E46 m54 BMW X5 2002 E53 M54 Engine Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2002, Model line: X5, Model: BMW X5 2002 E53Pages: 48, PDF Size: 2.52 MB

Page 2 of 48

M54 ENGINE

Models: E53 X5,

SOP: 3 liter - 4/00

Objectives of the Module:

Purpose of the System:

The M54 engine was developed to meet the needs for ULEV compliancy for emission con-

trol. The increase in displacement allows the engine to fit the X5 All Roads vehicle while still

meeting the demands for power and performance.

INTRODUCTION

The M54 - 6 cylinder engine is being introduced with the 2001 Model Year E53 - X5. The

displacement of the new engine for the X5 is 3 liters and the engine will replace the 2.8 liter

engine in the E46/Z3 series in 6/2000 and E39 series vehicles in 9/2000.

.

Design objectives for the M54 engine were to provide:

• Lower Emissions

• Maintain Fuel Economy

• Maintain Power and Performance levels

2

M54engMS43/ST036/6/2000

At the end of this section of the handout, you will be able to:

• Identify the changes to the M54 engines over the M52 TU engine.

• List the design objectives for the M54 engine.

Page 12 of 48

12

M54engMS43/ST036/6/2000

MS 43 NEW FUNCTIONS

ACCELERATOR PEDAL SENSOR

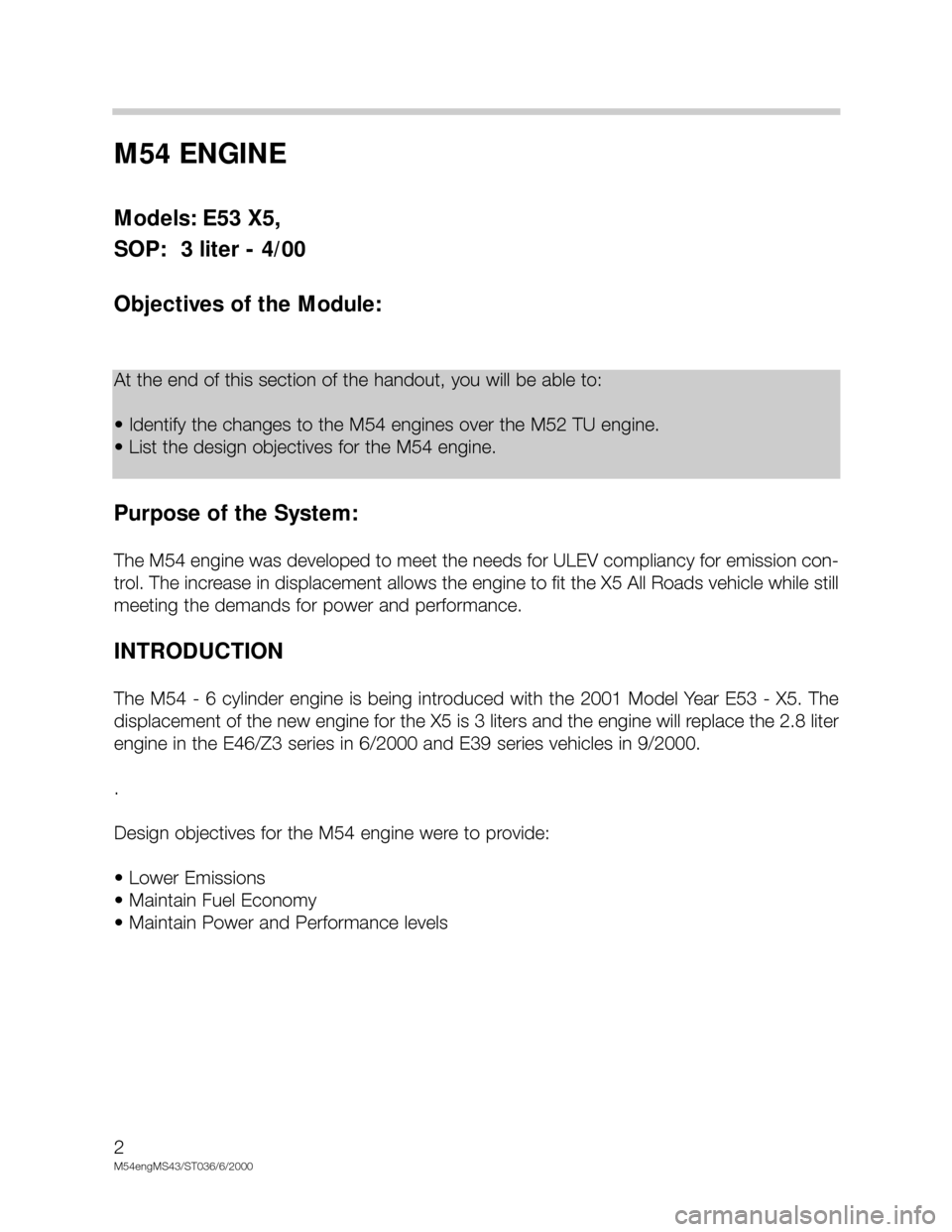

PWG SIGNAL MONITORING & PWG FAILSAFE OPERATION:

• As a redundant safety feature the PWG provides two separate signals from two integral

angle hall sensors (HS #1 and HS #2) representing the driver’s request for throttle acti-

vation.

• If the monitored PWG signals are not plausible, MS 43.0 will only use the lower of the

two signals as the driver’s pedal request input providing failsafe operation. Throttle

response will be slower and maximum throttle position will be reduced.

• When in PWG failsafe operation, MS 43.0 sets the EDK throttle plate and injection time

to idle (LL) whenever the brake pedal is depressed.

• When the system is in PWG failsafe operation, the instrument cluster matrix display will

post “Engine Emergency Program” and PWG specific fault(s) will be stored in memory.

_____________________________________________________________________________

_____________________________________________________________________________

E46ICPOT-SIG.

Page 13 of 48

13

M54engMS43/ST036/6/20000

MS 43 NEW FUNCTIONS

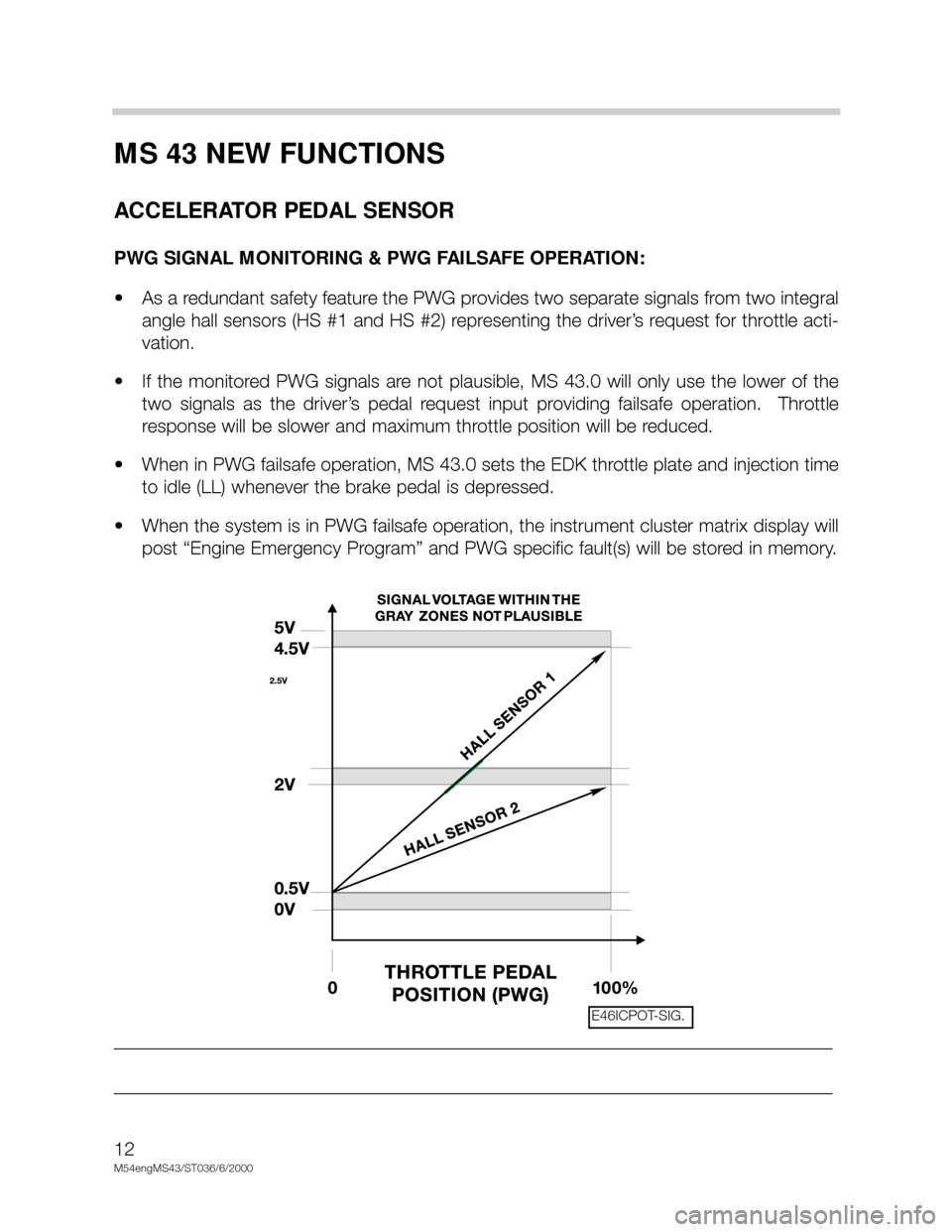

EDK THROTTLE POSITION FEEDBACK SIGNALS

The EDK throttle plate is monitored by two integrated potentiometers. The potentiometers

provide linear voltage feedback signals to the control module as the throttle plate is opened

and closed.

Feedback signal 1 provides a signal from 0.5 V (LL) to 4.5 V (VL).

Feedback signal 2 provides a signal from 4.5 V (LL) to 0.5 V (VL)

Potentiometer signal 1 is the primary feedback signal of throttle plate position and signal 2

is the plausibility cross check through the complete throttle plate movement.

ART-EDK.EPS1

ART-E46ICPWG2.

Page 15 of 48

15

M54engMS43/ST036/6/20000

MS 43 NEW FUNCTIONS

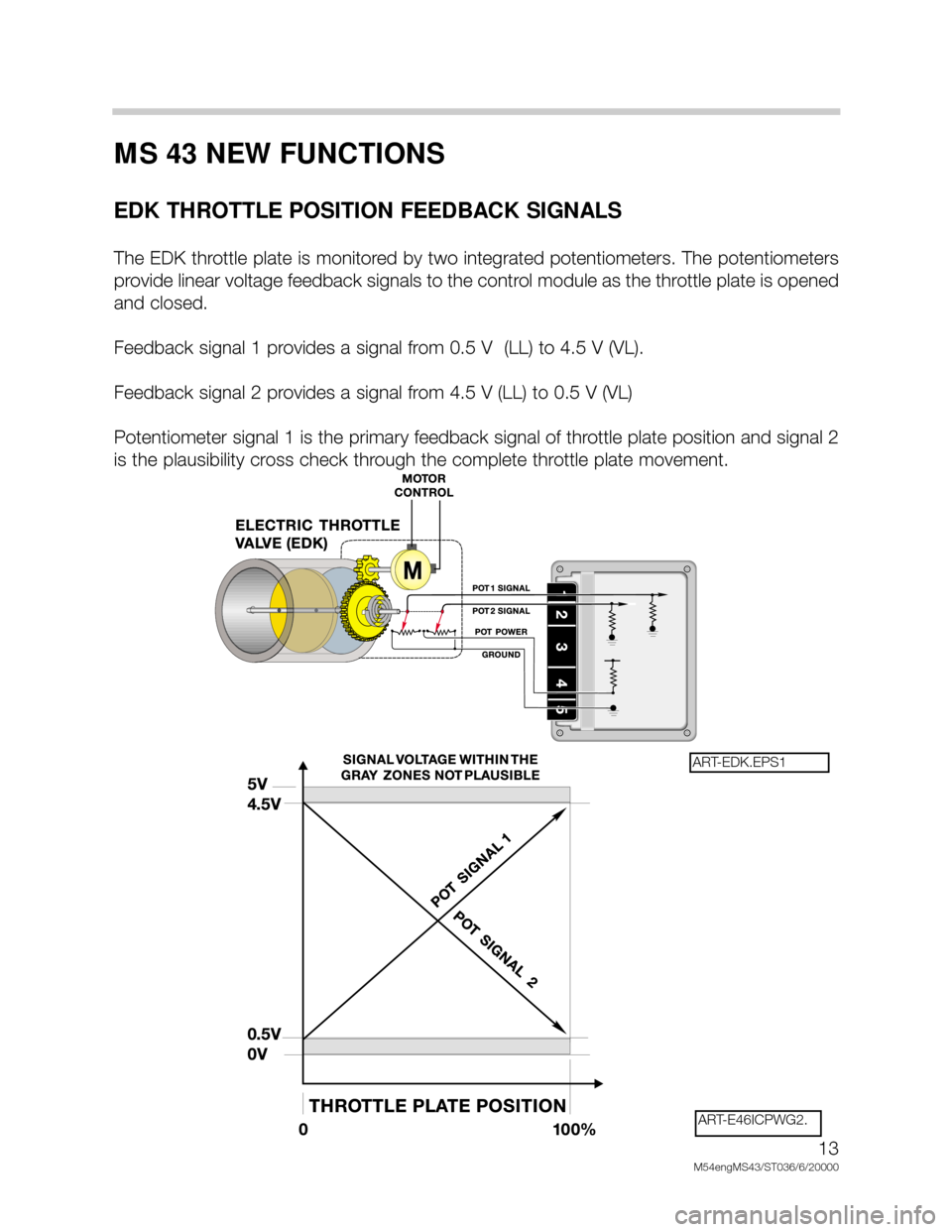

MAIN RELAY MONITOR

The MS 43.0 system incorporates a new monitoring feature for terminal 87 (KL 87) of the

main relay. The relay is monitored internally for the voltage level at KL 87. Five seconds after

the ignition key is switched on, and the voltage at the KL 15 input is greater than 9 volts,

the control module checks the voltage at KL 87.

If the voltage difference between the two terminals is greater than 3 volts, a fault will be

stored in the ECM.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

ART-E46ICMS43RELAY

Page 16 of 48

16

M54engMS43/ST036/6/2000

MS 43 NEW FUNCTIONS

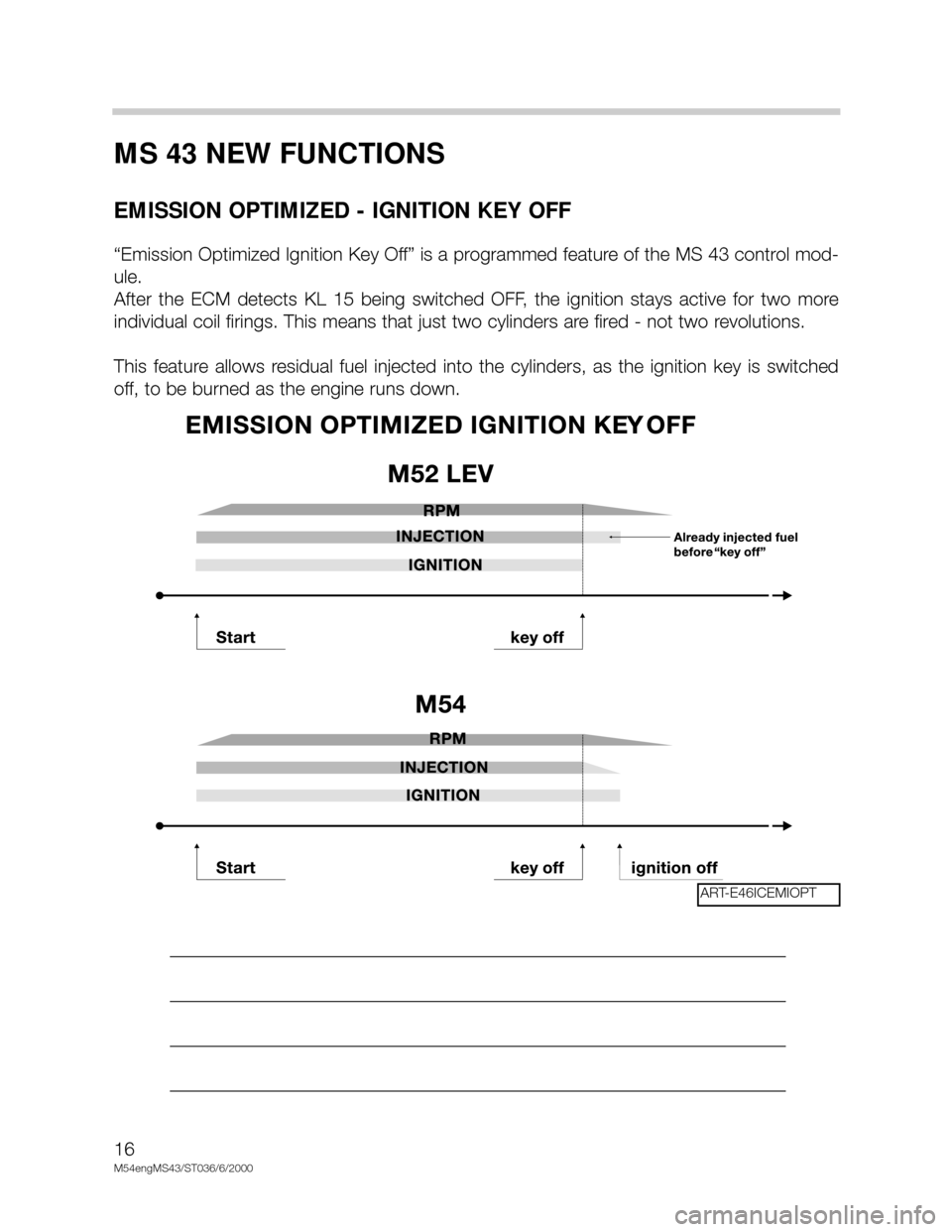

EMISSION OPTIMIZED - IGNITION KEY OFF

“Emission Optimized Ignition Key Off” is a programmed feature of the MS 43 control mod-

ule.

After the ECM detects KL 15 being switched OFF, the ignition stays active for two more

individual coil firings. This means that just two cylinders are fired - not two revolutions.

This feature allows residual fuel injected into the cylinders, as the ignition key is switched

off, to be burned as the engine runs down.

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

__________________________________________________________________

ART-E46ICEMIOPT

Page 18 of 48

18

M54engms43/STO36/6/00

123

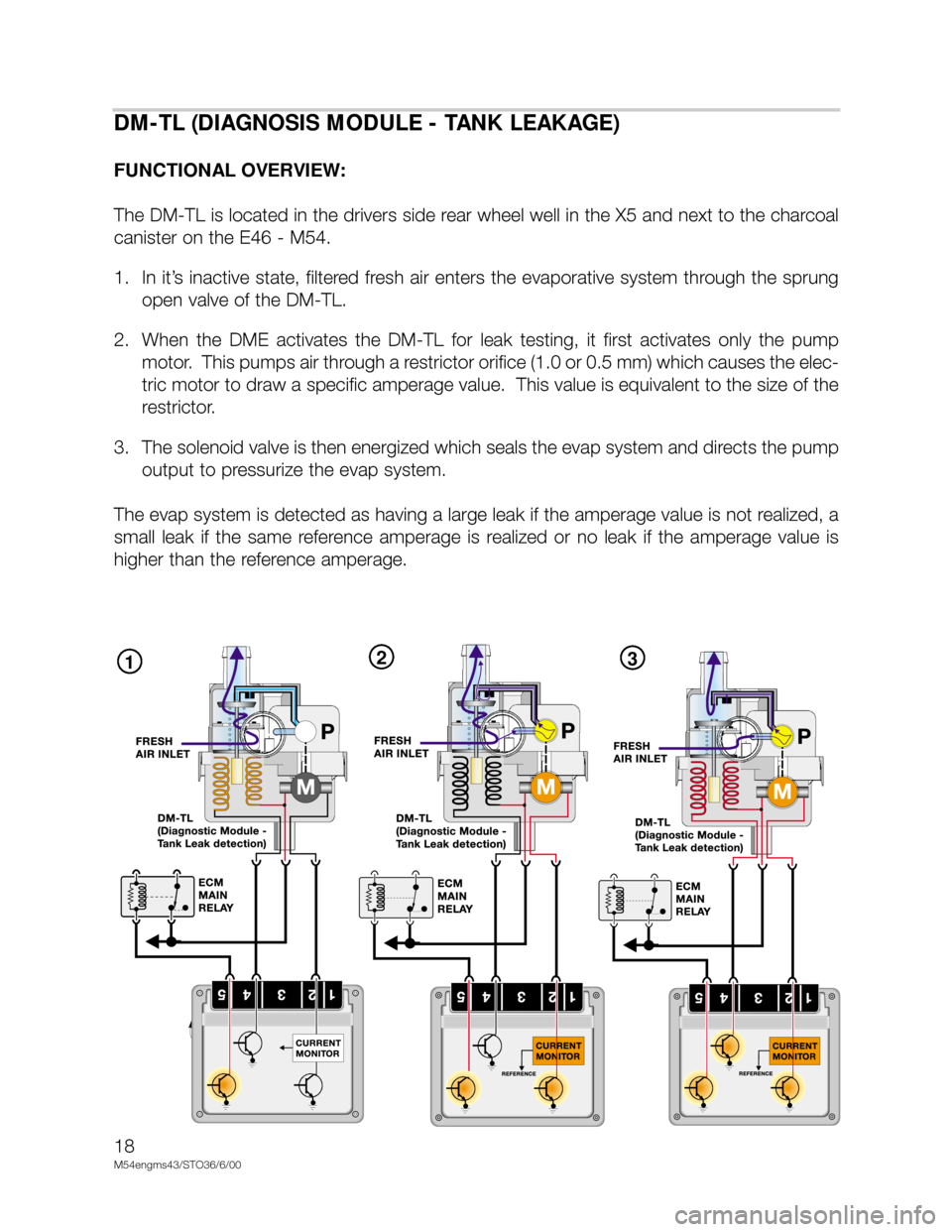

DM-TL (DIAGNOSIS MODULE - TANK LEAKAGE)

FUNCTIONAL OVERVIEW:

The DM-TL is located in the drivers side rear wheel well in the X5 and next to the charcoal

canister on the E46 - M54.

1. In it’s inactive state, filtered fresh air enters the evaporative system through the sprung

open valve of the DM-TL.

2. When the DME activates the DM-TL for leak testing, it first activates only the pump

motor. This pumps air through a restrictor orifice (1.0 or 0.5 mm) which causes the elec-

tric motor to draw a specific amperage value. This value is equivalent to the size of the

restrictor.

3. The solenoid valve is then energized which seals the evap system and directs the pump

output to pressurize the evap system.

The evap system is detected as having a large leak if the amperage value is not realized, a

small leak if the same reference amperage is realized or no leak if the amperage value is

higher than the reference amperage.