turn signal BMW X5 2001 E53 M62TU Engine Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: X5, Model: BMW X5 2001 E53Pages: 37, PDF Size: 3.87 MB

Page 5 of 37

5

BASIC FUNCTION OF BMW VANOS SYSTEMS

All BMW VANOS systems are operated through electric/hydraulic/mechanical control.

Electric Control: The engine control module is responsible for activating a VANOS sole-

noid valve based on DME program mapping. The activation parameters are influenced

by the following input signals:

• Engine speed

• Load (intake air mass)

• Engine temperature

• Camshaft position

• Oil temperature (MS 42.0 only)

Depending on the specific VANOS system, the solenoid valve is one of two types:

• Basic black/white (on/off) solenoid valve. Found on M50 TU and M52 engines.

• Variable position solenoid valve. Found on the M52 TU and M62 TU engines.

Hydraulic Control:The position of the solenoid valve directs the hydraulic flow of engine

oil. The controlled oil flow acts on the mechanical components of VANOS system to

position the camshaft.

Mechanical Control: The mechanical components of all VANOS systems operate under

the same principle. The controlled hydraulic engine oil flow is directed through advance

or retard activation oil ports. Each port exits into a sealed chamber on the opposite sides

of a control piston.

• The control piston on six cylinder engine systems (M50TU, M52 & M52TU) is con-

nected to a separate helical gear cup.

• The control piston on the M62TU VANOS system incorporates the helical gear.

In its default position the oil flow is directed to the rear surface of the piston. This pulls

the helical gear forward and maintains the retarded valve timing position.

When the oil flow is directed to the front surface of the piston, the oil pushesthe helical

gear in the opposite direction which rotates the matched helical gearing connected to the

camshaft.

The angled teeth of the helical gears cause thepushingmovement to be converted into

arotationalmovement. The rotational movement is added to the turning of the

camshaft providing the variable camshaft positioning.

Page 18 of 37

18

PWG SIGNAL MONITORING & PWG FAILSAFE OPERATION:

• As a redundant safety feature the PWG provides two separate signals from two integral

potentiometers (Pot 1 and Pot 2) representing the driver’s request for throttle activation.

• If the monitored PWG potentiometer signals are not plausible, ME 7.2 will only use the

lower of the two signals as the driver’s pedal request input providing failsafe operation.

Throttle response will be slower and maximum throttle position will be reduced.

• When in PWG failsafe operation, ME 7.2 sets the EDK throttle plate and injection time

to idle (LL) whenever the brake pedal is depressed.

• When the system is in PWG failsafe operation, the instrument cluster matrix display will

post “Engine Emergency Program” and PWG specific fault(s) will be stored in memory.

EDK FEEDBACK SIGNAL MONITORING & EDK FAILSAFE OPERATION:

• The EDK provides two separate signals from two integral potentiometers (Pot 1 and Pot

2) representing the exact position of the throttle plate.

• EDK Pot 1 provides the primary throttle plate position feedback. As a redundant safe-

ty feature, Pot 2 is continuously cross checked with Pot 1 for signal plausibility.

• If plausibility errors are detected between Pot 1 and Pot 2, ME 7.2 will calculate the

inducted engine air mass (from HFM signal) and only utilize the potentiometer signal that

closely matches the detected intake air mass.

- The ME 7.2 uses the air mass signalling as a “virtual potentiometer” (pot 3) for a

comparative source to provide failsafe operation.

- If ME 7.2 cannot calculate a plausible conclusion from the monitored pots (1 or 2

and virtual 3) the EDK motor is switched off and fuel injection cut out is activated

(no failsafe operation possible).

• The EDK is continuously monitored during all phases of engine operation. It is also

briefly activated when KL 15 is initially switched on as a “pre-flight check” to verify it’s

mechanical integrity (no binding, appropriate return spring tension, etc). This is accom-

plished by monitoring both the motor control amperage and the reaction speed of the

EDK feedback potentiometers. If faults are detected the EDK motor is switched off and

fuel injection cut off is activated (no failsafe operation possible). The engine does how-

ever continue to run extremely rough at idle speed.

• When a replacement EDK is installed, the ME 7.2 adapts to the new component

(required amperage draw for motor control, feedback pot tolerance differences, etc).

This occurs immediately after the next cycle of KL 15 for approximately 30 seconds.

During this period of adaptation, the maximum opening of the throttle plate is 25%.

Page 21 of 37

11

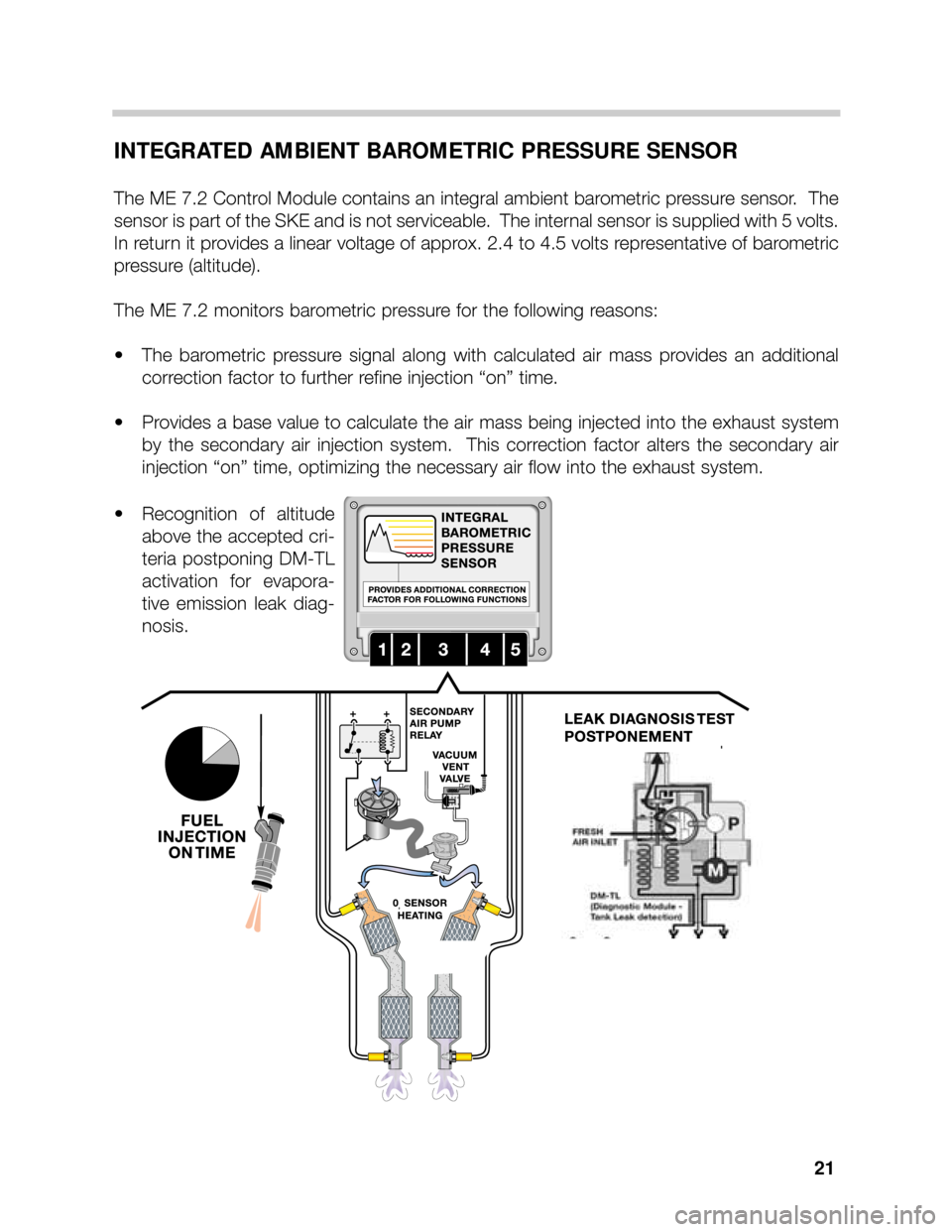

INTEGRATED AMBIENT BAROMETRIC PRESSURE SENSOR

The ME 7.2 Control Module contains an integral ambient barometric pressure sensor. The

sensor is part of the SKE and is not serviceable. The internal sensor is supplied with 5 volts.

In return it provides a linear voltage of approx. 2.4 to 4.5 volts representative of barometric

pressure (altitude).

The ME 7.2 monitors barometric pressure for the following reasons:

• The barometric pressure signal along with calculated air mass provides an additional

correction factor to further refine injection “on” time.

• Provides a base value to calculate the air mass being injected into the exhaust system

by the secondary air injection system. This correction factor alters the secondary air

injection “on” time, optimizing the necessary air flow into the exhaust system.

• Recognition of altitude

above the accepted cri-

teria postponing DM-TL

activation for evapora-

tive emission leak diag-

nosis.

21

Page 24 of 37

24

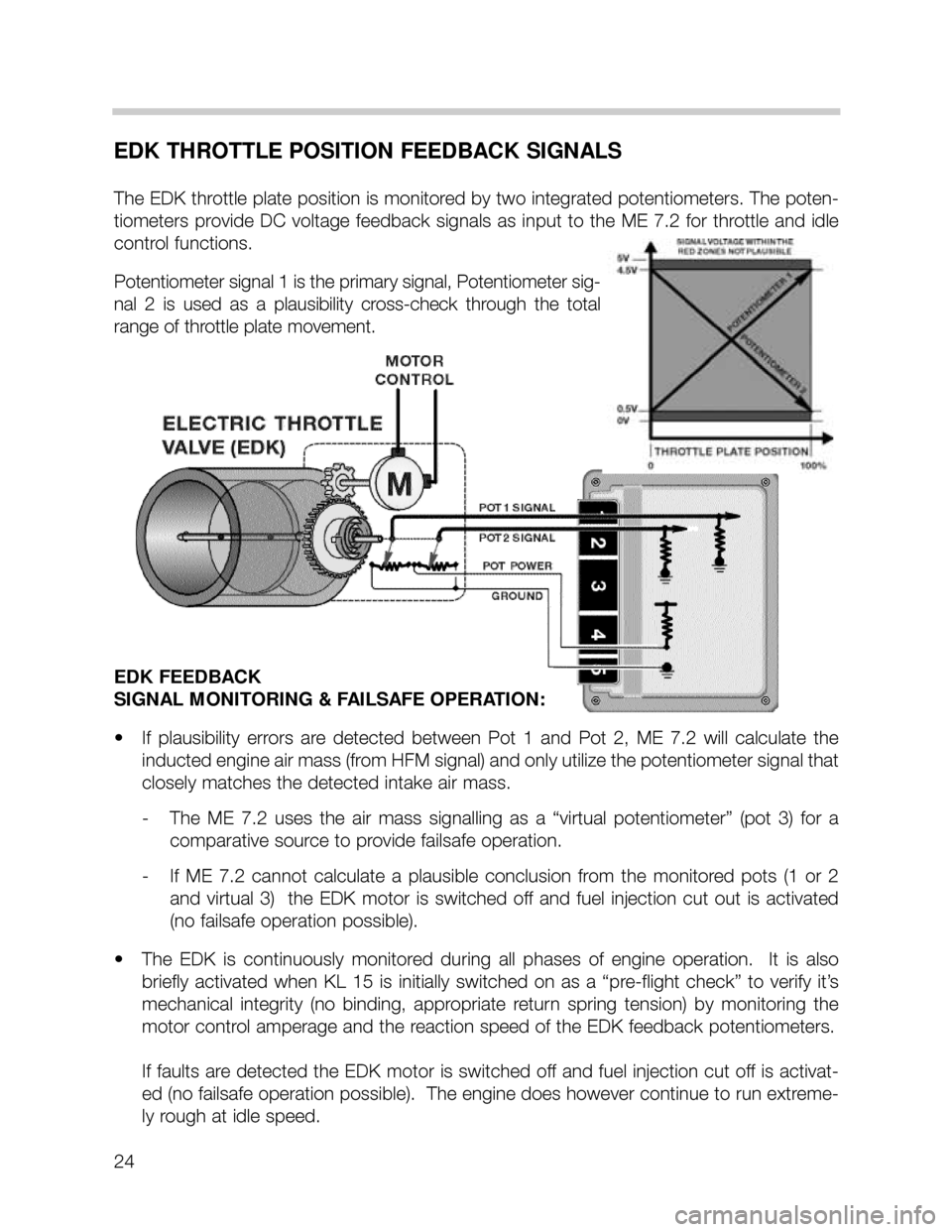

EDK THROTTLE POSITION FEEDBACK SIGNALS

The EDK throttle plate position is monitored by two integrated potentiometers. The poten-

tiometers provide DC voltage feedback signals as input to the ME 7.2 for throttle and idle

control functions.

Potentiometer signal 1 is the primary signal, Potentiometer sig-

nal 2 is used as a plausibility cross-check through the total

range of throttle plate movement.

EDK FEEDBACK

SIGNAL MONITORING & FAILSAFE OPERATION:

• If plausibility errors are detected between Pot 1 and Pot 2, ME 7.2 will calculate the

inducted engine air mass (from HFM signal) and only utilize the potentiometer signal that

closely matches the detected intake air mass.

- The ME 7.2 uses the air mass signalling as a “virtual potentiometer” (pot 3) for a

comparative source to provide failsafe operation.

- If ME 7.2 cannot calculate a plausible conclusion from the monitored pots (1 or 2

and virtual 3) the EDK motor is switched off and fuel injection cut out is activated

(no failsafe operation possible).

• The EDK is continuously monitored during all phases of engine operation. It is also

briefly activated when KL 15 is initially switched on as a “pre-flight check” to verify it’s

mechanical integrity (no binding, appropriate return spring tension) by monitoring the

motor control amperage and the reaction speed of the EDK feedback potentiometers.

If faults are detected the EDK motor is switched off and fuel injection cut off is activat-

ed (no failsafe operation possible). The engine does however continue to run extreme-

ly rough at idle speed.