BMW M5 SEDAN 2009 E60 Owner's Manual

Manufacturer: BMW, Model Year: 2009, Model line: M5 SEDAN, Model: BMW M5 SEDAN 2009 E60Pages: 266, PDF Size: 9.08 MB

Page 221 of 266

Mobility

219Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

12 in/30 cm from sensors, e.g. Park Distance

Control sensors or radar sensors.<

Hand washing

When washing the vehicle by hand, use plenty

of water and car washing shampoo. Clean the

vehicle with gentle pressure using a sponge or a

washing brush.

Before cleaning the windshield, deacti-

vate the rain sensor or switch off the igni-

tion to prevent unwanted wiper operation.<

Follow local guidelines for washing vehi-

cles by hand.<

Headlamps

Do not rub dry and never use abrasives or

strong solvents to clean the covers.

Loosen dirt, e.g. insects, with shampoo or

insect remover and wash away with plenty of

water.

Use a window de-icer to remove accumulated

ice and snow, not a scraper.

Windows

Use a glass cleaner to clean the inside and out-

side surfaces of the windows and the glass sur-

faces of the mirrors.

Do not use quartz-containing cleansers

to clean glass surfaces of the mirrors.<

Wiper blades

Clean with soapy water and replace regularly to

prevent streaking.

The presence of wax and sealant residues

and dirt on the windows leads to streaking

during wiper operation and results in premature

wear on wiper blades as well as interference

with the rain sensor.<

Caring for the vehicle finish

Regular care helps your vehicle retain its value

and protects the paint from the long-term

effects of aggressive substances.

Regionally occurring environmental factors can

affect and damage vehicle finish. It is therefore important to tailor the frequency and extent of

your car care accordingly.

Immediately remove particularly aggressive

substances such as spilled fuel, oil, grease,

brake fluid, tree resin, or bird droppings; other-

wise, they may damage your paint.

Repairing paint damage

Repair stone damage or scratches imme-

diately, depending on the severity of the

damage, to prevent the formation of rust.<

BMW recommends having paint damage pro-

fessionally repaired using Genuine BMW finish

materials in accordance with factory guidelines.

Waxing

Sealant is required when water no longer beads

on the clean surface of the paint. Use only prod-

ucts that contain carnauba wax or synthetic wax

to seal your finish.

Rubber gaskets

Treat only with water or a rubber care product.

To avoid noise or damage, do not use

products that contain silicone to care for

rubber gaskets.<

Chrome components

Particularly after exposure to road salt, thor-

oughly cleanse parts like the radiator grille, door

handles, or window frames with plenty of water

with shampoo added to it. For additional treat-

ment, use chrome polish.

Alloy wheels

Depending on your system, braking can gener-

ate dust, which settles on the light-alloy wheels.

Remove this dust regularly with acid-free wheel

cleaner.

Do not use aggressive, acid-containing,

strongly alkaline, or coarse cleansers and

do not use steam cleaners at temperatures

greater than 1407/606; otherwise you may

damage your vehicle.<

Page 222 of 266

Care

220

Outside sensors

Sensors on the outside of the vehicle, such as

Park Distance Control sensors or radar sensors,

should be kept clean and free of ice to retain

their full function.

Interior care

Upholstery materials/cloth-covered

paneling

Clean regularly with a vacuum cleaner in order

to remove surface dirt.

In the event of more serious soiling such as bev-

erage stains, use a soft sponge or a lint-free

microfiber cloth in combination with suitable

interior cleaners. Follow the instructions on the

packaging.

Clean upholstery material over a large

area extending out to the seams. Avoid

intense friction.<

Open Velcro fasteners on pants or other

items of clothing can cause damage to

the seat covering. Make sure that the Velcro

fasteners are closed.<

Leather/leather-covered paneling

The leather used by BMW is a high quality

natural product. Slight patterns in the

grain are part of the typical properties of a natu-

ral leather.

Dust and dirt from the road chafe in pores and

folds and result in considerable wear and cause

the leather surface to become prematurely brit-

tle. We therefore suggest that you clean the

leather with a dust cloth or vacuum cleaner at

regular intervals.<

Particularly with light-colored leather, make

sure to clean it regularly since it has a greater

tendency to become soiled.

Treat the leather twice a year with a leather

lotion since dirt and grease harm the protective

layer of the leather.

Carpets/luggage compartment

Carpeting, floor mats, and luggage compart-

ment rugs and paneling can be cleaned with a

vacuum or in the event of more serious soiling,

cleansed with an interior cleaner.

Floor mats and luggage compartment rugs can

be removed for cleaning. When inserting into

place, make sure that the seat rails do not pro-

trude over the floor mats; otherwise floor mats

can be damaged.

Fluff on new floor mats is a result of the produc-

tion process and can be removed by repeated

vacuuming.

Plastic components inside

Clean the glass cover of the instrument panel,

imitation leather surfaces, lamp lenses, and

matte components with water and, if necessary,

a solvent-free plastic cleaner.

Fine wooden components

Use a damp cloth to clean fine wooden trim

panels and components. Follow up by drying

with a soft cloth.

Safety belts

Do not use cleansers to clean the safety

belts since this can destroy the web-

bing.<

Inside sensors

Clean inside sensors such as those of the high-

beam assistant using a lint-free cloth moist-

ened with glass cleaner.

Displays

Clean displays like the radio or the Control Dis-

play using a display-cleaning cloth or a soft,

nonabrasive lint-free cloth.

Avoid using excessive pressure when

cleaning displays; otherwise, you could

damage them.<

Never use chemical-based cleansers or

household scouring products. Keep all

liquids away from the equipment. Otherwise

Page 223 of 266

Mobility

221Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

corrosion or damage to surfaces or electrical

components can occur.<

CD/DVD-player

Do not use cleaning CDs; they can dam-

age parts of the player.<

Storing your vehicle

When storing your vehicle for longer than three

months, please seek the advice of your BMW

center or a workshop that works in accordance

with BMW guidelines.

Page 224 of 266

Replacing components

222

Replacing components

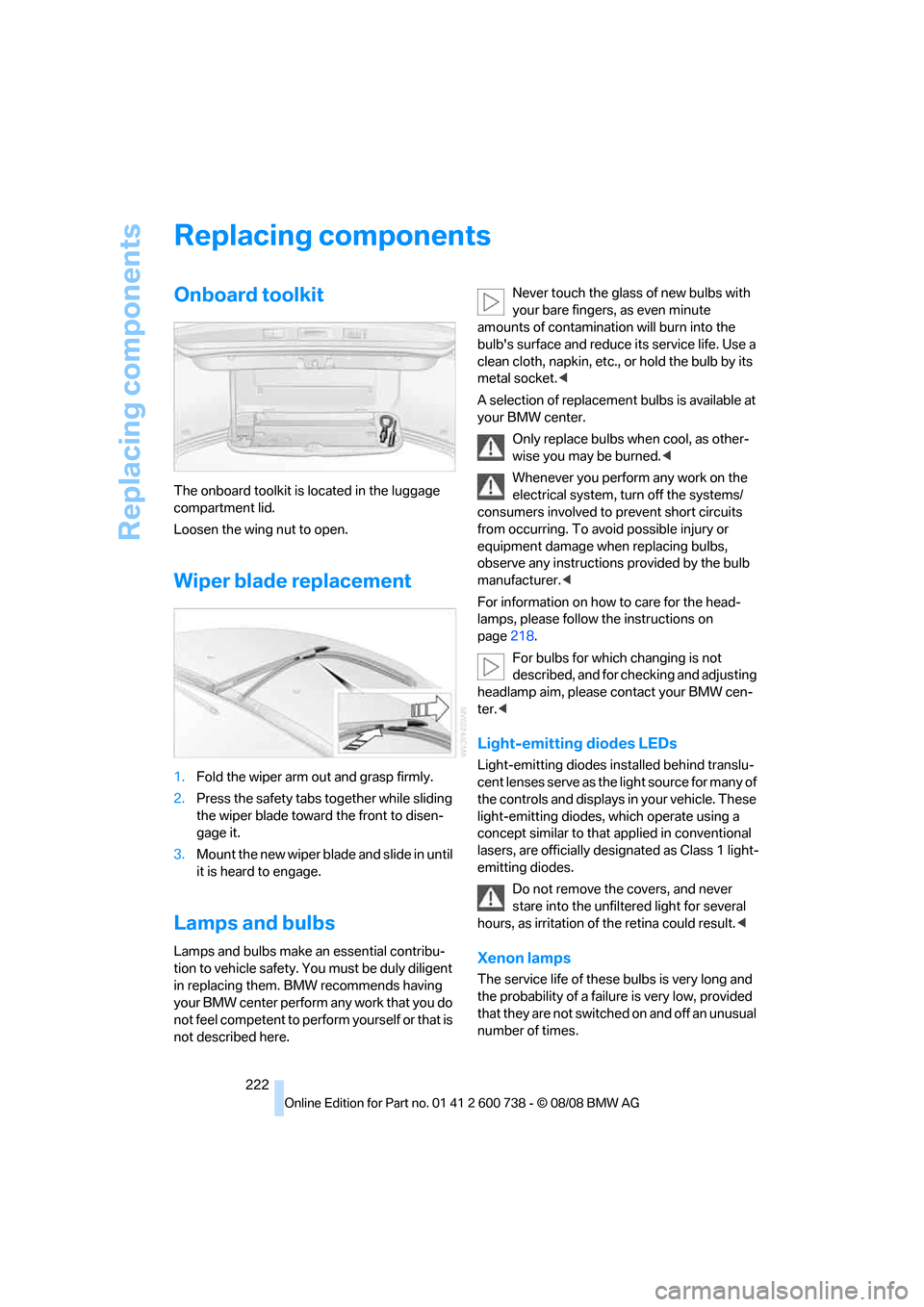

Onboard toolkit

The onboard toolkit is located in the luggage

compartment lid.

Loosen the wing nut to open.

Wiper blade replacement

1.Fold the wiper arm out and grasp firmly.

2.Press the safety tabs together while sliding

the wiper blade toward the front to disen-

gage it.

3.Mount the new wiper blade and slide in until

it is heard to engage.

Lamps and bulbs

Lamps and bulbs make an essential contribu-

tion to vehicle safety. You must be duly diligent

in replacing them. BMW recommends having

your BMW center perform any work that you do

not feel competent to perform yourself or that is

not described here.Never touch the glass of new bulbs with

your bare fingers, as even minute

amounts of contamination will burn into the

bulb's surface and reduce its service life. Use a

clean cloth, napkin, etc., or hold the bulb by its

metal socket.<

A selection of replacement bulbs is available at

your BMW center.

Only replace bulbs when cool, as other-

wise you may be burned.<

Whenever you perform any work on the

electrical system, turn off the systems/

consumers involved to prevent short circuits

from occurring. To avoid possible injury or

equipment damage when replacing bulbs,

observe any instructions provided by the bulb

manufacturer.<

For information on how to care for the head-

lamps, please follow the instructions on

page218.

For bulbs for which changing is not

described, and for checking and adjusting

headlamp aim, please contact your BMW cen-

ter.<

Light-emitting diodes LEDs

Light-emitting diodes installed behind translu-

cent lenses serve as the light source for many of

the controls and displays in your vehicle. These

light-emitting diodes, which operate using a

concept similar to that applied in conventional

lasers, are officially designated as Class 1 light-

emitting diodes.

Do not remove the covers, and never

stare into the unfiltered light for several

hours, as irritation of the retina could result.<

Xenon lamps

The service life of these bulbs is very long and

the probability of a failure is very low, provided

that they are not switched on and off an unusual

number of times.

Page 225 of 266

Mobility

223Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

Have work on the xenon lighting system

performed only by your BMW center or a

workshop that works according to BMW repair

procedures with correspondingly trained per-

sonnel. Due to the high voltage present in the

system, there is a danger of fatal injuries when

work is carried out improperly.<

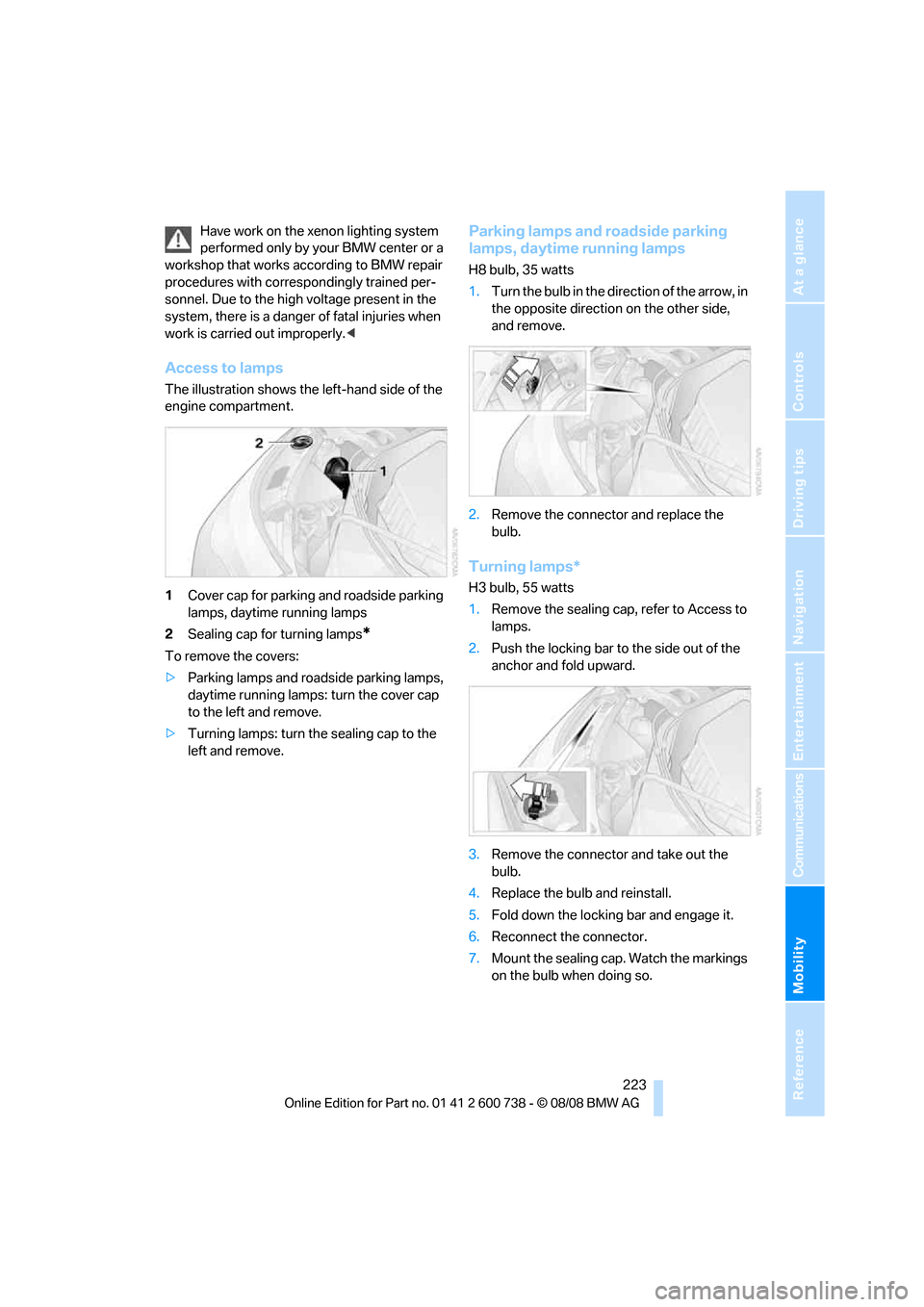

Access to lamps

The illustration shows the left-hand side of the

engine compartment.

1Cover cap for parking and roadside parking

lamps, daytime running lamps

2Sealing cap for turning lamps

*

To remove the covers:

>Parking lamps and roadside parking lamps,

daytime running lamps: turn the cover cap

to the left and remove.

>Turning lamps: turn the sealing cap to the

left and remove.

Parking lamps and roadside parking

lamps, daytime running lamps

H8 bulb, 35 watts

1.Turn the bulb in the direction of the arrow, in

the opposite direction on the other side,

and remove.

2.Remove the connector and replace the

bulb.

Turning lamps*

H3 bulb, 55 watts

1.Remove the sealing cap, refer to Access to

lamps.

2.Push the locking bar to the side out of the

anchor and fold upward.

3.Remove the connector and take out the

bulb.

4.Replace the bulb and reinstall.

5.Fold down the locking bar and engage it.

6.Reconnect the connector.

7.Mount the sealing cap. Watch the markings

on the bulb when doing so.

Page 226 of 266

Replacing components

224

Turn signals, front

21-watt bulb, PY21W

1.Turn the bulb holder to the left and remove.

2.Apply gentle pressure to the bulb while

turning it to the left for removal and replace-

ment.

Side-mounted turn signals

5-watt bulb, W5W

1.Press back against the front edge of the

lamp with the tip of your finger, then pivot it

out.

2.Turn the bulb holder to the left and remove.

3.Remove the bulb for replacement.

Side marker lamps, front and rear

To replace, please go to your BMW center or a

workshop that works according to BMW repair

procedures with correspondingly trained per-

sonnel.

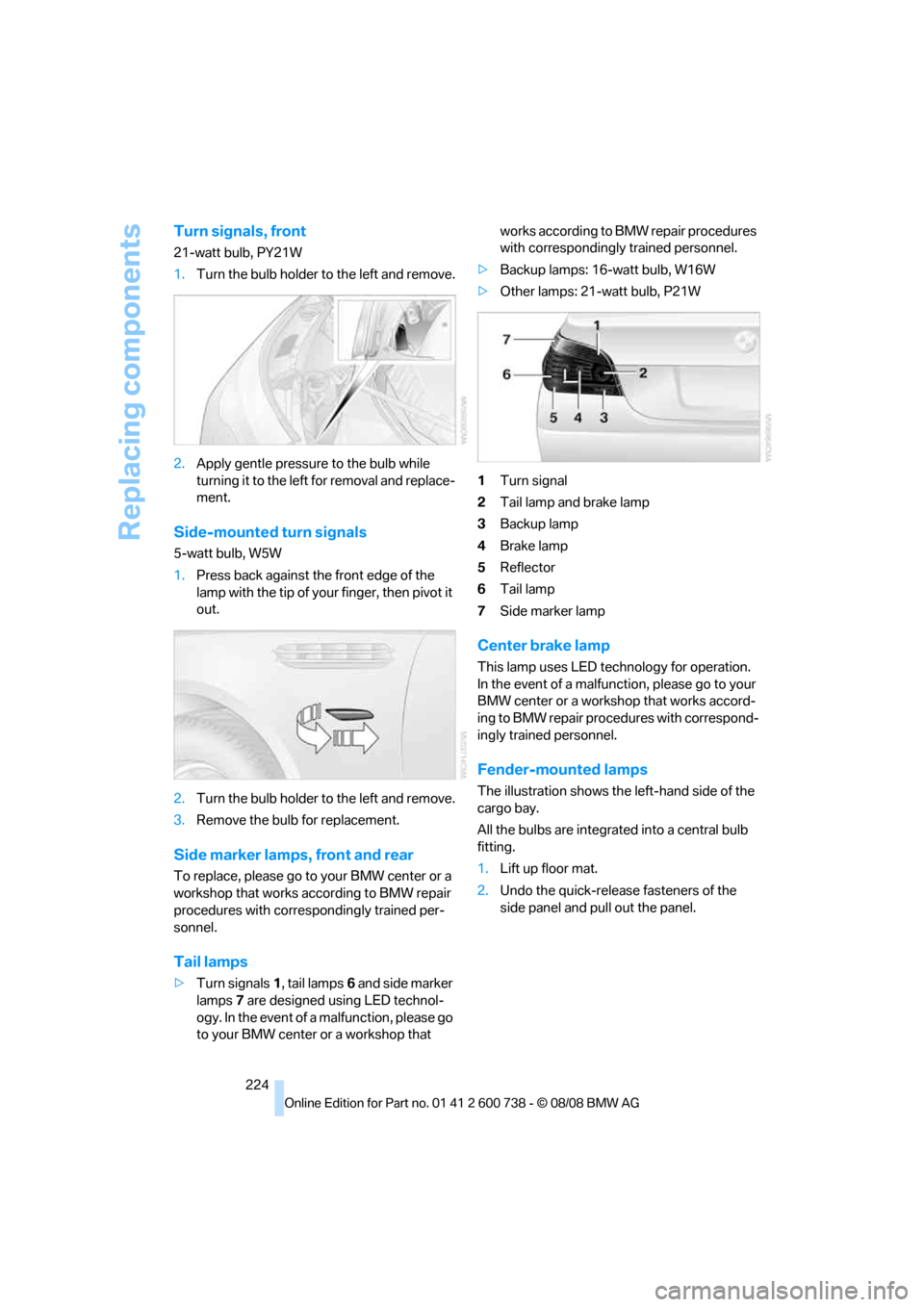

Tail lamps

>Turn signals1, tail lamps6 and side marker

lamps7 are designed using LED technol-

ogy. In the event of a malfunction, please go

to your BMW center or a workshop that works according to BMW repair procedures

with correspondingly trained personnel.

>Backup lamps: 16-watt bulb, W16W

>Other lamps: 21-watt bulb, P21W

1Turn signal

2Tail lamp and brake lamp

3Backup lamp

4Brake lamp

5Reflector

6Tail lamp

7Side marker lamp

Center brake lamp

This lamp uses LED technology for operation.

In the event of a malfunction, please go to your

BMW center or a workshop that works accord-

ing to BMW repair procedures with correspond-

ingly trained personnel.

Fender-mounted lamps

The illustration shows the left-hand side of the

cargo bay.

All the bulbs are integrated into a central bulb

fitting.

1.Lift up floor mat.

2.Undo the quick-release fasteners of the

side panel and pull out the panel.

Page 227 of 266

Mobility

225Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

3.Turn the lock to the left and remove the bulb

holder.

4.Backup lamps:

Remove and replace the bulb.

Other lamps:

Apply gentle pressure to the bulb while

turning it to the left for removal and replace-

ment.

Lamps in luggage compartment lid

License plate lamp

5-watt bulb, C5W

1.Insert screwdriver into the slot and press to

the right, refer to arrows. This releases the

lamp.

2.Remove the lamp and replace the bulb.

Repairing flat tire with

M Mobility System

To repair a flat tire, an M Mobility System is pro-

vided in the BMW M5. Using this system you

can apply a sealant in the inside of the tire, seal

off the damaged area, restore the tire inflation

pressure and then continue driving.Safety measures in case of a breakdown:

Park the vehicle as far as possible from

passing traffic and on solid ground. Switch on

the hazard warning flashers.

Apply the handbrake and engage the first or

reverse gear. Have all vehicle occupants get out

of the vehicle and ensure that they remain out-

side the immediate area in a safe place, such as

behind a guardrail.

If a warning triangle

* or portable hazard warning

lamp

* is required, set it up on the roadside at an

appropriate distance from the rear of the vehi-

cle. Comply with all safety guidelines and regu-

lations.<

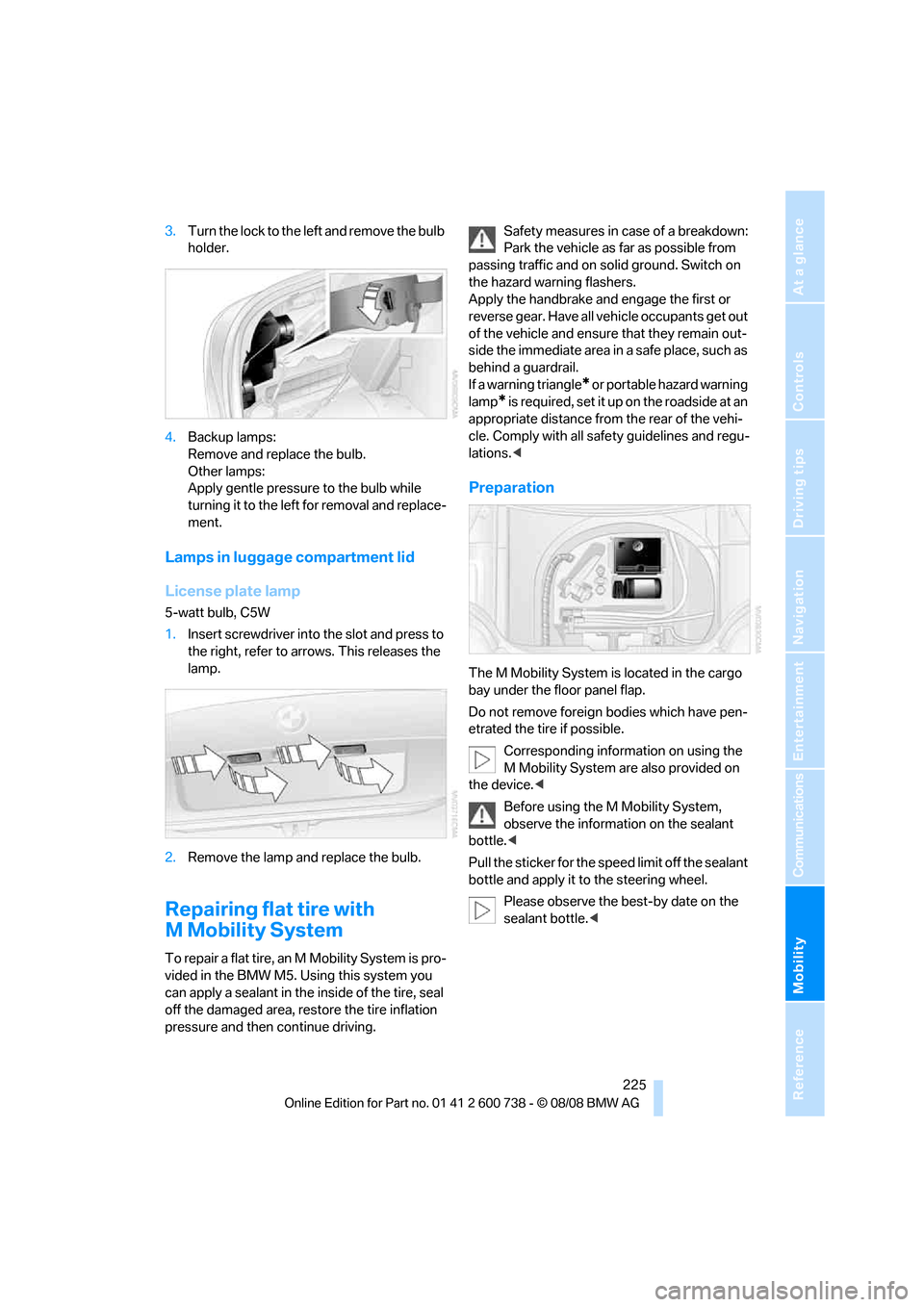

Preparation

The M Mobility System is located in the cargo

bay under the floor panel flap.

Do not remove foreign bodies which have pen-

etrated the tire if possible.

Corresponding information on using the

M Mobility System are also provided on

the device.<

Before using the M Mobility System,

observe the information on the sealant

bottle.<

Pull the sticker for the speed limit off the sealant

bottle and apply it to the steering wheel.

Please observe the best-by date on the

sealant bottle.<

Page 228 of 266

Replacing components

226

The M Mobility System consists of

1Sealant bottle and sticker with speed limit

2Filling hose from sealant bottle to wheel

Model with pressure gauge on hose*

3Connector and cable for lighter socket

4Mounting for sealing bottle

5Compressor

6On/Off switch

7Pressure gauge for indicating tire inflation

pressure

8Screw on pressure gauge for reducing tire

inflation pressure

9Connecting hose for connecting compres-

sor and sealant bottle or compressor and

wheel

Connector, cable and connecting hose are

stored in the compressor housing.

Model with pressure gauge integrated

in housing*

3Connector and cable for lighter socket

4Mounting for sealing bottle

5Compressor

6On/Off switch

7Pressure gauge for indicating tire inflation

pressure

8Button for reducing tire inflation pressure

9Connecting hose for connecting compres-

sor and sealant bottle or compressor and

wheel

Connector, cable and connecting hose are

stored on underside of compressor.

Using M Mobility System

To repair a flat tire with the M Mobility System,

proceed as follows:

>Fill sealant into wheel, refer to page226.

>Distribute sealant, refer to page227.

>Produce tire inflation pressure, refer to

page227.

Filling sealant into wheel

Strictly comply with the specified order,

otherwise highly pressurized sealant

could escape.<

1.Shake sealant bottle.

2.Screw hose9 onto connection of sealant

bottle.

3.For model with pressure gauge on hose:

Make sure that screw8 on pressure gauge

is closed.

Page 229 of 266

Mobility

227Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

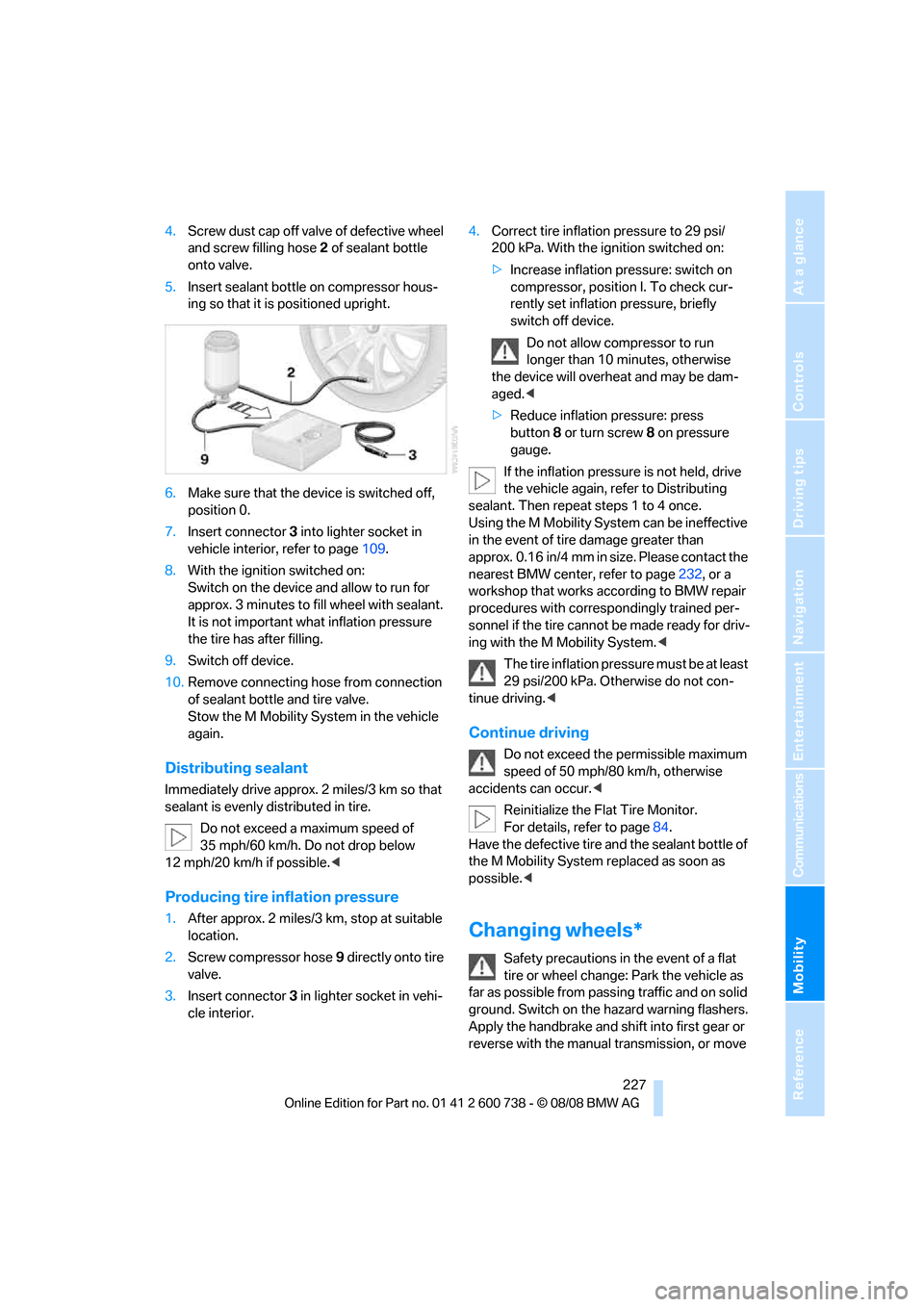

4.Screw dust cap off valve of defective wheel

and screw filling hose2 of sealant bottle

onto valve.

5.Insert sealant bottle on compressor hous-

ing so that it is positioned upright.

6.Make sure that the device is switched off,

position 0.

7.Insert connector3 into lighter socket in

vehicle interior, refer to page109.

8.With the ignition switched on:

Switch on the device and allow to run for

approx. 3 minutes to fill wheel with sealant.

It is not important what inflation pressure

the tire has after filling.

9.Switch off device.

10.Remove connecting hose from connection

of sealant bottle and tire valve.

Stow the M Mobility System in the vehicle

again.

Distributing sealant

Immediately drive approx. 2 miles/3 km so that

sealant is evenly distributed in tire.

Do not exceed a maximum speed of

35 mph/60 km/h. Do not drop below

12 mph/20 km/h if possible.<

Producing tire inflation pressure

1.After approx. 2 miles/3 km, stop at suitable

location.

2.Screw compressor hose9 directly onto tire

valve.

3.Insert connector 3 in lighter socket in vehi-

cle interior.4.Correct tire inflation pressure to 29 psi/

200 kPa. With the ignition switched on:

>Increase inflation pressure: switch on

compressor, position I. To check cur-

rently set inflation pressure, briefly

switch off device.

Do not allow compressor to run

longer than 10 minutes, otherwise

the device will overheat and may be dam-

aged.<

>Reduce inflation pressure: press

button8 or turn screw8 on pressure

gauge.

If the inflation pressure is not held, drive

the vehicle again, refer to Distributing

sealant. Then repeat steps 1 to 4 once.

Using the M Mobility System can be ineffective

in the event of tire damage greater than

approx. 0.16 in/4 mm in size. Please contact the

nearest BMW center, refer to page232, or a

workshop that works according to BMW repair

procedures with correspondingly trained per-

sonnel if the tire cannot be made ready for driv-

ing with the M Mobility System.<

The tire inflation pressure must be at least

29 psi/200 kPa. Otherwise do not con-

tinue driving.<

Continue driving

Do not exceed the permissible maximum

speed of 50 mph/80 km/h, otherwise

accidents can occur.<

Reinitialize the Flat Tire Monitor.

For details, refer to page84.

Have the defective tire and the sealant bottle of

the M Mobility System replaced as soon as

possible.<

Changing wheels*

Safety precautions in the event of a flat

tire or wheel change: Park the vehicle as

far as possible from passing traffic and on solid

ground. Switch on the hazard warning flashers.

Apply the handbrake and shift into first gear or

reverse with the manual transmission, or move

Page 230 of 266

Replacing components

228 the selector lever into a drive position with the

sequential transmission.

Have all vehicle occupants get out of the vehicle

and ensure that they remain outside the imme-

diate area in a safe place, such as behind a

guardrail.

If a warning triangle

* or portable hazard warning

lamp

* is required, set it up on the roadside at an

appropriate distance from the rear of the vehi-

cle. Comply with all safety guidelines and regu-

lations.

Change the wheel only on a level, firm surface

which is not slippery. The vehicle or the jack

could slip to the side if you attempt to raise the

vehicle on a soft or slippery surface such as

snow, ice, tiles, etc.

Position the jack on a firm support surface.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

To avoid serious or fatal injury: never lie under

the vehicle, and never start the engine while it is

supported by the jack.<

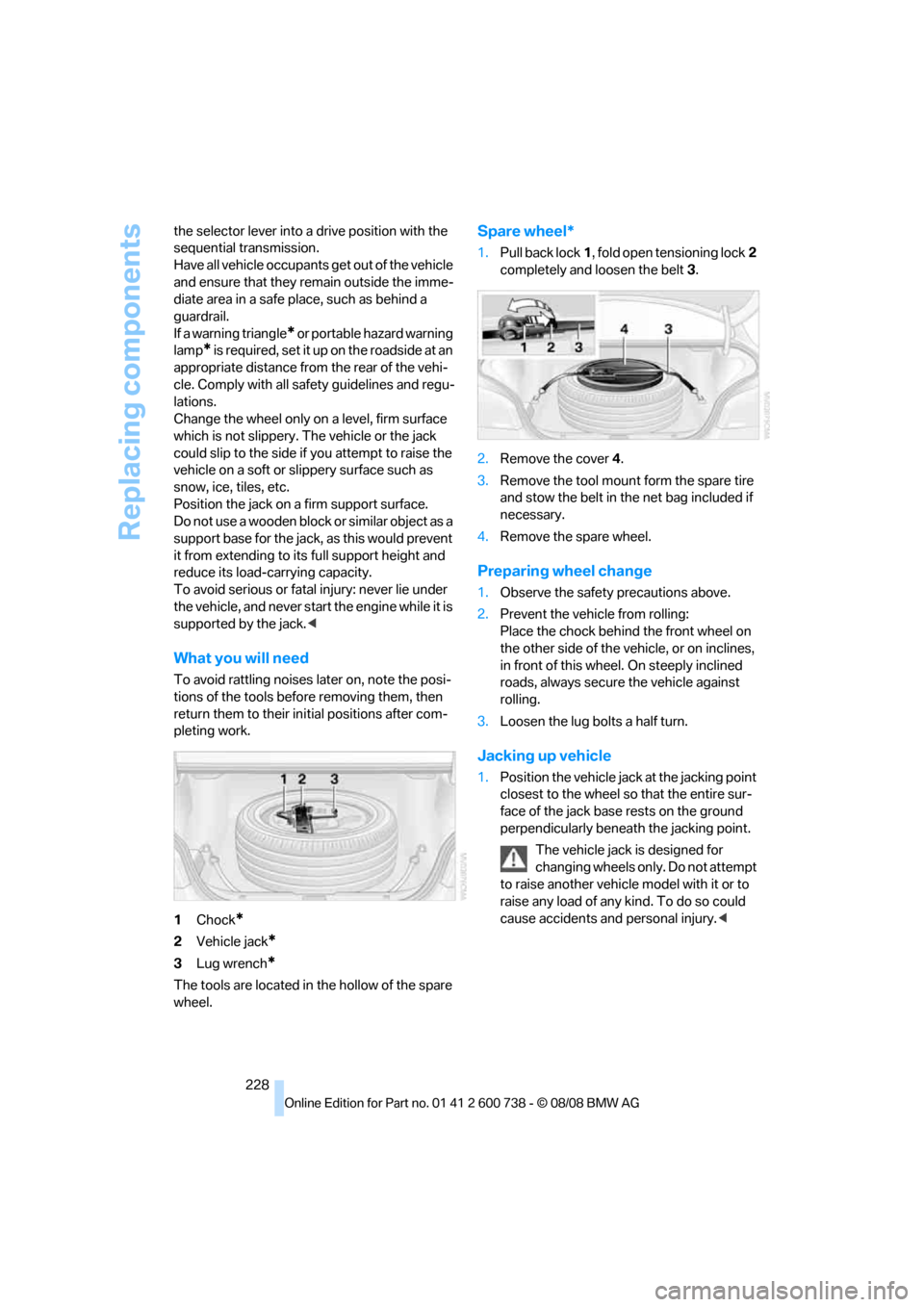

What you will need

To avoid rattling noises later on, note the posi-

tions of the tools before removing them, then

return them to their initial positions after com-

pleting work.

1Chock

*

2Vehicle jack*

3Lug wrench*

The tools are located in the hollow of the spare

wheel.

Spare wheel*

1.Pull back lock1, fold open tensioning lock2

completely and loosen the belt3.

2.Remove the cover4.

3.Remove the tool mount form the spare tire

and stow the belt in the net bag included if

necessary.

4.Remove the spare wheel.

Preparing wheel change

1.Observe the safety precautions above.

2.Prevent the vehicle from rolling:

Place the chock behind the front wheel on

the other side of the vehicle, or on inclines,

in front of this wheel. On steeply inclined

roads, always secure the vehicle against

rolling.

3.Loosen the lug bolts a half turn.

Jacking up vehicle

1.Position the vehicle jack at the jacking point

closest to the wheel so that the entire sur-

face of the jack base rests on the ground

perpendicularly beneath the jacking point.

The vehicle jack is designed for

changing wheels only. Do not attempt

to raise another vehicle model with it or to

raise any load of any kind. To do so could

cause accidents and personal injury.<