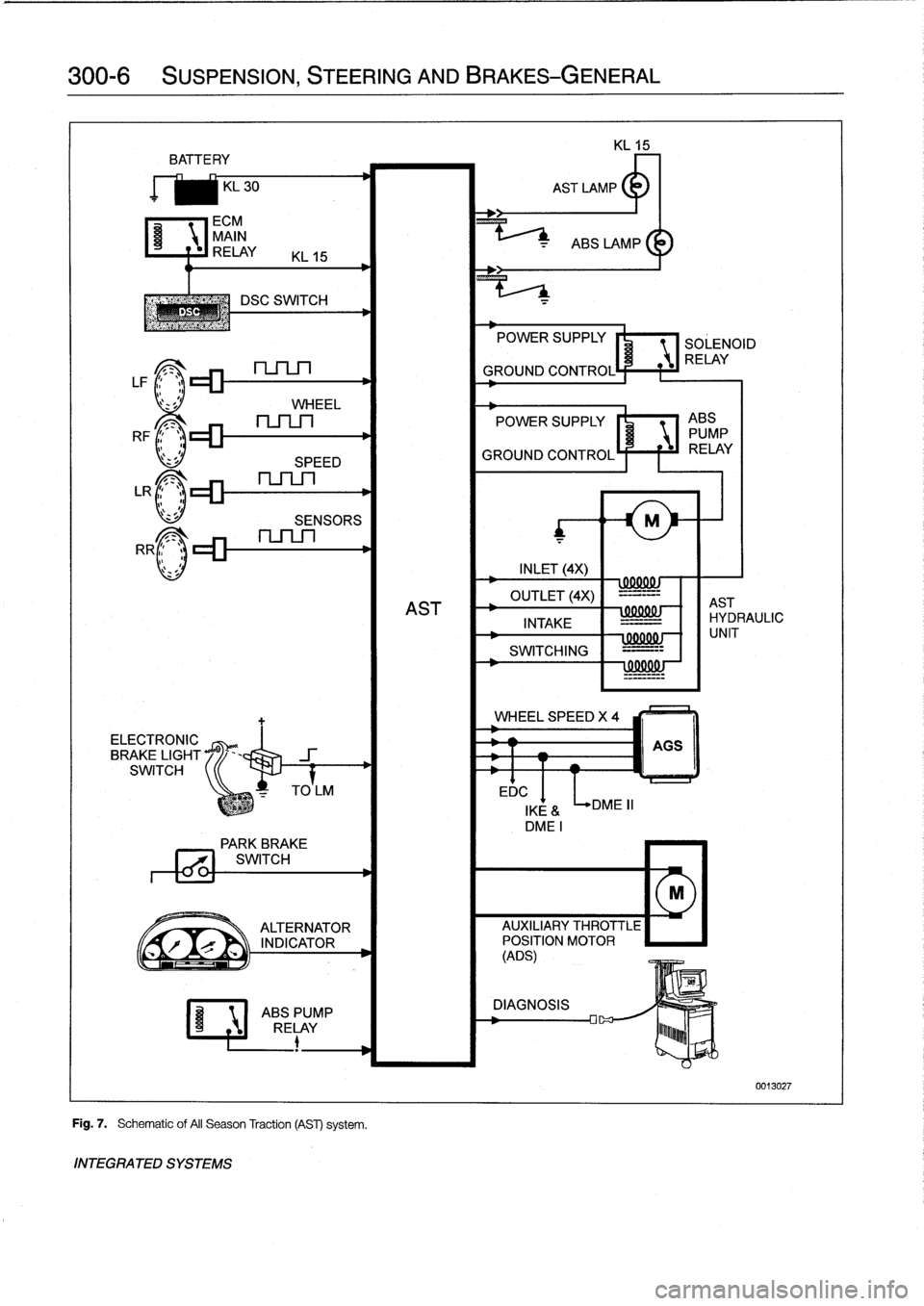

Fig

.

7

.

Schematic

of

AII

Season

Traction

(AST)

system

.

INTEGRATED

SYSTEMS

EDC

POWER

SUPPLY

SOLENOID

RELAY

GROUND

CONTROL

POWER

SUPPLY

I'

1

ABS

PUMP

GROUND

CONTROLÍ

F

f

iJ

RELAY

INLET

(4X)

wxxuw

OUTLET

(4X)

-=-=--

AST

AST

INTAKE

IHYDRAULIC

-

=-

SWITCHING

=---

!

99001

!J

WHEEL

SPEED

X

4

DME

II

000001

-

f

1

UNIT

AGS

IKE

&

DMEI

PARK

BREVE

771

SWITCH

M

ALTERNATOR

AUXILIARY

THROTTLE

r

`

INDICATOR

POSITION

MOTOR

(ADS)

ABSPUMP

DIAGNOSIS

RELAY

lu~~~b

0013027

Page 391 of 759

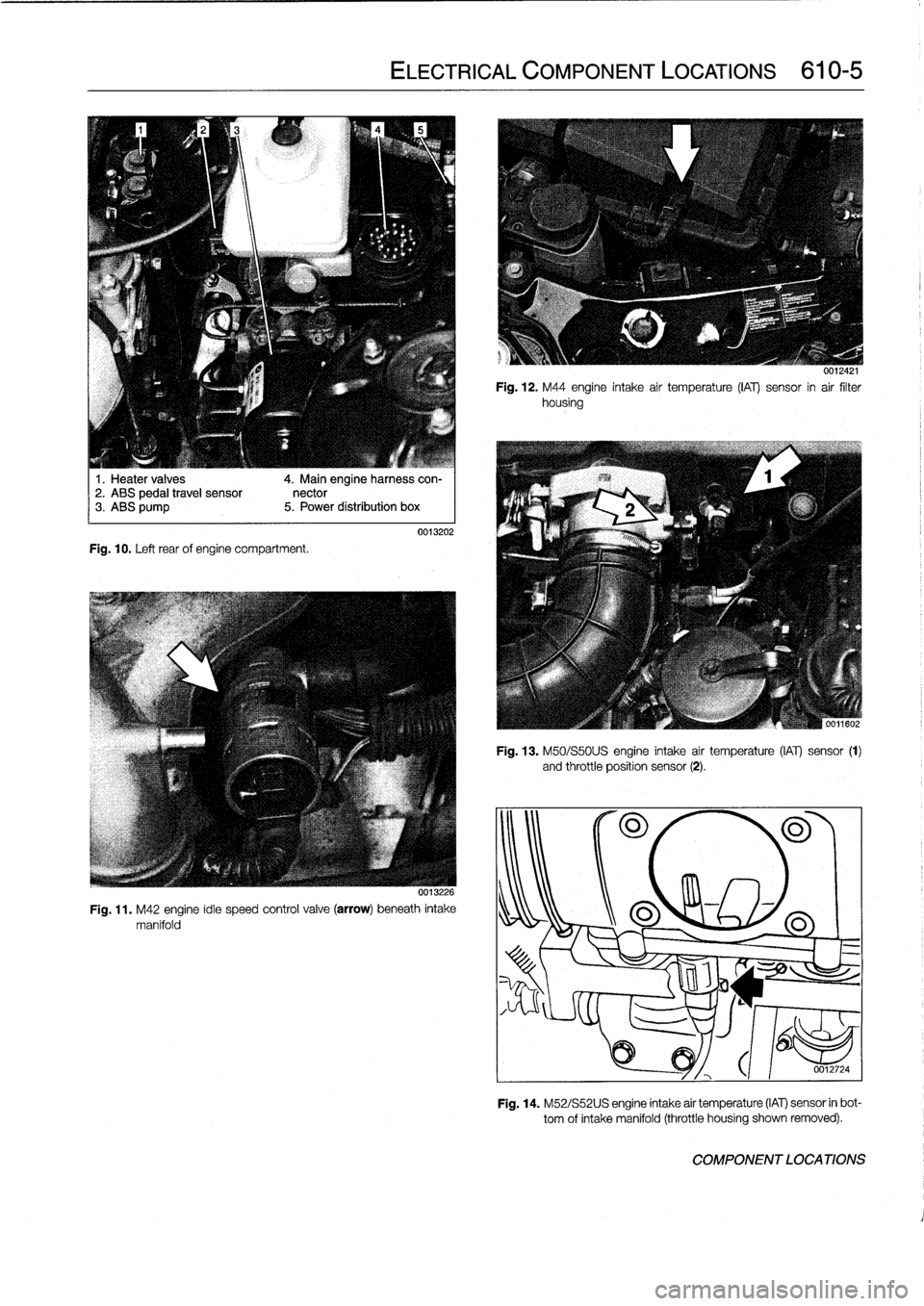

1

.

Heater

valves

2

.

ABS

pedal

travel

sensor3

.

ABS

pump

Fig

.

10

.

Left

rear

of

engine

compartment

.

4

.

Main

engineharness

con-

nector

5

.

Power

distribution

box

ELECTRICAL

COMPONENT

LOCATIONS

610-5

0013202

0013226

Fig

.

11

.

M42

engine

idie

speed

control

valve

(arrow)

beneath

intake

manifold

0012421

Fig

.

12

.

M44

engine

intake

air

temperature

(¡Al)

sensor

in

air

filter

housing

Fig

.

13

.

M50/S50U

S

engine

intake

air

temperature

(IAT)

sensor

(1)

and

throttle

position

sensor

(2)

.

301180

0012724

Fig

.

14

.

M52/S52U

S

engine

intake

air

temperature

(IAT)

sensor

in

bot-

tom

of

intake

manifold

(throttle

housing

shown

removed)

.

COMPONENT

LOCATIONS

Page 393 of 759

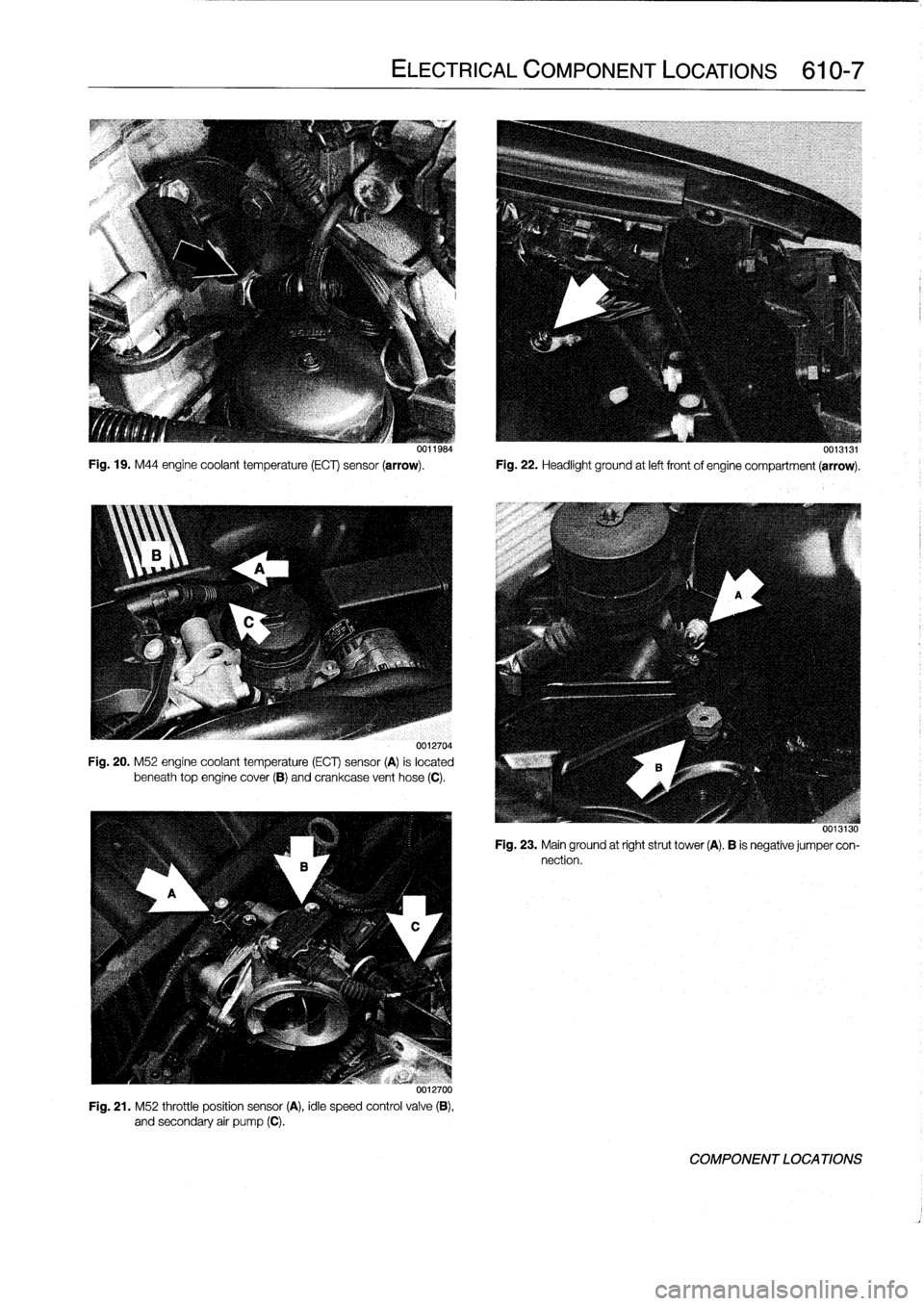

Fig

.

19

.

M44

engine

coolant

temperature

(ECT)

sensor

(arrow)

.

Fig

.

22

.

Headlight

ground

at

left

frontof

engine

compartment

(arrow)

.

0012704

Fig

.

20

.

M52

engine

coolant

temperature

(ECT)

sensor

(A)

is

located

beneath

top

enginecover

(B)

and

crankcase

vent

hose

(C)

.

uu12700

Fig

.

21

.

M52

throttle

position

sensor

(A),

idle

speed

control

valve

(B),

and

secondary

air

pump

(C)

.

ELECTRICAL

COMPONENT

LOCATIONS

610-7

00119s4

0013131

uvijijo

Fig

.

23

.

Mainground

at

right

strut

tower

(A)

.

B

is

negative

jumper

con-

nection

.

COMPONENT

LOCA

TIONS

Page 397 of 759

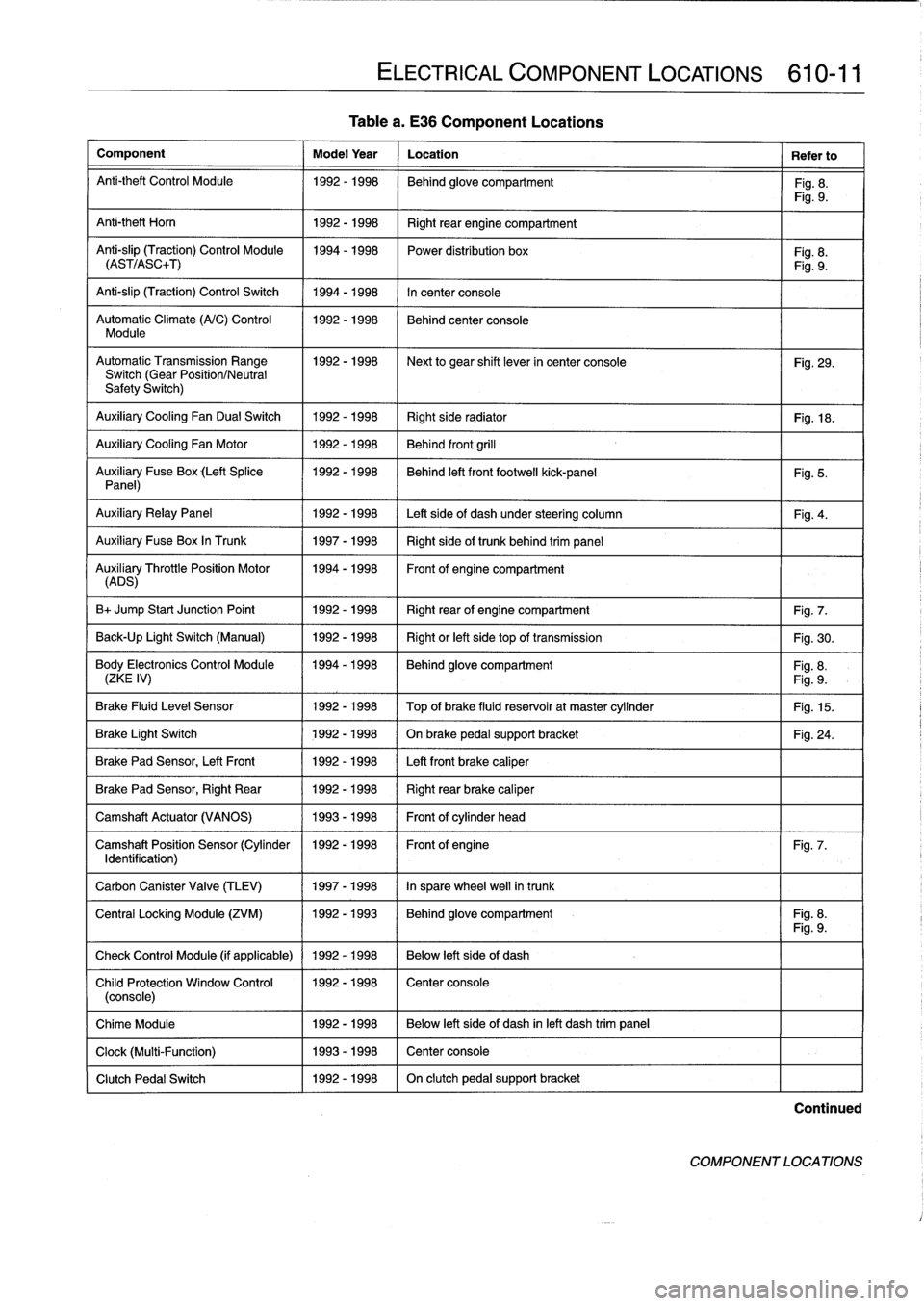

Table

a

.

E36

Component

Locations

Component

Model

Year

Location

Refer

to

Anti-theft

Control

Module

1992-1998

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

Anti-theft

Horn

1

1992-1998

1

Right

rear

engine

compartment

Anti-slip

(Traction)

Control

Module

1994-1998

Power

distribution

box

Fig

.

8

.

(AST/ASC+T)

Fig

.

9

.

Anti-slip

(Traction)

Control

Switch

1994-1998

In

center

console

Automatic

Climate

(A/C)

Control

1992-1998

Behind

center

console

Module

AutomaticTransmission

Range

1992-1998

~

Next

to

gear

shift

lever

in

center

console

Fig

.

29

.

Switch

(Gear

Position/Neutral

Safety

Switch)

Auxiliary

Cooling

Fan

Dual

Switch

1992-1998

Right

side

radiator

1

Fig

.

18

.

Auxiliary

Cooling

Fan

Motor

1992-1998

Behind

front

grill

Auxiliary

Fuse

Box

(Left

Splice

1992-1998

I

Behind

left

front

footwell

kick-panel

Panel)

Auxiliary

RelayPanel

1

1992-1998

1

Left

side

of

dash

under

steering

column

Auxiliary

Fuse

Box

In

Trunk

1

1997-1998

1

Right

sideof

trunk

behind

trim

panel

AuADSry

ThrottlePosition

Motor

11994-1998

Front

of

engine

compartment

B+

Jump

Start

Junction

Point

1992-1998

Right

rear

of

engine

compartment

Fig

.

7

.

Back-Up

Light

Switch

(Manual)

1992-1998

Right

or

left

side

top

of

transmission

Fig

.

30

.

Body

Electronics

Control

Module

1994-1998

Behindglove

compartment

Fig

.

8

.

(ZKE

IV)

Fig

.

9

.

Brake

Fluid

Level

Sensor

1992-1998

Top

of

brake

fluid

reservoir

at

master

cylinder

Fig

.

15

.

Brake

Light

Switch

1

1992-1998

1

On

brake

pedal

supportbracket

Brake

Pad

Sensor,

Left

Front

1

1992-1998

1

Left

front

brake

caliper

Brake

Pad

Sensor,

Right

Rear

1992-1998

Right

rear

brake

caliper

Camshaft

Actuator

(VANOS)

1993-1998

Front

of

cylinder

head

Camshaft

Position

Sensor

(Cylinder

1992-1998

Front

of

engine

Identification)

Carbon

Canister

Valve

(TLEV)

1

1997-1998

1

In

sparewheel

well

in

trunk

ELECTRICAL

COMPONENT

LOCATIONS

610-11

Fig

.

5

.

Fig

.

4

.

Fig

.

24

.

Fig

.

7

.

Central

Locking

Module

(ZVM)

11992-1993

1

Behindglove

compartment

I

Fig

.

8

.

Fig

.

9

.

Check

Control

Module

(if

applicable)

1

1992

-

1998

1

Below

left

side

of

dash

Child

Protection

Window

Control

1992-1998

Center

console

(console)

Chime

Module

1992-1998

Below

left

side

of

dash

inleft

dash

trim

panel

Clock

(Multi-Function)

1993-1998

Center

console

Clutch

Pedal

Switch

1992-1998

On

clutch

pedal

support

bracket

Continued

COMPONENT

LOCATIONS

Page 403 of 759

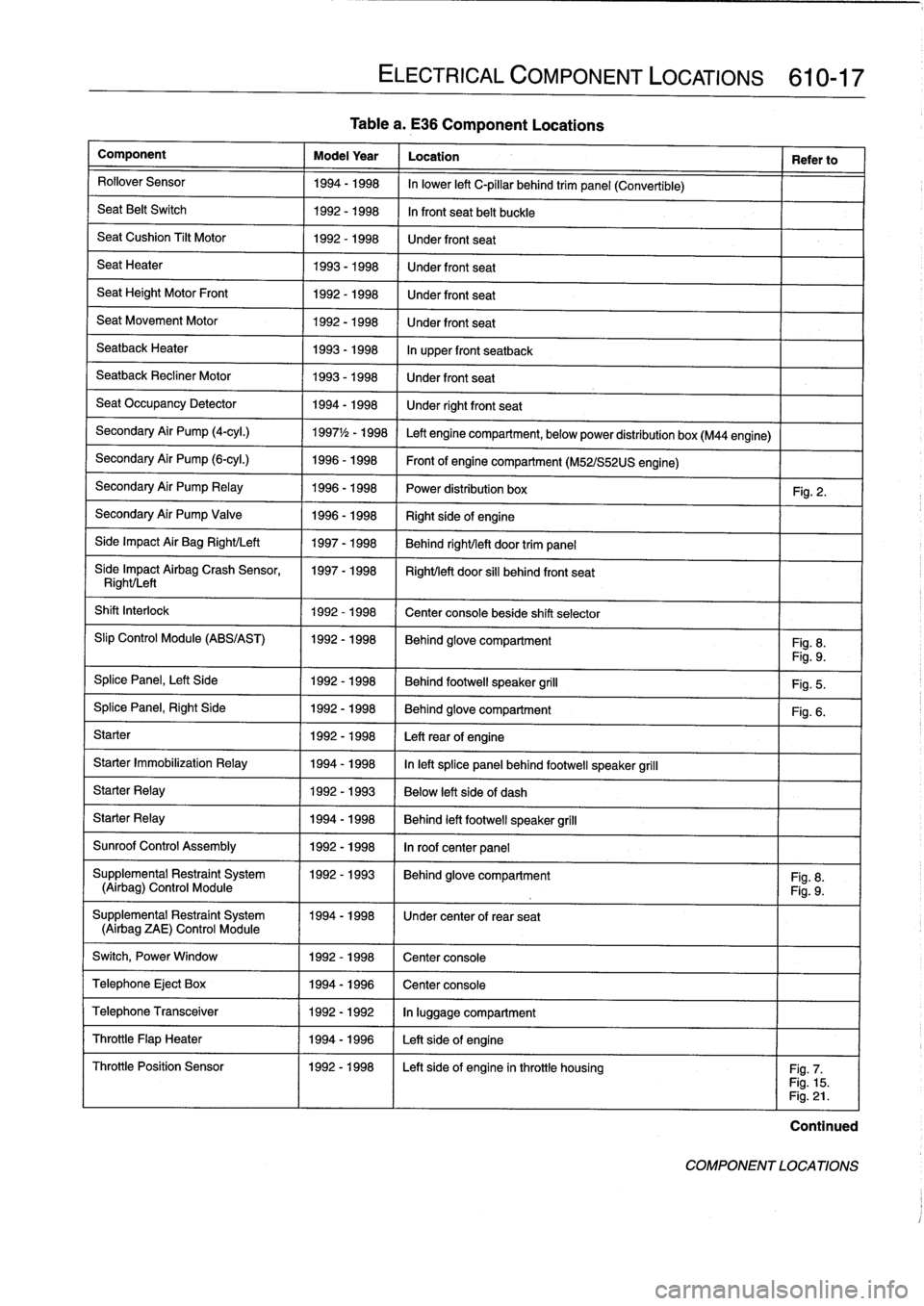

Tablea

.

E36

Component

Locations

Component

Model

Year

Location

Refer

to

Rollover

Sensor

1994-1998

In

lower

left

C-pillar

behind

trim

panel

(Convertible)

Seat

Belt

Switch

1992-1998

In

front

seat

belt

buckle

SeatCushion

Tilt

Motor

1992-1998

Under

front

seat

Seat

Heater

1993-1998

Under

front

seat

Seat

Height

Motor

Front

1992-1998

Under

front

seat

Seat

Movement

Motor

1992-1998

Under

front

seat

Seatback

Heater

1993-1998

In

upper

front

seatback

Seatback

Recliner

Motor

1993-1998

Under

front

seat

Seat

Occupancy

Detector

1994-1998

Under

rightfront

seat

Secondary

Air

Pump

(4-cyl

.)

1997

1

/2

-

1998

Left

engine

compartment,

belowpower

distribution

box

(M44

engine)

Secondary

Air

Pump

(6-cyl

.)

1996-1998

Front

of

engine

compartment

(M52/S52US

engine)

Secondary

Air

Pump

Relay

1996-1998

Power

distribution

box

Fig

.

2

.

Secondary

Air

Pump

Valve

1996-1998

Right

sideof

engine

Side

Impact

Air

Bag

Right/Left

1997-1998

Behind

right/left

door

trim

panel

Síde

Impact

Airbag

Crash

Sensor,

1997-1998

Right/left

door

si¡¡

behind

front

seat

Right/Left

Shift

Interlock

1992-1998

Center

console

beside

shift

selector

Slip

Control

Module

(ABS/AST)

1992-1998

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

Splice

Panel,

Left

Side

1992-1998

Behind

footwell

speaker

grill

Fig

.

5

.

SplicePanel,

Right

Side

1992-1998

Behind

glove

compartment

Fig

.

6

.

Starter

1992-1998

Leftrear

of

engine

Starter

Immobilization

Relay

1994-1998

In

left

splice

panelbehind

footwell

speaker

grill

Starter

Relay

1992-1993

Below

left

side

of

dash

Starter

Relay

1994-1998

Behind

left

footwell

speaker

grill

Sunroof

Control

Assembly

1992-1998

In

roof

center

panel

Supplemental

Restraint

System

11992-1993

I

Behind

glove

compartment

I

Fig

.

8

.

(Airbag)

Control

Module

Fig

.

9

.

Supplemental

Restraint

System

1994-1998

1

Under

center

of

rear

seat

(Airbag

ZAE)

Control

Module

Switch,

Power

Window

1

1992-1998

1

Center

console

Telephone

Eject

Box

1

1994-1996

1

Center

console

ELECTRICAL

COMPONENT

LOCATIONS

610-17

Telephone

Transceiver

1992-1992

In

luggage

compartment

Throttle

Flap

Heater

1994-1996

Left

sideof

engine

Throttle

Position

Sensor

1992-1998

I

Left

sideof

engine

inthrottle

housing

I

Fig

.

7

.

Fig

.

15

.

Fig

.

21

.

Continued

COMPONENT

LOCATIONS