Service BMW X3 2015 F25 Owner's Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2015, Model line: X3, Model: BMW X3 2015 F25Pages: 257, PDF Size: 5.26 MB

Page 208 of 257

StorageStore wheels and tires in a cool, dry place with

as little exposure to light as possible.

Always protect tires against all contact with oil,

grease and fuels.

Do not exceed the maximum tire inflation pres‐

sure indicated on the side wall of the tire.

Run-flat tires Label

RSC label on the tire sidewall.

The wheels consist of tires that are self-sup‐

porting, to a limited degree, and possibly spe‐

cial rims.

The support of the sidewall allows the tire to

remain drivable to a restricted degree in the

event of a tire inflation pressure loss.

Follow the instructions for continued driving

with a flat tire.

Changing run-flat tires

For your own safety, only use run-flat tires. No

spare tire is available in the case of a flat tire.

Your service center will be glad to advise you.

Mobility System

The concept With the Mobility System, minor tire damagecan be sealed quickly to enable continued

travel. To accomplish this, sealant is pumped

into the tires, which seals the damage from the inside.

The compressor can be used to check the tire inflation pressure.

Hints▷Follow the instructions on using the Mobi‐

lity System found on the compressor and

sealant container.▷Use of the Mobility System may be ineffec‐

tive if the tire puncture measures approx.

1/8 in/4 mm or more.▷Contact the nearest service center if the

tire cannot be made drivable.▷If possible, do not remove foreign bodies

that have penetrated the tire.▷Pull the speed limit sticker off the sealant

container and apply it to the steering

wheel.▷The use of a sealant can damage the TPM

wheel electronics. In this case, have the

electronics checked at the next opportu‐

nity and have them replaced if needed.

Enclosed areas

Do not let the engine run in enclosed

areas, since breathing in exhaust fumes may

lead to loss of consciousness and death. The

exhaust gases contain carbon monoxide, an

odorless and colorless but highly toxic gas.◀

Storage The Mobility System is located under the

cargo floor panel.

Seite 204MobilityWheels and tires204

Online Edition for Part no. 01 40 2 960 386 - II/15

Page 210 of 257

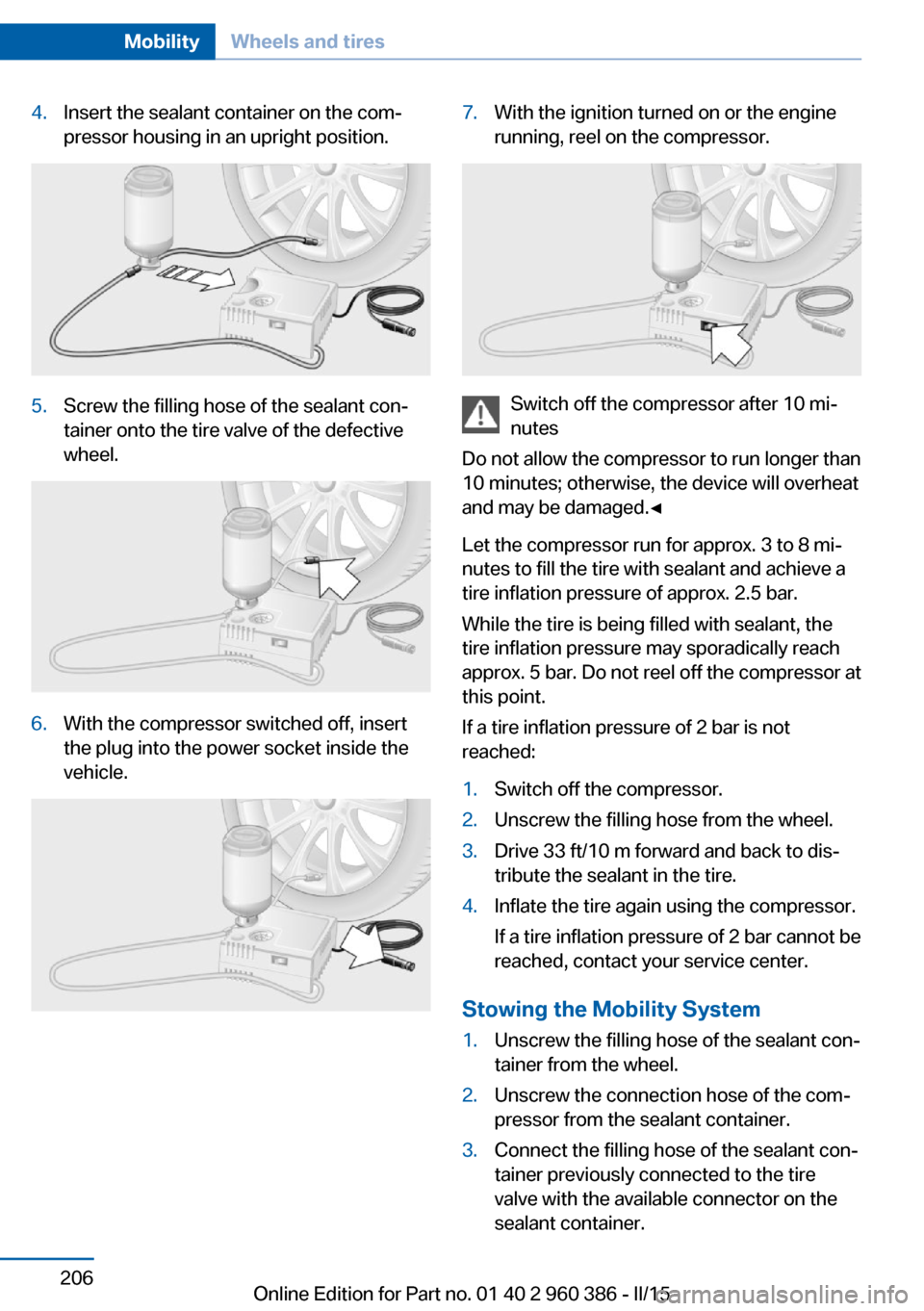

4.Insert the sealant container on the com‐

pressor housing in an upright position.5.Screw the filling hose of the sealant con‐

tainer onto the tire valve of the defective

wheel.6.With the compressor switched off, insert

the plug into the power socket inside the

vehicle.7.With the ignition turned on or the engine

running, reel on the compressor.

Switch off the compressor after 10 mi‐

nutes

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged.◀

Let the compressor run for approx. 3 to 8 mi‐

nutes to fill the tire with sealant and achieve a

tire inflation pressure of approx. 2.5 bar.

While the tire is being filled with sealant, the

tire inflation pressure may sporadically reach

approx. 5 bar. Do not reel off the compressor at

this point.

If a tire inflation pressure of 2 bar is not

reached:

1.Switch off the compressor.2.Unscrew the filling hose from the wheel.3.Drive 33 ft/10 m forward and back to dis‐

tribute the sealant in the tire.4.Inflate the tire again using the compressor.

If a tire inflation pressure of 2 bar cannot be

reached, contact your service center.

Stowing the Mobility System

1.Unscrew the filling hose of the sealant con‐

tainer from the wheel.2.Unscrew the connection hose of the com‐

pressor from the sealant container.3.Connect the filling hose of the sealant con‐

tainer previously connected to the tire

valve with the available connector on the

sealant container.Seite 206MobilityWheels and tires206

Online Edition for Part no. 01 40 2 960 386 - II/15

Page 211 of 257

This prevents leftover sealant from escap‐

ing from the container.4.Wrap the empty sealant container in suita‐

ble material to avoid dirtying the cargo

area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive approx. 5 miles/10 km to en‐

sure that the sealant is evenly distributed in the

tire.

Do not exceed a speed of 50 mph/80 km/h.

If possible, do not drive at speeds less than

12 mph/20 km/h.

To correct the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose of the com‐

pressor directly onto the tire valve stem.3.Insert the connector into the power socket

inside the vehicle.4.Correct the tire inflation pressure to

2.5 bar.▷Increase pressure: with the ignition

turned on or the engine running, reel

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

Continuing the trip

Do not exceed the maximum permissible

speed of 50 mph/80 km/h.

Reinitialize the Flat Tire Monitor.

Reinitialize the Tire Pressure Monitor.

Replace the defective tire and the sealant con‐

tainer of the Mobility System as soon as possi‐

ble.

Snow chains

Fine-link snow chains Only certain types of fine-link snow chains

have been tested by the manufacturer of the

vehicle, classified as road-safe and approved.

Information about the approved snow chains

are available from the service center.

Use Use only in pairs on the rear wheels, equipped

with the tires of the following size:▷205/65 R 17.▷225/60 R 17.▷245/50 R 18.▷245/45 R 19.

No snow chains on size 245/55 R 17 tires

Do not mount snow chains on size

245/55 R 17 tires; otherwise, the vehicle may

become damaged.◀

Follow the snow chain manufacturer's instruc‐

tions.

Make sure that the snow chains are always

sufficiently tight. Retighten as needed accord‐

ing to the chain manufacturer's instructions.

Do not initialize the Flat Tire Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

Do not initialize the Tire Pressure Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

When driving with snow chains, briefly activate

Dynamic Traction Control if needed.

Maximum speed with snow chains Do not exceed a speed of 30 mph/50 km/hwhen using snow chains.

Seite 207Wheels and tiresMobility207

Online Edition for Part no. 01 40 2 960 386 - II/15

Page 212 of 257

Engine compartmentVehicle features and optionsThis chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due tothe selected options or country versions. This

also applies to safety-related functions and

systems. The respectively applicable country

provisions must be observed when using the

respective features and systems.

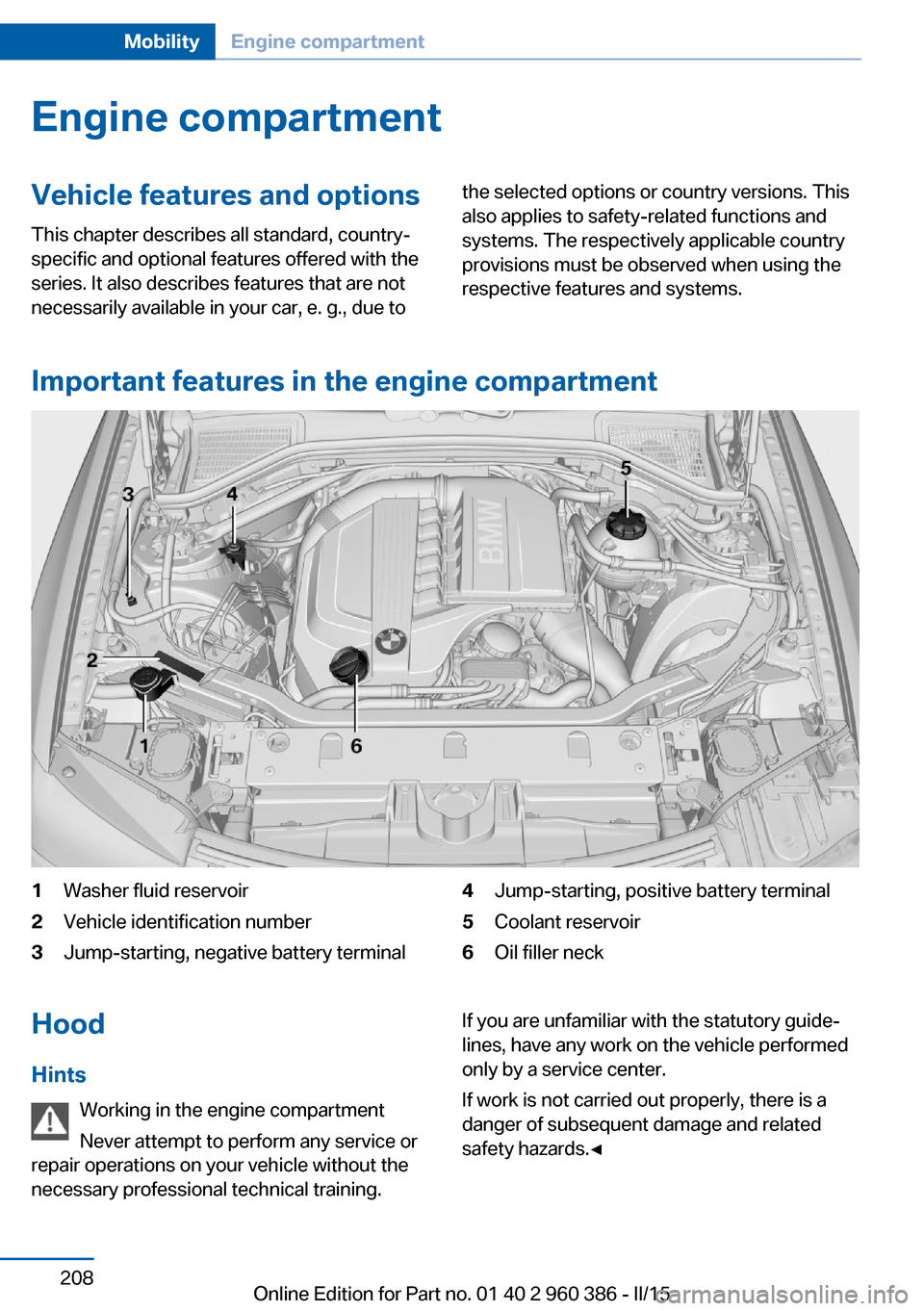

Important features in the engine compartment

1Washer fluid reservoir2Vehicle identification number3Jump-starting, negative battery terminal4Jump-starting, positive battery terminal5Coolant reservoir6Oil filler neckHood

Hints Working in the engine compartment

Never attempt to perform any service or

repair operations on your vehicle without the

necessary professional technical training.If you are unfamiliar with the statutory guide‐

lines, have any work on the vehicle performed

only by a service center.

If work is not carried out properly, there is a

danger of subsequent damage and related

safety hazards.◀Seite 208MobilityEngine compartment208

Online Edition for Part no. 01 40 2 960 386 - II/15

Page 216 of 257

The engine oil quality is critical for the life of

the engine.

Suitable engine oil types

You can add engine oils that meet the follow‐

ing oil rating standards:Gasoline engineBMW Longlife-01.BMW Longlife-01 FE.Diesel engineBMW Longlife-04.

Further information regarding the oil specifica‐

tions and viscosities of engine oils can be in‐

quired with the service center.

Alternative engine oil types If an engine oil suitable for continuous use is

not available, up to 1 US quart/liter of an en‐

gine oil with the following oil rating can be

added:

Gasoline engineAPI SM or superior oil rating.Diesel engineAPI CJ-4.

Engine oil change:

The vehicle manufacturer recommends that

you let the service center change the motor oil.

Seite 212MobilityEngine oil212

Online Edition for Part no. 01 40 2 960 386 - II/15

Page 217 of 257

CoolantVehicle features and optionsThis chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and

systems. The respectively applicable country

provisions must be observed when using the

respective features and systems.

Hints Danger of burns from hot engine

Do not open the cooling system while

the engine is hot; otherwise, esliding coolant

may cause burns.◀

Suitable additives

Only use suitable additives; otherwise,

engine damage may occur. The additives are

harmful to your health.◀

Coolant consists of water and additives.

Not all commercially available additives are

suitable for the vehicle. Information about the

suitable additives are available from the service

center.

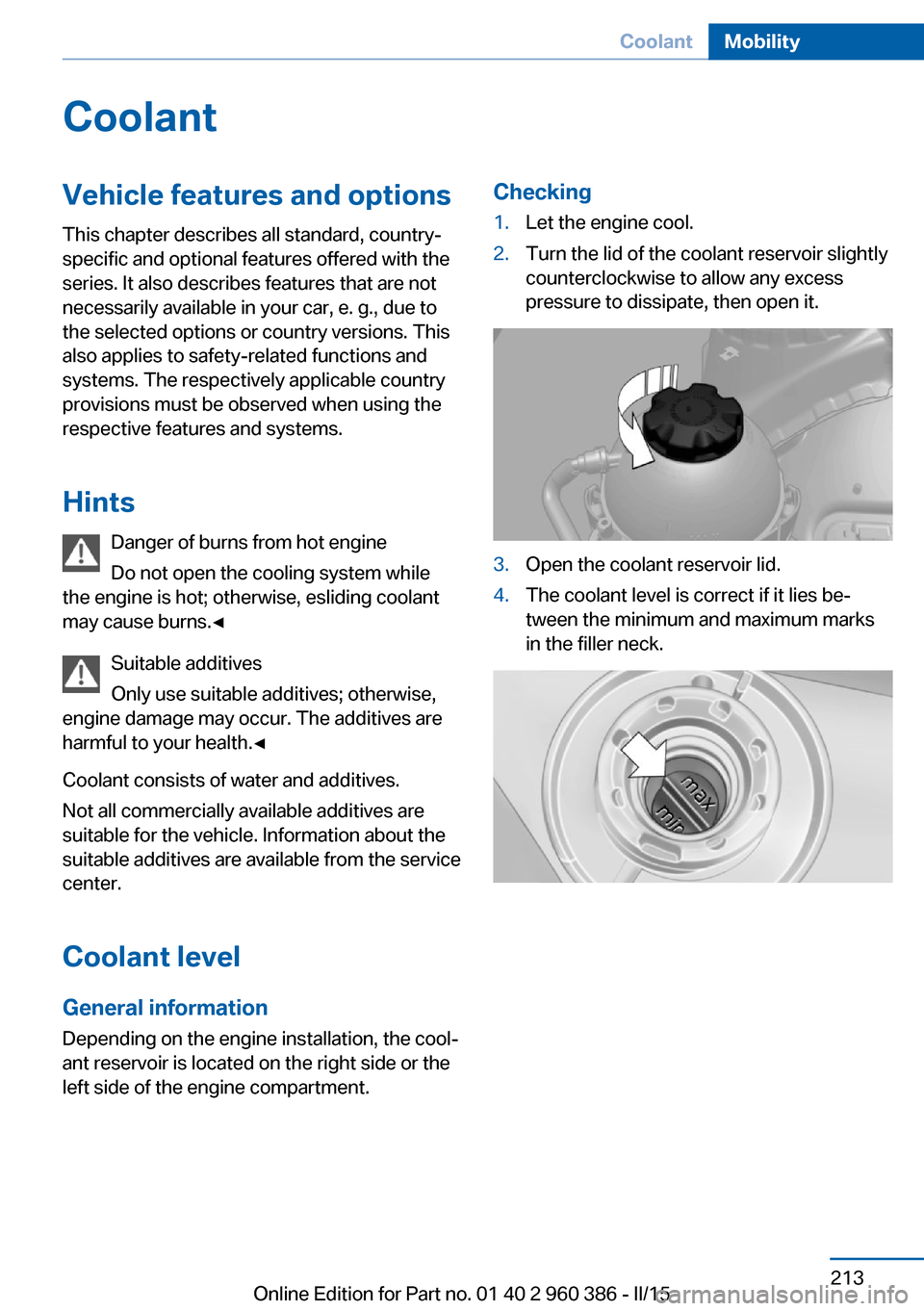

Coolant level

General information

Depending on the engine installation, the cool‐

ant reservoir is located on the right side or the

left side of the engine compartment.Checking1.Let the engine cool.2.Turn the lid of the coolant reservoir slightly

counterclockwise to allow any excess

pressure to dissipate, then open it.3.Open the coolant reservoir lid.4.The coolant level is correct if it lies be‐

tween the minimum and maximum marks

in the filler neck.Seite 213CoolantMobility213

Online Edition for Part no. 01 40 2 960 386 - II/15

Page 219 of 257

MaintenanceVehicle features and options

This chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and

systems. The respectively applicable country

provisions must be observed when using the

respective features and systems.

BMW maintenance system The maintenance system indicates required

maintenance measures, and thereby provides

support in maintaining road safety and the op‐

erational reliability of the vehicle.

In some cases scopes and intervals may vary

according to the country-specific version. Re‐

placement work, spare parts, fuels and lubri‐

cants and wear materials are calculated sepa‐

rately. Additional information is available from

the service center.

Condition Based Service

CBS

Sensors and special algorithms take into ac‐

count the driving conditions of your vehicle.

Based on this, Condition Based Service recog‐

nizes the maintenance requirements.

The system makes it possible to adapt the

amount of maintenance corresponding to your

user profile.

Detailed information on service requirements,

refer to page 86, can be displayed on the Con‐

trol Display.Service data in the remote control

Information on the required maintenance is

continuously stored in the remote control. Your service center will read out this data and

suggest the right array of service procedures for your vehicle.

Therefore, hand your service specialist the re‐

mote control with which the vehicle was driven

most recently.

Storage periods Storage periods during which the vehicle bat‐

tery was disconnected are not taken into ac‐

count.

If this occurs, have a service center update the

time-dependent maintenance procedures,

such as checking brake fluid and, if needed,

changing the engine oil and the microfilter/

activated-charcoal filter.

Service and Warranty

Information Booklet for US

models and Warranty and

Service Guide Booklet for

Canadian models

Please consult your Service and Warranty In‐

formation Booklet for US models and Warranty

and Service Guide Booklet for Canadian mod‐

els for additional information on service re‐

quirements.

Maintenance and repair should be performed

by your service center. Make sure to have reg‐

ular maintenance procedures recorded in the

vehicle's Service and Warranty Information

Booklet for US models, and in the Warranty

and Service Guide Booklet for Canadian mod‐

els. These entries are proof of regular mainte‐

nance.Seite 215MaintenanceMobility215

Online Edition for Part no. 01 40 2 960 386 - II/15

Page 220 of 257

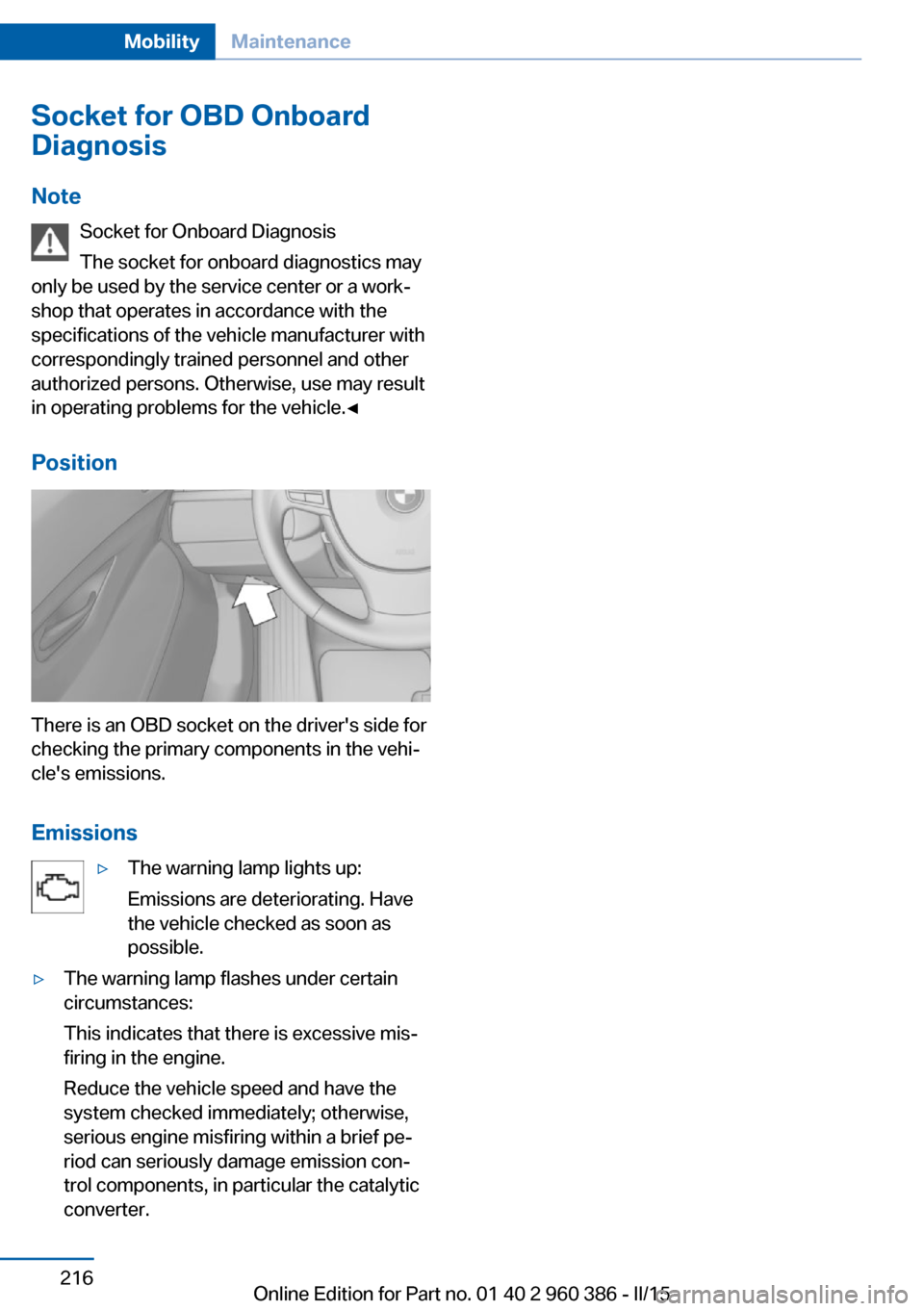

Socket for OBD Onboard

Diagnosis

Note Socket for Onboard Diagnosis

The socket for onboard diagnostics may

only be used by the service center or a work‐

shop that operates in accordance with the

specifications of the vehicle manufacturer with

correspondingly trained personnel and other

authorized persons. Otherwise, use may result

in operating problems for the vehicle.◀

Position

There is an OBD socket on the driver's side for

checking the primary components in the vehi‐

cle's emissions.

Emissions

▷The warning lamp lights up:

Emissions are deteriorating. Have

the vehicle checked as soon as

possible.▷The warning lamp flashes under certain

circumstances:

This indicates that there is excessive mis‐

firing in the engine.

Reduce the vehicle speed and have the

system checked immediately; otherwise,

serious engine misfiring within a brief pe‐

riod can seriously damage emission con‐

trol components, in particular the catalytic

converter.Seite 216MobilityMaintenance216

Online Edition for Part no. 01 40 2 960 386 - II/15

Page 222 of 257

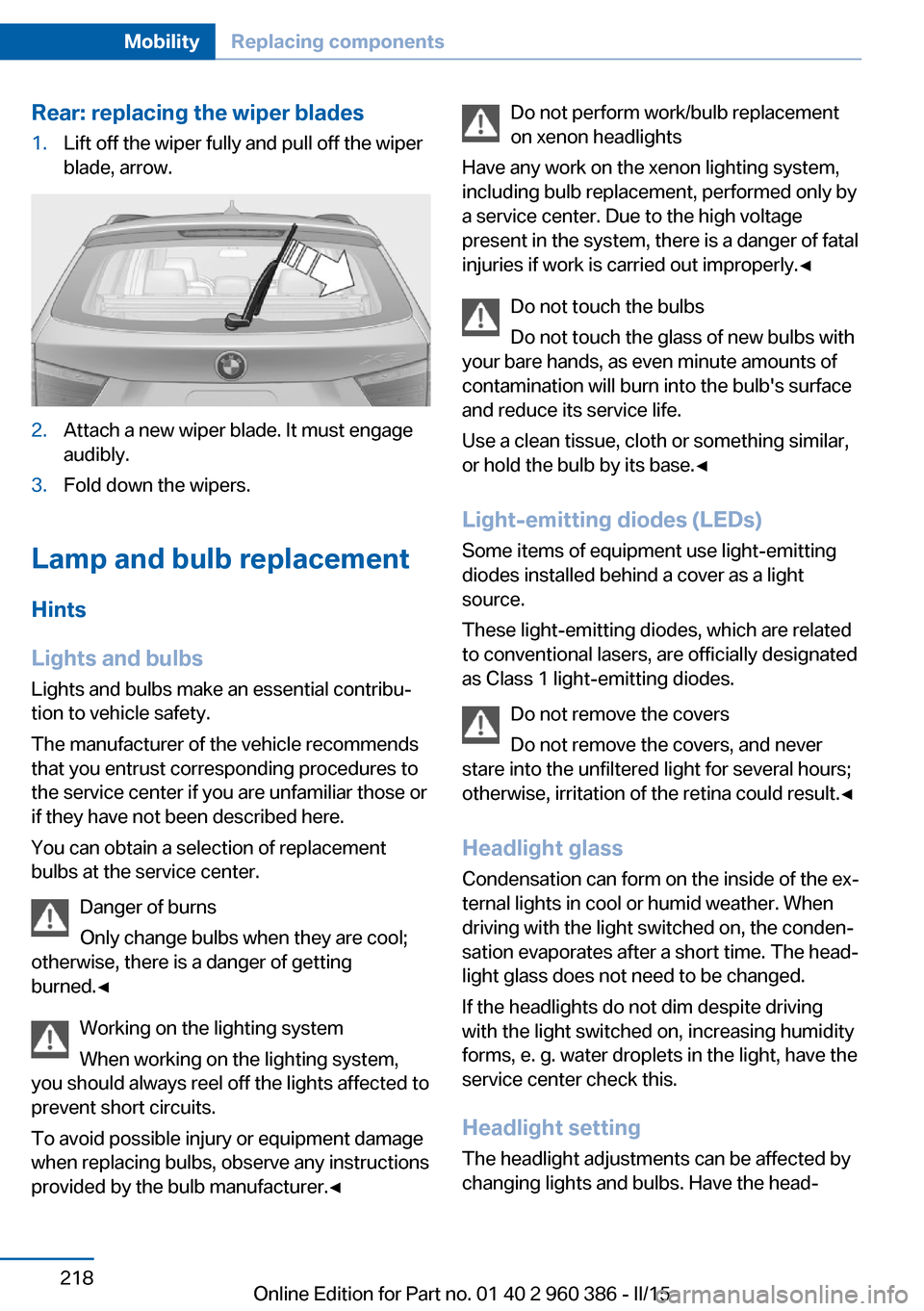

Rear: replacing the wiper blades1.Lift off the wiper fully and pull off the wiper

blade, arrow.2.Attach a new wiper blade. It must engage

audibly.3.Fold down the wipers.

Lamp and bulb replacement

Hints

Lights and bulbs

Lights and bulbs make an essential contribu‐

tion to vehicle safety.

The manufacturer of the vehicle recommends

that you entrust corresponding procedures to

the service center if you are unfamiliar those or

if they have not been described here.

You can obtain a selection of replacement

bulbs at the service center.

Danger of burns

Only change bulbs when they are cool;

otherwise, there is a danger of getting

burned.◀

Working on the lighting system

When working on the lighting system,

you should always reel off the lights affected to

prevent short circuits.

To avoid possible injury or equipment damage

when replacing bulbs, observe any instructions

provided by the bulb manufacturer.◀

Do not perform work/bulb replacement

on xenon headlights

Have any work on the xenon lighting system,

including bulb replacement, performed only by

a service center. Due to the high voltage

present in the system, there is a danger of fatal

injuries if work is carried out improperly.◀

Do not touch the bulbs

Do not touch the glass of new bulbs with

your bare hands, as even minute amounts of

contamination will burn into the bulb's surface

and reduce its service life.

Use a clean tissue, cloth or something similar,

or hold the bulb by its base.◀

Light-emitting diodes (LEDs)

Some items of equipment use light-emitting

diodes installed behind a cover as a light

source.

These light-emitting diodes, which are related

to conventional lasers, are officially designated as Class 1 light-emitting diodes.

Do not remove the covers

Do not remove the covers, and never

stare into the unfiltered light for several hours;

otherwise, irritation of the retina could result.◀

Headlight glass

Condensation can form on the inside of the ex‐

ternal lights in cool or humid weather. When

driving with the light switched on, the conden‐

sation evaporates after a short time. The head‐

light glass does not need to be changed.

If the headlights do not dim despite driving

with the light switched on, increasing humidity

forms, e. g. water droplets in the light, have the

service center check this.

Headlight setting

The headlight adjustments can be affected by

changing lights and bulbs. Have the head‐Seite 218MobilityReplacing components218

Online Edition for Part no. 01 40 2 960 386 - II/15

Page 224 of 257

High beams/headlight flasher

55-watt bulb, H7.1.Tip the connector with the bulb up slightly

and pull out carefully.2.Pull the bulb off the connector and insert

the new bulb.3.Install the new bulb in reverse order of re‐

moval.4.Place the cover according to the arrow

markings on the headlight housing.5.Close the headlight housing with the lid.

Daytime running lights

21-watt bulb, W21W.

1.Turn the bulb holder counterclockwise and

remove.2.Carefully remove the bulb from the socket.3.Install the new bulb in reverse order of re‐

moval.4.Place the cover according to the arrow

markings on the headlight housing.5.Close the headlight housing with the lid.

Xenon headlights

Hints

Because of the long life of these bulbs, the

likelihood of failure is very low. Switching the

lights on and off frequently shortens their life.

If a bulb fails, reel on the front fog lights and

continue the trip with great care. Comply with

local regulations.

Do not perform work/bulb replacement

on xenon headlights

Have any work on the xenon lighting system,

including bulb replacement, performed only by

a service center. Due to the high voltage

present in the system, there is a danger of fatal

injuries if work is carried out improperly.◀

For checking and adjusting headlamp aim,

please contact your BMW center.

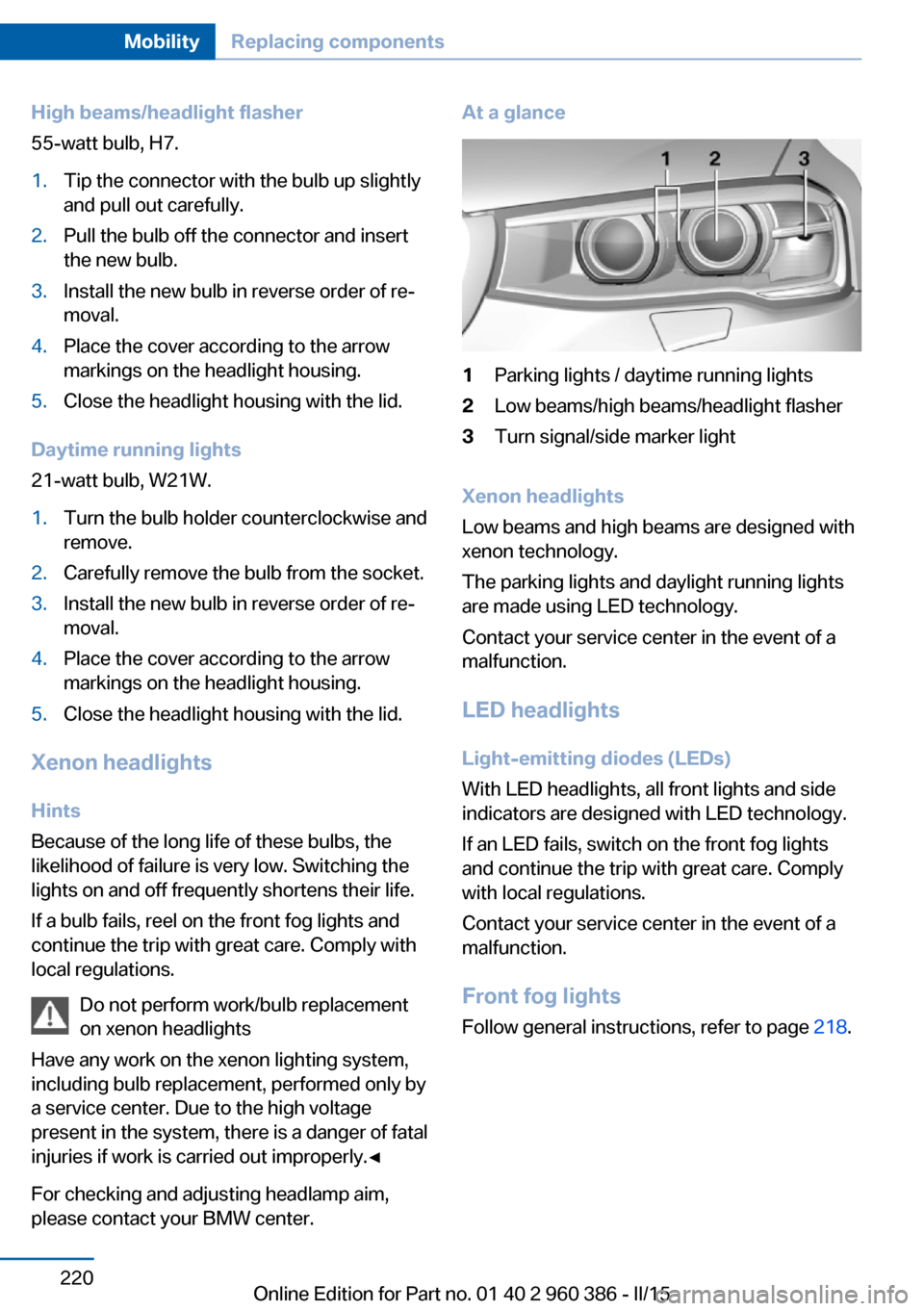

At a glance1Parking lights / daytime running lights2Low beams/high beams/headlight flasher3Turn signal/side marker light

Xenon headlights

Low beams and high beams are designed with

xenon technology.

The parking lights and daylight running lights

are made using LED technology.

Contact your service center in the event of a

malfunction.

LED headlightsLight-emitting diodes (LEDs)

With LED headlights, all front lights and side

indicators are designed with LED technology.

If an LED fails, switch on the front fog lights and continue the trip with great care. Complywith local regulations.

Contact your service center in the event of a

malfunction.

Front fog lights

Follow general instructions, refer to page 218.

Seite 220MobilityReplacing components220

Online Edition for Part no. 01 40 2 960 386 - II/15