sensor BMW X5 2002 E53 DSC System Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2002, Model line: X5, Model: BMW X5 2002 E53Pages: 24, PDF Size: 1.77 MB

Page 1 of 24

TABLE OF CONTENTS

Subject Page

Dynamic Stability Control (DSC III) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Corner Braking Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Electronic Brake Proportioning (EBV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Dynamic Braking System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

DSC New Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

DSC New Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Control Module Hydraulic Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Rotation Rate/Transverse Acceleration Sensor . . . . . . . . . . . . . . . . . . . . . . . .19

Brake Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

DSC III Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Steering Angle Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Brake Fluid Level Warning Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Page 3 of 24

3

TRACTION CONTROL SYSTEM OVERVIEW (ASC)

THEORY OF TRACTION CONTROL

Traction Control Systems are referred to as Automatic Stability Control (ASC), Automatic

Stability + Traction Control (ASC+T), Dynamic Stability Control (DSC) or All Season Traction

(marketing term). The traction control system has gone through several changes since its

introduction in Model Year 1988. While each new version offered new innovations, the prin-

ciple of traction control remains the same for any of these versions.

The link between the vehicle and its driving environment is established by the frictional con-

tact between the tires and the road surface. The ability to control the vehicle while driving,

is lost as a result of excessive wheel spin or slip if either rear tire exceeds its ability to:

• Maintain traction

• Accept side forces to maintain directional control (lateral locating forces)

The primary function of the traction control system is to maintain traction and stability of the

vehicle regardless of the road surface condition. This is achieved by reducing the drive

torque applied to the rear wheels or pulsing the rear wheel brakes to eliminate wheel slip

depending on the version of traction control installed.

The electronics for traction control operation are incorporated in the ABS control module

and share many of the same components and sensors. The module determines the speed

of the vehicle through a calculated average of the four wheel speed sensor inputs. Wheel

slip/spin is then recognized by comparing the speed of the driven wheels to the front

wheels.

A critical slip ratio of greater than 5% between the wheels will cause the traction control regu-

lation to begin. This slip ratio is established when the control module detects a wheel speed

difference of 2 MPH or higher.

Page 7 of 24

7

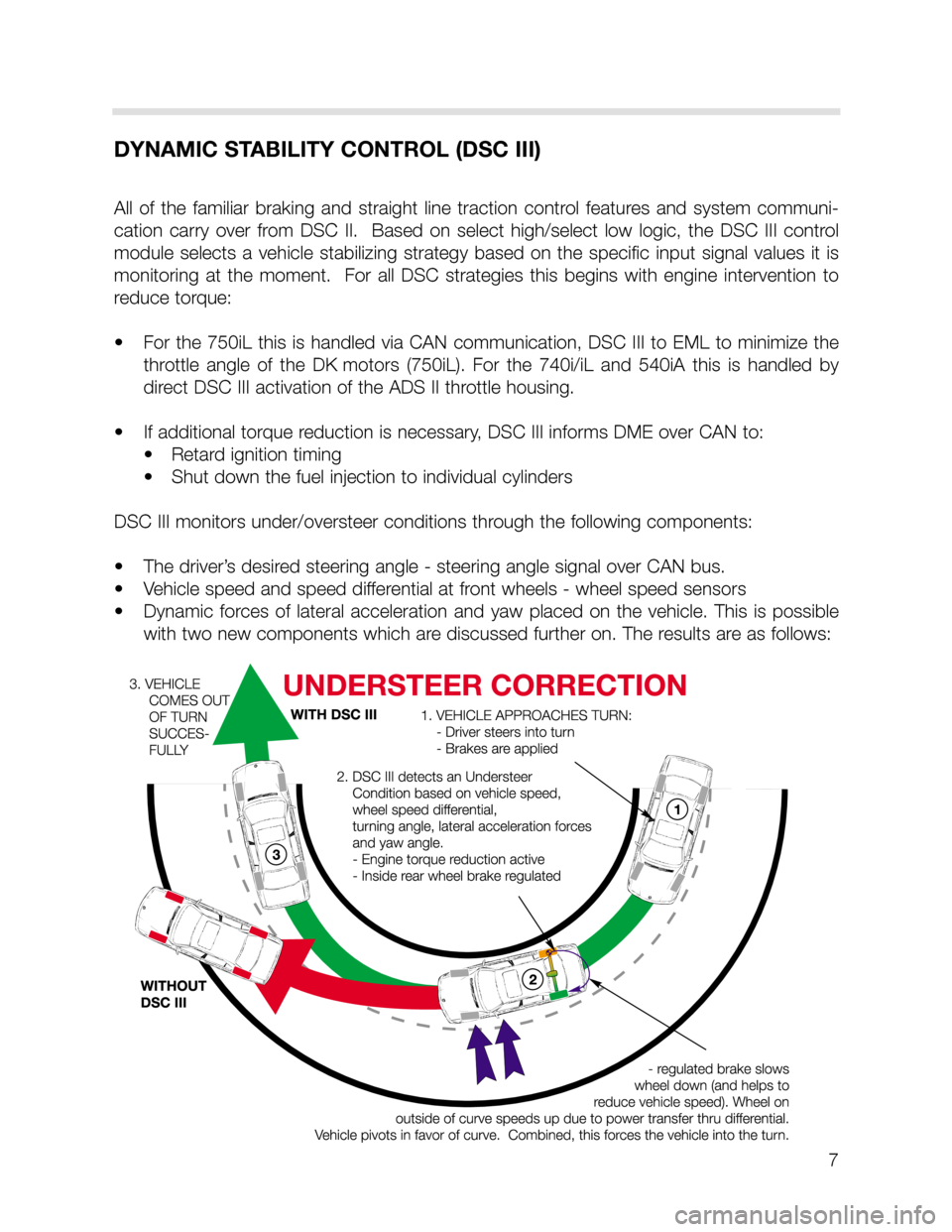

DYNAMIC STABILITY CONTROL (DSC III)

All of the familiar braking and straight line traction control features and system communi-

cation carry over from DSC II. Based on select high/select low logic, the DSC III control

module selects a vehicle stabilizing strategy based on the specific input signal values it is

monitoring at the moment. For all DSC strategies this begins with engine intervention to

reduce torque:

•For the 750iL this is handled via CAN communication, DSC III to EML to minimize the

throttle angle of the DK motors (750iL). For the 740i/iL and 540iA this is handled by

direct DSC III activation of the ADS II throttle housing.

• If additional torque reduction is necessary, DSC III informs DME over CAN to:

• Retard ignition timing

• Shut down the fuel injection to individual cylinders

DSC III monitors under/oversteer conditions through the following components:

• The driver’s desired steering angle - steering angle signal over CAN bus.

• Vehicle speed and speed differential at front wheels - wheel speed sensors

• Dynamic forces of lateral acceleration and yaw placed on the vehicle. This is possible

with two new components which are discussed further on. The results are as follows:

Page 10 of 24

10

ELECTRONIC BRAKE PROPORTIONING (EBV)

Electronic brake proportioning allows the DSC system to adjust the braking force to the rear

wheels based on the vehicle’s loading to maximize the braking force at all wheels.

The DSC control module monitors the wheel speed sensors inputs when the brakes are

applied, for activation of this feature. The control module compares the speed at which the

front and rear axles are slowing down to determine vehicle loading.

If the rear axle is slowing at a similar rate to the front, it indicates that the vehicle is loaded

and more braking force can be applied to the rear calipers to slow and stop the vehicle.

If the decel rate of the rear axle is much less than the front, the vehicle is lightly loaded and

less force can be applied to the rear. If the same force were applied, then the vehicle could

become unstable.

OPERATION

The values for the decel rate are programmed in the DSC control module. Equal force will

be applied to the front and rear axles until the threshold values are exceeded. At this point,

the DSC control module will cycle the inlet valves at the rear calipers to reduce the braking

force on the rear axle.

Page 11 of 24

11

DYNAMIC BRAKING SYSTEM

The dynamic braking system is designed to enhance the braking control of the DSC for the

driver of the vehicle. The dynamic braking control and maximum braking control are func-

tions that are programmed into the control electronics of the DSC with no additional hard-

ware changes.

DYNAMIC BRAKING CONTROL (DBC)

The DBC function is designed to provide the maximum braking force available during rapid

(panic) braking situations. The DSC control module looks at the inputs from the brake pedal

switch and the signal from the brake pressure sensor on the master cylinder. The criteria

for activation of DBC is how rapidly is the brake pressure built up with the brake pedal

depressed. The total criteria required for DBC activation includes:

• Brake switch ON

• Brake pressure build up > threshold value

• Vehicle road speed > 5MPH

• Vehicle not in reverse

• Not all wheels in ABS regulation

If the threshold for DBC activation is achieved, the DSC control module will activate a pres-

sure build up regulation phase through the hydraulic unit. The pressure at all wheels is

increased up to the ABS regulation point. This occurs even if the driver does not achieve

the ABS regulation point with the pedal.

The rear axle brakes are controlled with select-low regulation and the front axle brakes are

controlled individually. ABS regulation will continue until the driver releases the pedal and

the pressure in the master cylinder drops below the threshold value stored in the DSC con-

trol module.

MAXIMUM BRAKE CONTROL (MBC)

The MBC function is also designed to enhance a driver initiated braking procedure. The

MBC will build up the pressure in the rear brake circuit when the front brakes are already in

an ABS regulation cycle. The additional braking pressure at the rear wheels will shorten the

stopping distance. The following criteria must be met before the DSC control module will

activate MBC:

• Both front wheel brakes in ABS regulation

• Vehicle speed > 5 MPH

• Vehicle not in reverse

• DBC and pressure sensor initialization test OK

• Rear wheels not in ABS regulation

Page 15 of 24

15

DSC - NEW FEATURE

TRACTION CONTROL

The traction control feature of the DSC III on the X5 cannot be switched OFF with the DSC

switch. Pressing the button will only switch off the dynamic stability control function of the

DSC.

The traction control feature is needed at all times to provide anti-spin control especially

when driving the vehicle off road. The DSC warning lamp in the instrument cluster will still

come on when the system is switched off manually or there is a fault in the system.

Off road traction control or HDC regulation places an additional load on the brakes. To pre-

vent overheating of the brakes and rotors, the temperature of the rotors is calculated over

time from the road speed and amount of brake application. If the temperature of one or

more rotors goes above 600o

C, the traction control or HDC function for that wheel will be

cancelled temporarily. Once the temperature of the rotor goes below 500o

C, the traction

application will be re-activated.

The normal braking function (including ABS) is always active at any temperatures.

DSC - NEW FEATURE

OFF-ROAD ABS Control Module Programming

The programming for ABS regulation have changed to allow a higher threshold for ABS reg-

ulation when driving off-road in loose gravel or dirt. A locked wheel is more effective in slow-

ing or stopping the vehicle because of the wedge that is built up in front of the tire.

The programming in the DSC control module allows one or both front wheel(s) to lock up

to a speed of 12 MPH as long as the vehicle is traveling straight ahead. If the DSC control

module receives a signal from the steering angle sensor indicating a turn, ABS regulation

will activate to prevent the lock and allow the vehicle to be steered.

Page 19 of 24

19

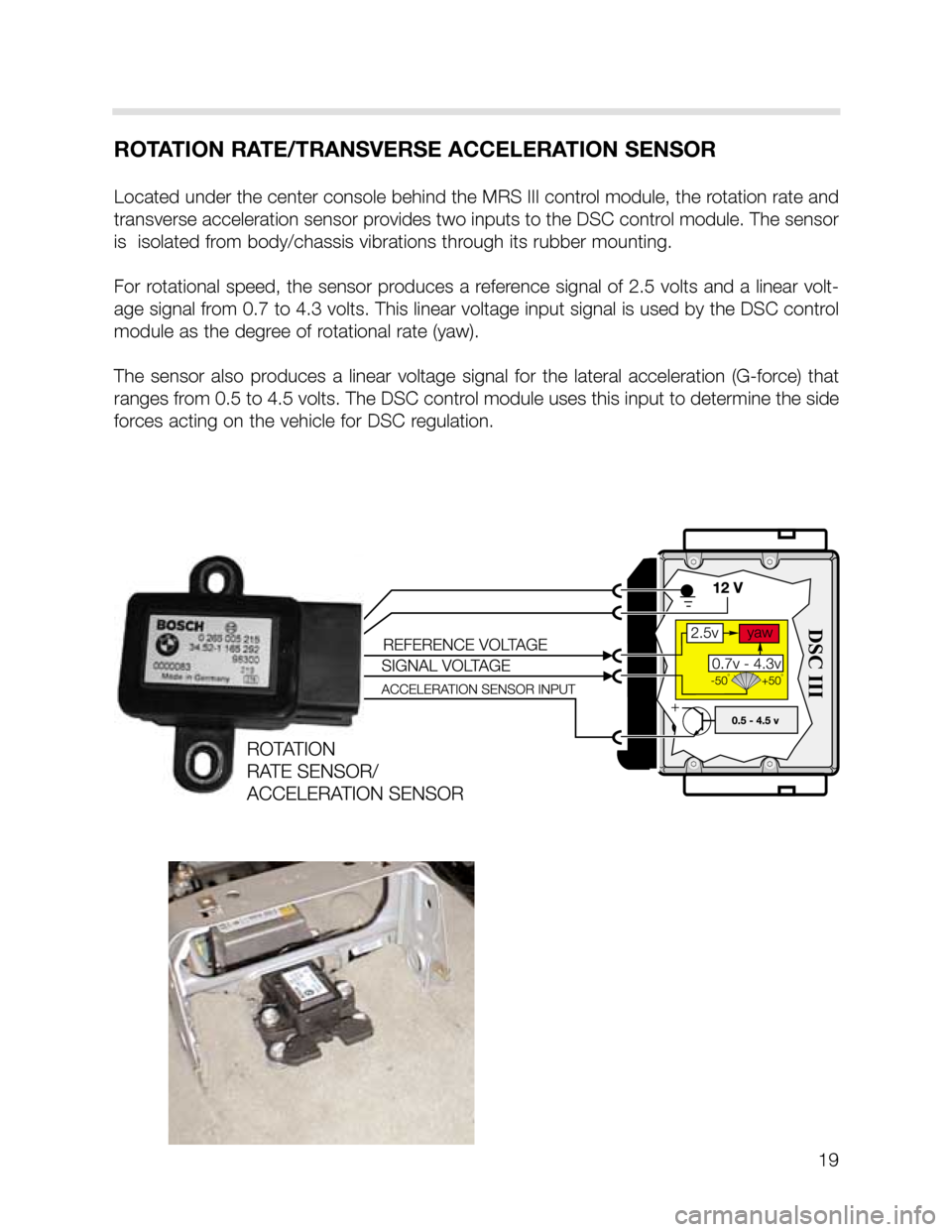

ROTATION RATE/TRANSVERSE ACCELERATION SENSOR

Located under the center console behind the MRS III control module, the rotation rate and

transverse acceleration sensor provides two inputs to the DSC control module. The sensor

is isolated from body/chassis vibrations through its rubber mounting.

For rotational speed, the sensor produces a reference signal of 2.5 volts and a linear volt-

age signal from 0.7 to 4.3 volts. This linear voltage input signal is used by the DSC control

module as the degree of rotational rate (yaw).

The sensor also produces a linear voltage signal for the lateral acceleration (G-force) that

ranges from 0.5 to 4.5 volts. The DSC control module uses this input to determine the side

forces acting on the vehicle for DSC regulation.

Page 20 of 24

20

BRAKE PRESSURE SENSOR

A brake pressure sensor is installed in the hydraulic unit to determine the degree of pres-

sure build-up for Dynamic Brake Control. It is installed in the front axle brake circuit.

The sensor receives its power supply from the DSC control module and produces a linear

voltage input signal ranging from 0.5 to 4.5 volts depending on how hard the brakes are

applied.

Page 21 of 24

21

DSC III COMPONENTS

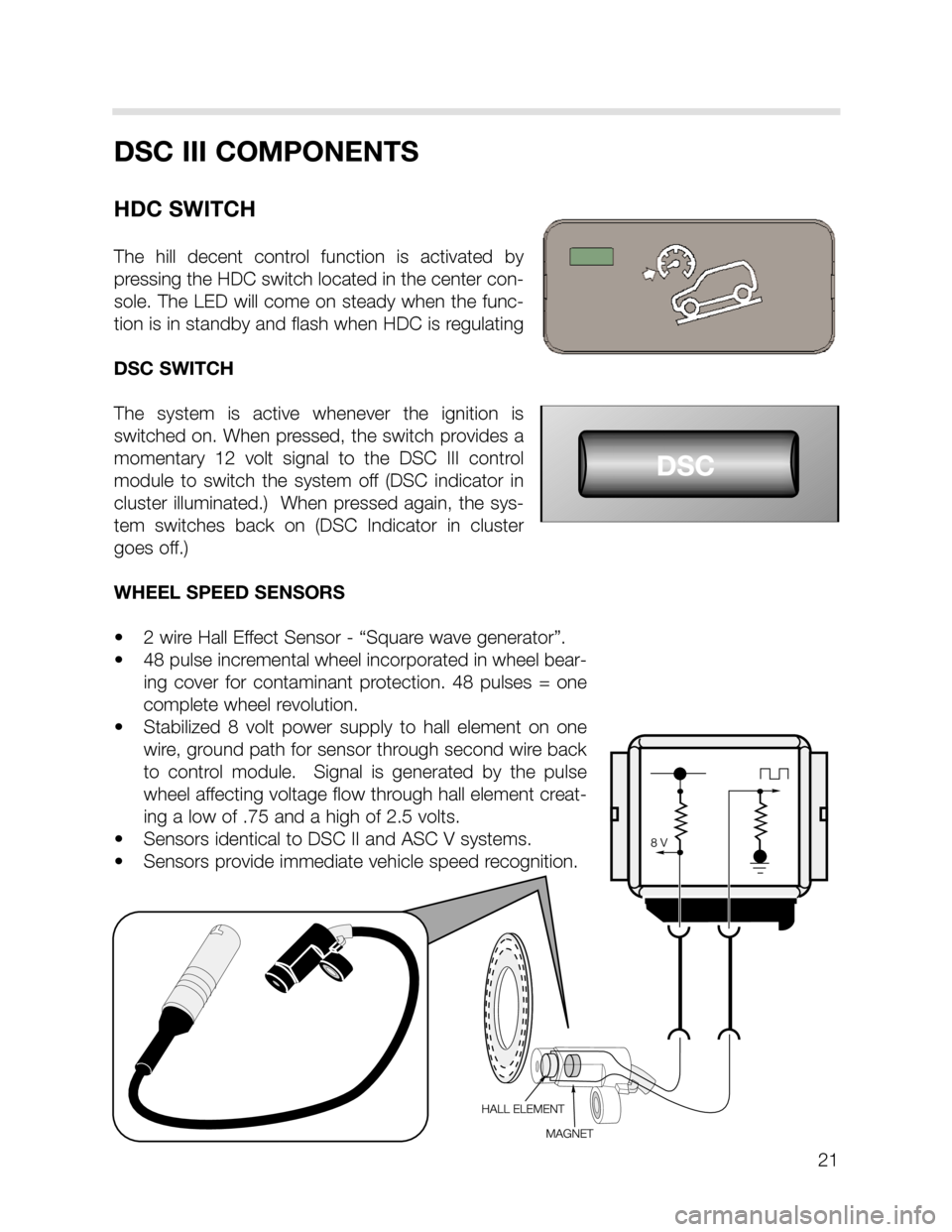

HDC SWITCH

The hill decent control function is activated by

pressing the HDC switch located in the center con-

sole. The LED will come on steady when the func-

tion is in standby and flash when HDC is regulating

DSC SWITCH

The system is active whenever the ignition is

switched on. When pressed, the switch provides a

momentary 12 volt signal to the DSC III control

module to switch the system off (DSC indicator in

cluster illuminated.) When pressed again, the sys-

tem switches back on (DSC Indicator in cluster

goes off.)

WHEEL SPEED SENSORS

• 2 wire Hall Effect Sensor - “Square wave generator”.

• 48 pulse incremental wheel incorporated in wheel bear-

ing cover for contaminant protection. 48 pulses = one

complete wheel revolution.

• Stabilized 8 volt power supply to hall element on one

wire, ground path for sensor through second wire back

to control module. Signal is generated by the pulse

wheel affecting voltage flow through hall element creat-

ing a low of .75 and a high of 2.5 volts.

• Sensors identical to DSC II and ASC V systems.

• Sensors provide immediate vehicle speed recognition.

Page 22 of 24

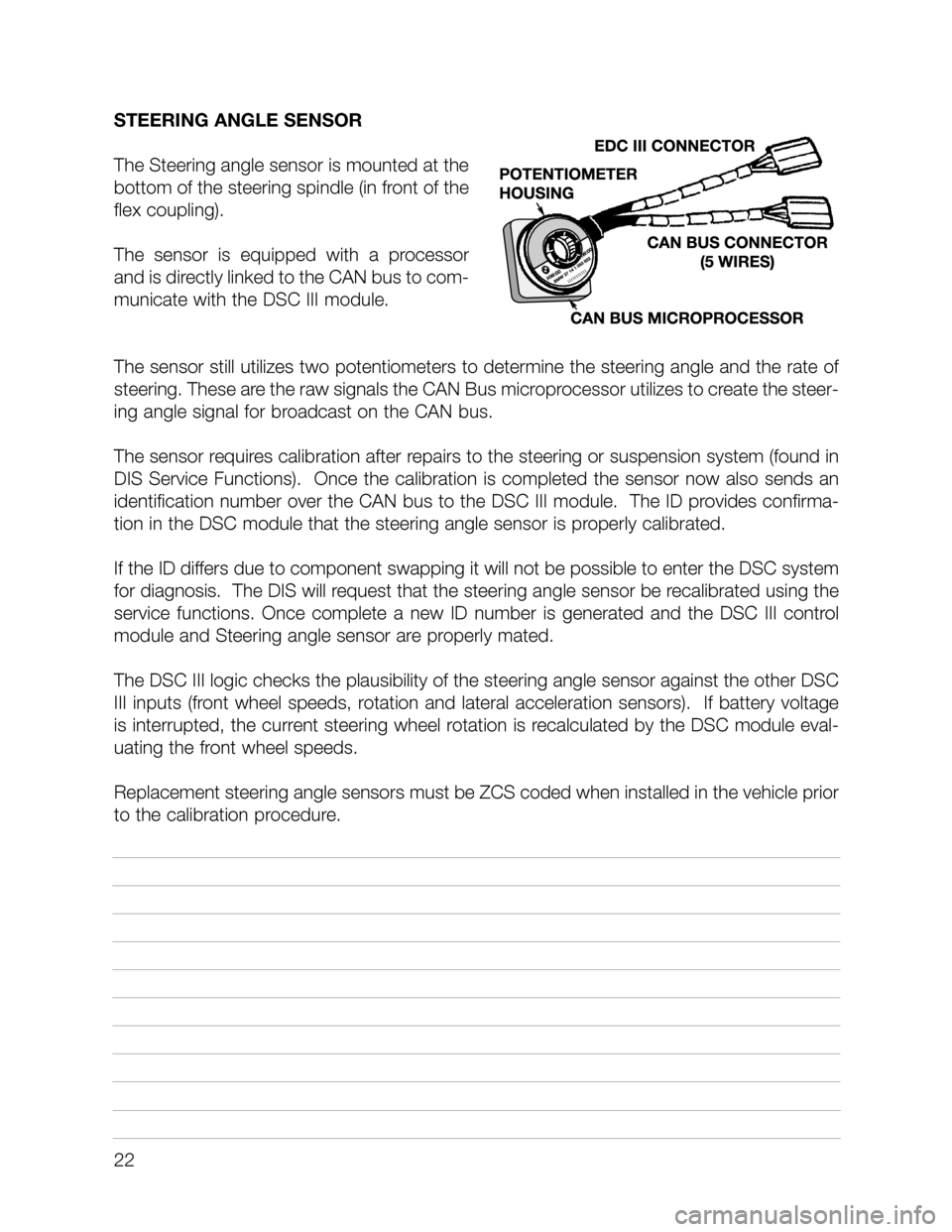

STEERING ANGLE SENSOR

The Steering angle sensor is mounted at the

bottom of the steering spindle (in front of the

flex coupling).

The sensor is equipped with a processor

and is directly linked to the CAN bus to com-

municate with the DSC III module.

The sensor still utilizes two potentiometers to determine the steering angle and the rate of

steering. These are the raw signals the CAN Bus microprocessor utilizes to create the steer-

ing angle signal for broadcast on the CAN bus.

The sensor requires calibration after repairs to the steering or suspension system (found in

DIS Service Functions). Once the calibration is completed the sensor now also sends an

identification number over the CAN bus to the DSC III module. The ID provides confirma-

tion in the DSC module that the steering angle sensor is properly calibrated.

If the ID differs due to component swapping it will not be possible to enter the DSC system

for diagnosis. The DIS will request that the steering angle sensor be recalibrated using the

service functions. Once complete a new ID number is generated and the DSC III control

module and Steering angle sensor are properly mated.

The DSC III logic checks the plausibility of the steering angle sensor against the other DSC

III inputs (front wheel speeds, rotation and lateral acceleration sensors). If battery voltage

is interrupted, the current steering wheel rotation is recalculated by the DSC module eval-

uating the front wheel speeds.

Replacement steering angle sensors must be ZCS coded when installed in the vehicle prior

to the calibration procedure.

22