tire BMW M6 CONVERTIBLE 2007 E64 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2007, Model line: M6 CONVERTIBLE, Model: BMW M6 CONVERTIBLE 2007 E64Pages: 256, PDF Size: 8.11 MB

Page 200 of 256

Wheels and tires

198

Tire identification marks

Knowledge of the labeling on the side of the tire

makes it easier to identify and choose the right

tires.

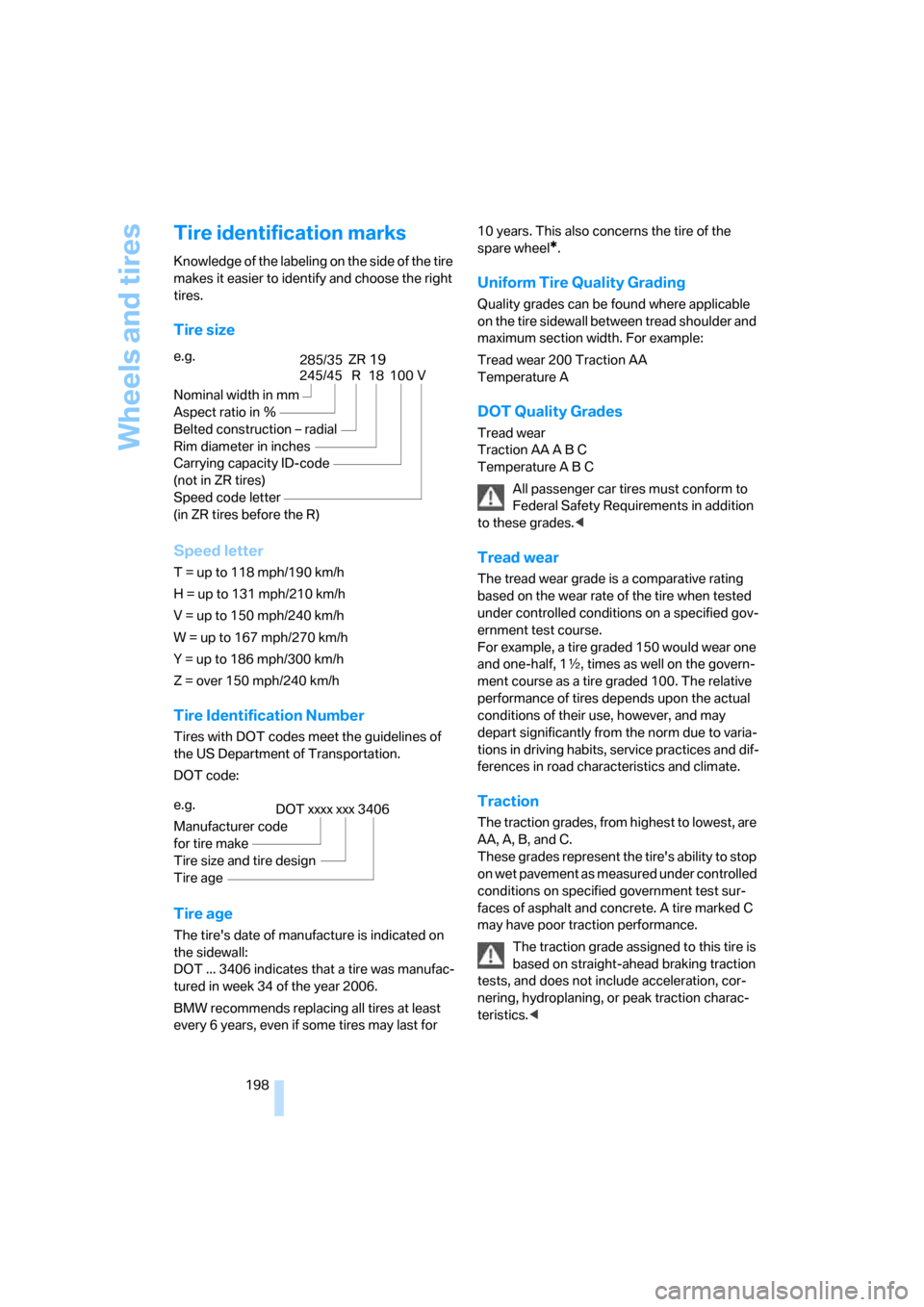

Tire size

Speed letter

T = up to 118 mph/190 km/h

H = up to 131 mph/210 km/h

V = up to 150 mph/240 km/h

W = up to 167 mph/270 km/h

Y = up to 186 mph/300 km/h

Z = over 150 mph/240 km/h

Tire Identification Number

Tires with DOT codes meet the guidelines of

the US Department of Transportation.

DOT code:

Tire age

The tire's date of manufacture is indicated on

the sidewall:

DOT ... 3406 indicates that a tire was manufac-

tured in week 34 of the year 2006.

BMW recommends replacing all tires at least

every 6 years, even if some tires may last for 10 years. This also concerns the tire of the

spare wheel

*.

Uniform Tire Quality Grading

Quality grades can be found where applicable

on the tire sidewall between tread shoulder and

maximum section width. For example:

Tread wear 200 Traction AA

Temperature A

DOT Quality Grades

Tread wear

Traction AA A B C

Temperature A B C

All passenger car tires must conform to

Federal Safety Requirements in addition

to these grades.<

Tread wear

The tread wear grade is a comparative rating

based on the wear rate of the tire when tested

under controlled conditions on a specified gov-

ernment test course.

For example, a tire graded 150 would wear one

and one-half, 1γ, times as well on the govern-

ment course as a tire graded 100. The relative

performance of tires depends upon the actual

conditions of their use, however, and may

depart significantly from the norm due to varia-

tions in driving habits, service practices and dif-

ferences in road characteristics and climate.

Traction

The traction grades, from highest to lowest, are

AA, A, B, and C.

These grades represent the tire's ability to stop

on wet pavement as measured under controlled

conditions on specified government test sur-

faces of asphalt and concrete. A tire marked C

may have poor traction performance.

The traction grade assigned to this tire is

based on straight-ahead braking traction

tests, and does not include acceleration, cor-

nering, hydroplaning, or peak traction charac-

teristics.< e.g.

Nominal width in mm

Aspect ratio in Ξ

Belted construction – radial

Rim diameter in inches

Carrying capacity ID-code

(not in ZR tires)

Speed code letter

(in ZR tires before the R)

245/45 R 18 100 V

285/3519ZR

e.g.

Manufacturer code

for tire make

Tire size and tire design

Tire age

DOT xxxx xxx 3406

Page 201 of 256

Mobility

199Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

Temperature

The temperature grades are A, the highest, B,

and C, representing the tire's resistance to the

generation of heat and its ability to dissipate

heat when tested under controlled conditions

on a specified indoor laboratory test wheel.

Sustained high temperature can cause the

material of the tire to degenerate and reduce

tire life, and excessive temperature can lead to

sudden tire failure. The grade C corresponds to

a level of performance which all passenger car

tires must meet under the Federal Motor Vehi-

cle Safety Standard No. 109. Grades B and A

represent higher levels of performance on the

laboratory test wheel than the minimum

required by law.

The temperature grade for this tire is

established for a tire that is properly

inflated and not overloaded. Excessive speed,

underinflation, or excessive loading, either sep-

arately or in combination, can cause heat

buildup and possible tire failure.<

M+S

Winter and all-season tires.

These have better winter properties than sum-

mer tires.

XL

Indicates specially reinforced tires.

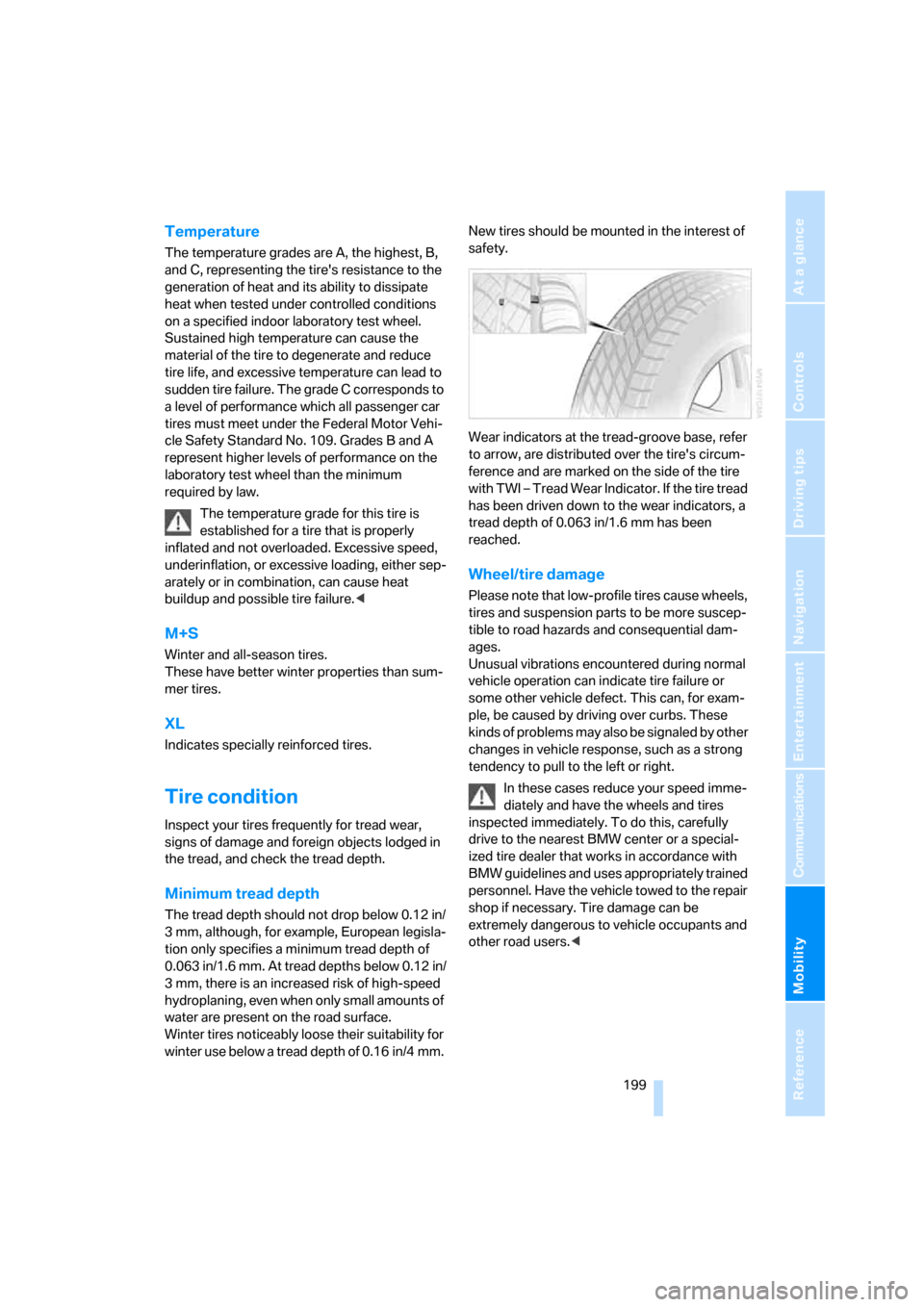

Tire condition

Inspect your tires frequently for tread wear,

signs of damage and foreign objects lodged in

the tread, and check the tread depth.

Minimum tread depth

The tread depth should not drop below 0.12 in/

3 mm, although, for example, European legisla-

tion only specifies a minimum tread depth of

0.063 in/1.6 mm. At tread depths below 0.12 in/

3 mm, there is an increased risk of high-speed

hydroplaning, even when only small amounts of

water are present on the road surface.

Winter tires noticeably loose their suitability for

winter use below a tread depth of 0.16 in/4 mm. New tires should be mounted in the interest of

safety.

Wear indicators at the tread-groove base, refer

to arrow, are distributed over the tire's circum-

ference and are marked on the side of the tire

with TWI – Tread Wear Indicator. If the tire tread

has been driven down to the wear indicators, a

tread depth of 0.063 in/1.6 mm has been

reached.

Wheel/tire damage

Please note that low-profile tires cause wheels,

tires and suspension parts to be more suscep-

tible to road hazards and consequential dam-

ages.

Unusual vibrations encountered during normal

vehicle operation can indicate tire failure or

some other vehicle defect. This can, for exam-

ple, be caused by driving over curbs. These

kinds of problems may also be signaled by other

changes in vehicle response, such as a strong

tendency to pull to the left or right.

In these cases reduce your speed imme-

diately and have the wheels and tires

inspected immediately. To do this, carefully

drive to the nearest BMW center or a special-

ized tire dealer that works in accordance with

BMW guidelines and uses appropriately trained

personnel. Have the vehicle towed to the repair

shop if necessary. Tire damage can be

extremely dangerous to vehicle occupants and

other road users.<

Page 202 of 256

Wheels and tires

200

New wheels and tires

Only have new wheels and tires mounted

by a BMW center or a repair shop that

works in accordance with BMW guidelines and

uses appropriately trained personnel. If this

work is performed inexpertly, there is a danger

of damage and associated safety risks. Make

sure that the new wheels are balanced.<

Retreaded tires

BMW does not recommend the use of

retreaded tires; otherwise, driving safety

may be reduced. Potentially substantial varia-

tions in the design and the age of the carcasses

can result in a reduced service life.<

The right wheels and tires

BMW recommends that you use only

wheel and tire combinations that BMW

has tested and approved for your particular

vehicle. Variations in factors such as manufac-

turing tolerances mean that even wheels and

tires with identical official size ratings could

actually have different dimensions than the

approved units – these differences could lead to

body contact, and with it the risk of severe acci-

dents. When selecting the tires, also ensure

that they have a sufficient load-carrying capac-

ity. If non-approved wheels and tires are used,

BMW cannot evaluate their suitability, and

therefore cannot be held liable for driving

safety.<

You can find out the right wheel-tire combina-

tion from your BMW center.

The right wheel-and-tire combination is

another vital factor in ensuring reliable opera-

tion of various vehicle systems such as ABS

and DSC.

To maintain good handling and vehicle

response, use only tires of a single tread config-

uration from a single manufacturer. After a tire is

damaged, always remember to have the original

wheel and tire combination remounted on the

vehicle as soon as possible.

Wheels with electronics for

TPM Tire Pressure Monitor

When mounting new tires or converting from

summer to winter tires or vice versa, only use

wheels with TPM electronics, otherwise the

Tire Pressure Monitor cannot detect a flat tire,

refer to page86. Your BMW center will be

happy to advise you on this subject.

Recommended tire brands

BMW recommends particular tire brands for

each tire size. You can recognize these from the

clearly visible BMW marking on the tire sidewall.

With proper use, these tires meet the highest

standards for safety and handling characteris-

tics.

Special characteristics of winter tires

BMW recommends winter tires for use in cold

winter driving conditions. Although all-season

M+S tires provide better winter traction than

summer tires, they generally fail to provide the

same levels of cold-weather performance as

winter tires.

Watch speed

Always observe the maximum permissi-

ble speed for the winter tires, otherwise

t i re d a m a g e m a y o c cu r , w h ic h c a n re s u l t i n a c c i-

dents.<

Page 203 of 256

Mobility

201Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

After changing wheels/tires

After changing tires or wheels, the slip detec-

tion of the Sequential Manual Transmission

must become familiar with the changed state.

Reinitialize the system for this purpose:

1.Move the selector lever into the idling

position N on a straight stretch of road at a

speed between 20 mph/30 km/h and

90 mph/150 km/h.

2.Pull both shift paddles for approx. 2 sec-

onds.

If you do not carry out initialization, the system

will automatically learn the changed state grad-

ually during driving. This may be noticeable

from the clutch opening and closing briefly.

Storage

Store wheels and tires in a cool, dry place with

as little exposure to light as possible. Always

protect tires against all contact with oil, grease

and fuels. Do not exceed the maximum tire

inflation pressure indicated on the side wall of

the tire.

Rotating wheels between axles

BMW does not recommend moving the front

wheels to the rear or vice versa, as otherwise

the handling characteristics may be impaired.

Snow chains*

BMW only tests certain fine-link snow chains,

classifies them as road-safe and recommends

them. Consult your BMW center for more infor-

mation.

Use is only permitted in pairs, with winter tires

of the size 245/45 R 18 on the rear wheels.

Observe the manufacturer's instructions when

mounting snow chains. Do not exceed a speed

of 30 mph/50 km/h with the chains mounted.

Make sure that the snow chains are always suf-

ficiently tensioned. Retension in accordance

with the chain manufacturer's specifications if

necessary.Do not initialize the Flat Tire Monitor after

installing snow chains as this could cause

the Flat Tire Monitor to malfunction.

After mounting or removing snow chains, the

slip detection of the Sequential Manual Trans-

mission must become familiar with the altered

state. To do this, reinitialize the system, refer to

After changing wheels/tires.<

Page 214 of 256

Replacing components

212

Rear turn signals

21-watt bulb, PY21W

The illustrations shows the left section of the

luggage compartment.

1.Remove the cover.

2.Unclip the bulb holder and remove.

3.Apply gentle pressure to the bulb while

turning it to the left for removal and replace-

ment.

License plate lamps

5-watt bulb, W5W

1.Push a screwdriver from the left under the

lamp and pry out the lamp toward the right.

2.Turn the bulb holder to the left by 905 and

remove.

3.Remove and replace the bulb.

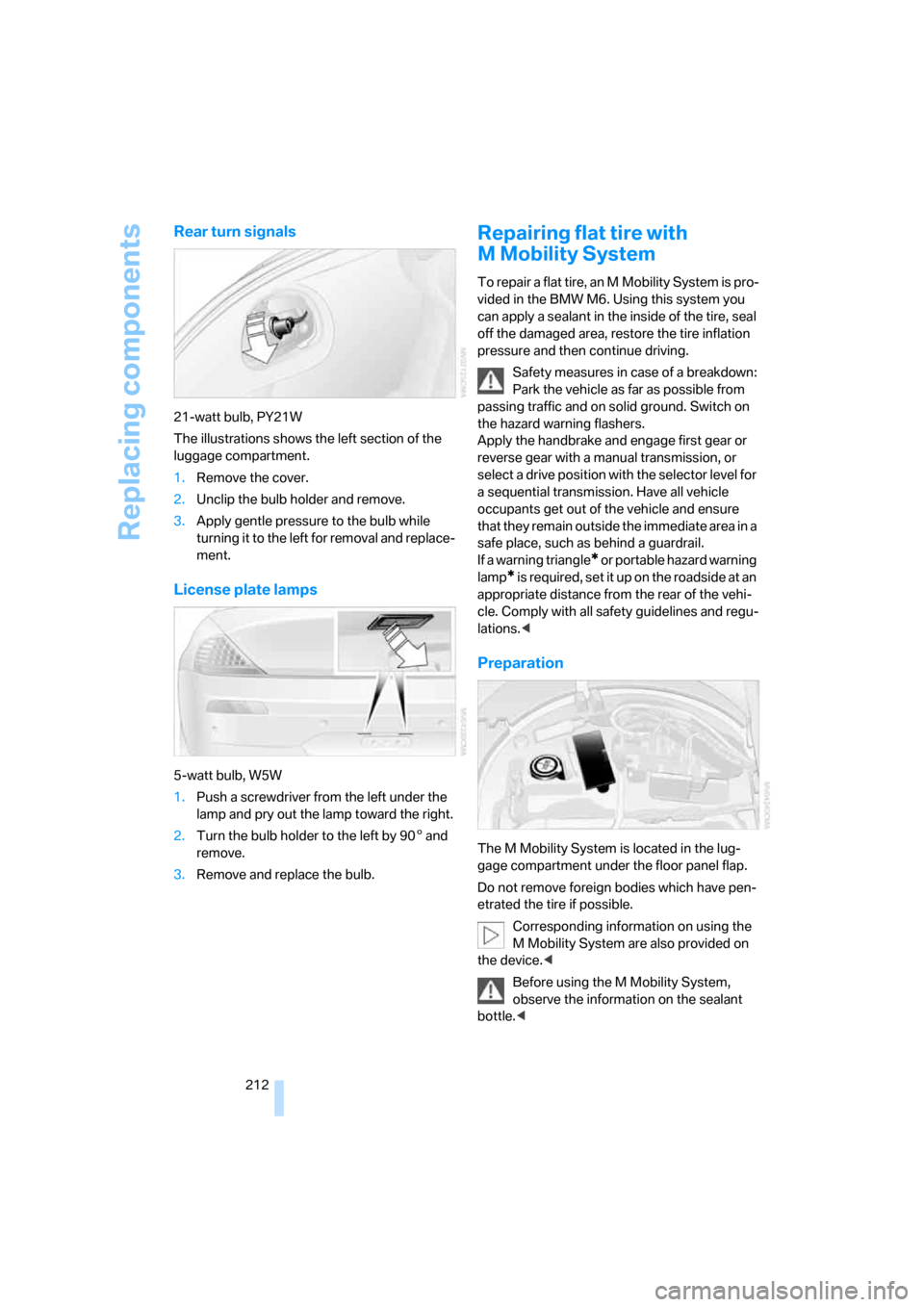

Repairing flat tire with

M Mobility System

To repair a flat tire, an M Mobility System is pro-

vided in the BMW M6. Using this system you

can apply a sealant in the inside of the tire, seal

off the damaged area, restore the tire inflation

pressure and then continue driving.

Safety measures in case of a breakdown:

Park the vehicle as far as possible from

passing traffic and on solid ground. Switch on

the hazard warning flashers.

Apply the handbrake and engage first gear or

reverse gear with a manual transmission, or

select a drive position with the selector level for

a sequential transmission. Have all vehicle

occupants get out of the vehicle and ensure

that they remain outside the immediate area in a

safe place, such as behind a guardrail.

If a warning triangle

* or portable hazard warning

lamp

* is required, set it up on the roadside at an

appropriate distance from the rear of the vehi-

cle. Comply with all safety guidelines and regu-

lations.<

Preparation

The M Mobility System is located in the lug-

gage compartment under the floor panel flap.

Do not remove foreign bodies which have pen-

etrated the tire if possible.

Corresponding information on using the

M Mobility System are also provided on

the device.<

Before using the M Mobility System,

observe the information on the sealant

bottle.<

Page 215 of 256

Mobility

213Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

Pull the sticker for the speed limit off the sealant

bottle and apply it to the steering wheel.

Please observe the best-by date on the

sealant bottle.<

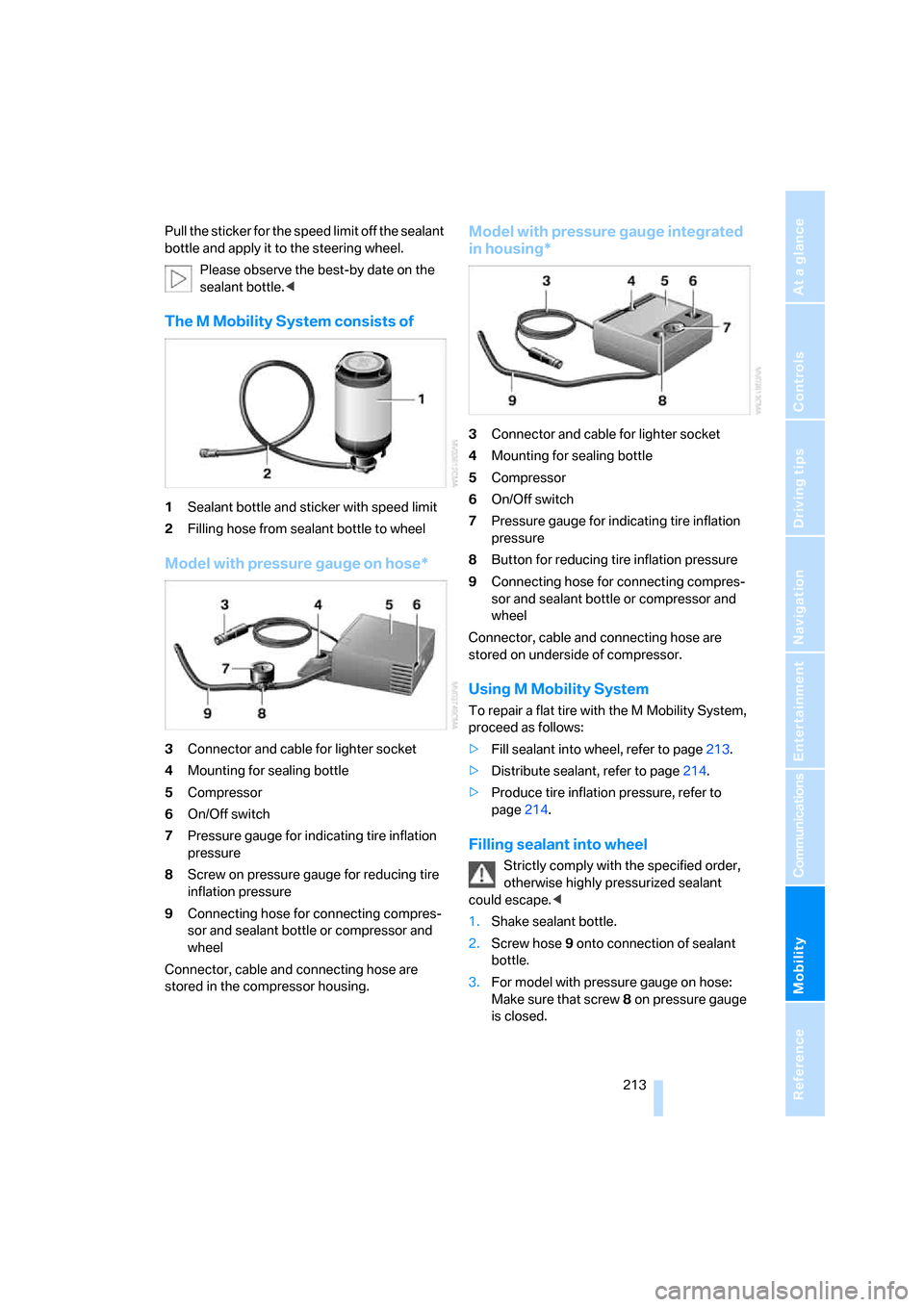

The M Mobility System consists of

1Sealant bottle and sticker with speed limit

2Filling hose from sealant bottle to wheel

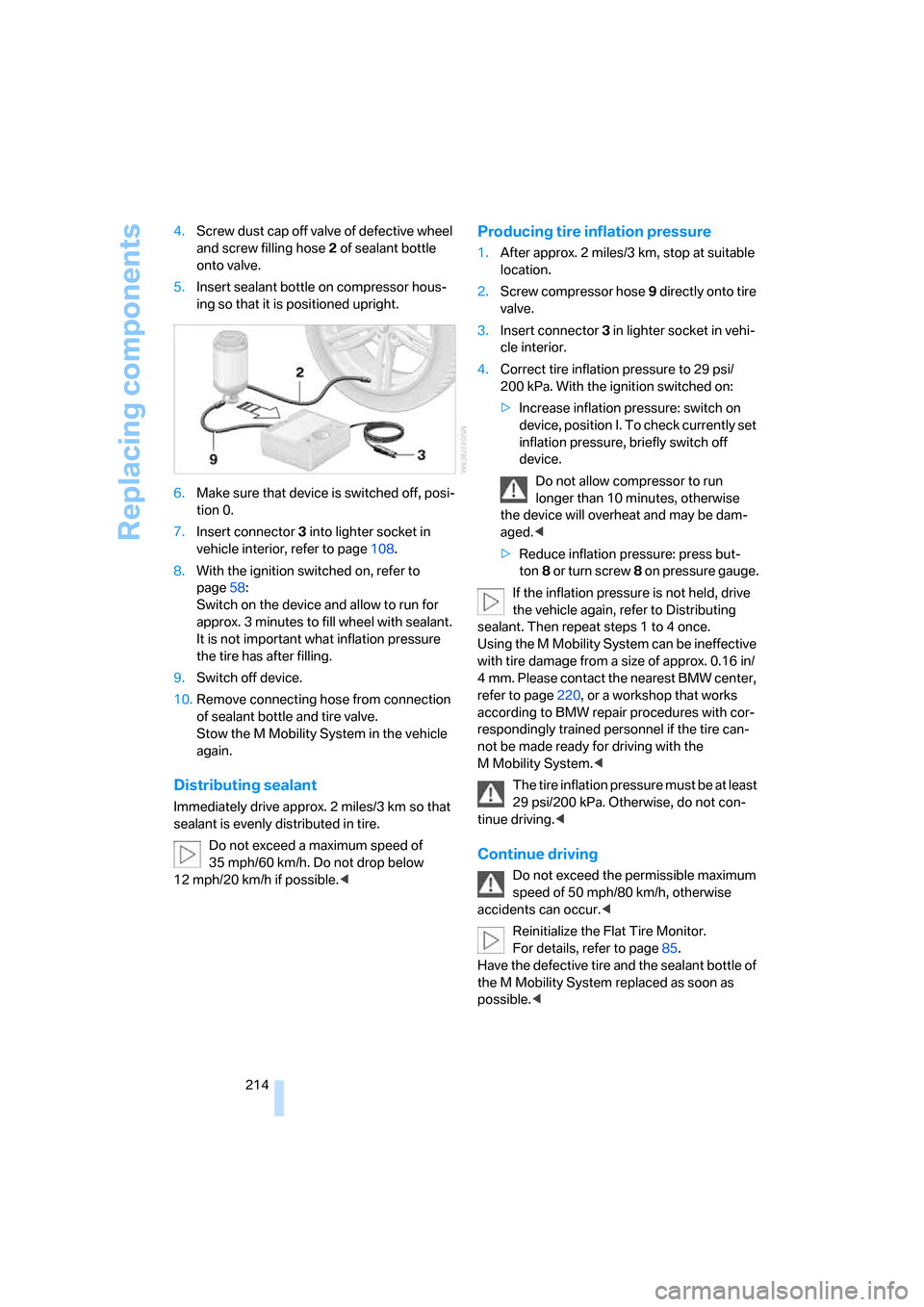

Model with pressure gauge on hose*

3Connector and cable for lighter socket

4Mounting for sealing bottle

5Compressor

6On/Off switch

7Pressure gauge for indicating tire inflation

pressure

8Screw on pressure gauge for reducing tire

inflation pressure

9Connecting hose for connecting compres-

sor and sealant bottle or compressor and

wheel

Connector, cable and connecting hose are

stored in the compressor housing.

Model with pressure gauge integrated

in housing*

3Connector and cable for lighter socket

4Mounting for sealing bottle

5Compressor

6On/Off switch

7Pressure gauge for indicating tire inflation

pressure

8Button for reducing tire inflation pressure

9Connecting hose for connecting compres-

sor and sealant bottle or compressor and

wheel

Connector, cable and connecting hose are

stored on underside of compressor.

Using M Mobility System

To repair a flat tire with the M Mobility System,

proceed as follows:

>Fill sealant into wheel, refer to page213.

>Distribute sealant, refer to page214.

>Produce tire inflation pressure, refer to

page214.

Filling sealant into wheel

Strictly comply with the specified order,

otherwise highly pressurized sealant

could escape.<

1.Shake sealant bottle.

2.Screw hose9 onto connection of sealant

bottle.

3.For model with pressure gauge on hose:

Make sure that screw8 on pressure gauge

is closed.

Page 216 of 256

Replacing components

214 4.Screw dust cap off valve of defective wheel

and screw filling hose2 of sealant bottle

onto valve.

5.Insert sealant bottle on compressor hous-

ing so that it is positioned upright.

6.Make sure that device is switched off, posi-

tion 0.

7.Insert connector3 into lighter socket in

vehicle interior, refer to page108.

8.With the ignition switched on, refer to

page58:

Switch on the device and allow to run for

approx. 3 minutes to fill wheel with sealant.

It is not important what inflation pressure

the tire has after filling.

9.Switch off device.

10.Remove connecting hose from connection

of sealant bottle and tire valve.

Stow the M Mobility System in the vehicle

again.

Distributing sealant

Immediately drive approx. 2 miles/3 km so that

sealant is evenly distributed in tire.

Do not exceed a maximum speed of

35 mph/60 km/h. Do not drop below

12 mph/20 km/h if possible.<

Producing tire inflation pressure

1.After approx. 2 miles/3 km, stop at suitable

location.

2.Screw compressor hose9 directly onto tire

valve.

3.Insert connector 3 in lighter socket in vehi-

cle interior.

4.Correct tire inflation pressure to 29 psi/

200 kPa. With the ignition switched on:

>Increase inflation pressure: switch on

device, position I. To check currently set

inflation pressure, briefly switch off

device.

Do not allow compressor to run

longer than 10 minutes, otherwise

the device will overheat and may be dam-

aged.<

>Reduce inflation pressure: press but-

ton8 or turn s crew8 on pressure gauge.

If the inflation pressure is not held, drive

the vehicle again, refer to Distributing

sealant. Then repeat steps 1 to 4 once.

Using the M Mobility System can be ineffective

with tire damage from a size of approx. 0.16 in/

4 mm. Please contact the nearest BMW center,

refer to page220, or a workshop that works

according to BMW repair procedures with cor-

respondingly trained personnel if the tire can-

not be made ready for driving with the

M Mobility System.<

The tire inflation pressure must be at least

29 psi/200 kPa. Otherwise, do not con-

tinue driving.<

Continue driving

Do not exceed the permissible maximum

speed of 50 mph/80 km/h, otherwise

accidents can occur.<

Reinitialize the Flat Tire Monitor.

For details, refer to page85.

Have the defective tire and the sealant bottle of

the M Mobility System replaced as soon as

possible.<

Page 217 of 256

Mobility

215Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

Changing wheels*

Safety precautions in the event of a flat

tire or wheel change: Park the vehicle as

far as possible from passing traffic and on solid

ground. Switch on the hazard warning flashers.

Apply the handbrake and engage first gear or

reverse gear with a manual transmission, or

select a drive position with the selector level for

a sequential transmission.

Have all vehicle occupants get out of the vehicle

and ensure that they remain outside the imme-

diate area in a safe place, such as behind a

guardrail.

If a warning triangle

* or portable hazard warning

lamp

* is r e q u ir e d , s e t i t up o n t h e ro a d s id e a t a n

appropriate distance from the rear of the vehi-

cle. Comply with all safety guidelines and regu-

lations.

Change the wheel only on a level, firm surface

which is not slippery. The vehicle or the jack

could slip to the side if you attempt to raise the

vehicle on a soft or slippery surface such as

snow, ice, tiles, etc.

Position the jack on a firm support surface.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

To avoid serious or fatal injury: never lie under

the vehicle, and never start the engine while it is

supported by the jack.<

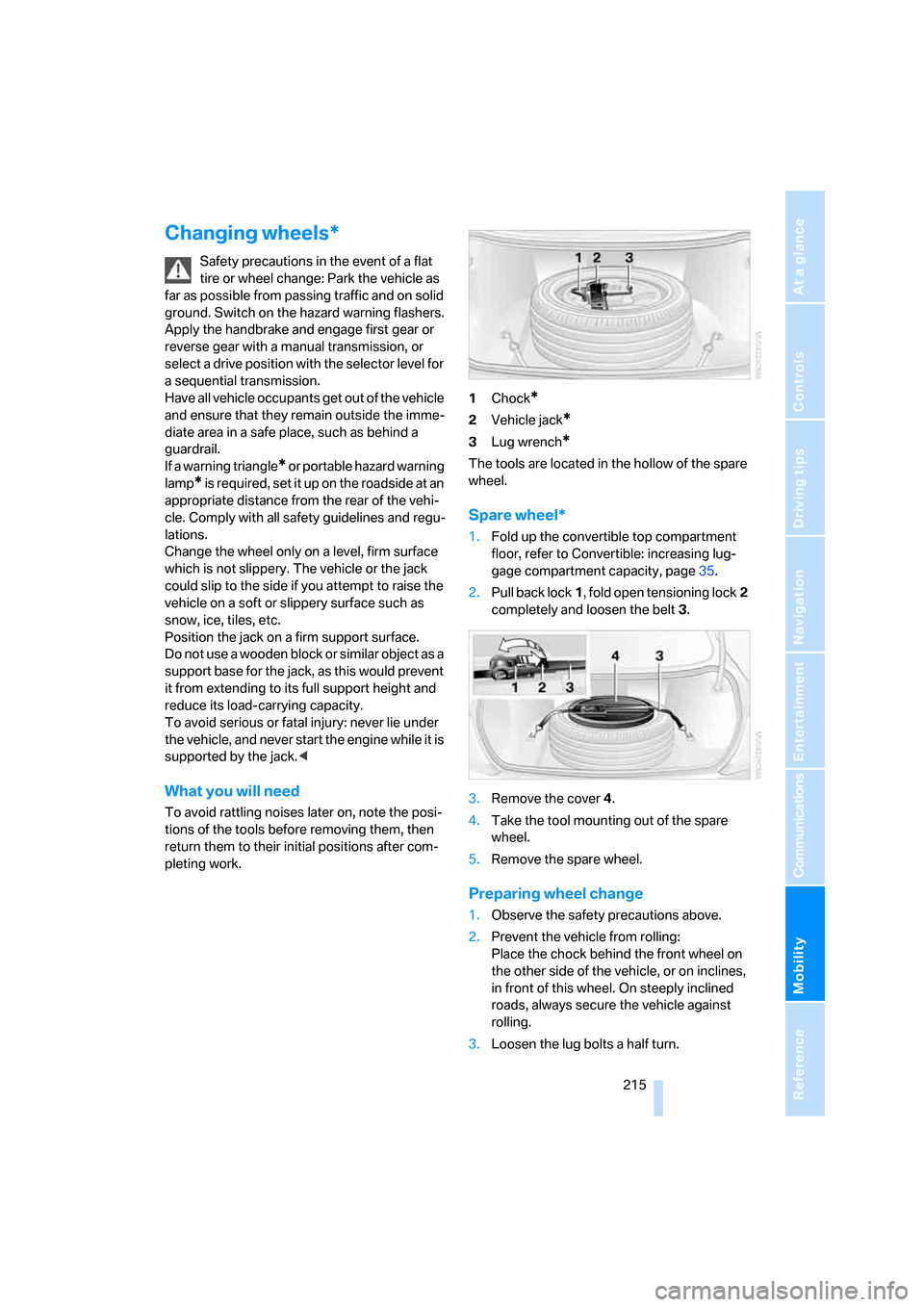

What you will need

To avoid rattling noises later on, note the posi-

tions of the tools before removing them, then

return them to their initial positions after com-

pleting work.1Chock

*

2Vehicle jack*

3Lug wrench*

The tools are located in the hollow of the spare

wheel.

Spare wheel*

1.Fold up the convertible top compartment

floor, refer to Convertible: increasing lug-

gage compartment capacity, page35.

2.Pull back lock1, fold open tensioning lock2

completely and loosen the belt3.

3.Remove the cover4.

4.Take the tool mounting out of the spare

wheel.

5.Remove the spare wheel.

Preparing wheel change

1.Observe the safety precautions above.

2.Prevent the vehicle from rolling:

Place the chock behind the front wheel on

the other side of the vehicle, or on inclines,

in front of this wheel. On steeply inclined

roads, always secure the vehicle against

rolling.

3.Loosen the lug bolts a half turn.

Page 218 of 256

Replacing components

216

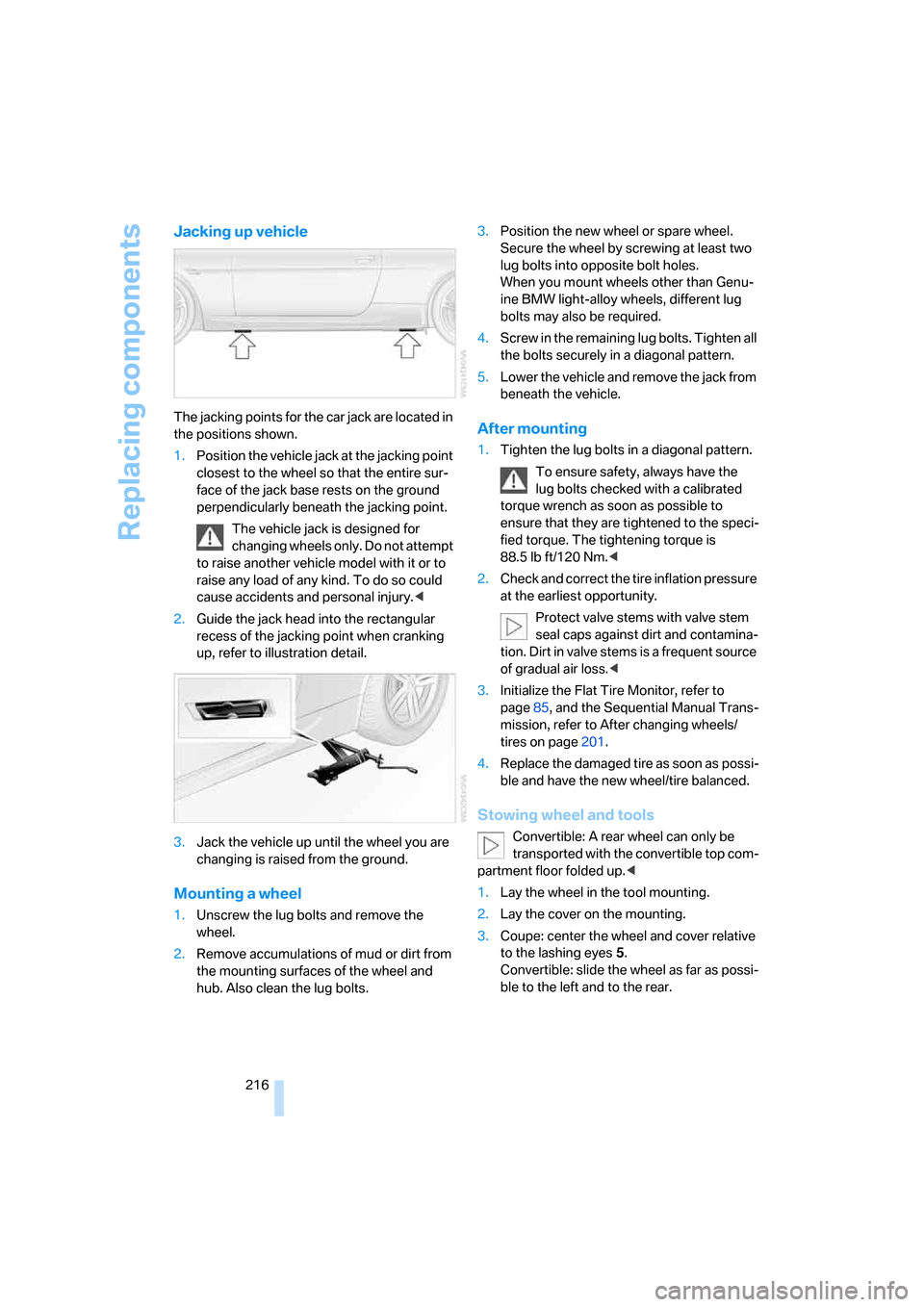

Jacking up vehicle

The jacking points for the car jack are located in

the positions shown.

1.Position the vehicle jack at the jacking point

closest to the wheel so that the entire sur-

face of the jack base rests on the ground

perpendicularly beneath the jacking point.

The vehicle jack is designed for

changing wheels only. Do not attempt

to raise another vehicle model with it or to

raise any load of any kind. To do so could

cause accidents and personal injury.<

2.Guide the jack head into the rectangular

recess of the jacking point when cranking

up, refer to illustration detail.

3.Jack the vehicle up until the wheel you are

changing is raised from the ground.

Mounting a wheel

1.Unscrew the lug bolts and remove the

wheel.

2.Remove accumulations of mud or dirt from

the mounting surfaces of the wheel and

hub. Also clean the lug bolts.3.Position the new wheel or spare wheel.

Secure the wheel by screwing at least two

lug bolts into opposite bolt holes.

When you mount wheels other than Genu-

ine BMW light-alloy wheels, different lug

bolts may also be required.

4.Screw in the remaining lug bolts. Tighten all

the bolts securely in a diagonal pattern.

5.Lower the vehicle and remove the jack from

beneath the vehicle.

After mounting

1.Tighten the lug bolts in a diagonal pattern.

To ensure safety, always have the

lug bolts checked with a calibrated

torque wrench as soon as possible to

ensure that they are tightened to the speci-

fied torque. The tightening torque is

88.5 lb ft/120 Nm.<

2.Check and correct the tire inflation pressure

at the earliest opportunity.

Protect valve stems with valve stem

seal caps against dirt and contamina-

tion. Dirt in valve stems is a frequent source

of gradual air loss.<

3.Initialize the Flat Tire Monitor, refer to

page85, and the Sequential Manual Trans-

mission, refer to After changing wheels/

tires on page201.

4.Replace the damaged tire as soon as possi-

ble and have the new wheel/tire balanced.

Stowing wheel and tools

Convertible: A rear wheel can only be

transported with the convertible top com-

partment floor folded up.<

1.Lay the wheel in the tool mounting.

2.Lay the cover on the mounting.

3.Coupe: center the wheel and cover relative

to the lashing eyes5.

Convertible: slide the wheel as far as possi-

ble to the left and to the rear.

Page 219 of 256

Mobility

217Reference

At a glance

Controls

Driving tips

Communications

Navigation

Entertainment

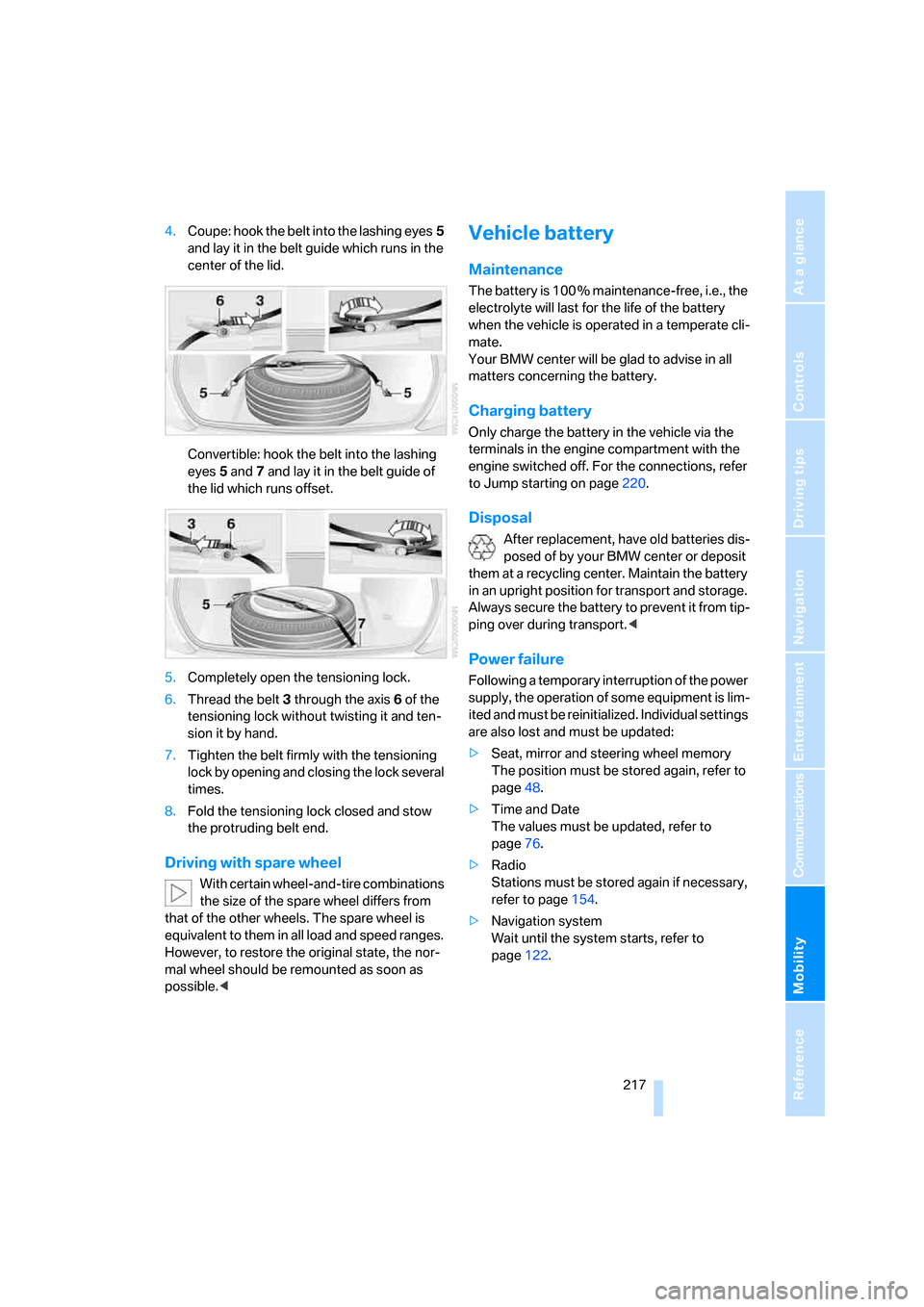

4.Coupe: hook the belt into the lashing eyes5

and lay it in the belt guide which runs in the

center of the lid.

Convertible: hook the belt into the lashing

eyes5 and7 and lay it in the belt guide of

the lid which runs offset.

5.Completely open the tensioning lock.

6.Thread the belt3 through the axis6 of the

tensioning lock without twisting it and ten-

sion it by hand.

7.Tighten the belt firmly with the tensioning

lock by opening and closing the lock several

times.

8.Fold the tensioning lock closed and stow

the protruding belt end.

Driving with spare wheel

With certain wheel-and-tire combinations

the size of the spare wheel differs from

that of the other wheels. The spare wheel is

equivalent to them in all load and speed ranges.

However, to restore the original state, the nor-

mal wheel should be remounted as soon as

possible.<

Vehicle battery

Maintenance

The battery is 100 % maintenance-free, i.e., the

electrolyte will last for the life of the battery

when the vehicle is operated in a temperate cli-

mate.

Your BMW center will be glad to advise in all

matters concerning the battery.

Charging battery

Only charge the battery in the vehicle via the

terminals in the engine compartment with the

engine switched off. For the connections, refer

to Jump starting on page220.

Disposal

After replacement, have old batteries dis-

posed of by your BMW center or deposit

them at a recycling center. Maintain the battery

in an upright position for transport and storage.

Always secure the battery to prevent it from tip-

ping over during transport.<

Power failure

Following a temporary interruption of the power

supply, the operation of some equipment is lim-

ited and must be reinitialized. Individual settings

are also lost and must be updated:

>Seat, mirror and steering wheel memory

The position must be stored again, refer to

page48.

>Time and Date

The values must be updated, refer to

page76.

>Radio

Stations must be stored again if necessary,

refer to page154.

>Navigation system

Wait until the system starts, refer to

page122.