cooling fan BMW M3 1995 E36 Owner's Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1995, Model line: M3, Model: BMW M3 1995 E36Pages: 759

Page 201 of 759

5

.

Slowly

add

coolant

until

it

spills

from

bleed

screws

.

When

coolant

spillíng

from

bleed

screws

is

free

of

air

bubbies,

tighten

screws

.

6

.

Run

engine

until

it

reaches

operatíng

temperature

.

Af-

ter

engine

has

cooled,

recheck

coolant

level

and

top

up

as

necessary

.

CAUTION-

Always

use

genuine

BMW

coolant

or

its

equiva-

lent

to

avoid

the

formation

of

harmful,

clogging

de-

posits

in

the

cooling

system

.

Use

of

other

antifreeze

solutions

may

be

harmful

to

the

cooling

system

.

Tightening

Torque

"

Radiator

bleed

screw

to

thermostat

housing

...

.

.

........

8

Nm

(71

in-lb)

Belt-driven

cooling

fan,

replacing

1

.

Usinga32

mm

wrench

on

fan

clutch

nut,

turn

wrench

quickly

in

a

clockwise

direction

(working

from

front

of

car)

to

loosen

.

Spin

fan

off

pump

.

See

Fig

.

8

.

NOTE-

"

The

radiator

cooling

fan

nut(32

mm

wrench)

has

left-

hand

threads

.

"

The

nut

may

be

difficult

to

loosen

.

Use

a

tool

to

hold

the

coolant

pump

pulleystationary

.

BMW

hasa

spe-

cial

tool

forthis

purpose

(BMW

special

tool

no

.

115

030)

.

2

.

Remove

expansion

rivets

holding

shroud

to

radiator

.

See

Fig

.

9

.

Remove

fan

and

shroud

together

.

NOTE-

Store

the

removed

fan

clutch

assembly

in

an

upright

(installed)

positionto

prevent

lossof

clutch

fluid

.

RADIATOR

AND

COOLING

SYSTEM

170-

7

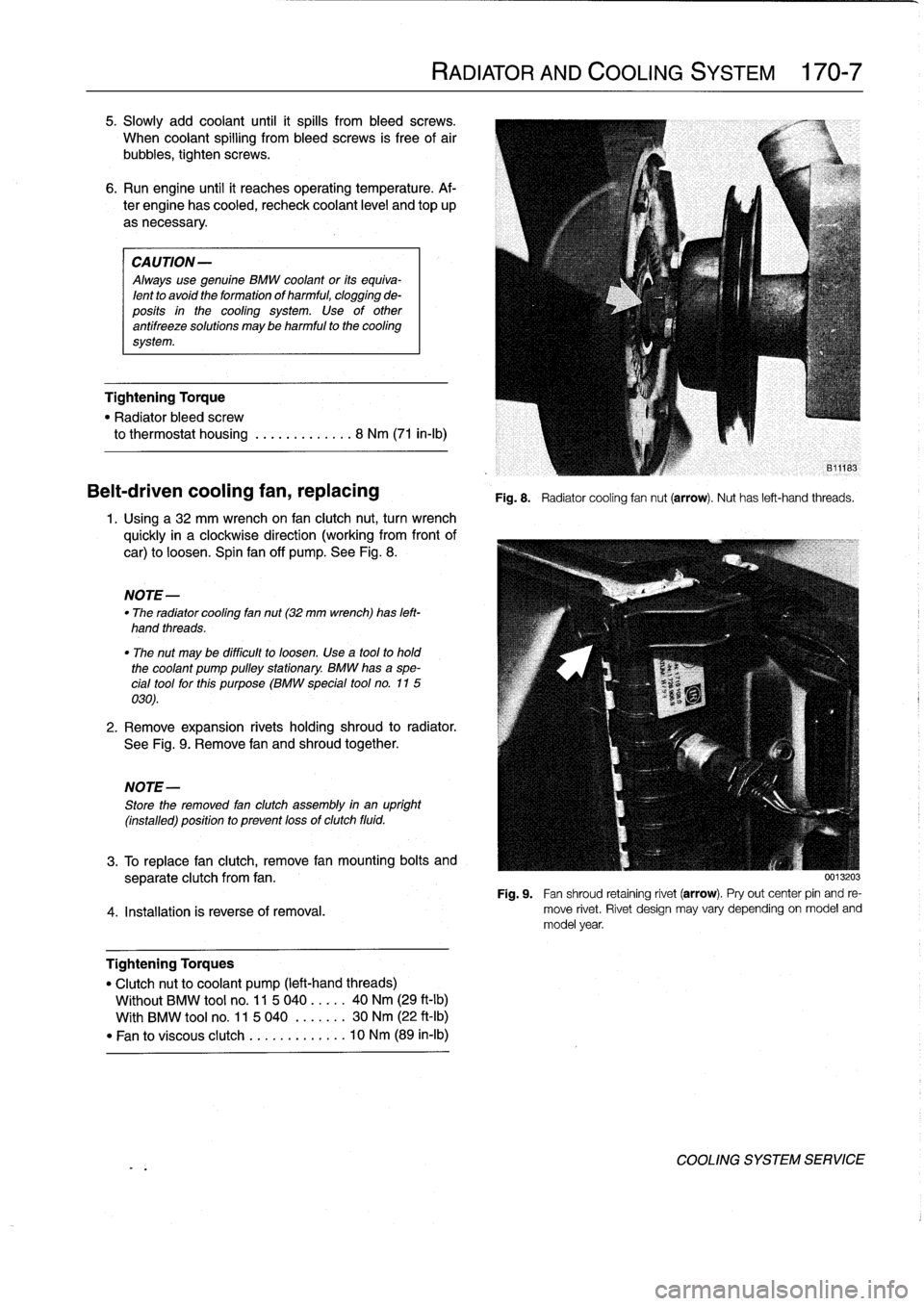

Fig

.

8

.

Radiatorcooling

fannut

(arrow)

.

Nuthas

left-hand

threads

.

3

.

To

replace

fan

clutch,

remove

fan

mounting

bolts

and

separate

clutch

from

fan

.

Fig

.

9

.

Fan

shroud

retaining

rivet

(arrow)

.

Pryout

center

pin

and

re

4

.

Installation

is

reverse

of

rernoval

.

move

rivet

.

Rivet

design

may

vary

depending

on

model

and

model

year

.

Tightening

Torques

"

Clutchnut

to

coolant

pump

(left-hand

threads)

Wíthout

BMW

tool

no

.

11

5

040

.....

40

Nm

(29

ft-lb)

With

BMW

tool

no

.

11

5

040

.

......

30

Nm

(22

ft-Ib)

"

Fan

to

viscous

clutch

...

.

..

.

......

10

Nm

(89

in-lb)

0013203

COOLING

SYSTEM

SERVICE

Page 202 of 759

170-8

RADIATOR

AND

COOLING

SYSTEM

Electric

cooling

fan,

replacing

On

late

4-cylinder

models

(M44

engine)

with

manual

trans-

mission,

the

primary

cooling

fan

is

electrically

operated

and

is

mounted

on

the

engine

side

of

the

radiator

.

1

.

If

necessary,

remove

cover

from

top

of

radiator

.

See

Fig

.

10

.

0012505

Fig

.

10

.

Air

cover

in

back

of

radiator

.

Unclip

cover

from

fan

shroud

af-

ter

removing

mounting

screws

.

2

.

Disconnect

fan

harness

connector

at

bottom

left

of

ra-

diator

.

3

.

Remove

fan

shroud

mountingscrews

at

left

and

right

side

of

radiator

.

Lift

fan

assembly

straight

up

and

offra-

diator

.

4

.

Installation

is

reverse

of

removal

.

Be

sure

to

align

side

tabs

on

fan

housíng

with

retaining

tabs

on

radiator

when

reinstalling

fan

.

Auxiliary

cooling

fan,

replacing

The

auxiliary

electric

cooling

fan

is

mounted

behind

the

front

bumper,

in

front

of

the

A/C

condenser

.

There

aretwo

ver-

sions

of

auxiliary

fans

installed,

depending

on

model

and

en-

gine

installed

.

TType

1

(u

p

to

9192)

1

.

Remove

front

radiator

air

shroud

.

See

Fig

.

11

.

2

.

Remove

fan

mountingscrews

.

See

Fig

.

12

.

3

.

Tilt

fan

forward

.

Disconnect

electrical

harness

connec-

tor

before

lifting

fan

up

.

COOLING

SYSTEM

SERVICE

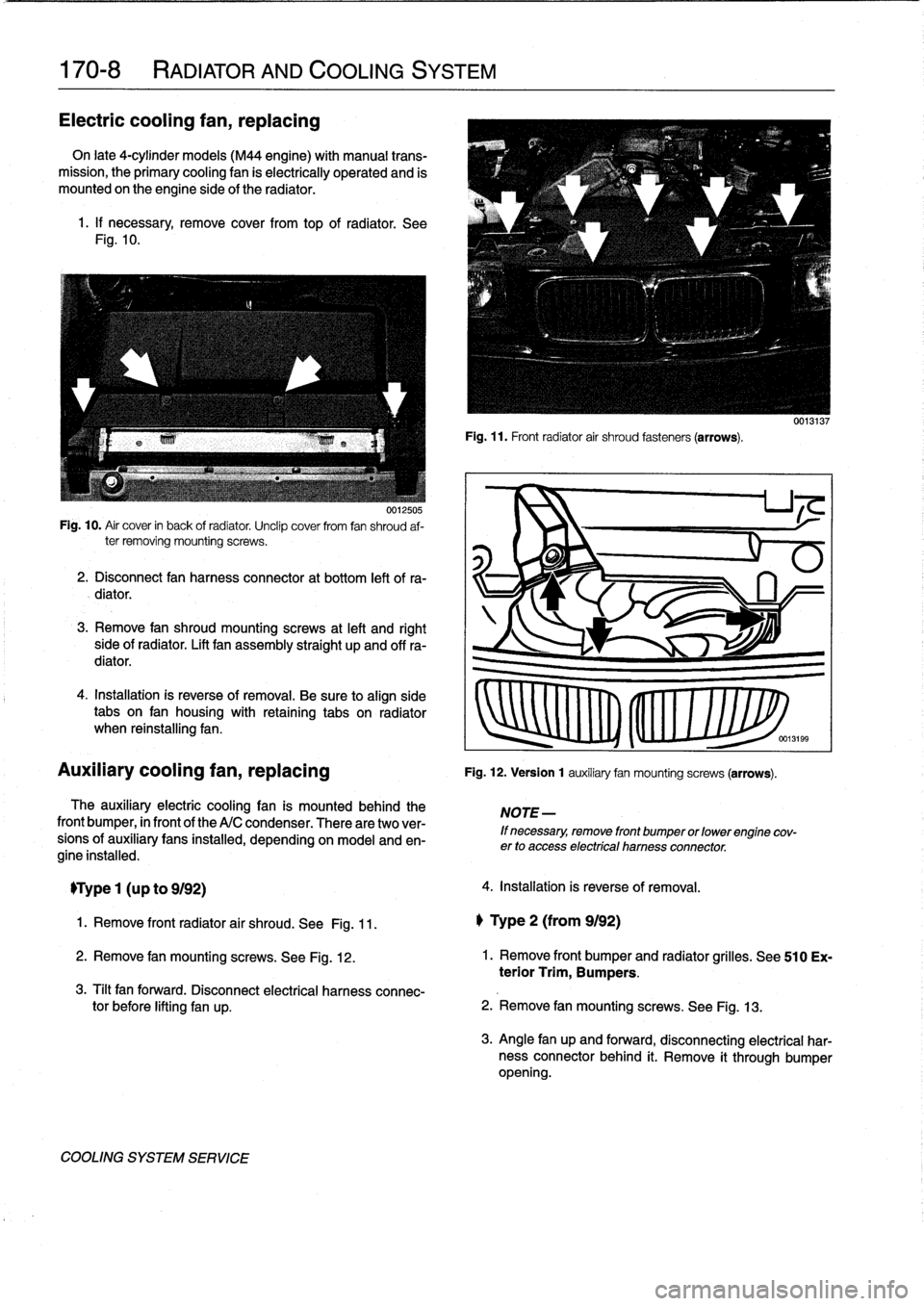

Fig

.

11

.

Front

radiator

air

shroud

fasteners

(arrows)

.

Fig

.

12

.

Version

1

auxiliary

fan

mountingscrews

(arrows)

.

NOTE

-

If

necessary,

remove

front

bumper

or

lowerengine

cov-

erto

access

electrical

harnessconnector

.

4

.

Installation

is

reverse

of

removal

.

l)

Type

2

(from

9192)

2

.

Remove

fan

mounting

screws

.

See

Fig

.

13

.

0013137

1.

Remove

front

bumper

and

radiator

grilles

.

See

510

Ex-

terior

Trim,

Bumpers

.

3

.

Angle

fan

up

and

forward,

disconnecting

electrical

har-

nessconnectorbehind

it

.

Remove

it

through

bumper

opening

.

Page 203 of 759

Fig

.

13

.

Version

2

auxiliary

fan

mounting

screws

(arrows)

.

Front

bumper

hasbeen

removed

.

4

.

Installation

is

reverse

of

removal

.

Thermostat,

replacing

0013146

The

coolant

thermostat

is

instalied

in

a

housing

at

the

front

of

the

cylinder

head

.

See

Fig

.

14

.

Fig

.

14

.

Coolantthermostat

and

housíng

.

NOTE-

On

M44

engines,

the

thermostat

is

integrated

into

the

thermostat

housíng

.

If

the

thermostat

requiresreplace-

ment,

the

complete

thermostathousing

mustbe

replaced

.

RADIATOR

AND

COOLING

SYSTEM

170-

9

WARNING

-

Allow

the

cooling

system

to

cool

before

opening

ordraining

the

system

.

2

.

Remove

belt-driven

cooling

fan

and

fan

shroudas

de-

scribed

earlier

.

3

.

On

M52/S52US

engines

:

Unclip

wiring

duct

retaining

clips

and

remove

duct

from

above

thermostat

housing

.

Also

remove

engine

front

lifting

bracket

.

4

.

Remove

thermostat

housing

from

front

of

engine

.

See

Fig

.

15

.

Fig

.

15

.

Thermostat

housíng

shown

removed

(6-cylinder

engine)

.

NOTE-

Some

thermostats

have

a

direction

arrowor

venthole

near

the

edge

.

Install

the

thermostat

so

that

either

the

arrow

or

hole

are

at

thetop

.

CAUTION

-

Be

sure

to

reconnect

ground

wire(s)

at

thermostat

housing

mounting

bolt,

where

applicable

.

5

.

Remove

thermostat

.

Note

thermostat

direction

and

ori-

entation

before

removing

.

6

.

Insta¡¡

new

thermostat

and/or

thermostat

housing

using

new

O-ring

and

gasket(s)

as

necessary

.

oo131ss

7

.

Installation

is

reverseof

removal

.

Fill

system

with

cool-

ant

as

described

under

Coolant,draining

and

filling

.

Tightening

Torques

1

.

Drain

radiator

as

described

above

under

Coolant,

"

Thermostat

housing

cover

draining

and

filling

.

to

housing

orcoolant

pump

..

..

....

10

Nm

(89

in-lb)

"

Engine

lifting

bracket

bolt

to

thermostat

housing

(M52/S52US

engine)(M8)

....

..

...

22

Nm

(17

ft-Ib)

COOLING

SYSTEM

SERVICE

Page 204 of 759

170-10

RADIATOR

AND

COOLING

SYSTEM

Coolant

pump,

replacing

The

engine

coolant

pump

is

mounted

in

the

frontof

the

en-

gine

on

the

timing

cover

.

See

Fig

.

16

.

Fig

.

16

.

Coolant

pump

mounted

on

timing

cover

.

NOTE-

Onlyreplacement

coolant

pumps

with

metal

¡mpellers

should

be

installed

.

Pumps

with

plastic

impellers

should

not

be

used

.

1.

Drain

cooling

system

as

described

earlier

.

0013197

WARNING

-

Allow

cool¡ng

system

to

cool

before

open¡ngor

drain¡ng

system

.

2

.

Remove

primary

cooling

fan

shroud

and

cooling

fan

(belt-driven

or

electric)

as

described

earlier

.

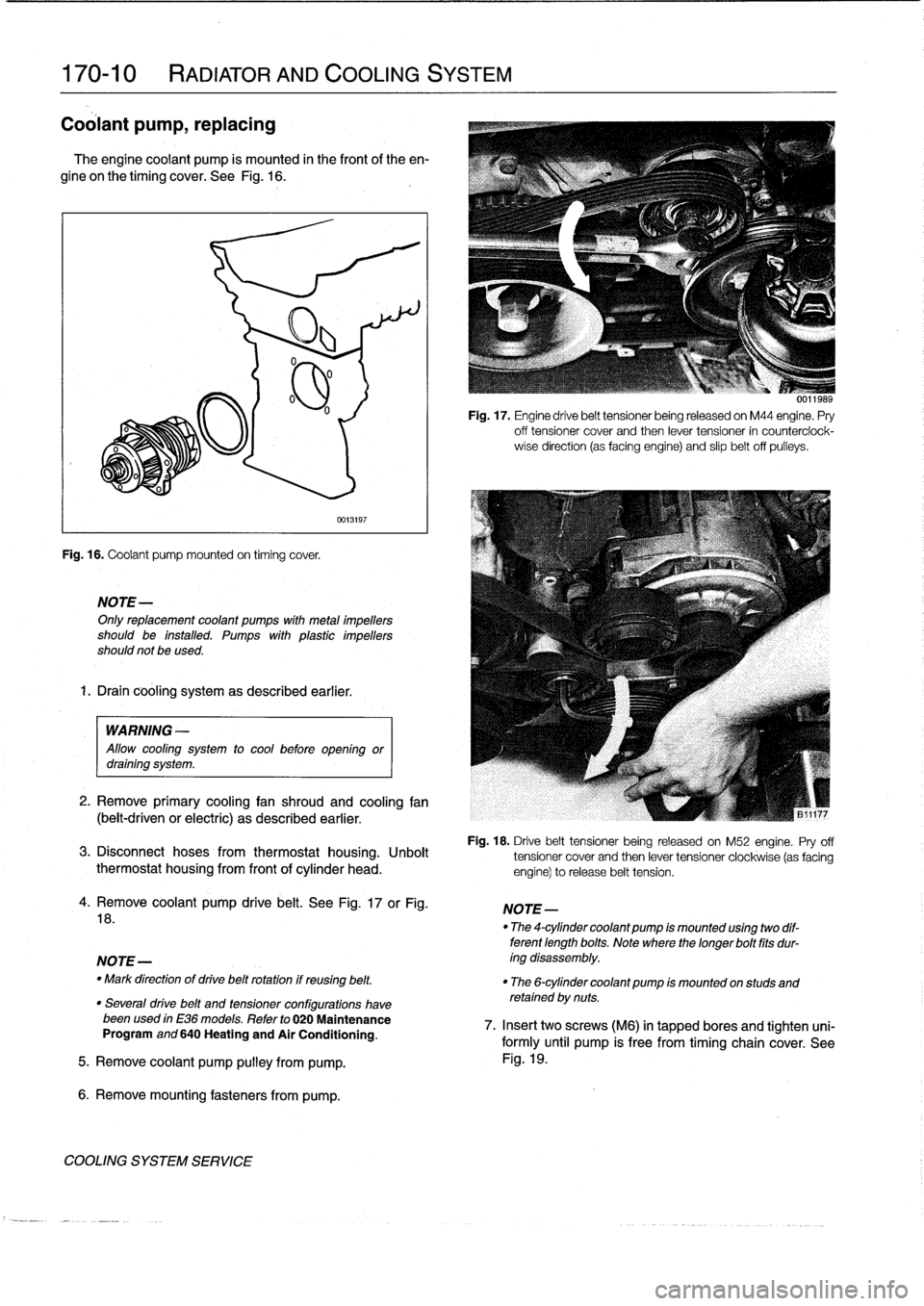

Fig

.

17

.

Engine

drive

belt

tensioner

being

released

on

M44

engine

.

Pry

off

tensioner

cover

and

then

lever

tensioner

in

counterciock-

wise

direction

(as

facing

engine)

and

slip

belt

off

pulleys

.

Fig

.

18

.

Drive

belt

tensioner

being

released

on

M52

engine

.

Pry

off

3

.

Disconnect

hoses

from

thermostat

housing

.

Unbolt

tensioner

cover

and

then

lever

tensioner

clockwise

(as

facing

thermostat

housing

from

front

of

cylinder

head

.

engine)torelease

belt

tension

.

4

.

Remove

coolant

pump

drive

belt

.

See

Fig

.

17

or

Fig

.

18

.

NOTE-

-

Mark

direction

of

drive

belt

rotation

if

reusing

belt

.

"

The

6-cylinder

coolant

pump

¡s

mounted

on

studs

and

retained

by

nuts

.

"

Severa¡

drive

belt

and

tensioner

configurations

havebeenused

in

E36

models

.

Refer

to

020

Maintenance

Program

and

640

Heating

and

Air

Conditioning

.

5

.

Remove

coolant

pump

pulley

from

pump

.

6

.

Remove

mounting

fasteners

from

pump

.

COOLING

SYSTEM

SERVICE

NOTE-

"

The

4-cylinder

coolant

pump

¡s

mounted

us¡ng

two

dif-

terent

length

bolts

.

Note

where

thelonger

bolt

fits

dur-

ing

disassembly

.

0011989

7

.

Insert

twoscrews

(M6)

in

tapped

bores

and

tighten

uni-

formly

until

pump

is

free

from

timing

chain

cover

.

See

Fig

.

19

.

Page 205 of 759

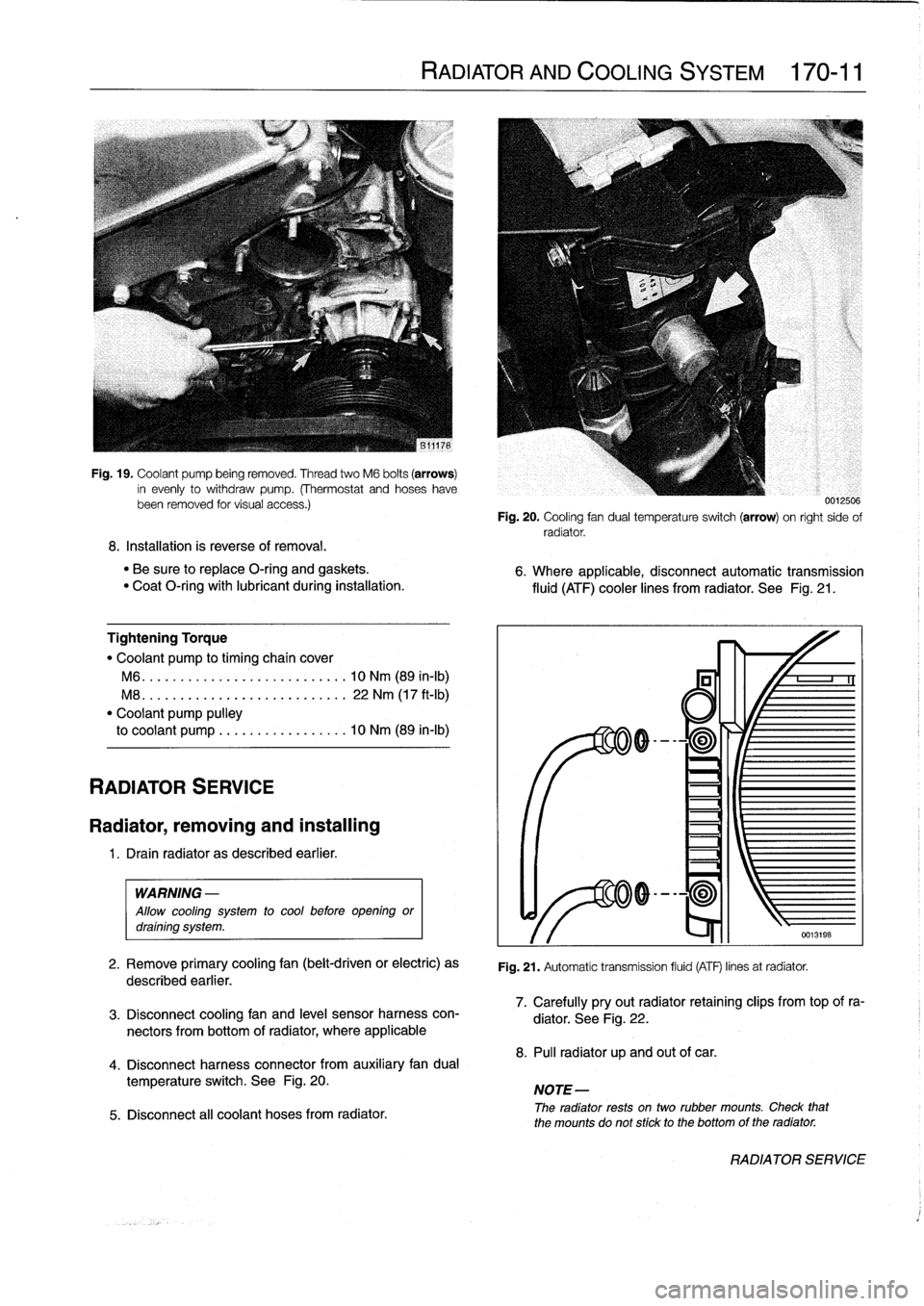

Fig

.

19

.

Coolant

pump

being

removed

.

Thread

two

M6

bolts

(arrows)

in

evenly

to

withdraw

pump

.

(Thermostat

and

hoseshavebeen

removed

tor

visual

access

.)

8

.

Installation

is

reverse

of

removal

.

"

Be

sure

to

replace

O-ring

and

gaskets

.

"

Coat

O-ring

with

lubricant

during

installation

.

Tightening

Torque

"

Coolant

pump

to

timing

chaincover

M6

...

.

...................

..

.

.

10

Nm

(89

in-lb)

M8

.

..

.

....................

.

.

.

22

Nm

(17

ft-Ib)

"

Coolant

pump

pulley

to

coolant

pump

.................

10

Nm

(89

in-lb)

RADIATOR

SERVICE

Radiator,

removing

and

installing

1

.

Drain

radiator

as

described

earlier

.

WARNING

-

Allow

cooling

system

to

cool

before

opening

ordraining

system

.

2

.

Remove

primary

cooling

fan

(belt-driven

or

electric)

as

described

earlier

.

3

.

Disconnect

coolingfan

and

leve¡

sensor

harness

con-

nectors

from

bottom

of

radiator,

where

applicable

4

.

Disconnect

harness

connector

from

auxiliary

fandual

temperature

switch

.

See

Fig

.

20

.

5

.

Disconnect

all

coolant

hoses

from

radiator

.

RADIATOR

AND

COOLING

SYSTEM

170-11

0012500

Fig

.

20

.

Cooling

fan

dual

temperatura

switch

(arrow)

on

right

sido

of

radiator

.

6

.

Where

applicable,

disconnectautomatic

transmission

fluid

(ATF)

cooler

lines

from

radiator

.

See

Fig

.

21

.

Fig

.

21

.

Automatic

transmission

fluid

(ATF)

linos

at

radiator

.

7

.

Carefully

pryout

radiator

retaining

clips

from

top

of

ra-

diator

.

See

Fig

.

22

.

8

.

Pul¡

radiator

up

and

out

of

car

.

NOTE-

The

radiator

rests

ontwo

rubber

mounts

.

Check

that

the

mounts

do

not

stick

to

the

bottomof

the

radiator

.

RADIATOR

SERVICE

Page 312 of 759

410-4

FENDERS,

ENGINE

HOOD

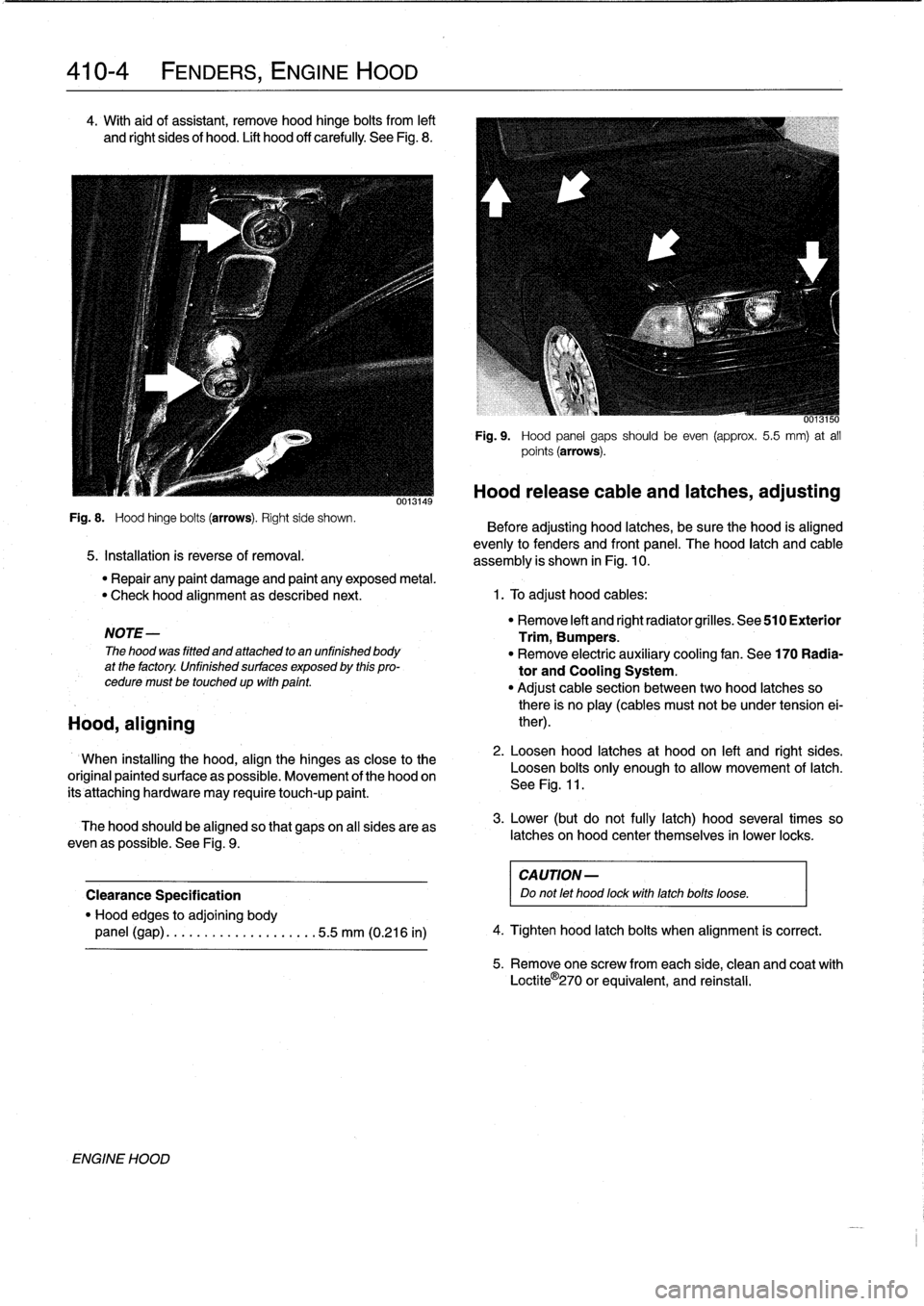

4

.

With

aid

of

assistant,

remove

hood

hinge

bolts

from

left

and

Rght

sides

of

hood

.

Lift

hood

off

carefully

See

Fig

.

8

.

Fig

.

8

.

Hood

hinge

bolts

(arrows)

.

Right

side

shown

.

5

.

Installation

is

reverse

of

removal

.

NOTE-

The

hood

was

fitted

and

attached

to

an

unfinished

body

at

the

factory

.

Unfinished

surfaces

exposed

by

this

pro-

cedure

must

betouchedup

wfth

pafnt

.

Hood,

aligning

ENGINE

HOOD

0013149

6013150

Fig

.

9

.

Hood

panel

gaps

should

be

even

(approx

.

5

.5

mm)

at

all

points

(arrows)

.

Hood

release

cable

and

latches,

adjusting

Before

adjusting

hood

latches,

be

sure

the

hood

is

aligned

evenly

to

fenders

and

front

panel

.

The

hood

latch

and

cable

assembly

is

shown

in

Fig

.

10

.

"

Repair

any

paint

damage

and

paint

any

exposed

metal

.

"

Check

hood

alignment

as

described

next

.

1

.

To

adjust

hood

cables

:

When

installing

the

hood,

align

the

hinges

as

close

to

the

original

paintedsurface

as

possible

.

Movement

of

the

hood

on

its'attaching

hardware

may

require

touch-up

paint

.

The

hood

should

be

aligned

so

that

gapson

all

sides

areas

even

as

possible

.

See

Fig

.

9

.

Clearance

Specification

"

Hood

edges

to

adjoining

body

panel

(gap)

........

..

..

..

.....

.5

.5

mm

(0.216

in)

"

Remove

left

and

right

radiator

grilles

.

See

510

Exterior

Trim,

Bumpers

.

"

Remove

electric

auxíliary

cooling

fan

.

See

170

Radia-

tor

and

Cooling

System

.

"

Adjust

cable

section

between

two

hood

latches

so

there

is

no

play

(cables

must

not

be

under

tension

ei-

ther)

.

2

.

Loosen

hood

latches

at

hood

on

left

and

right

sides

.

Loosen

bolts

only

enough

to

allow

movement

of

latch

.

See

Fig

.

11

.

3

.

Lower

(but

do

not

fully

latch)

hood

severa¡

times

so

latches

on

hood

center

themselves

in

lower

locks

.

CA

UTION-

Do

not

let

hood

fockwith

latchbolts

loose

.

4

.

Tighten

hood

latch

bolts

when

alignment

is

correct

.

5

.

Remove

one

screw

fromeach

side,

clean

and

coat

with

Loctite

O

270

or

equivalent,

and

reinstall

.

Page 392 of 759

610-6

ELECTRICAL

COMPONENT

LOCATIONS

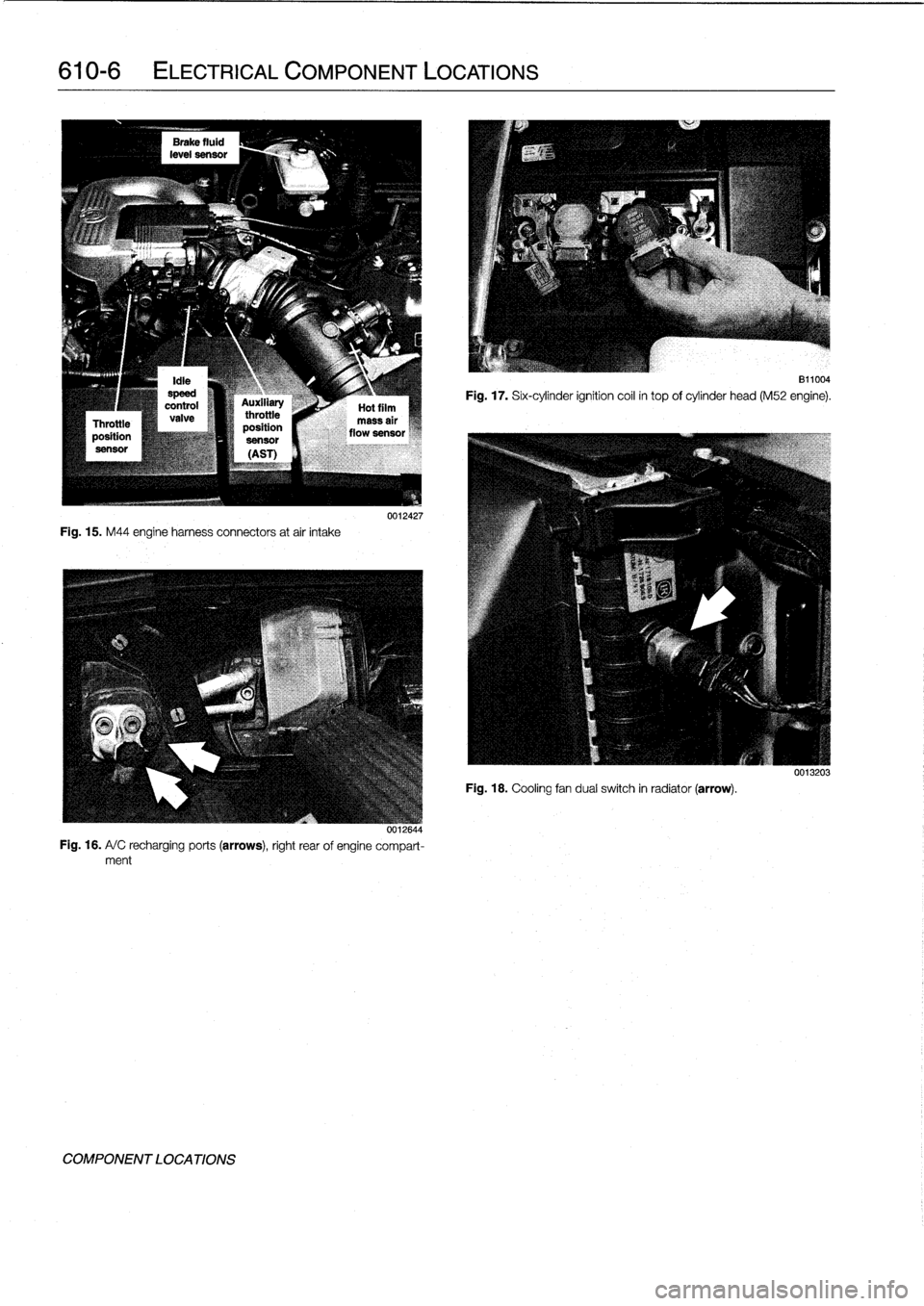

Fig

.

15

.

M44

engine

harness

connectors

atair

intake

0011644

Fig

.

16

.

A/

C

recharging

ports

(arrows),

right

rear

of

engine

compart-ment

COMPONENT

LOCATIONS

0012427

811004

Fig

.

17

.

Six-cylinder

ignition

coil

in

top

of

cylinder

head

(M52

engine)

.

Fig

.

18

.

Cooling

fan

dualswitch

in

radiator

(arrow)

.

0013203

Page 397 of 759

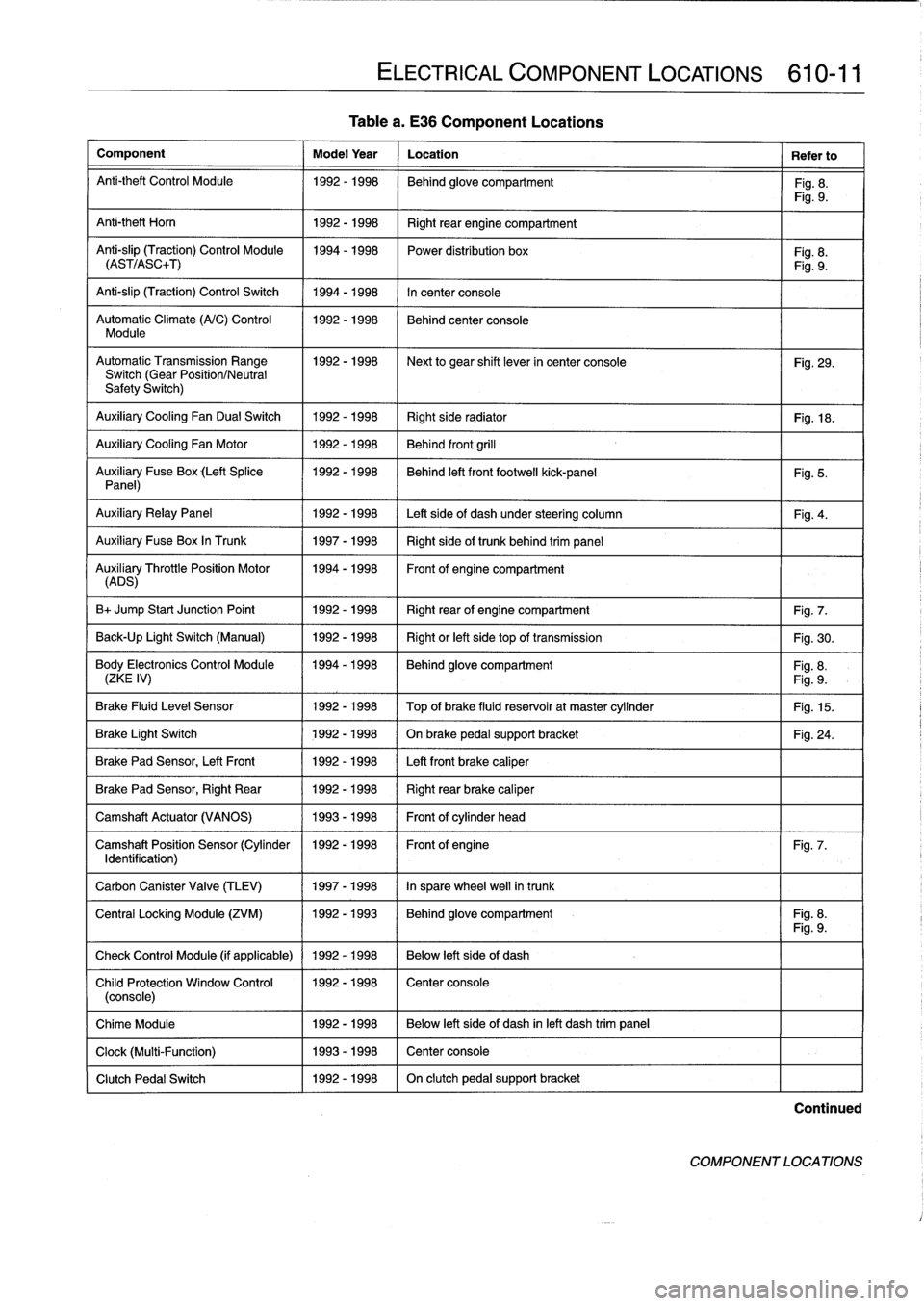

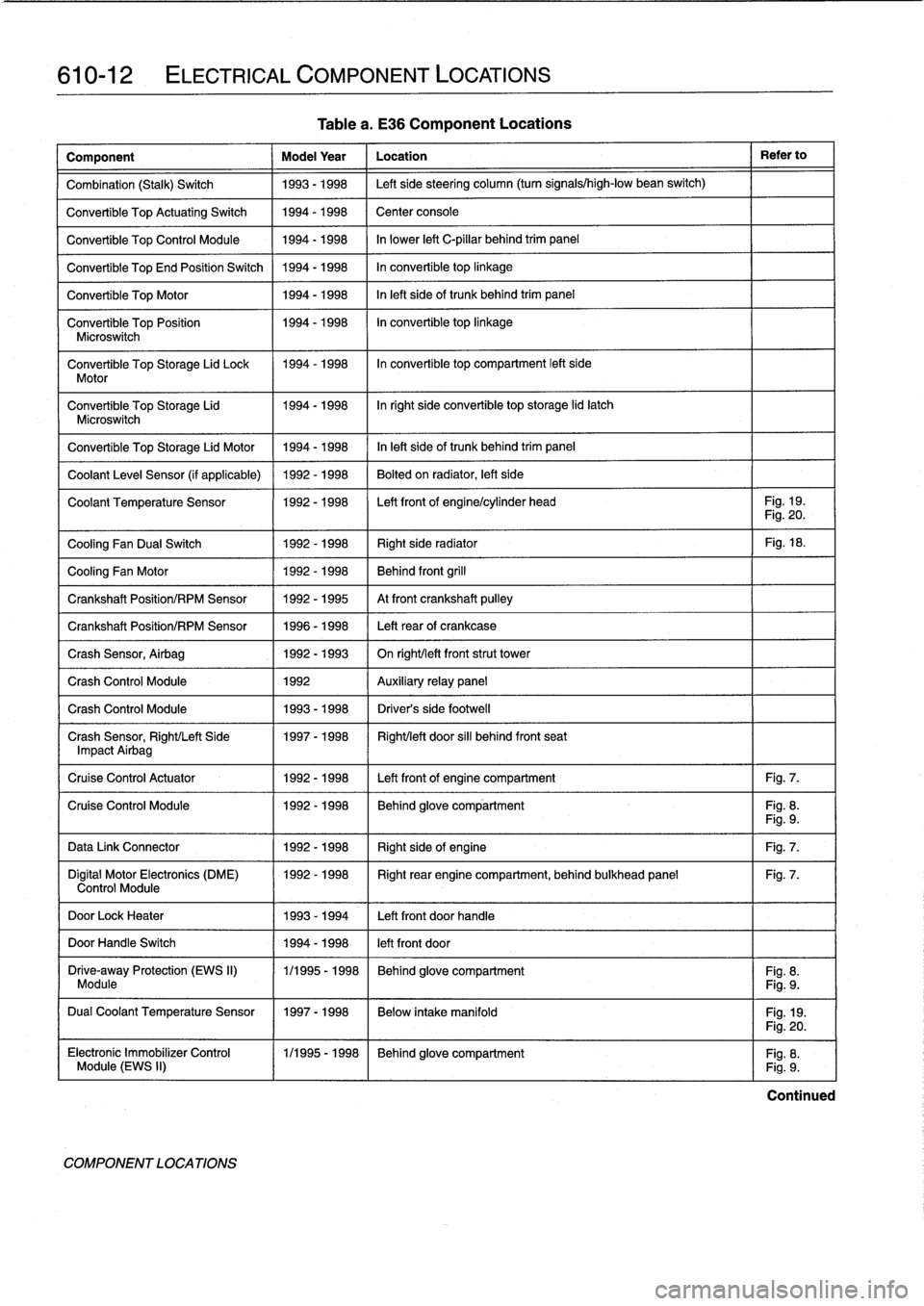

Table

a

.

E36

Component

Locations

Component

Model

Year

Location

Refer

to

Anti-theft

Control

Module

1992-1998

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

Anti-theft

Horn

1

1992-1998

1

Right

rear

engine

compartment

Anti-slip

(Traction)

Control

Module

1994-1998

Power

distribution

box

Fig

.

8

.

(AST/ASC+T)

Fig

.

9

.

Anti-slip

(Traction)

Control

Switch

1994-1998

In

center

console

Automatic

Climate

(A/C)

Control

1992-1998

Behind

center

console

Module

AutomaticTransmission

Range

1992-1998

~

Next

to

gear

shift

lever

in

center

console

Fig

.

29

.

Switch

(Gear

Position/Neutral

Safety

Switch)

Auxiliary

Cooling

Fan

Dual

Switch

1992-1998

Right

side

radiator

1

Fig

.

18

.

Auxiliary

Cooling

Fan

Motor

1992-1998

Behind

front

grill

Auxiliary

Fuse

Box

(Left

Splice

1992-1998

I

Behind

left

front

footwell

kick-panel

Panel)

Auxiliary

RelayPanel

1

1992-1998

1

Left

side

of

dash

under

steering

column

Auxiliary

Fuse

Box

In

Trunk

1

1997-1998

1

Right

sideof

trunk

behind

trim

panel

AuADSry

ThrottlePosition

Motor

11994-1998

Front

of

engine

compartment

B+

Jump

Start

Junction

Point

1992-1998

Right

rear

of

engine

compartment

Fig

.

7

.

Back-Up

Light

Switch

(Manual)

1992-1998

Right

or

left

side

top

of

transmission

Fig

.

30

.

Body

Electronics

Control

Module

1994-1998

Behindglove

compartment

Fig

.

8

.

(ZKE

IV)

Fig

.

9

.

Brake

Fluid

Level

Sensor

1992-1998

Top

of

brake

fluid

reservoir

at

master

cylinder

Fig

.

15

.

Brake

Light

Switch

1

1992-1998

1

On

brake

pedal

supportbracket

Brake

Pad

Sensor,

Left

Front

1

1992-1998

1

Left

front

brake

caliper

Brake

Pad

Sensor,

Right

Rear

1992-1998

Right

rear

brake

caliper

Camshaft

Actuator

(VANOS)

1993-1998

Front

of

cylinder

head

Camshaft

Position

Sensor

(Cylinder

1992-1998

Front

of

engine

Identification)

Carbon

Canister

Valve

(TLEV)

1

1997-1998

1

In

sparewheel

well

in

trunk

ELECTRICAL

COMPONENT

LOCATIONS

610-11

Fig

.

5

.

Fig

.

4

.

Fig

.

24

.

Fig

.

7

.

Central

Locking

Module

(ZVM)

11992-1993

1

Behindglove

compartment

I

Fig

.

8

.

Fig

.

9

.

Check

Control

Module

(if

applicable)

1

1992

-

1998

1

Below

left

side

of

dash

Child

Protection

Window

Control

1992-1998

Center

console

(console)

Chime

Module

1992-1998

Below

left

side

of

dash

inleft

dash

trim

panel

Clock

(Multi-Function)

1993-1998

Center

console

Clutch

Pedal

Switch

1992-1998

On

clutch

pedal

support

bracket

Continued

COMPONENT

LOCATIONS

Page 398 of 759

610-12

ELECTRICAL

COMPONENT

LOCATIONS

Table

a

.

E36

Component

Locations

Component

Model

Year

Location

Refer

to

Combination

(Stalk)

Switch

1993-1998

Left

sidesteering

column

(turn

signals/high-low

bean

switch)

Convertible

Top

ActuatingSwitch

1994-1998

Center

console

Convertible

Top

Control

Module

1994-1998

In

lower

left

C-pillar

behind

trim

panel

Convertible

TopEnd

Position

Switch

1994-1998

In

convertible

top

linkage

Convertible

Top

Motor

1994-1998

In

left

sideof

trunk

behind

trim

panel

Convertible

Top

Position

1994-1998

In

convertible

top

linkage

Microswitch

Convertible

Top

Storage

Lid

Lock

1994-1998

In

convertible

top

compartment

left

side

Motor

Convertible

Top

Storage

Lid

1994-1998

Inright

side

convertible

top

storage

lid

latch

Microswitch

Convertible

Top

Storage

Lid

Motor

1994-1998

In

left

side

of

trunk

behind

trim

panel

Coolant

Leve¡

Sensor

(if

applicable)

1992-1998

Bolted

on

radiator,

left

side

Coolant

Temperature

Sensor

1992-1998

Left

front

of

engine/cylinder

head

Fig

.

19

.

Fig

.

20

.

Cooling

Fan

Dual

Switch

1992-1998

Right

side

radiator

Fig

.

18

.

Cooling

Fan

Motor

1992-1998

Behind

front

grill

Crankshaft

Position/RPM

Sensor

1992-1995

At

front

crankshaft

pulley

Crankshaft

Position/RPM

Sensor

1996-1998

Left

rearof

crankcase

Crash

Sensor,

Airbag

1992-1993

On

right/left

frontstrut

tower

Crash

Control

Module

1992

Auxiliary

relay

panel

Crash

Control

Module

1993-1998

Driver's

side

footwell

Crash

Sensor,

Right/Left

Side

1997-1998

Right/left

door

sill

behind

front

seat

Impact

Airbag

Cruise

Control

Actuator

1992-1998

Left

front

of

engine

compartment

Fig

.

7

.

Cruise

Control

Module

1992-1998

Behind

glove

compartment

Fig

.

8

.

Fig

.

9

.

Data

Link

Connector

1992-1998

Right

sideof

engine

Fig

.

7

.

Digital

Motor

Electronics

(DME)

1992-1998

Right

rear

engine

compartment,

behind

bulkhead

panel

Fig

.

7

.

Control

Module

DoorLock

Heater

1993-1994

Left

front

doorhandle

DoorHandle

Switch

1994-1998

left

front

door

Drive-away

Protection

(EWS

II)

1/1995

-

1998

Behind

glove

compartment

Fig

.

8

.

Module

Fig

.

9

.

Dual

Coolant

Temperature

Sensor

1997-1998

Below

intake

manifold

Fig

.

19

.

COMPONENT

LOCATIONS

Fig

.

20

.

Electronic

Immobilizer

Control

(

1/1995-1998

~

Behind

glove

compartment

Fig

.

8

.

Module

(EWS

II)

Fig

.

9

.

Continued

Page 401 of 759

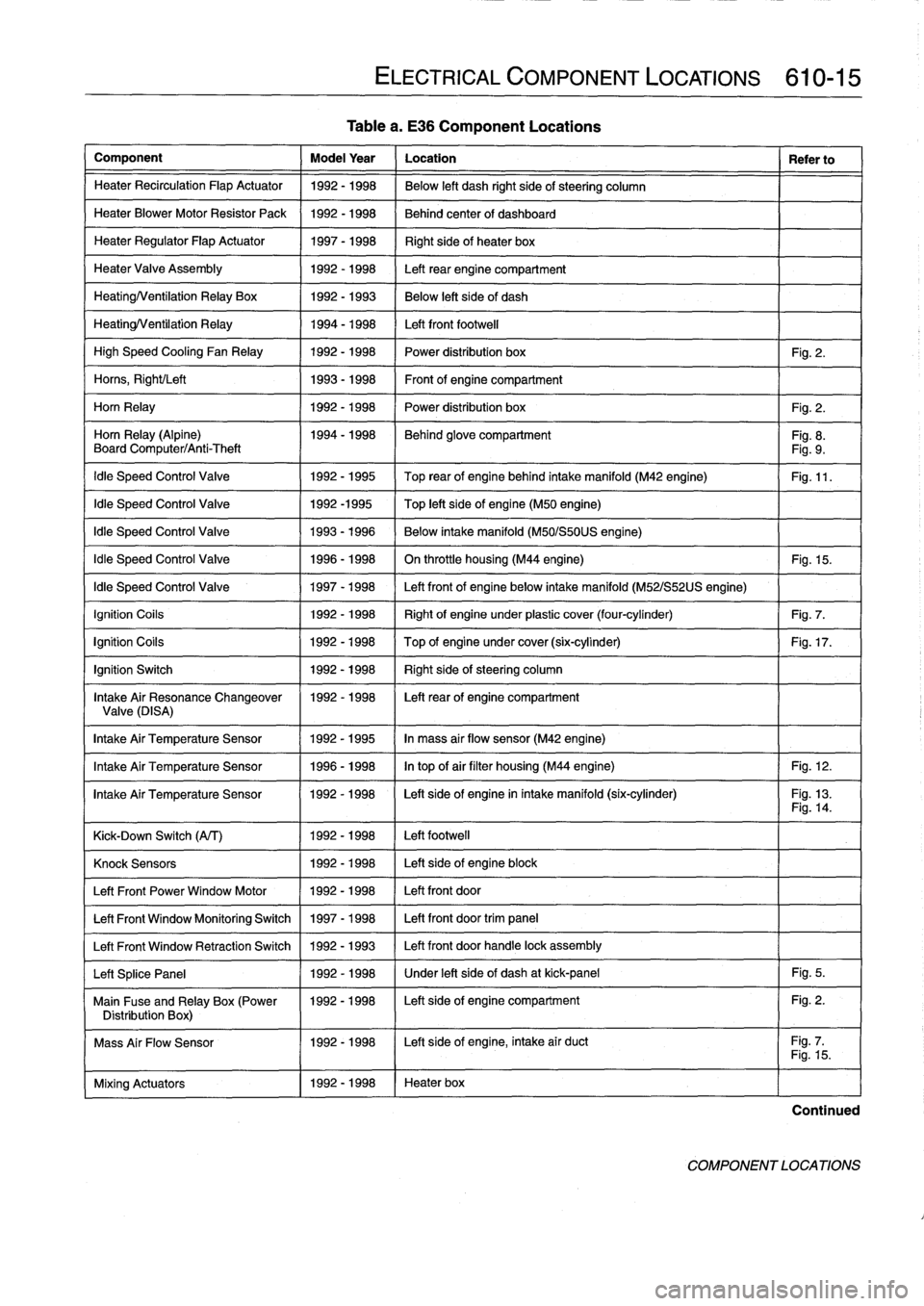

Component

Model

Year

Location

Refer

to

Heater

Recirculation

Flap

Actuator

1992-1998

Below

left

dash

right

side

of

steering

column

HeaterBlowerMotor

Resistor

Pack

1992-1998

Behind

center

of

dashboard

Heater

Regulator

FlapActuator

1997-1998

Right

side

of

heater

box

HeaterValve

Assembly

1992-1998

Left

rear

engine

compartment

HeatingNentilation

Relay

Box

1992-1993

Below

left

side

of

dash

HeatingNentilation

Relay

1994-1998

Left

front

footwell

High

Speed

Cooling

Fan

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

Homs,

Right/Left

1993-1998

Front

of

engine

compartment

Horn

Relay

1992-1998

Power

distribution

box

Fig

.

2

.

Horn

Relay

(Alpine)

1994-1998

Behind

glove

compartment

Fig

.

8

.

Board

Computer/Anti-Theft

Fig

.

9

.

Idle

Speed

Control

Valve

1992-1995

Top

rearof

enginebehind

intake

manifold

(M42

engine)

Fig

.

11

.

Idle

Speed

Control

Valve

1992-1995

Top

left

side

of

engine

(M50

engine)

Idle

Speed

Control

Valve

1993-1996

Below

intake

manifold

(M50/S50US

engine)

Idle

Speed

Control

Valve

1996-1998

On

throttle

housing

(M44

engine)

Fig

.

15

.

Idle

Speed

Control

Valve

1997-1998

Left

front

of

engine

below

intake

manifold

(M52/S52US

engine)

Ignition

Coils

1992-1998

Right

of

engineunder

plastic

cover

(four-cylinder)

Fig

.

7

.

Ignition

Cofs

1992-1998

Top

of

engine

undercover

(six-cylinder)

Fig

.

17

.

Ignition

Switch

1992-1998

Right

sídeofsteering

column

Intake

Air

Resonance

Changeover

1992-1998

Leftrear

of

engine

compartment

Valve(DISA)

Intake

Air

Temperature

Sensor

1992-1995

In

mass

air

flow

sensor

(M42

engine)

Intake

Air

TemperatureSensor

1996-1998

In

top

ofair

filter

housing

(M44

engine)

Fig

.

12

.

Intake

Air

Temperature

Sensor

1992-1998

I

Left

sídeof

engine

in

intake

manifold

(six-cylinder)

-

-

I

Fig

.

13

.

Fig

.

14

.

Kick-Down

Switch

(A/T)

1

1992-1998

1

Left

footwell

Mixing

Actuators

1

1992-1998

1

Heater

box

ELECTRICAL

COMPONENT

LOCATIONS

610-15

Table

a

.

E36

Component

Locations

Knock

Sensors

1

1992-1998

1

Left

side

of

engine

block

Left

Front

Power

Window

Motor

11992-1998

/

Left

front

door

Left

Front

Window

Monitoring

Switch

1

1997-1998

1

Left

front

door

trim

panel

Left

Front

Window

Retraction

Switch

1

1992

-

1993

1

Left

front

door

handle

lock

assembly

Left

Splice

Panel

1

1992-1998

1

Under

left

side

of

dash

at

kick-panel

1

Fig

.

5

.

Main

Fuse

and

Relay

Box

(Power

1992-1998

I

Left

sideof

engine

compartment

Fig

.

2

.

Distribution

Box)

1

I

Mass

Air

Flow

Sensor

1992-1998

I

Left

side

of

engine,

intake

air

duct

Fig

.

7

.1

I

Fig

.

15

.

Continued

COMPONENT

LOCATIONS