Idle BMW X5 2002 E53 M54 Engine Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2002, Model line: X5, Model: BMW X5 2002 E53Pages: 48, PDF Size: 2.52 MB

Page 1 of 48

Initial Print Date: 02/2000Revision Date: 6/2000

Subject Page

M54 Engine

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mechanical changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Review Questions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Siemen’s MS 43.0 System

• Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

• I - P - O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MS 43.0 New functions

• Electronic throttle Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

• Accelerator Pedal Sensor (PWG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

• Electronic Throttle Valve (EDK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

• Main Relay Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

• Engine Optimized Ignition Key OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

• Diagnosis Module Tank Leakage (DM-TL) . . . . . . . . . . . . . . . . . . . . . . .17

• DM-TL Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

• DM-TL Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Carry Over Functions

Inputs

• Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

• Camshaft Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

• Crankshaft Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

• Misfire Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

• OBD Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

• Mass Air Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Outputs

• VANOS Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

• Electric Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

• Secondary Air Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

• Engine Speed Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

• RZV Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

• Resonance - Turbulence Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

• Idle Speed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

• Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

• Purge Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table of Contents

Page 5 of 48

M54 ENGINE

MECHANICAL CHANGES

NON RETURN FUEL RAIL SYSTEM

The M54 engine with MS 43.0 control uses the non return fuel rail system introduced on

the M62 TU engine. The system meets running loss compliance without the use of the 3/2-

way solenoid valve currently used on the M52 TU engine.

The regulated fuel supply is controlled by

the fuel pressure regulator integrated in

the fuel filter. The fuel return line is also

located on the filter.

The M54 engine uses an Electronic Controlled

Throttle Valve (EDK) for intake air control. The

idle control valve and turbulence function of the

intake manifold carries over from the M52 TU

engine.

5

M54engMS43/ST036/6/20000

ART-FUELRAIL

Page 12 of 48

12

M54engMS43/ST036/6/2000

MS 43 NEW FUNCTIONS

ACCELERATOR PEDAL SENSOR

PWG SIGNAL MONITORING & PWG FAILSAFE OPERATION:

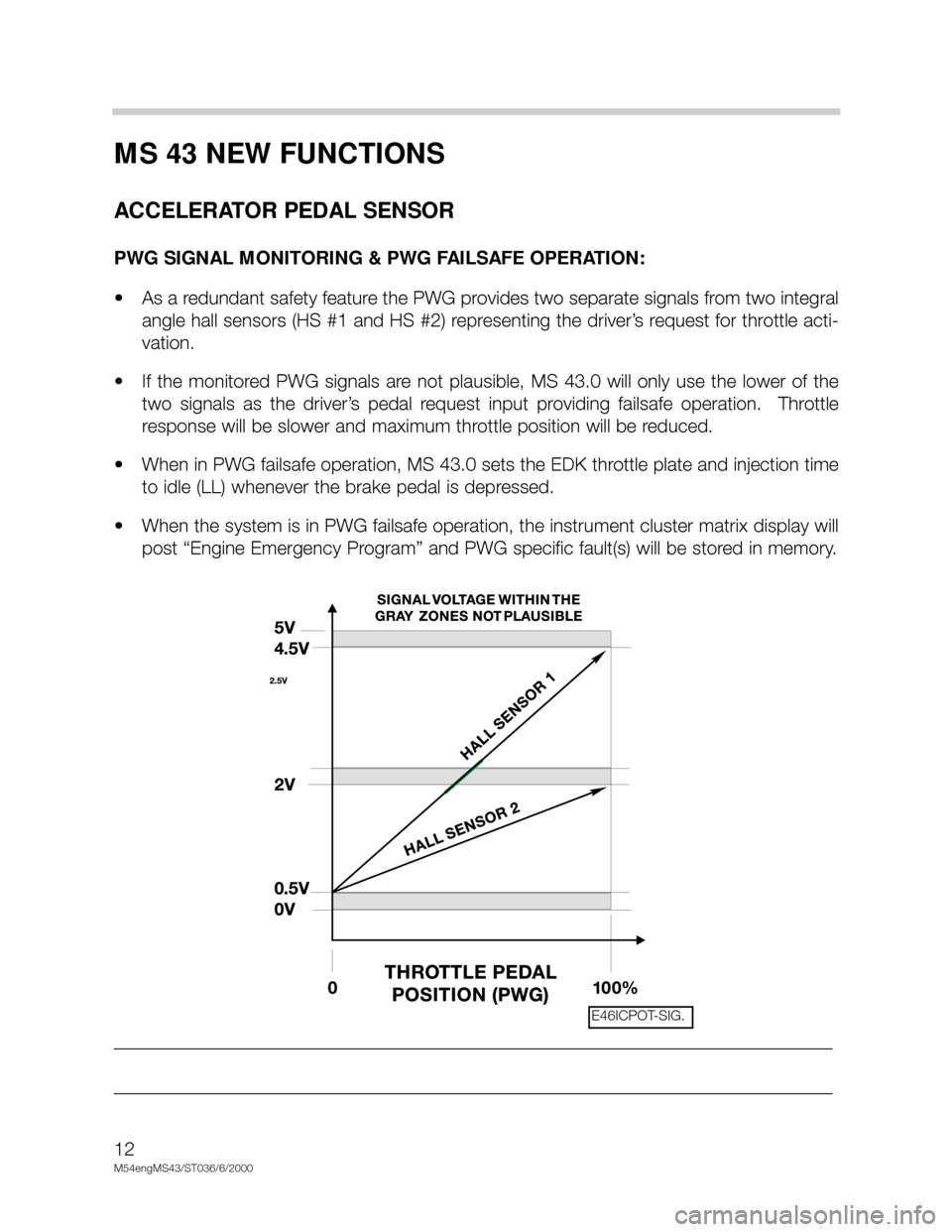

• As a redundant safety feature the PWG provides two separate signals from two integral

angle hall sensors (HS #1 and HS #2) representing the driver’s request for throttle acti-

vation.

• If the monitored PWG signals are not plausible, MS 43.0 will only use the lower of the

two signals as the driver’s pedal request input providing failsafe operation. Throttle

response will be slower and maximum throttle position will be reduced.

• When in PWG failsafe operation, MS 43.0 sets the EDK throttle plate and injection time

to idle (LL) whenever the brake pedal is depressed.

• When the system is in PWG failsafe operation, the instrument cluster matrix display will

post “Engine Emergency Program” and PWG specific fault(s) will be stored in memory.

_____________________________________________________________________________

_____________________________________________________________________________

E46ICPOT-SIG.

Page 14 of 48

14

M54engMS43/ST036/6/2000

MS 43 NEW FUNCTIONS

EDK THROTTLE POSITION FEEDBACK SIGNALS

EDK FEEDBACK SIGNAL MONITORING & EDK FAILSAFE OPERATION:

• The EDK provides two separate signals from two integral potentiometers (Pot 1 and Pot

2) representing the exact position of the throttle plate.

• EDK Pot 1 provides the primary throttle plate position feedback. As a redundant safe-

ty feature, Pot 2 is continuously cross checked with Pot 1 for signal plausibility.

• If plausibility errors are detected between Pot 1 and Pot 2, MS 43.0 will calculate the

inducted engine air mass (from HFM signal) and only utilize the potentiometer signal that

closely matches the detected intake air mass.

- The MS 43.0 uses the air mass signalling as a “virtual potentiometer” (pot 3) for a

comparative source to provide failsafe operation.

- If MS 43.0 cannot calculate a plausible conclusion from the monitored pots (1 or 2

and virtual 3) the EDK motor is switched off and fuel injection cut out is activated

(no failsafe operation possible).

• The EDK is continuously monitored during all phases of engine operation. It is also

briefly activated when KL 15 is initially switched on as a “pre-flight check” to verify it’s

mechanical integrity (no binding, appropriate return spring tension, etc). This is accom-

plished by monitoring both the motor control amperage and the reaction speed of the

EDK feedback potentiometers. If faults are detected the EDK motor is switched off and

fuel injection cut off is activated (no failsafe operation possible). The engine does how-

ever continue to run extremely rough at idle speed.

• When a replacement EDK is installed, the MS 43.0 adapts to the new component

(required amperage draw for motor control, feedback pot tolerance differences, etc).

This occurs immediately after the next cycle of KL 15 for approximately 30 seconds.

During this period of adaptation, the maximum opening of the throttle plate is 25%.

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

_____________________________________________________________________________

Page 32 of 48

32

M54engMS43/ST036/6/2000

MS 43 CARRY OVER FUNCTIONS

OUTPUT FUNCTIONS -VANOS CONTROL

With the double VANOS system, the valve timing is changed on both the intake and the

exhaust camshafts.

Double VANOS provides the following benefits:

• Torque increase in the low to mid (1500 - 2000 RPM) range without power loss in the

upper RPM range.

• Less incomplete combustion when idling due to less camshaft overlap (also improves

idle speed characteristics).

• Internal exhaust gas recirculation (EGR) in the part load range (reduces NOx and post-

combustion of residual gasses in the exhaust)

• Rapid catalyst warm up and lower “raw” emissions after cold start.

• Reduction in fuel consumption

Double VANOS consists of the following parts:

• Intake and exhaust camshafts with helical gear insert

• Sprockets with adjustable gears

• VANOS actuators for each camshaft

• 2 three-way solenoid switching valves

• 2 impulse wheels for detecting camshaft position

• 2 camshaft position sensors (Hall effect)

The “initial” timing is set by gear positioning (refer to the Repair Instructions for details) and

the chain tensioner. As with the previous VANOS, the hydraulically controlled actuators

move the helical geared cups to regulate camshaft timing. The angled teeth of the helical

gears cause the pushing

movement of the helical cup to be converted into a rotational

movement. This rotational movement is added to the turning of the camshafts and cause

the camshafts to “advance” or “retard”. The adjustment rate is dependent oil temperature,

oil pressure, and engine RPM.

Page 35 of 48

35

M54engMS43/ST036/6/20000

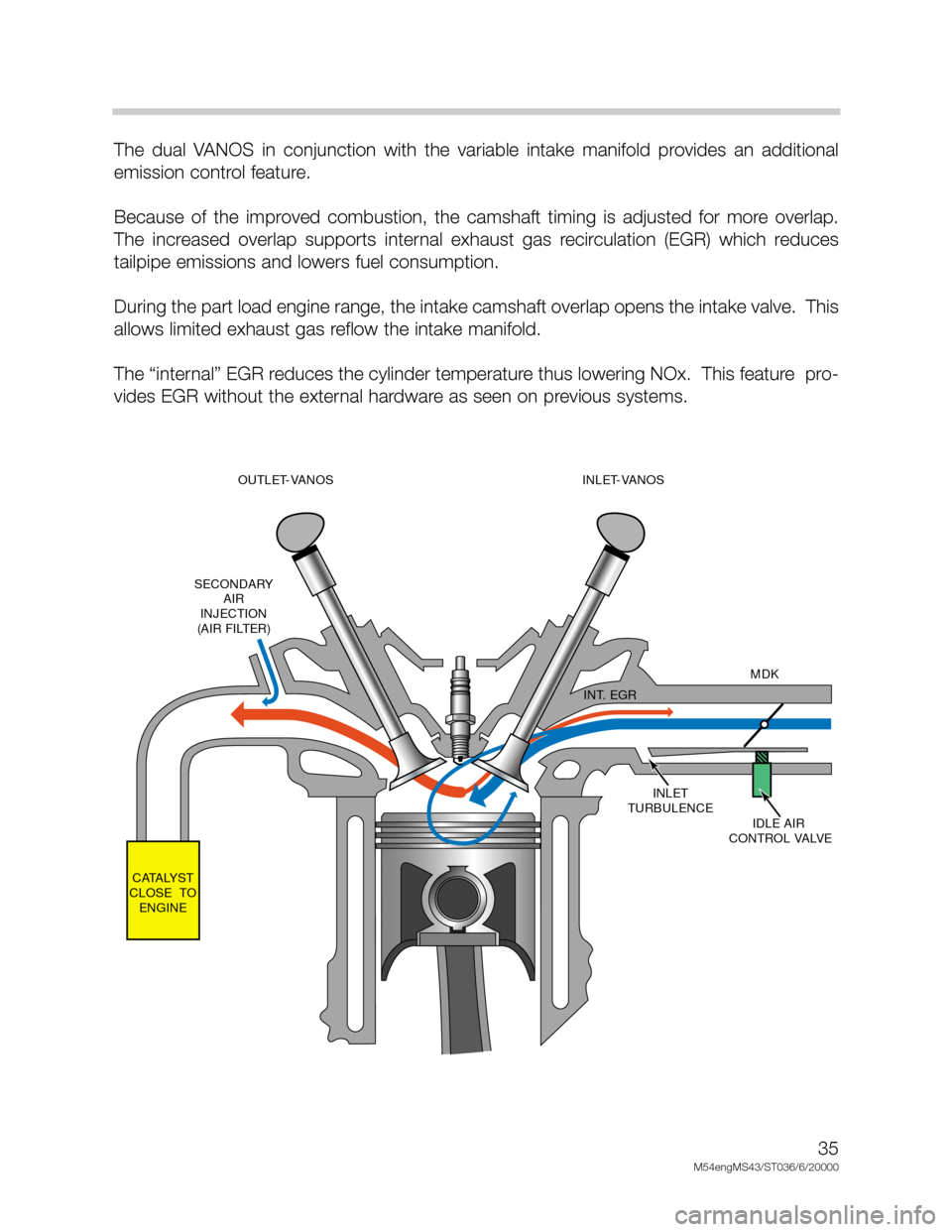

The dual VANOS in conjunction with the variable intake manifold provides an additional

emission control feature.

Because of the improved combustion, the camshaft timing is adjusted for more overlap.

The increased overlap supports internal exhaust gas recirculation (EGR) which reduces

tailpipe emissions and lowers fuel consumption.

During the part load engine range, the intake camshaft overlap opens the intake valve. This

allows limited exhaust gas reflow the intake manifold.

The “internal” EGR reduces the cylinder temperature thus lowering NOx. This feature pro-

vides EGR without the external hardware as seen on previous systems.

INLET

TURBULENCE

IDLE AIR

CONTROL VALVEMDK

INT. EGR

CATALYST

CLOSE TO

ENGINESECONDARY

AIR

INJECTION

(AIR FILTER)OUTLET-VANOS

(228/80-105)INLET-VANOS

(228/80-120)

Page 41 of 48

41

M54engMS43/ST036/6/20000

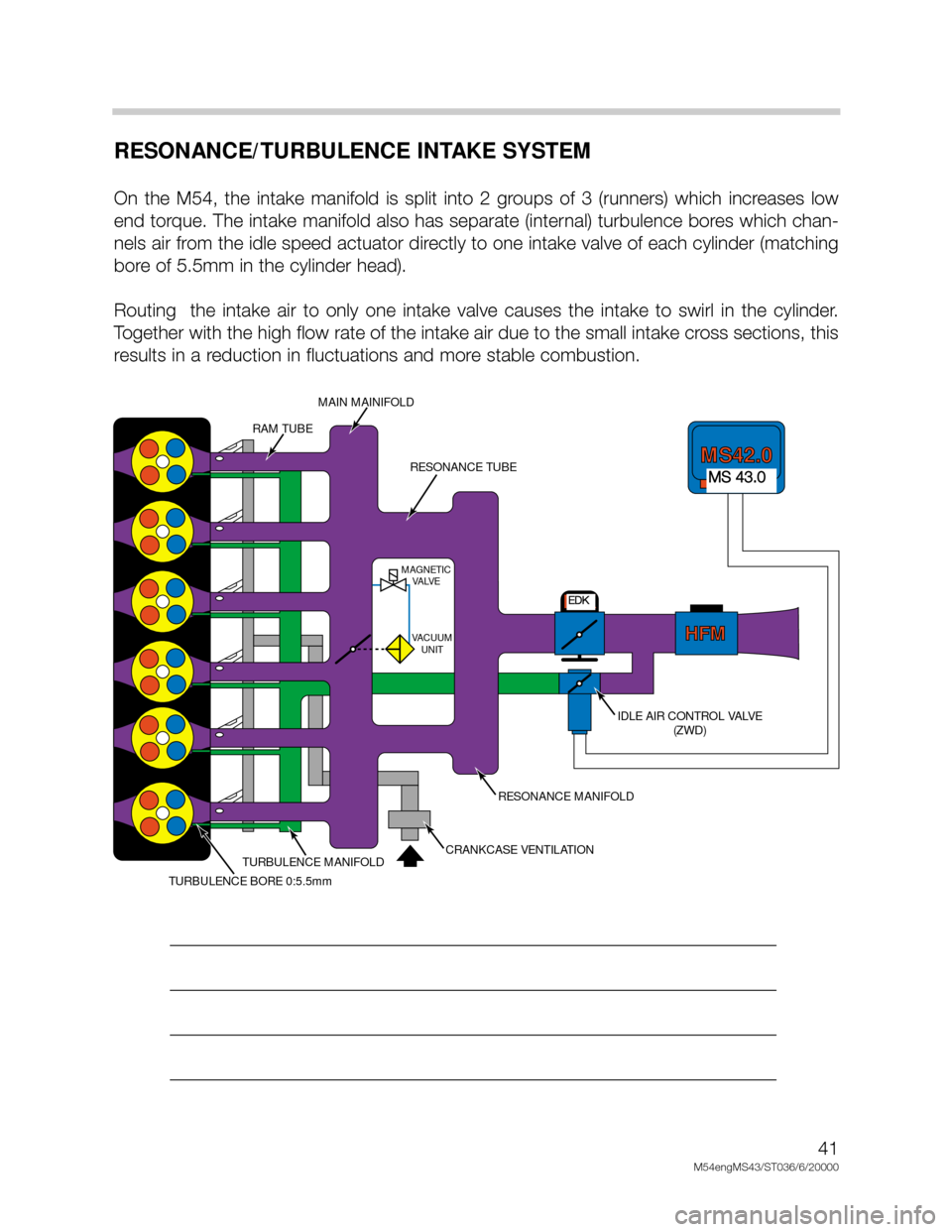

RESONANCE/TURBULENCE INTAKE SYSTEM

On the M54, the intake manifold is split into 2 groups of 3 (runners) which increases low

end torque. The intake manifold also has separate (internal) turbulence bores which chan-

nels air from the idle speed actuator directly to one intake valve of each cylinder (matching

bore of 5.5mm in the cylinder head).

Routing the intake air to only one intake valve causes the intake to swirl in the cylinder.

Together with the high flow rate of the intake air due to the small intake cross sections, this

results in a reduction in fluctuations and more stable combustion.

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

MDK

HFMHFM

MAGNETIC

VALVE

VACUUM

UNIT

MS42.0MS42.0

RAM TUBE

MAIN MAINIFOLD

RESONANCE TUBE

IDLE AIR CONTROL VALVE

(ZWD)

RESONANCE MANIFOLD

CRANKCASE VENTILATIONTURBULENCE MANIFOLD

TURBULENCE BORE 0:5.5mm

MS 43.0

EDK

Page 45 of 48

45

M54engMS43/ST036/6/20000

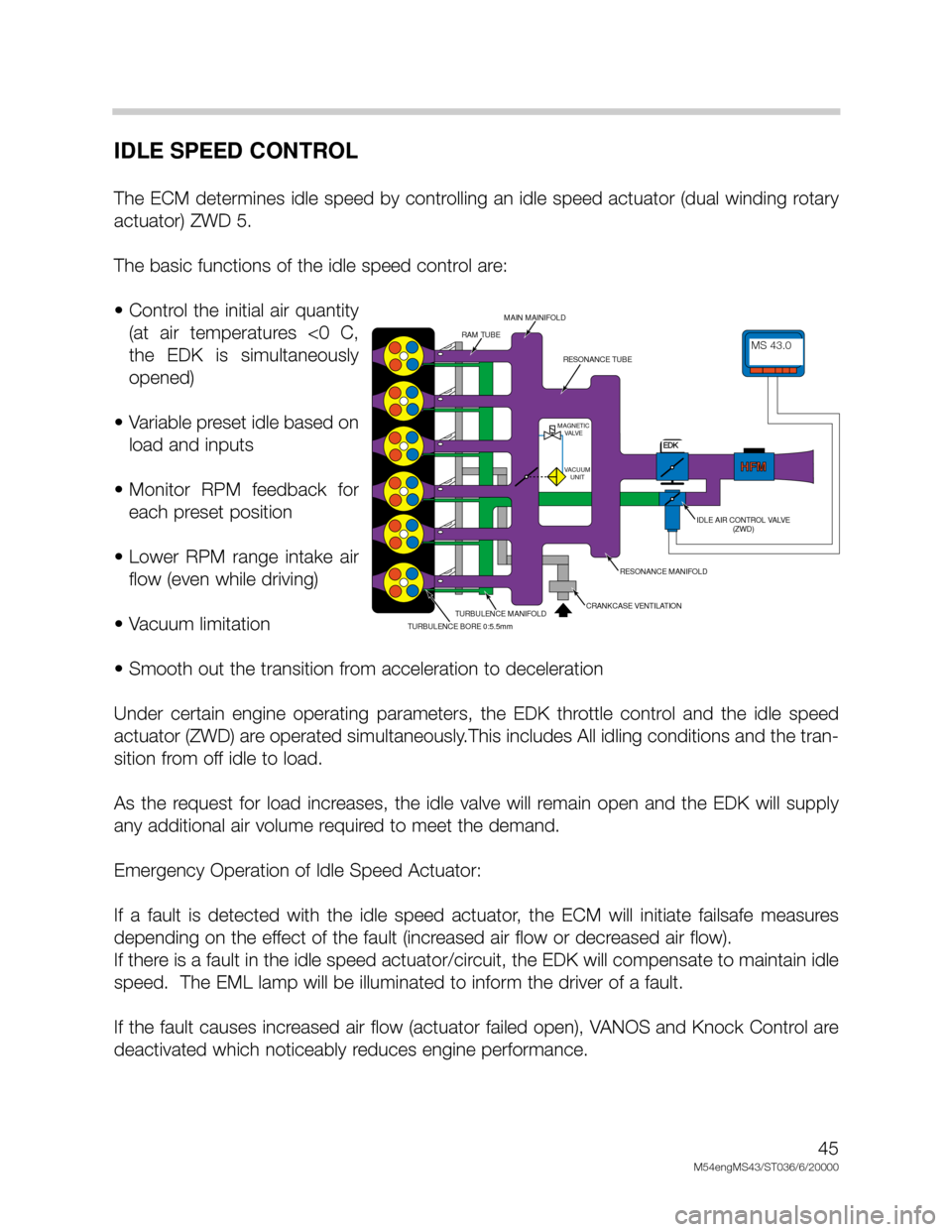

IDLE SPEED CONTROL

The ECM determines idle speed by controlling an idle speed actuator (dual winding rotary

actuator) ZWD 5.

The basic functions of the idle speed control are:

• Control the initial air quantity

(at air temperatures <0 C,

the EDK is simultaneously

opened)

• Variable preset idle based on

load and inputs

• Monitor RPM feedback for

each preset position

• Lower RPM range intake air

flow (even while driving)

• Vacuum limitation

• Smooth out the transition from acceleration to deceleration

Under certain engine operating parameters, the EDK throttle control and the idle speed

actuator (ZWD) are operated simultaneously.This includes All idling conditions and the tran-

sition from off idle to load.

As the request for load increases, the idle valve will remain open and the EDK will supply

any additional air volume required to meet the demand.

Emergency Operation of Idle Speed Actuator:

If a fault is detected with the idle speed actuator, the ECM will initiate failsafe measures

depending on the effect of the fault (increased air flow or decreased air flow).

If there is a fault in the idle speed actuator/circuit, the EDK will compensate to maintain idle

speed. The EML lamp will be illuminated to inform the driver of a fault.

If the fault causes increased air flow (actuator failed open), VANOS and Knock Control are

deactivated which noticeably reduces engine performance.

MDK

HFMHFM

MAGNETIC

VALVE

VACUUM

UNIT

MS42.0MS42.0

RAM TUBE

MAIN MAINIFOLD

RESONANCE TUBE

IDLE AIR CONTROL VALVE

(ZWD)

RESONANCE MANIFOLD

CRANKCASE VENTILATIONTURBULENCE MANIFOLD

TURBULENCE BORE 0:5.5mm

MS 43.0

EDK