torque BMW MOTORRAD K 1200 R 2006 Rider's Manual (in English)

[x] Cancel search | Manufacturer: BMW MOTORRAD, Model Year: 2006, Model line: K 1200 R, Model: BMW MOTORRAD K 1200 R 2006Pages: 160, PDF Size: 1.79 MB

Page 8 of 160

OverviewChapter 2 of this Rider's

Manual will provide you with

an initial overview of your

motorcycle. All maintenance

and servicing work on the

motorcycle is documented in

Chapter 10. This record of

the maintenance work you

have had performed on your

motorcycle is a precondition

for generous treatment of

goodwill claims.

When the time comes to sell

your BMW, please remem-

ber to hand over this Rider's

Manual; it is an important part

of the motorcycle.Abbreviations and

symbols

Indicates warnings that

you must comply with for

reasons of your safety and the

safety of others, and to pro- tect your motorcycle against

damage.

Specific instructions on

how to operate, control,

adjust or look after items of

equipment on the motorcycle.

Indicates the end of an

item of information.

Instruction.

Result of an activity.

Reference to a page

with more detailed in-

formation.

Indicates the end of

a passage relating to

specific accessories or

items of equipment.

Tightening torque. Item of technical data.

OE Optional extra Your motorcycle was

assembled complete

with all the BMW

optional extras you

ordered.

OA Optional accessory You can obtain option-

al accessories through

your authorised BMW

Motorrad dealer; op-

tional accessories

have to be retrofitted

to the motorcycle.

EWS Electronic immobiliser

(Elektronische Weg-

fahrsicherung).

16zGeneral instructions

Page 88 of 160

General instructionsThe 'Maintenance' chapter

describes work involving the

replacement of wear parts

that can be performed with

minimum effort.

Special tightening torques are

listed as applicable.

If you are interested in inform-

ation on more extensive work,

we recommend the repair

manual on CD-ROM which

applies to your particular mo-

torcycle. You can obtain a

copy from your authorised

BMW Motorrad dealer.

Some of the work calls for

special tools and a thorough

knowledge of motorcycles.

If you are in doubt consult a

specialist workshop, prefer-

ably your authorised BMW

Motorrad dealer.

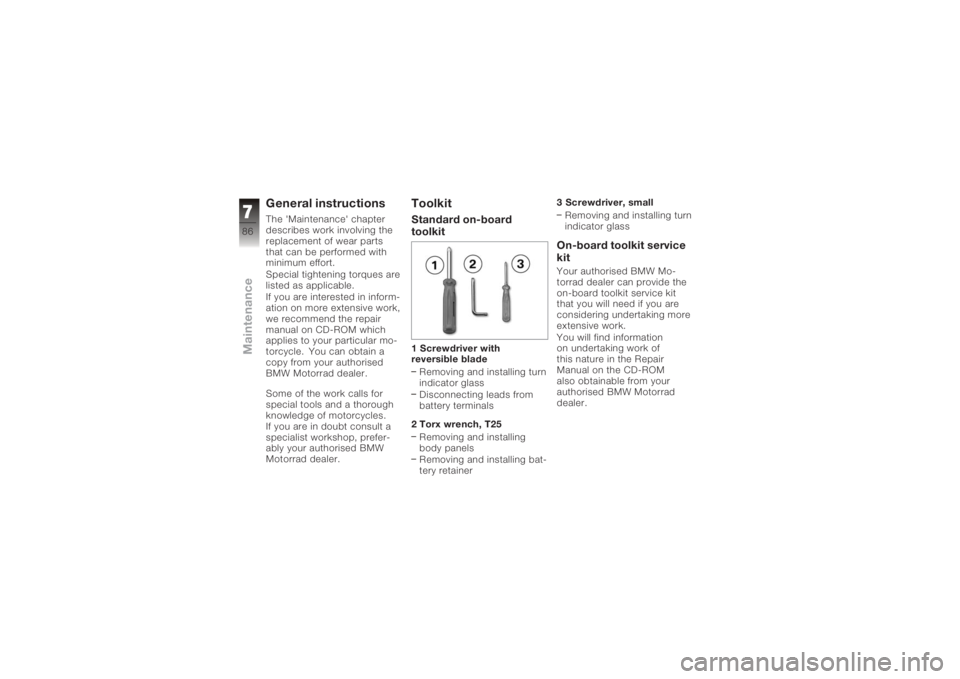

ToolkitStandard on-board

toolkit1 Screwdriver with

reversible bladeRemoving and installing turn

indicator glass

Disconnecting leads from

battery terminals

2 Torx wrench, T25 Removing and installing

body panels

Removing and installing bat-

tery retainer 3 Screwdriver, small

Removing and installing turn

indicator glass

On-board toolkit service

kitYour authorised BMW Mo-

torrad dealer can provide the

on-board toolkit service kit

that you will need if you are

considering undertaking more

extensive work.

You will find information

on undertaking work of

this nature in the Repair

Manual on the CD-ROM

also obtainable from your

authorised BMW Motorrad

dealer.

786zMaintenance

Page 100 of 160

with OE BMW Motorrad

Integral ABS:The left axle clamping

screw locates the

threaded bush in the front

suspension. If the threaded

bush is not correctly aligned

the gap between the ABS

sensor ring and the ABS

sensor will not be correct and

this can cause the ABS to

malfunction or allow the ABS

sensor to be damaged.

In order to ensure that the

threaded bush remains cor-

rectly aligned, do not slacken

or remove the left axle camp-

ing screw.

Remove right-hand axle

clamping screw 6.

Remove quick-release

axle 7, holding the wheel as

you do so. Lower the front wheel to the

ground between the front

forks.

Roll the front wheel forward

to remove.

with OE BMW Motorrad

Integral ABS:

Take care not to damage

the ABS sensor when

rolling out the front wheel.

Note the ABS sensor when

rolling out the front wheel.

Roll the front wheel forward

to remove.

Installing front wheel

ABS malfunctions on ac-

count of incorrect speed

signal.

Segmentation differs between

individual types of sensor

ring; it is very important to en-

sure that the correct sensor

ring is installed. Install only

the sensor ring that matches the motorcycle's construction

status.

Threaded fasteners not

tightened to the spe-

cified torque can work loose

or their threads can suffer

damage.

Always have the security of

the fasteners checked by a

specialist workshop, prefer-

ably an authorised BMW Mo-

torrad dealer.

The front wheel must be

installed right way round

to rotate in the correct direc-

tion.

Note the direction-of-rotation

arrows on the tyre or the

wheel rim.

Roll the front wheel into

position between the front

forks.

798zMaintenance

Page 101 of 160

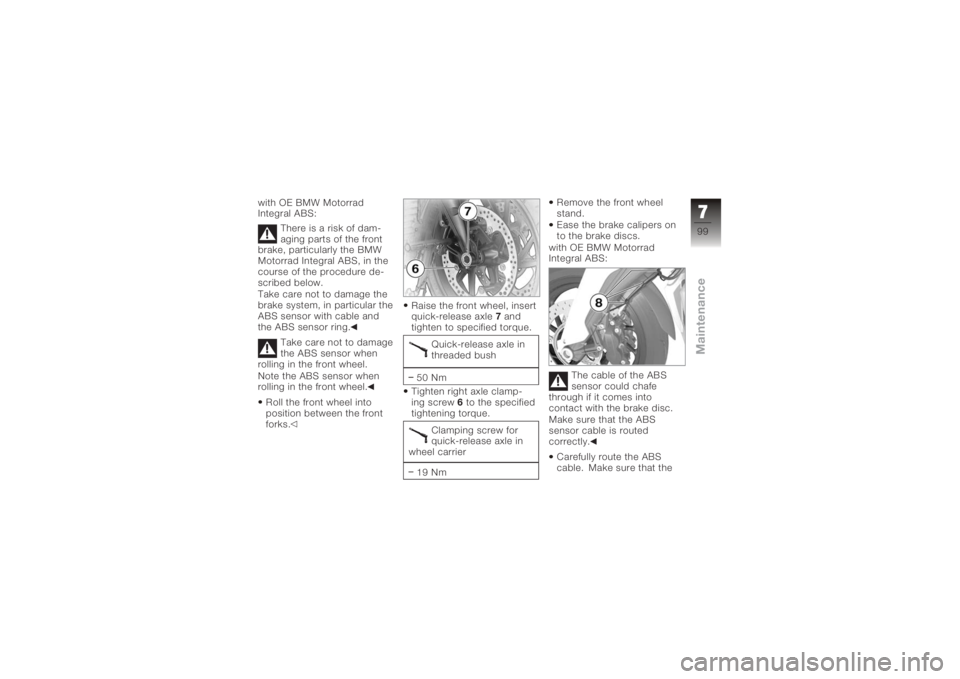

with OE BMW Motorrad

Integral ABS:There is a risk of dam-

aging parts of the front

brake, particularly the BMW

Motorrad Integral ABS, in the

course of the procedure de-

scribed below.

Take care not to damage the

brake system, in particular the

ABS sensor with cable and

the ABS sensor ring.

Take care not to damage

the ABS sensor when

rolling in the front wheel.

Note the ABS sensor when

rolling in the front wheel.

Roll the front wheel into

position between the front

forks. Raise the front wheel, insert

quick-release axle

7and

tighten to specified torque.

Quick-release axle in

threaded bush

50 Nm

Tighten right axle clamp-

ing screw 6to the specified

tightening torque.

Clamping screw for

quick-release axle in

wheel carrier

19 Nm Remove the front wheel

stand.

Ease the brake calipers on

to the brake discs.

with OE BMW Motorrad

Integral ABS:

The cable of the ABS

sensor could chafe

through if it comes into

contact with the brake disc.

Make sure that the ABS

sensor cable is routed

correctly.

Carefully route the ABS

cable. Make sure that the

799zMaintenance

Page 104 of 160

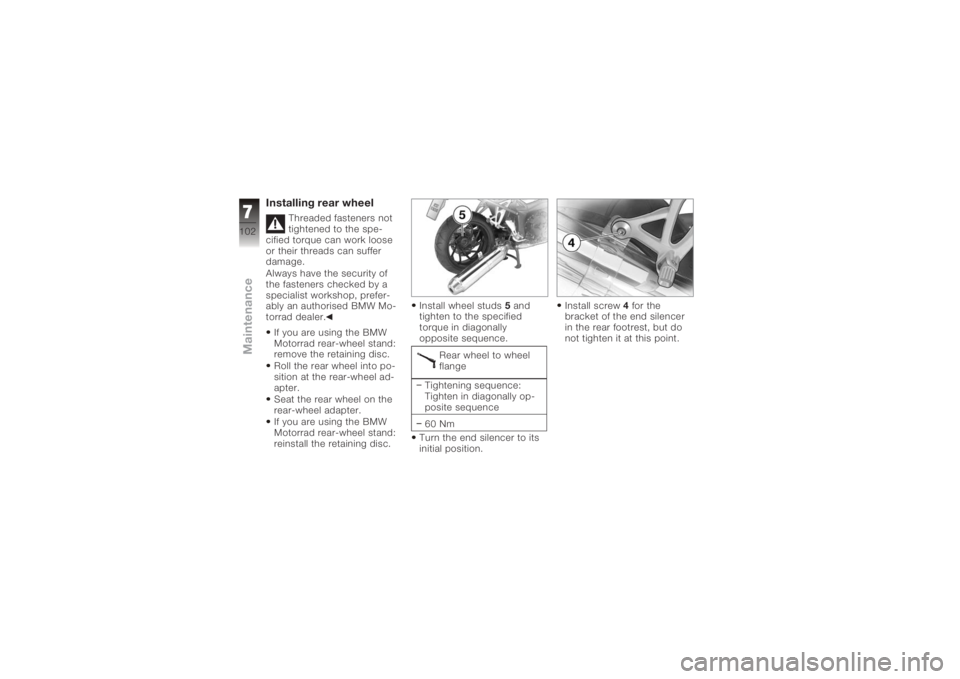

Installing rear wheel

Threaded fasteners not

tightened to the spe-

cified torque can work loose

or their threads can suffer

damage.

Always have the security of

the fasteners checked by a

specialist workshop, prefer-

ably an authorised BMW Mo-

torrad dealer.

If you are using the BMW

Motorrad rear-wheel stand:

remove the retaining disc.

Roll the rear wheel into po-

sition at the rear-wheel ad-

apter.

Seat the rear wheel on the

rear-wheel adapter.

If you are using the BMW

Motorrad rear-wheel stand:

reinstall the retaining disc. Install wheel studs

5and

tighten to the specified

torque in diagonally

opposite sequence.

Rear wheel to wheel

flange

Tightening sequence:

Tighten in diagonally op-

posite sequence

60 Nm

Turn the end silencer to its

initial position. Install screw

4for the

bracket of the end silencer

in the rear footrest, but do

not tighten it at this point.

7102zMaintenance

Page 105 of 160

Align clamp3on the end

silencer with mark A(arrow)

on oxygen sensor B.

Tighten clamp 3on the end

silencer to the specified

tightening torque.

Silencer to manifold

35 Nm If the gap between the

rear wheel and the end

silencer is too small, the rear

wheel can overheat.

The clearance between the

rear wheel and the end silen-

cer must be at least 10 mm.

Tighten screw 4for the

bracket of the end silencer

in the rear footrest to the

specified torque.

Silencer to rear

footrest, right

16 Nm Push silencer cover

2with

guides Ainto retainers B.

Install screw 1in silencer

cover 2.

Remove the auxiliary stand,

if installed.

7103zMaintenance

Page 133 of 160

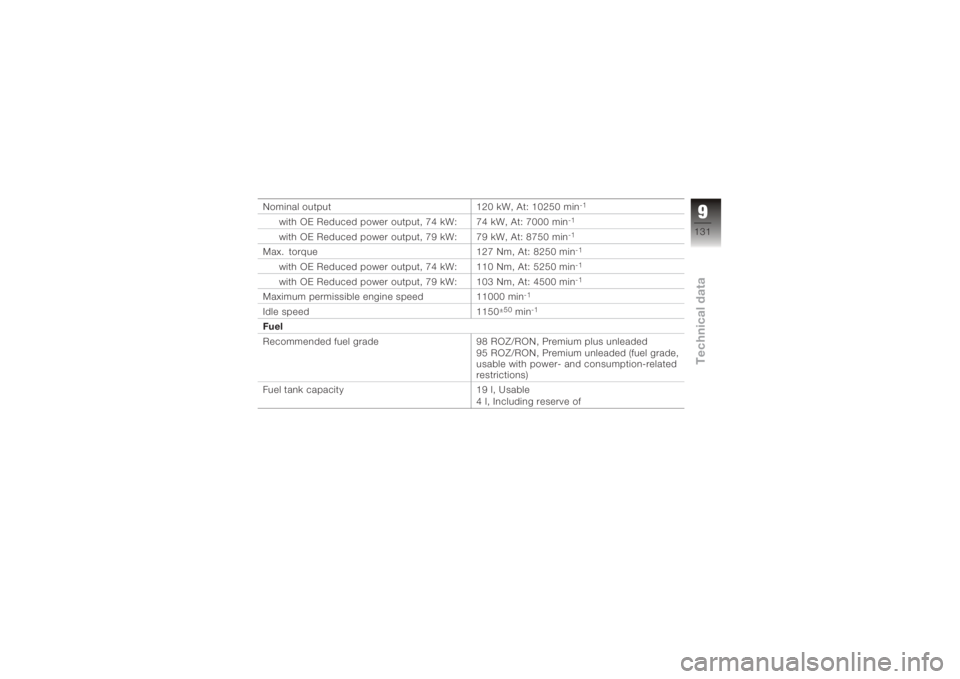

Nominal output120 kW, At: 10250 min

-1

with OE Reduced power output, 74 kW: 74 kW, At: 7000 min

-1

with OE Reduced power output, 79 kW: 79 kW, At: 8750 min

-1

Max. torque127 Nm, At: 8250 min

-1

with OE Reduced power output, 74 kW: 110 Nm, At: 5250 min

-1

with OE Reduced power output, 79 kW: 103 Nm, At: 4500 min

-1

Maximum permissible engine speed11000 min

-1

Idle speed1150

±50

min

-1

Fuel

Recommended fuel grade 98 ROZ/RON, Premium plus unleaded

95 ROZ/RON, Premium unleaded (fuel grade,

usable with power- and consumption-related

restrictions)

Fuel tank capacity 19 l, Usable 4 l, Including reserve of

9131zTechnical data

Page 157 of 160

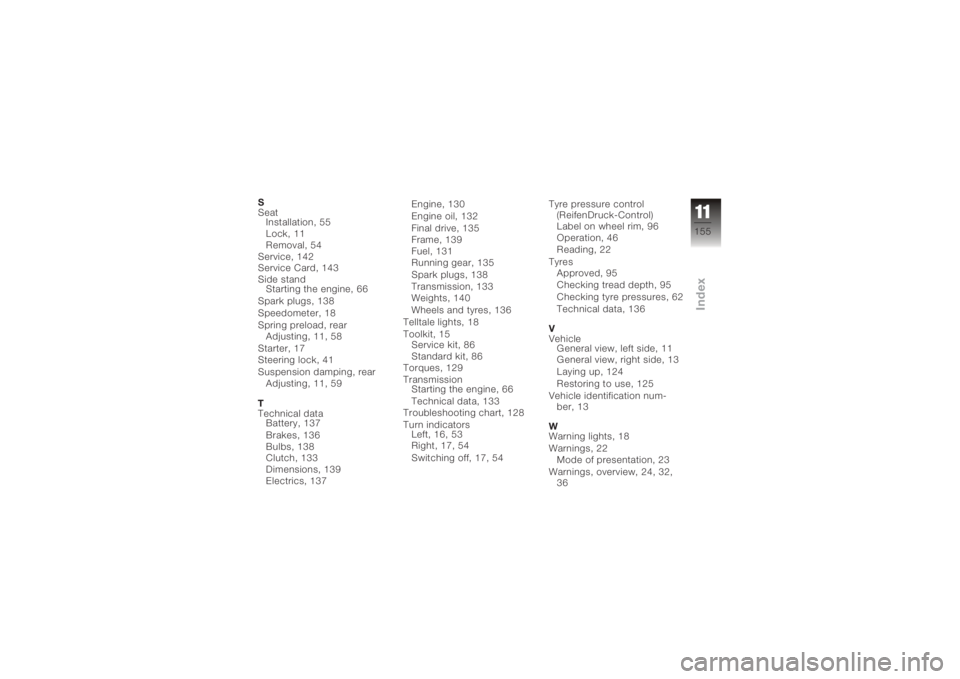

S

SeatInstallation, 55

Lock, 11

Removal, 54

Service, 142

Service Card, 143

Side stand Starting the engine, 66

Spark plugs, 138

Speedometer, 18

Spring preload, rear Adjusting, 11, 58

Starter, 17

Steering lock, 41

Suspension damping, rear Adjusting, 11, 59

T

Technical data Battery, 137

Brakes, 136

Bulbs, 138

Clutch, 133

Dimensions, 139

Electrics, 137 Engine, 130

Engine oil, 132

Final drive, 135

Frame, 139

Fuel, 131

Running gear, 135

Spark plugs, 138

Transmission, 133

Weights, 140

Wheels and tyres, 136

Telltale lights, 18

Toolkit, 15 Service kit, 86

Standard kit, 86

Torques, 129

Transmission Starting the engine, 66

Technical data, 133

Troubleshooting chart, 128

Turn indicators Left, 16, 53

Right, 17, 54

Switching off, 17, 54 Tyre pressure control

(ReifenDruck-Control)

Label on wheel rim, 96

Operation, 46

Reading, 22

Tyres Approved, 95

Checking tread depth, 95

Checking tyre pressures, 62

Technical data, 136

V

Vehicle General view, left side, 11

General view, right side, 13

Laying up, 124

Restoring to use, 125

Vehicle identification num- ber, 13

W

Warning lights, 18

Warnings, 22 Mode of presentation, 23

Warnings, overview, 24, 32, 36

11155zIndex