wheel BMW M4 2015 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2015, Model line: M4, Model: BMW M4 2015Pages: 228, PDF Size: 4.87 MB

Page 178 of 228

45: aspect ratio in %

R: radial tire code

18: rim diameter in inches

96: load rating, not for ZR tires

Y: speed rating, before the R on ZR tires

Speed letter

Q = up to 100 mph, 160 km/h

R = up to 106 mph, 170 km/h

S = up to 112 mph, 180 km/h

T = up to 118 mph, 190 km/h

H = up to 131 mph, 210 km/h

V = up to 150 mph, 240 km/h

W = up to 167 mph, 270 km/h

Y = up to 186 mph, 300 km/h

Tire Identification NumberDOT code: DOT xxxx xxx 0115

xxxx: manufacturer code for the tire brand

xxx: tire size and tire design

0115: tire age

Tires with DOT codes meet the guidelines of

the U.S. Department of Transportation.

Tire age DOT … 0115: the tire was manufactured in the

1st week of 2015.

Recommendation

Regardless of wear and tear, replace tires at

least every 6 years.

Uniform Tire Quality Grading Quality grades can be found where applicable

on the tire sidewall between tread shoulder

and maximum section width.

For example: Treadwear 200; Traction AA;

Temperature ADOT Quality Grades

Treadwear

Traction AA A B C

Temperature A B C

All passenger car tires must conform to Fed‐

eral Safety Requirements in addition to these

grades.

Treadwear The treadwear grade is a comparative rating

based on the wear rate of the tire when tested

under controlled conditions on a specified gov‐

ernment test course. For example, a tire

graded 150 would wear one and one-half, 1 g,

times as well on the government course as a

tire graded 100. The relative performance of

tires depends upon the actual conditions of

their use, however, and may depart signifi‐

cantly from the norm due to variations in driv‐

ing habits, service practices and differences in

road characteristics and climate.

Traction

The traction grades, from highest to lowest,

are AA, A, B, and C.

Those grades represent the tire's ability to

stop on wet pavement as measured under

controlled conditions on specified government

test surfaces of asphalt and concrete. A tire

marked C may have poor traction performance.

The traction grade assigned to this tire is

based on straight-ahead braking traction tests,

and does not include acceleration, cornering,

hydroplaning, or peak traction characteristics.

Temperature The temperature grades are A, the highest, B,

and C, representing the tire's resistance to the

generation of heat and its ability to dissipate

heat when tested under controlled conditions

on a specified indoor laboratory test wheel.

Sustained high temperature can cause the ma‐

terial of the tire to degenerate and reduce tire

life, and excessive temperature can lead toSeite 174MobilityWheels and tires174

Online Edition for Part no. 01 40 2 960 786 - II/15

Page 179 of 228

sudden tire failure. The grade C corresponds

to a level of performance which all passenger

car tires must meet under the Federal Motor

Vehicle Safety Standard No. 109. Grades Band

A represent higher levels of performance on

the laboratory test wheel than the minimum re‐

quired by law.

Temperature grade for this tire

The temperature grade for this tire is es‐

tablished for a tire that is properly inflated and

not overloaded. Excessive speed, underinfla‐

tion, or excessive loading, either separately or

in combination, can cause heat buildup and

possible tire failure.

If necessary, have the vehicle towed.◀

M+S

Winter and all-season tires with better cold

weather performance than summer tires.

Tire tread Summer tires Do not drive with a tire tread depth of less than

0.12 in/3 mm.

There is an increased danger of hydroplaning if

the tire tread depth is less than 0.12 in/3 mm.

Winter tires

Do not drive with a tire tread depth of less than

0.16 in/4 mm.

Below a tread depth of 0.16 in/4 mm, tires are

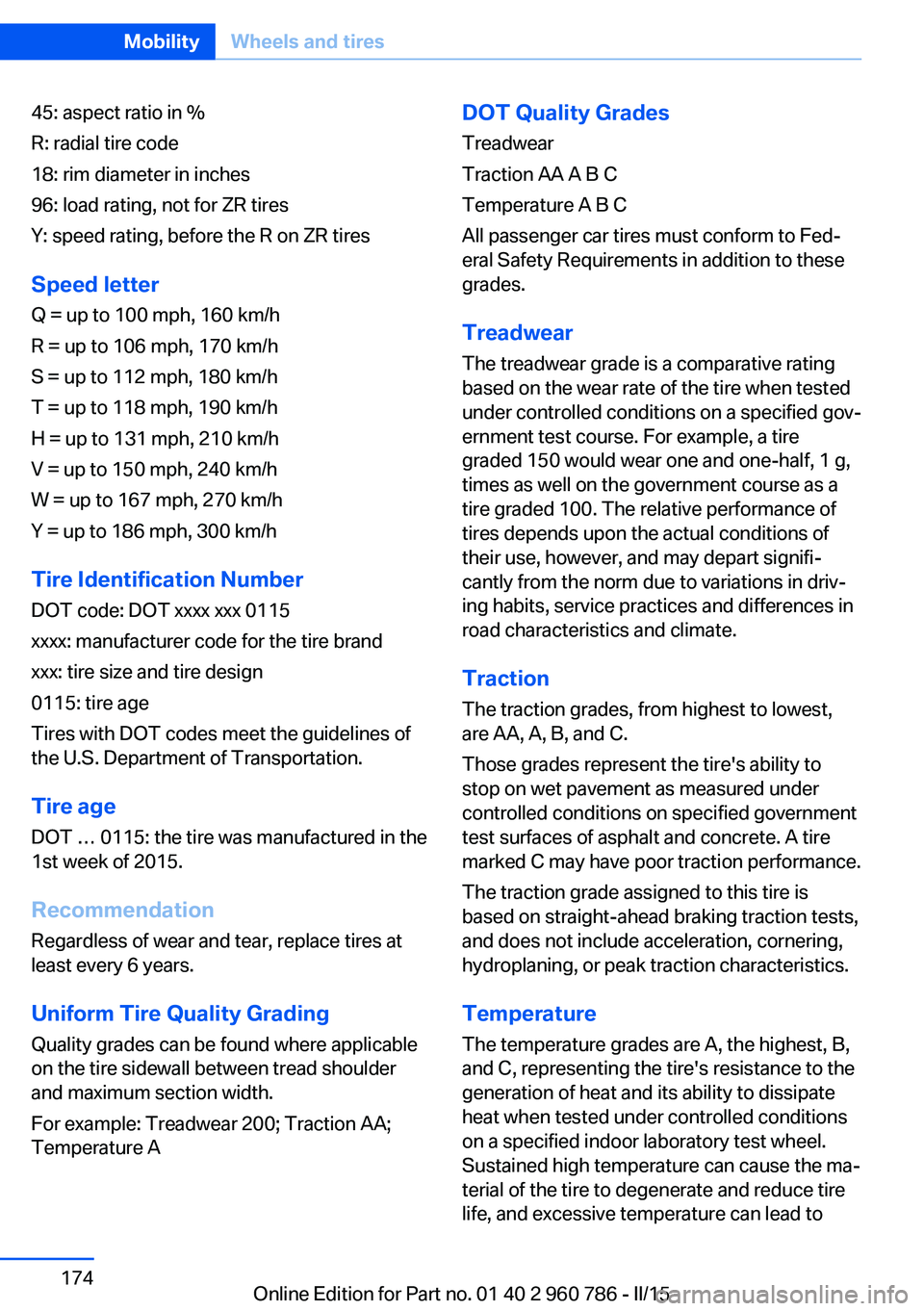

less suitable for winter operation.Minimum tread depth

Wear indicators are distributed around the

tire's circumference and have the legally re‐

quired minimum height of 0.063 in/1.6 mm.

They are marked on the side of the tire with

TWI, Tread Wear Indicator.

Tire damage

General information

Inspect your tires often for damage, foreign

objects lodged in the tread, and tread wear.

Hints

Driving over rough or damaged road surfaces,

as well as debris, curbs and other obstacles

can cause serious damage to wheels, tires and

suspension parts. This is more likely to occur

with low-profile tires, which provide less cush‐

ioning between the wheel and the road. Be

careful to avoid road hazards and reduce your

speed, especially if your vehicle is equipped

with low-profile tires.

Indications of tire damage or other vehicle de‐

fects:

▷Unusual vibrations while driving.▷Unusual handling such as a strong ten‐

dency to pull to the left or right.

Damage can, e. g., be caused by driving over

curbs, road damage, or similar things.

Seite 175Wheels and tiresMobility175

Online Edition for Part no. 01 40 2 960 786 - II/15

Page 180 of 228

In case of tire damage

If there are indications of tire damage, re‐

duce your speed immediately and have the

rims and tires checked right away; otherwise,

there is the increased risk of an accident.

Drive carefully to the nearest service center. If

necessary, have the vehicle towed or trans‐

ported there. Otherwise, tire damage can be‐

come life threatening for vehicle occupants

and also other traffic.◀

Repair of tire damage

For safety reasons, the manufacturer of

your vehicle recommends that you do not have

damaged tires repaired; they should be re‐

placed. Otherwise, damage can occur as a re‐

sult.◀

Changing wheels and tires

Mounting Information on mounting tires

Have mounting and balancing performed

only by a service center.

If work is not carried out properly, there is a

danger of subsequent damage and related

safety hazards.◀

Wheel and tire combination

You can ask the service center about the right

wheel/tire combination and wheel rim versions

for the vehicle.

Incorrect wheel and tire combinations impair

the function of a variety of systems such as

ABS or DSC.

To maintain good handling and vehicle re‐

sponse, use only tires with a single tread con‐

figuration from a single manufacturer.

Following tire damage, have the original wheel

and tire combination remounted on the vehicle

as soon as possible.Approved wheels and tires

You should only use wheels and tires

that have been approved by the vehicle manu‐

facturer for your vehicle type; otherwise, e.g.,

despite having the same official size ratings,

variations can lead to chassis contact and with

it, the risk of severe accidents

The manufacturer of your vehicle cannot eval‐

uate non-approved wheels and tires to deter‐

mine if they are suited for use, and therefore

cannot guarantee the operating safety of the

vehicle.◀

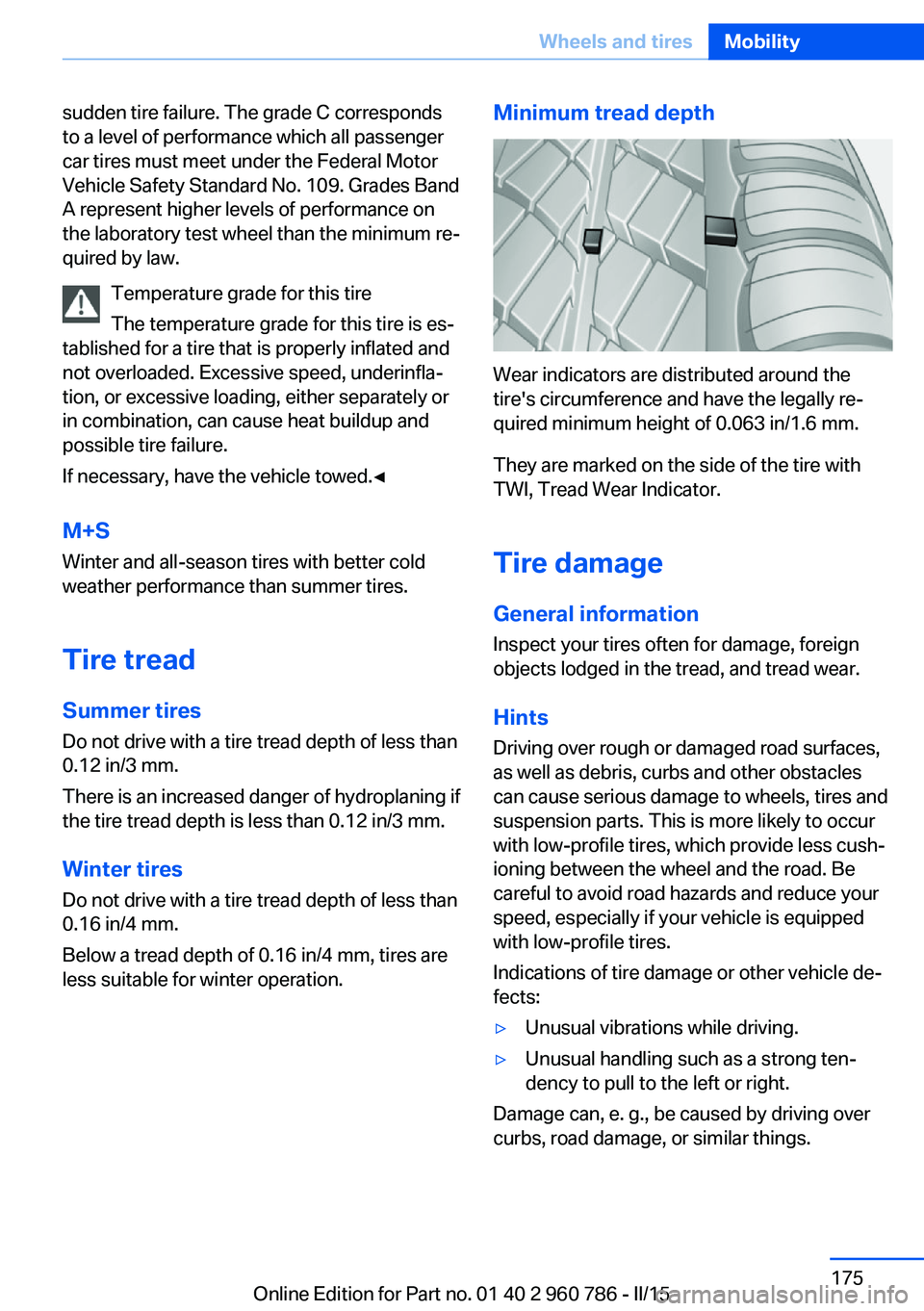

Recommended tire brands

For each tire size, the manufacturer of your ve‐

hicle recommends certain tire brands. These

can be identified by a star on the tire sidewall.

With proper use, these tires meet the highest

standards for safety and handling.

New tires Tire traction is not optimal due to manufactur‐

ing circumstances when tires are brand-new;

they achieve their full traction potential after a

break-in time.

Drive conservatively for the first

200 miles/300 km.

Retreaded tires

The manufacturer of your vehicle does not rec‐

ommend the use of retreaded tires.

Seite 176MobilityWheels and tires176

Online Edition for Part no. 01 40 2 960 786 - II/15

Page 181 of 228

Retreaded tires

Possibly substantial variations in the de‐

sign and age of the tire casing structures can

limit service life and have a negative impact on

road safety.◀

Winter tires

Winter tires are recommended for operating on

winter roads.

Although so-called all-season M+S tires pro‐

vide better winter traction than summer tires, they do not provide the same level of perform‐

ance as winter tires.

Maximum speed of winter tires If the maximum speed of the vehicle is higher

than the permissible speed for the winter tires,

then a respective symbol is displayed in your

field of vision. You can obtain this sign from the

tire specialist or from your service center.

Maximum speed for winter tires

Do not exceed the maximum speed for

the respective winter tires; otherwise, tire dam‐

age and accidents can occur.◀

Rotating wheels between axles The manufacturer of your vehicle advises

against switching wheels between the front

and rear axles. This can impair the handling

characteristics.

Rotating the tires is not permissible on vehi‐

cles with different tire sizes or rim sizes on the

front and rear axles.

StorageStore wheels and tires in a cool, dry place with

as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres‐

sure indicated on the side wall of the tire.Mobility System

The concept

With the Mobility System, minor tire damage

can be sealed quickly to enable continued

travel. To accomplish this, sealant is pumped

into the tires, which seals the damage from the

inside.

The compressor can be used to check the tire

inflation pressure.

Hints▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant container.▷Use of the Mobility System may be ineffec‐

tive if the tire puncture measures approx.

1/8 in/4 mm or more.▷Contact the nearest service center if the

tire cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

container and apply it to the steering

wheel.▷The use of a sealant can damage the TPM

wheel electronics. In this case, have the

electronics checked at the next opportu‐

nity and have them replaced if needed.

Enclosed areas

Do not let the engine run in enclosed

areas, since breathing in exhaust fumes may

lead to loss of consciousness and death. The

exhaust gases contain carbon monoxide, an

odorless and colorless but highly toxic gas.◀

Storage The Mobility System is located under the

cargo floor panel.

Seite 177Wheels and tiresMobility177

Online Edition for Part no. 01 40 2 960 786 - II/15

Page 182 of 228

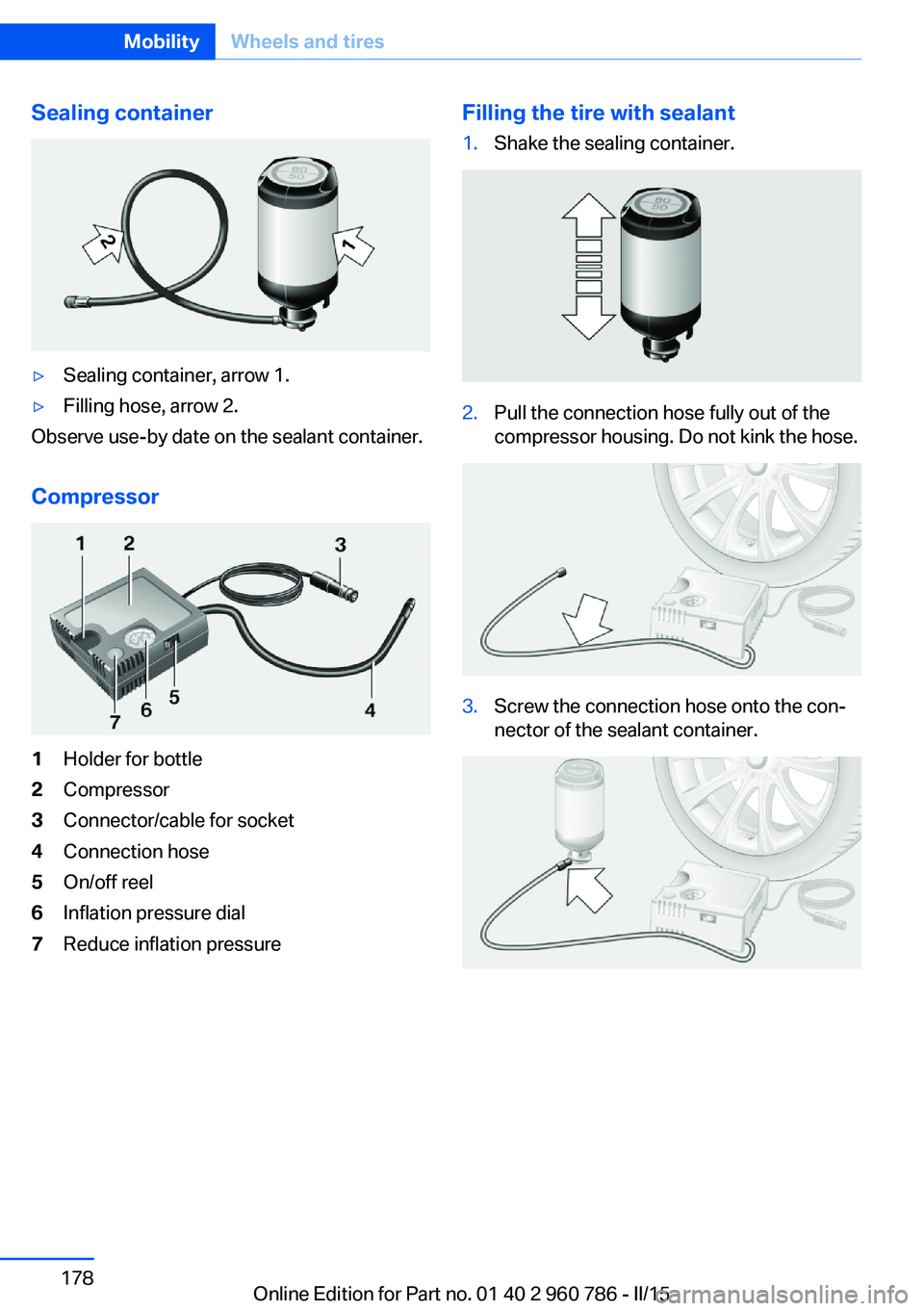

Sealing container▷Sealing container, arrow 1.▷Filling hose, arrow 2.

Observe use-by date on the sealant container.

Compressor

1Holder for bottle2Compressor3Connector/cable for socket4Connection hose5On/off reel6Inflation pressure dial7Reduce inflation pressureFilling the tire with sealant1.Shake the sealing container.2.Pull the connection hose fully out of the

compressor housing. Do not kink the hose.3.Screw the connection hose onto the con‐

nector of the sealant container.Seite 178MobilityWheels and tires178

Online Edition for Part no. 01 40 2 960 786 - II/15

Page 183 of 228

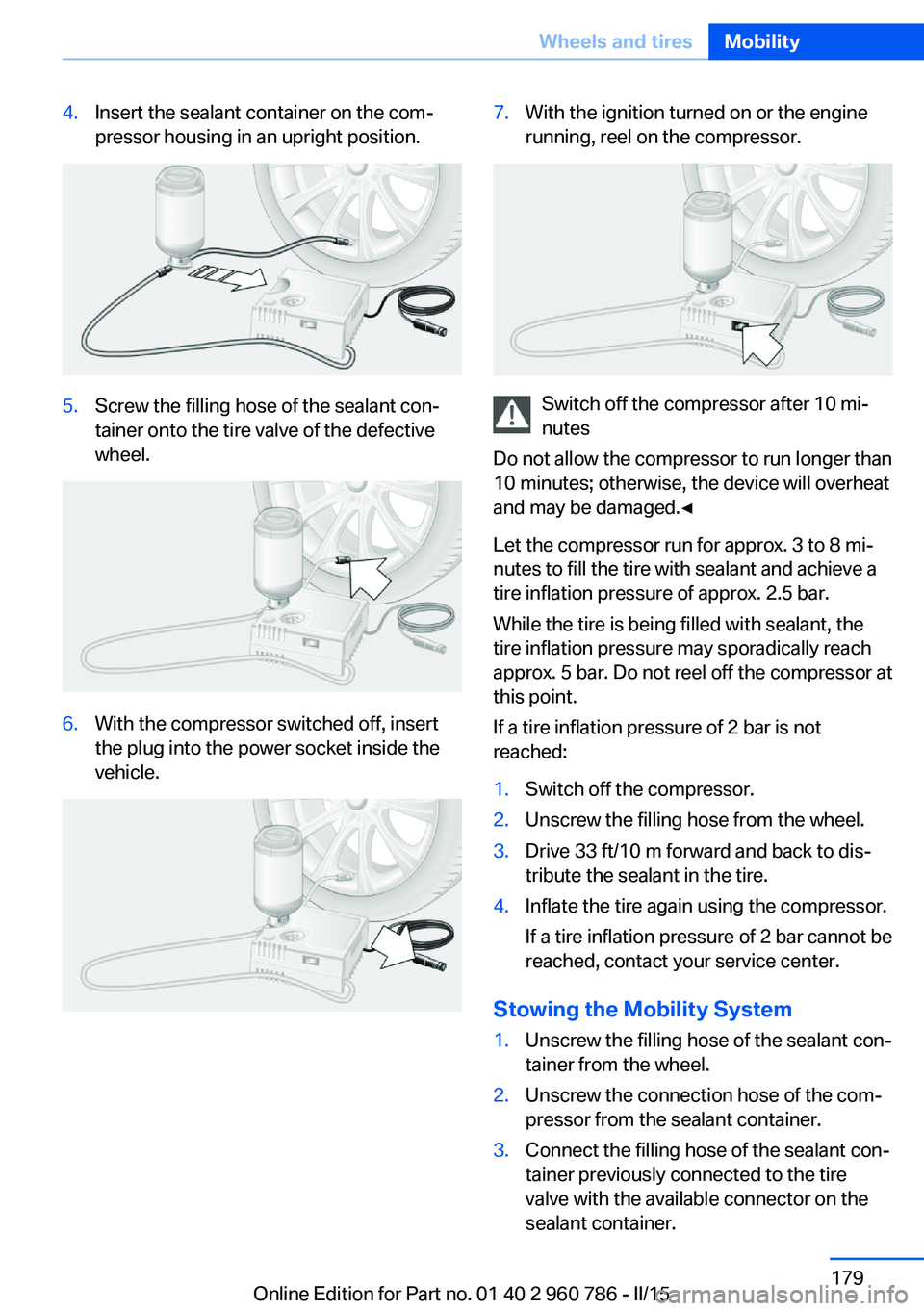

4.Insert the sealant container on the com‐

pressor housing in an upright position.5.Screw the filling hose of the sealant con‐

tainer onto the tire valve of the defective

wheel.6.With the compressor switched off, insert

the plug into the power socket inside the

vehicle.7.With the ignition turned on or the engine

running, reel on the compressor.

Switch off the compressor after 10 mi‐

nutes

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged.◀

Let the compressor run for approx. 3 to 8 mi‐

nutes to fill the tire with sealant and achieve a

tire inflation pressure of approx. 2.5 bar.

While the tire is being filled with sealant, the

tire inflation pressure may sporadically reach

approx. 5 bar. Do not reel off the compressor at

this point.

If a tire inflation pressure of 2 bar is not

reached:

1.Switch off the compressor.2.Unscrew the filling hose from the wheel.3.Drive 33 ft/10 m forward and back to dis‐

tribute the sealant in the tire.4.Inflate the tire again using the compressor.

If a tire inflation pressure of 2 bar cannot be

reached, contact your service center.

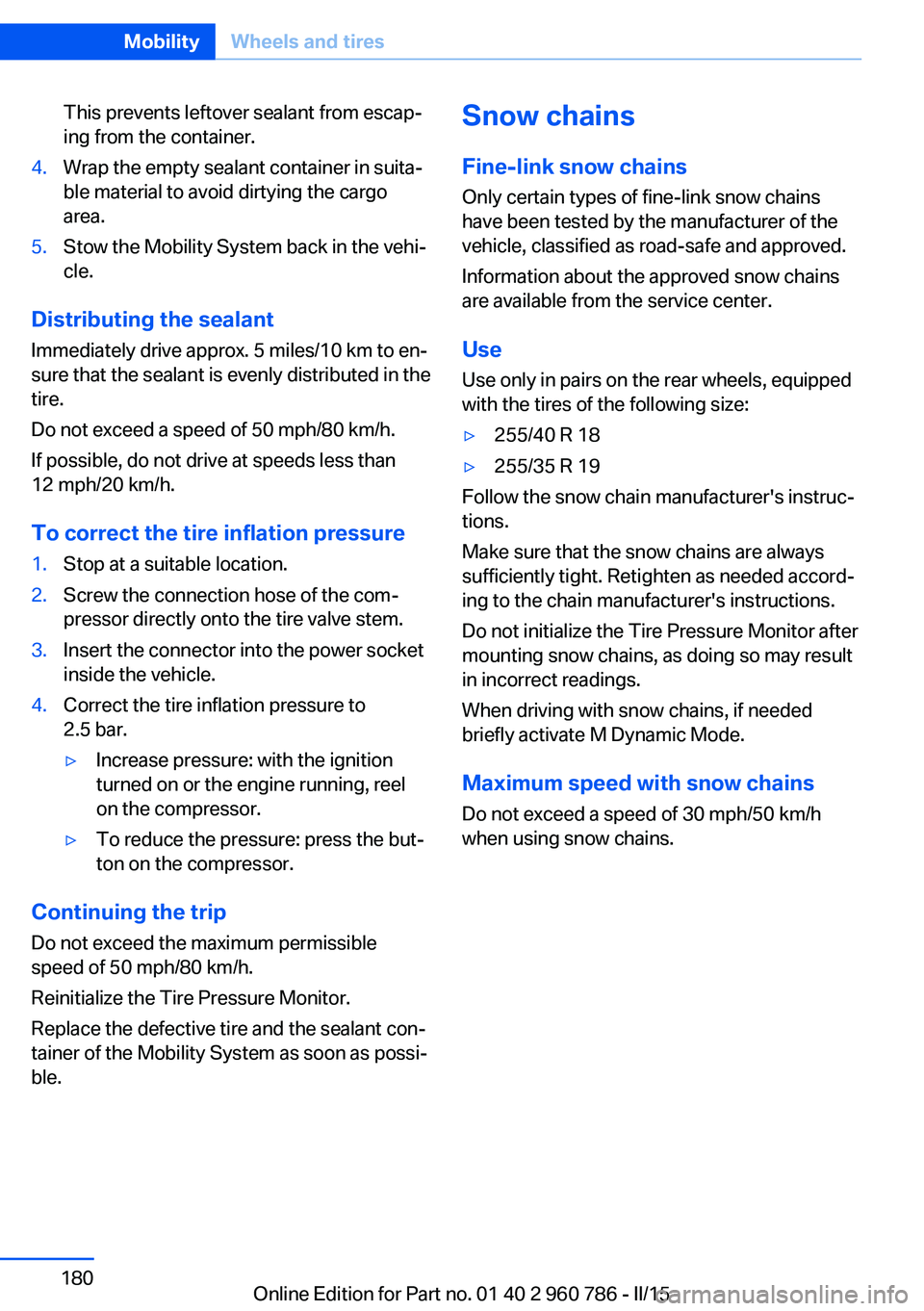

Stowing the Mobility System

1.Unscrew the filling hose of the sealant con‐

tainer from the wheel.2.Unscrew the connection hose of the com‐

pressor from the sealant container.3.Connect the filling hose of the sealant con‐

tainer previously connected to the tire

valve with the available connector on the

sealant container.Seite 179Wheels and tiresMobility179

Online Edition for Part no. 01 40 2 960 786 - II/15

Page 184 of 228

This prevents leftover sealant from escap‐

ing from the container.4.Wrap the empty sealant container in suita‐

ble material to avoid dirtying the cargo

area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive approx. 5 miles/10 km to en‐

sure that the sealant is evenly distributed in the

tire.

Do not exceed a speed of 50 mph/80 km/h.

If possible, do not drive at speeds less than

12 mph/20 km/h.

To correct the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose of the com‐

pressor directly onto the tire valve stem.3.Insert the connector into the power socket

inside the vehicle.4.Correct the tire inflation pressure to

2.5 bar.▷Increase pressure: with the ignition

turned on or the engine running, reel

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

Continuing the trip

Do not exceed the maximum permissible

speed of 50 mph/80 km/h.

Reinitialize the Tire Pressure Monitor.

Replace the defective tire and the sealant con‐

tainer of the Mobility System as soon as possi‐

ble.

Snow chains

Fine-link snow chains Only certain types of fine-link snow chains

have been tested by the manufacturer of the

vehicle, classified as road-safe and approved.

Information about the approved snow chains

are available from the service center.

Use Use only in pairs on the rear wheels, equipped

with the tires of the following size:▷255/40 R 18▷255/35 R 19

Follow the snow chain manufacturer's instruc‐

tions.

Make sure that the snow chains are always

sufficiently tight. Retighten as needed accord‐

ing to the chain manufacturer's instructions.

Do not initialize the Tire Pressure Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

When driving with snow chains, if needed

briefly activate M Dynamic Mode.

Maximum speed with snow chains

Do not exceed a speed of 30 mph/50 km/h

when using snow chains.

Seite 180MobilityWheels and tires180

Online Edition for Part no. 01 40 2 960 786 - II/15

Page 196 of 228

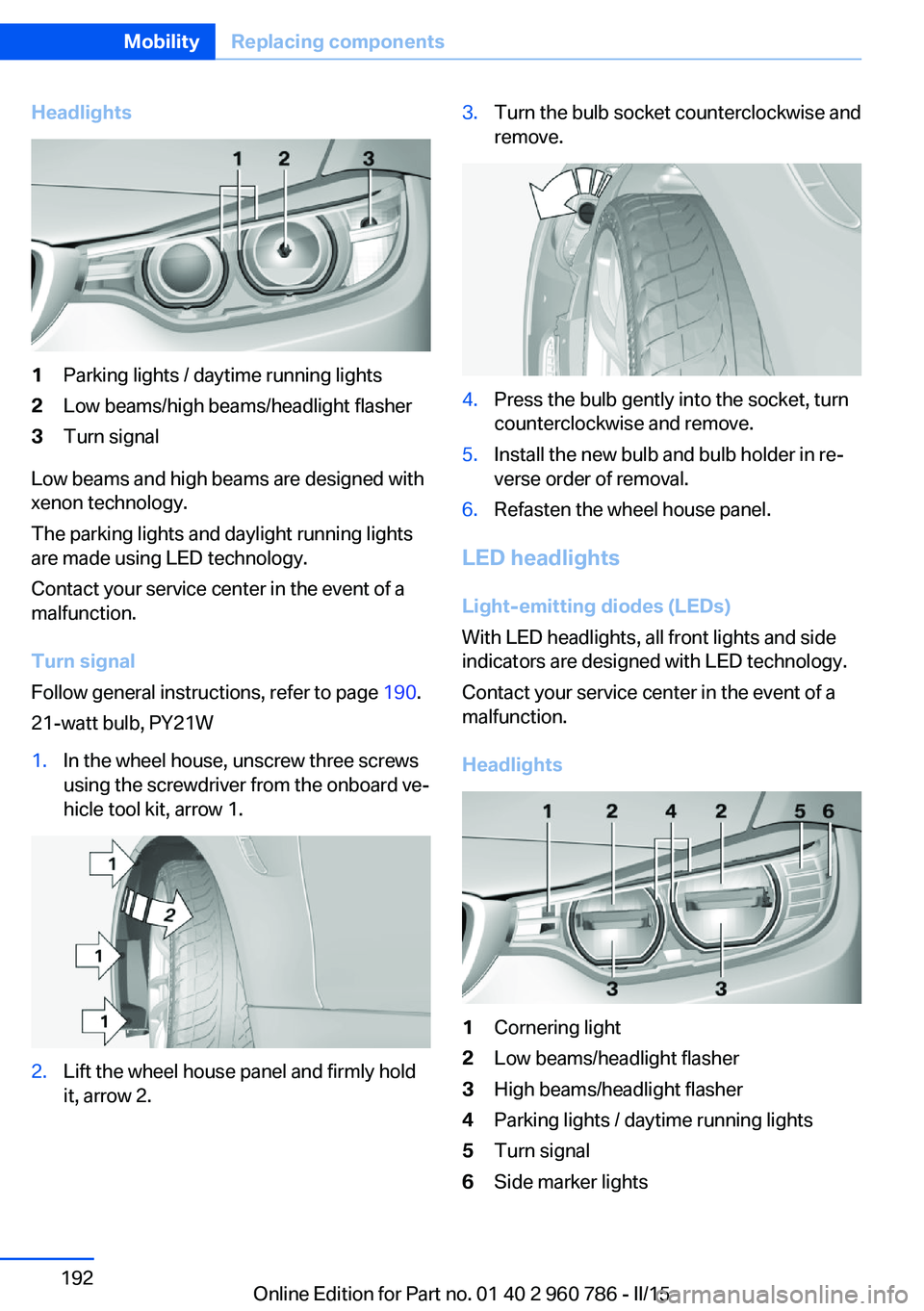

Headlights1Parking lights / daytime running lights2Low beams/high beams/headlight flasher3Turn signal

Low beams and high beams are designed with

xenon technology.

The parking lights and daylight running lights

are made using LED technology.

Contact your service center in the event of a

malfunction.

Turn signal

Follow general instructions, refer to page 190.

21-watt bulb, PY21W

1.In the wheel house, unscrew three screws

using the screwdriver from the onboard ve‐

hicle tool kit, arrow 1.2.Lift the wheel house panel and firmly hold

it, arrow 2.3.Turn the bulb socket counterclockwise and

remove.4.Press the bulb gently into the socket, turn

counterclockwise and remove.5.Install the new bulb and bulb holder in re‐

verse order of removal.6.Refasten the wheel house panel.

LED headlights

Light-emitting diodes (LEDs)

With LED headlights, all front lights and side

indicators are designed with LED technology.

Contact your service center in the event of a

malfunction.

Headlights

1Cornering light2Low beams/headlight flasher3High beams/headlight flasher4Parking lights / daytime running lights5Turn signal6Side marker lightsSeite 192MobilityReplacing components192

Online Edition for Part no. 01 40 2 960 786 - II/15

Page 199 of 228

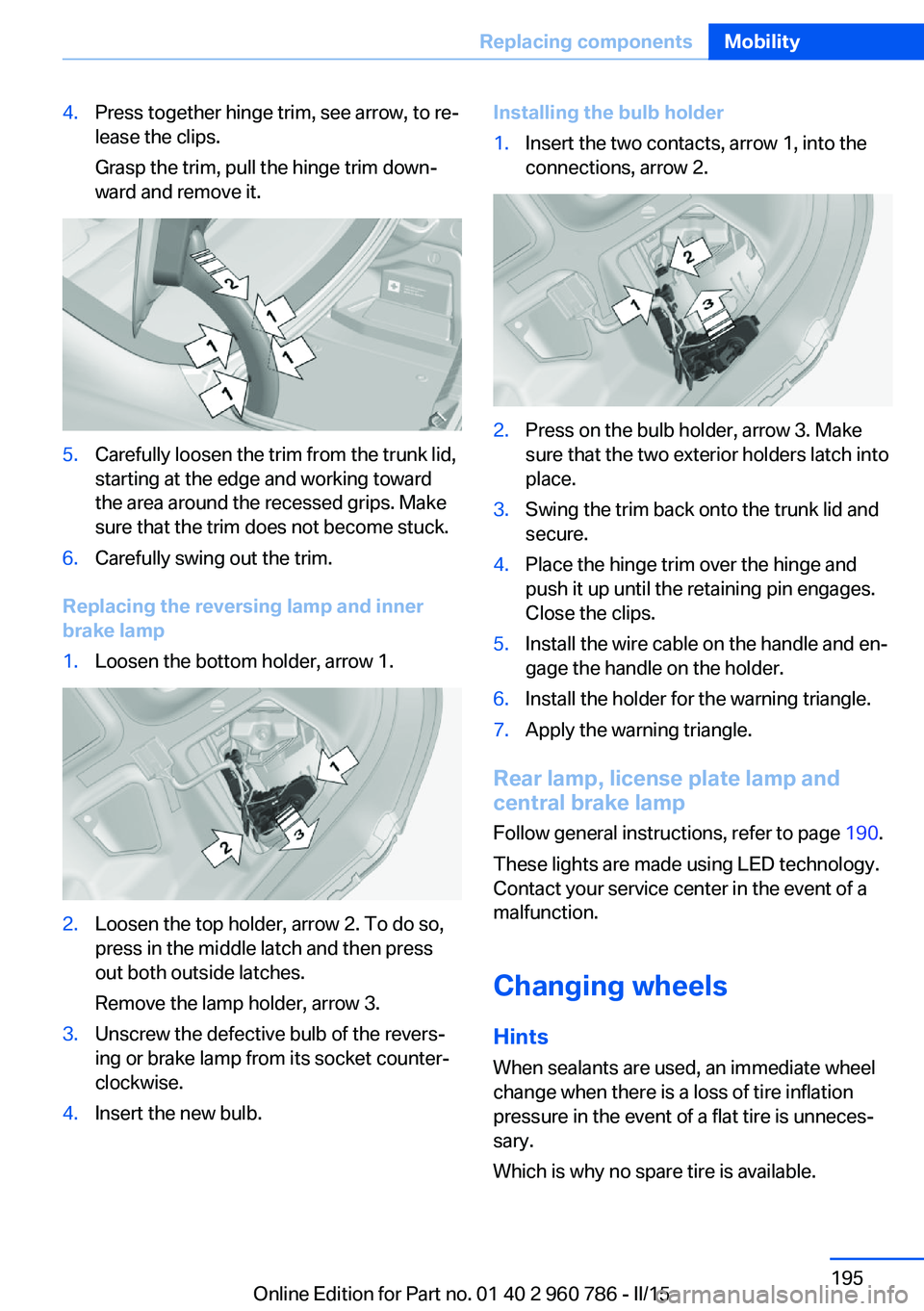

4.Press together hinge trim, see arrow, to re‐

lease the clips.

Grasp the trim, pull the hinge trim down‐

ward and remove it.5.Carefully loosen the trim from the trunk lid,

starting at the edge and working toward

the area around the recessed grips. Make

sure that the trim does not become stuck.6.Carefully swing out the trim.

Replacing the reversing lamp and inner

brake lamp

1.Loosen the bottom holder, arrow 1.2.Loosen the top holder, arrow 2. To do so,

press in the middle latch and then press

out both outside latches.

Remove the lamp holder, arrow 3.3.Unscrew the defective bulb of the revers‐

ing or brake lamp from its socket counter‐

clockwise.4.Insert the new bulb.Installing the bulb holder1.Insert the two contacts, arrow 1, into the

connections, arrow 2.2.Press on the bulb holder, arrow 3. Make

sure that the two exterior holders latch into

place.3.Swing the trim back onto the trunk lid and

secure.4.Place the hinge trim over the hinge and

push it up until the retaining pin engages.

Close the clips.5.Install the wire cable on the handle and en‐

gage the handle on the holder.6.Install the holder for the warning triangle.7.Apply the warning triangle.

Rear lamp, license plate lamp and

central brake lamp

Follow general instructions, refer to page 190.

These lights are made using LED technology.

Contact your service center in the event of a

malfunction.

Changing wheels

Hints When sealants are used, an immediate wheel

change when there is a loss of tire inflation

pressure in the event of a flat tire is unneces‐

sary.

Which is why no spare tire is available.

Seite 195Replacing componentsMobility195

Online Edition for Part no. 01 40 2 960 786 - II/15

Page 200 of 228

The tools for changing wheels are available as

accessories from your service center.

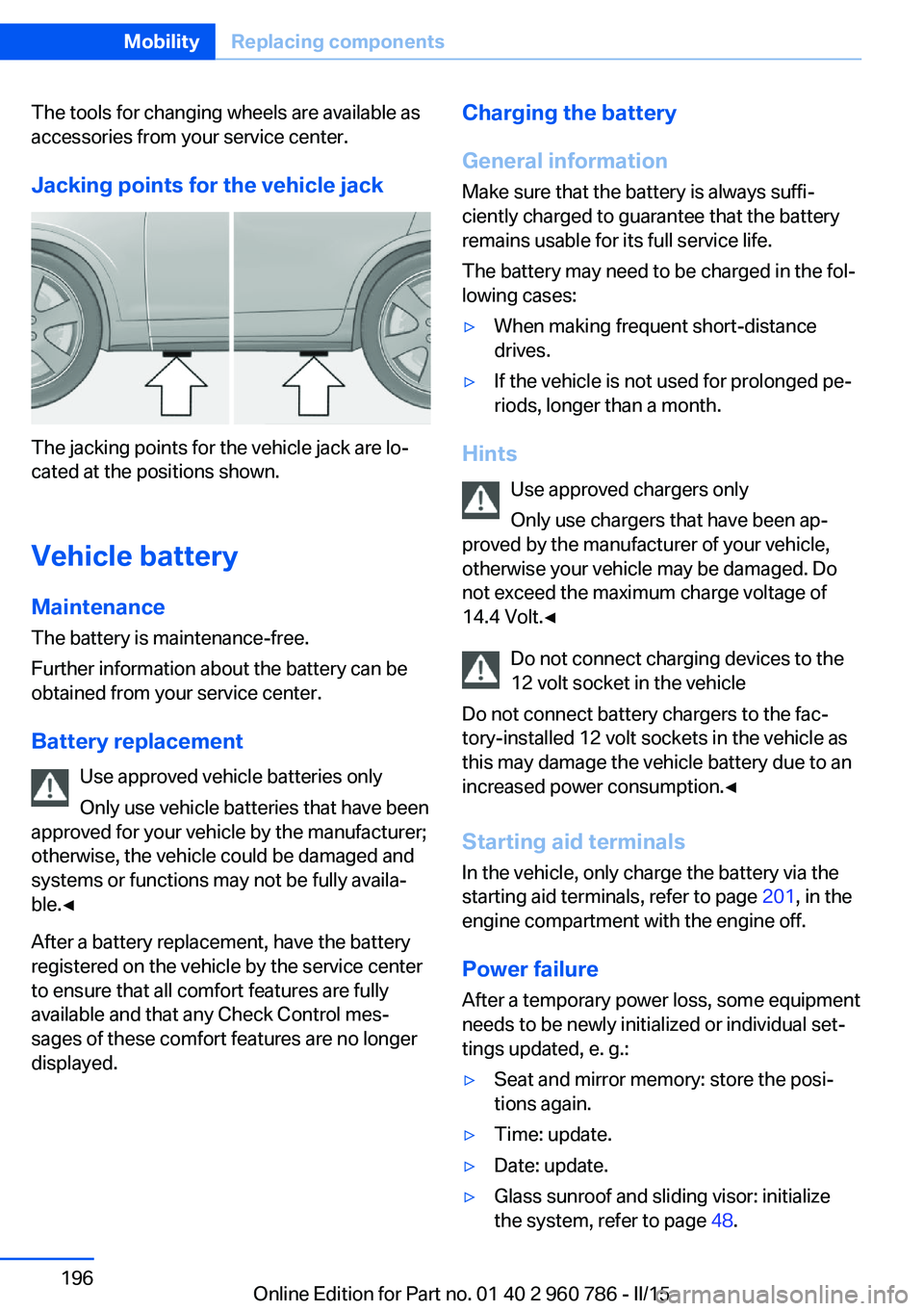

Jacking points for the vehicle jack

The jacking points for the vehicle jack are lo‐

cated at the positions shown.

Vehicle battery Maintenance

The battery is maintenance-free.

Further information about the battery can be

obtained from your service center.

Battery replacement Use approved vehicle batteries only

Only use vehicle batteries that have been

approved for your vehicle by the manufacturer;

otherwise, the vehicle could be damaged and

systems or functions may not be fully availa‐

ble.◀

After a battery replacement, have the battery

registered on the vehicle by the service center

to ensure that all comfort features are fully

available and that any Check Control mes‐

sages of these comfort features are no longer

displayed.

Charging the battery

General information

Make sure that the battery is always suffi‐

ciently charged to guarantee that the battery

remains usable for its full service life.

The battery may need to be charged in the fol‐

lowing cases:▷When making frequent short-distance

drives.▷If the vehicle is not used for prolonged pe‐

riods, longer than a month.

Hints

Use approved chargers only

Only use chargers that have been ap‐

proved by the manufacturer of your vehicle, otherwise your vehicle may be damaged. Do

not exceed the maximum charge voltage of

14.4 Volt.◀

Do not connect charging devices to the

12 volt socket in the vehicle

Do not connect battery chargers to the fac‐

tory-installed 12 volt sockets in the vehicle as

this may damage the vehicle battery due to an

increased power consumption.◀

Starting aid terminals

In the vehicle, only charge the battery via the

starting aid terminals, refer to page 201, in the

engine compartment with the engine off.

Power failure

After a temporary power loss, some equipment

needs to be newly initialized or individual set‐

tings updated, e. g.:

▷Seat and mirror memory: store the posi‐

tions again.▷Time: update.▷Date: update.▷Glass sunroof and sliding visor: initialize

the system, refer to page 48.Seite 196MobilityReplacing components196

Online Edition for Part no. 01 40 2 960 786 - II/15