engine coolant BMW X5 2002 E53 M54 Engine Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2002, Model line: X5, Model: BMW X5 2002 E53Pages: 48, PDF Size: 2.52 MB

Page 33 of 48

33

M54engMS43/ST036/6/20000

NOTE: With extremely hot oil temperatures Vanos is deactivated (Power loss). If the oil is

too thick (wrong viscosity) a fault could be set.

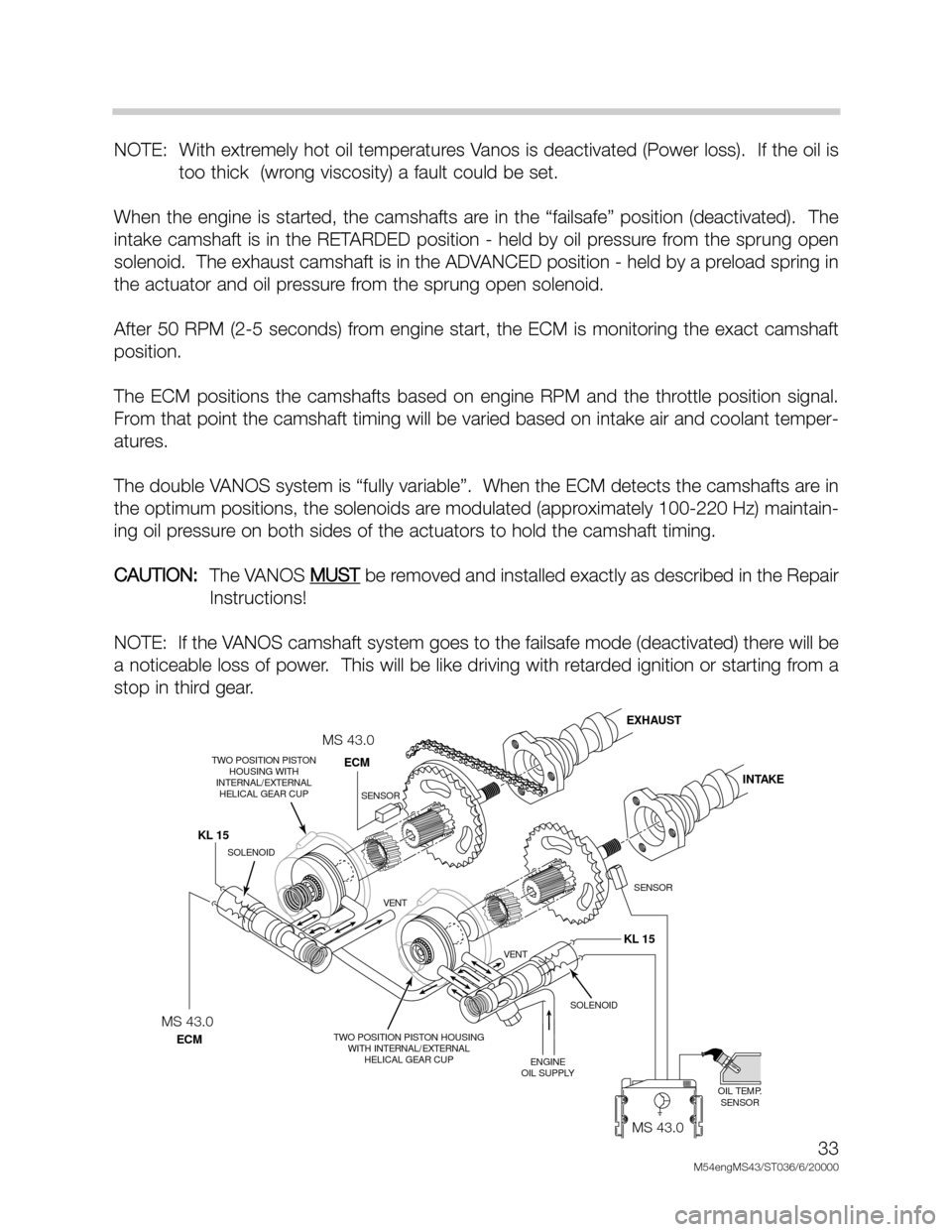

When the engine is started, the camshafts are in the “failsafe” position (deactivated). The

intake camshaft is in the RETARDED position - held by oil pressure from the sprung open

solenoid. The exhaust camshaft is in the ADVANCED position - held by a preload spring in

the actuator and oil pressure from the sprung open solenoid.

After 50 RPM (2-5 seconds) from engine start, the ECM is monitoring the exact camshaft

position.

The ECM positions the camshafts based on engine RPM and the throttle position signal.

From that point the camshaft timing will be varied based on intake air and coolant temper-

atures.

The double VANOS system is “fully variable”. When the ECM detects the camshafts are in

the optimum positions, the solenoids are modulated (approximately 100-220 Hz) maintain-

ing oil pressure on both sides of the actuators to hold the camshaft timing.

CAUTION:

The VANOS MUST

be removed and installed exactly as described in the Repair

Instructions!

NOTE: If the VANOS camshaft system goes to the failsafe mode (deactivated) there will be

a noticeable loss of power. This will be like driving with retarded ignition or starting from a

stop in third gear.

KL 15 KL 15

MS42.0

SOLENOID

OIL TEMP.

SENSOR TWO POSITION PISTON HOUSING

WITH INTERNAL/EXTERNAL

HELICAL GEAR CUP TWO POSITION PISTON

HOUSING WITH

INTERNAL/EXTERNAL

HELICAL GEAR CUP

ENGINE

OIL SUPPLY VENT VENT

SOLENOID

SENSOR SENSOR

MS42

ECMEXHAUST

INTAKE

MS42.0

ECM

MS 43.0

MS 43.0

MS 43.0

Page 36 of 48

36

M54engMS43/ST036/6/2000

ELECTRIC FAN

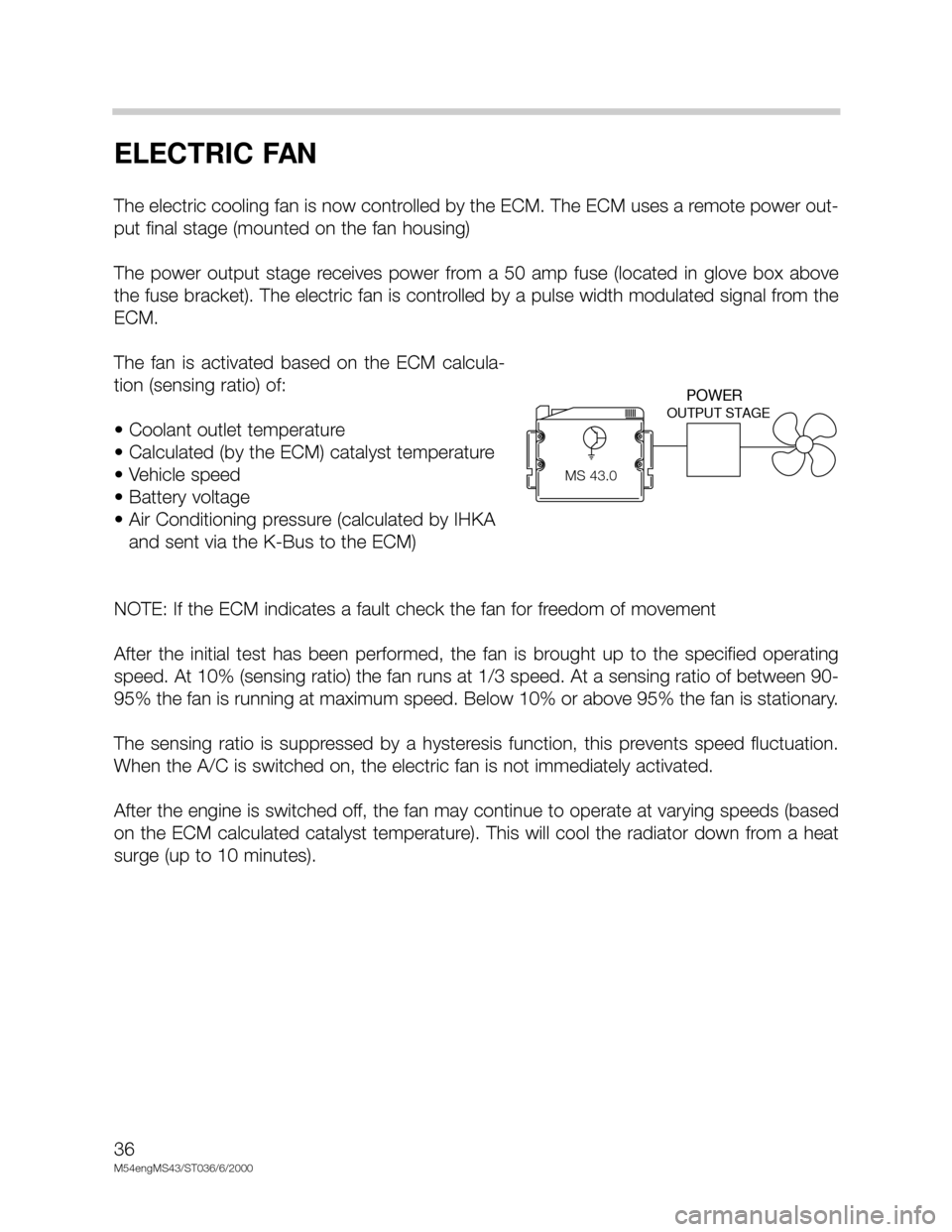

The electric cooling fan is now controlled by the ECM. The ECM uses a remote power out-

put final stage (mounted on the fan housing)

The power output stage receives power from a 50 amp fuse (located in glove box above

the fuse bracket). The electric fan is controlled by a pulse width modulated signal from the

ECM.

The fan is activated based on the ECM calcula-

tion (sensing ratio) of:

• Coolant outlet temperature

• Calculated (by the ECM) catalyst temperature

• Vehicle speed

• Battery voltage

• Air Conditioning pressure (calculated by IHKA

and sent via the K-Bus to the ECM)

NOTE: If the ECM indicates a fault check the fan for freedom of movement

After the initial test has been performed, the fan is brought up to the specified operating

speed. At 10% (sensing ratio) the fan runs at 1/3 speed. At a sensing ratio of between 90-

95% the fan is running at maximum speed. Below 10% or above 95% the fan is stationary.

The sensing ratio is suppressed by a hysteresis function, this prevents speed fluctuation.

When the A/C is switched on, the electric fan is not immediately activated.

After the engine is switched off, the fan may continue to operate at varying speeds (based

on the ECM calculated catalyst temperature). This will cool the radiator down from a heat

surge (up to 10 minutes).

OUTPUT STAGE

MS42.0

POWER

MS 43.0

Page 37 of 48

37

M54engMS43/ST036/6/20000

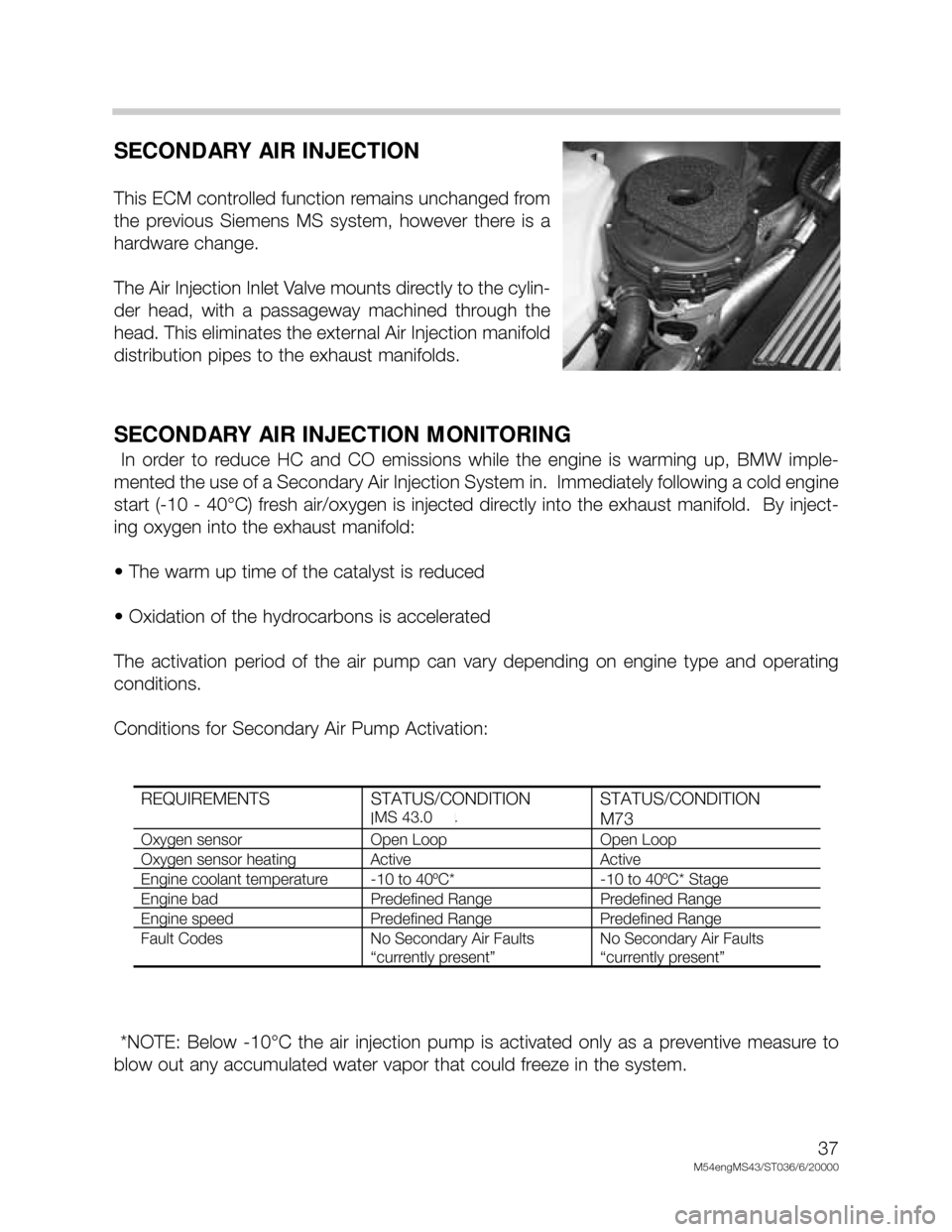

SECONDARY AIR INJECTION

This ECM controlled function remains unchanged from

the previous Siemens MS system, however there is a

hardware change.

The Air Injection Inlet Valve mounts directly to the cylin-

der head, with a passageway machined through the

head. This eliminates the external Air Injection manifold

distribution pipes to the exhaust manifolds.

SECONDARY AIR INJECTION MONITORING

In order to reduce HC and CO emissions while the engine is warming up, BMW imple-

mented the use of a Secondary Air Injection System in. Immediately following a cold engine

start (-10 - 40°C) fresh air/oxygen is injected directly into the exhaust manifold. By inject-

ing oxygen into the exhaust manifold:

• The warm up time of the catalyst is reduced

• Oxidation of the hydrocarbons is accelerated

The activation period of the air pump can vary depending on engine type and operating

conditions.

Conditions for Secondary Air Pump Activation:

*NOTE: Below -10°C the air injection pump is activated only as a preventive measure to

blow out any accumulated water vapor that could freeze in the system.

REQUIREMENTS STATUS/CONDITION

M52 & M44STATUS/CONDITION

M73

Oxygen sensor Open Loop Open Loop

Oxygen sensor heating Active Active

Engine coolant temperature -10 to 40ºC* -10 to 40ºC* Stage

Engine bad Predefined Range Predefined Range

Engine speed Predefined Range Predefined Range

Fault Codes No Secondary Air Faults

“currently present”

No Secondary Air Faults

“currently present”

MS 43.0