BMW X5 2002 E53 M62TU Engine Owner's Manual

Manufacturer: BMW, Model Year: 2002, Model line: X5, Model: BMW X5 2002 E53Pages: 37, PDF Size: 3.87 MB

Page 21 of 37

11

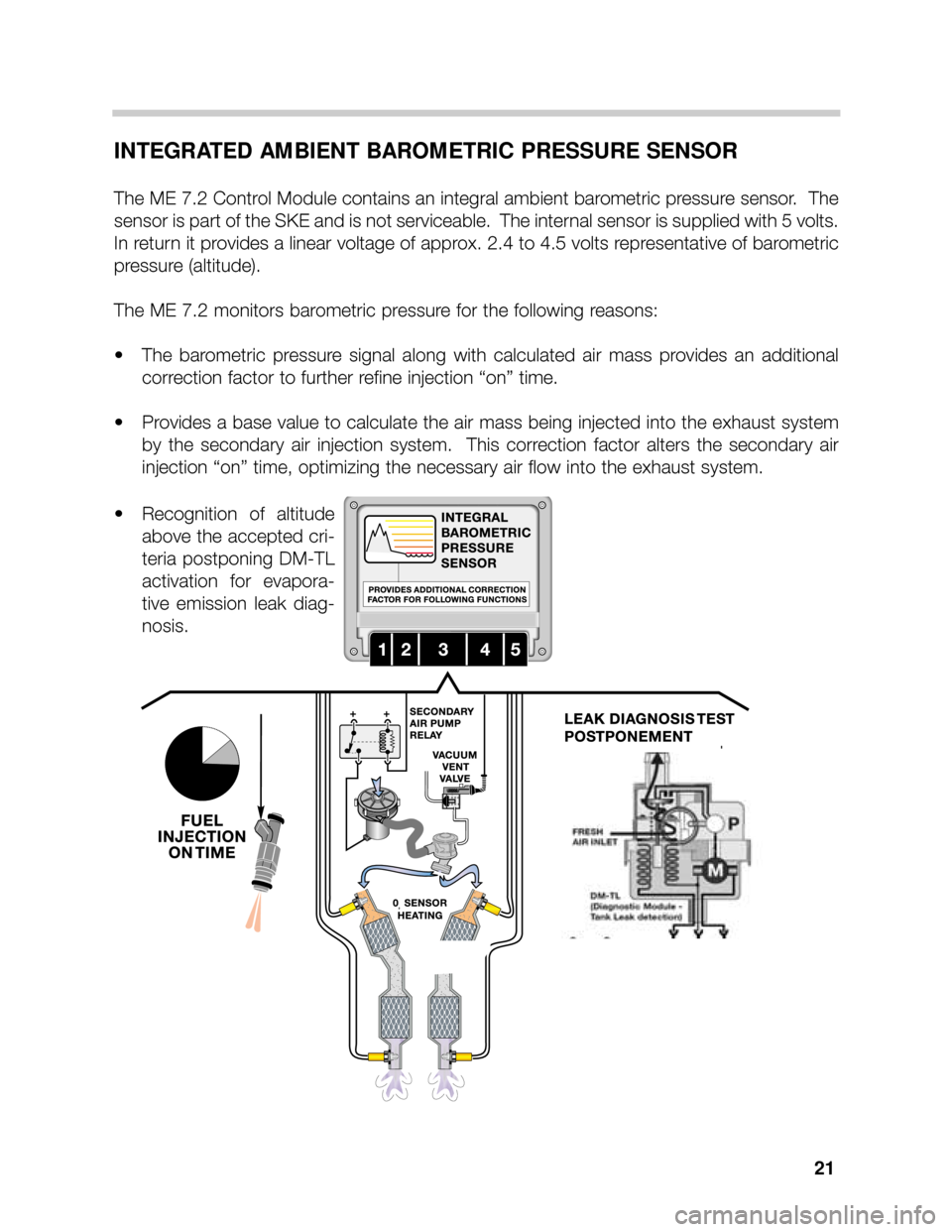

INTEGRATED AMBIENT BAROMETRIC PRESSURE SENSOR

The ME 7.2 Control Module contains an integral ambient barometric pressure sensor. The

sensor is part of the SKE and is not serviceable. The internal sensor is supplied with 5 volts.

In return it provides a linear voltage of approx. 2.4 to 4.5 volts representative of barometric

pressure (altitude).

The ME 7.2 monitors barometric pressure for the following reasons:

• The barometric pressure signal along with calculated air mass provides an additional

correction factor to further refine injection “on” time.

• Provides a base value to calculate the air mass being injected into the exhaust system

by the secondary air injection system. This correction factor alters the secondary air

injection “on” time, optimizing the necessary air flow into the exhaust system.

• Recognition of altitude

above the accepted cri-

teria postponing DM-TL

activation for evapora-

tive emission leak diag-

nosis.

21

Page 22 of 37

22

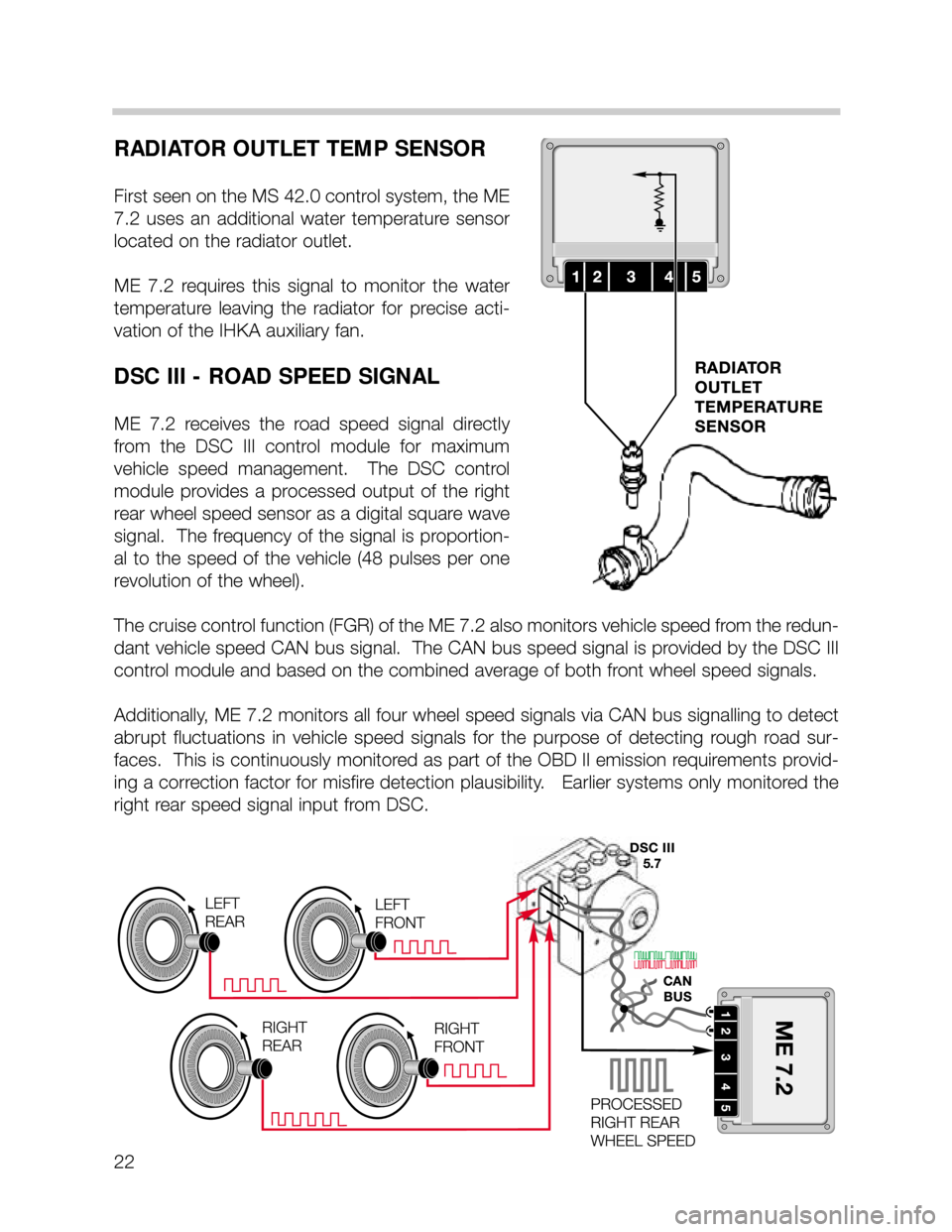

RADIATOR OUTLET TEMP SENSOR

First seen on the MS 42.0 control system, the ME

7.2 uses an additional water temperature sensor

located on the radiator outlet.

ME 7.2 requires this signal to monitor the water

temperature leaving the radiator for precise acti-

vation of the IHKA auxiliary fan.

DSC III - ROAD SPEED SIGNAL

ME 7.2 receives the road speed signal directly

from the DSC III control module for maximum

vehicle speed management. The DSC control

module provides a processed output of the right

rear wheel speed sensor as a digital square wave

signal. The frequency of the signal is proportion-

al to the speed of the vehicle (48 pulses per one

revolution of the wheel).

The cruise control function (FGR) of the ME 7.2 also monitors vehicle speed from the redun-

dant vehicle speed CAN bus signal. The CAN bus speed signal is provided by the DSC III

control module and based on the combined average of both front wheel speed signals.

Additionally, ME 7.2 monitors all four wheel speed signals via CAN bus signalling to detect

abrupt fluctuations in vehicle speed signals for the purpose of detecting rough road sur-

faces. This is continuously monitored as part of the OBD II emission requirements provid-

ing a correction factor for misfire detection plausibility. Earlier systems only monitored the

right rear speed signal input from DSC.

Page 23 of 37

23

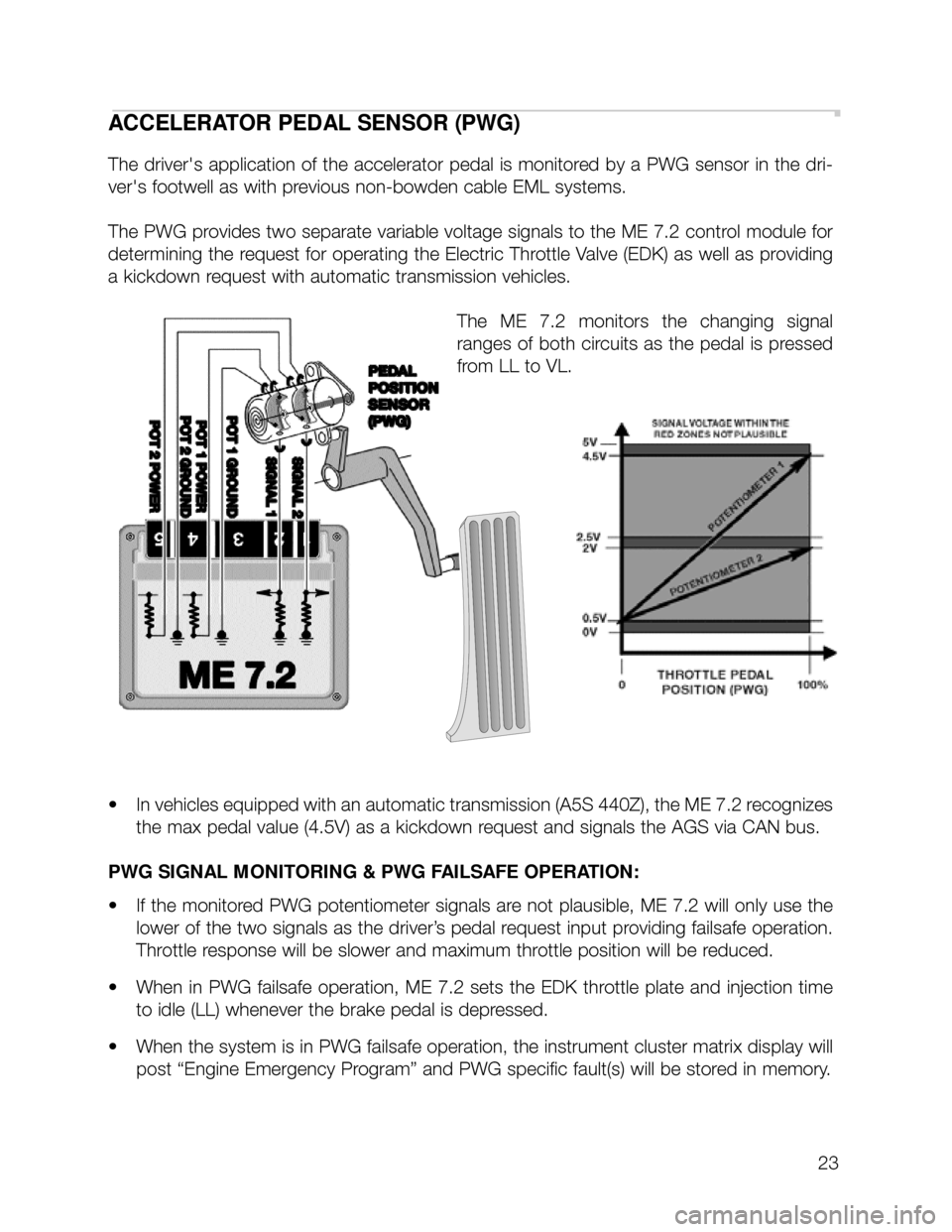

ACCELERATOR PEDAL SENSOR (PWG)

The driver's application of the accelerator pedal is monitored by a PWG sensor in the dri-

ver's footwell as with previous non-bowden cable EML systems.

The PWG provides two separate variable voltage signals to the ME 7.2 control module for

determining the request for operating the Electric Throttle Valve (EDK) as well as providing

a kickdown request with automatic transmission vehicles.

The ME 7.2 monitors the changing signal

ranges of both circuits as the pedal is pressed

from LL to VL.

• In vehicles equipped with an automatic transmission (A5S 440Z), the ME 7.2 recognizes

the max pedal value (4.5V) as a kickdown request and signals the AGS via CAN bus.

PWG SIGNAL MONITORING & PWG FAILSAFE OPERATION:

• If the monitored PWG potentiometer signals are not plausible, ME 7.2 will only use the

lower of the two signals as the driver’s pedal request input providing failsafe operation.

Throttle response will be slower and maximum throttle position will be reduced.

• When in PWG failsafe operation, ME 7.2 sets the EDK throttle plate and injection time

to idle (LL) whenever the brake pedal is depressed.

• When the system is in PWG failsafe operation, the instrument cluster matrix display will

post “Engine Emergency Program” and PWG specific fault(s) will be stored in memory.

Page 24 of 37

24

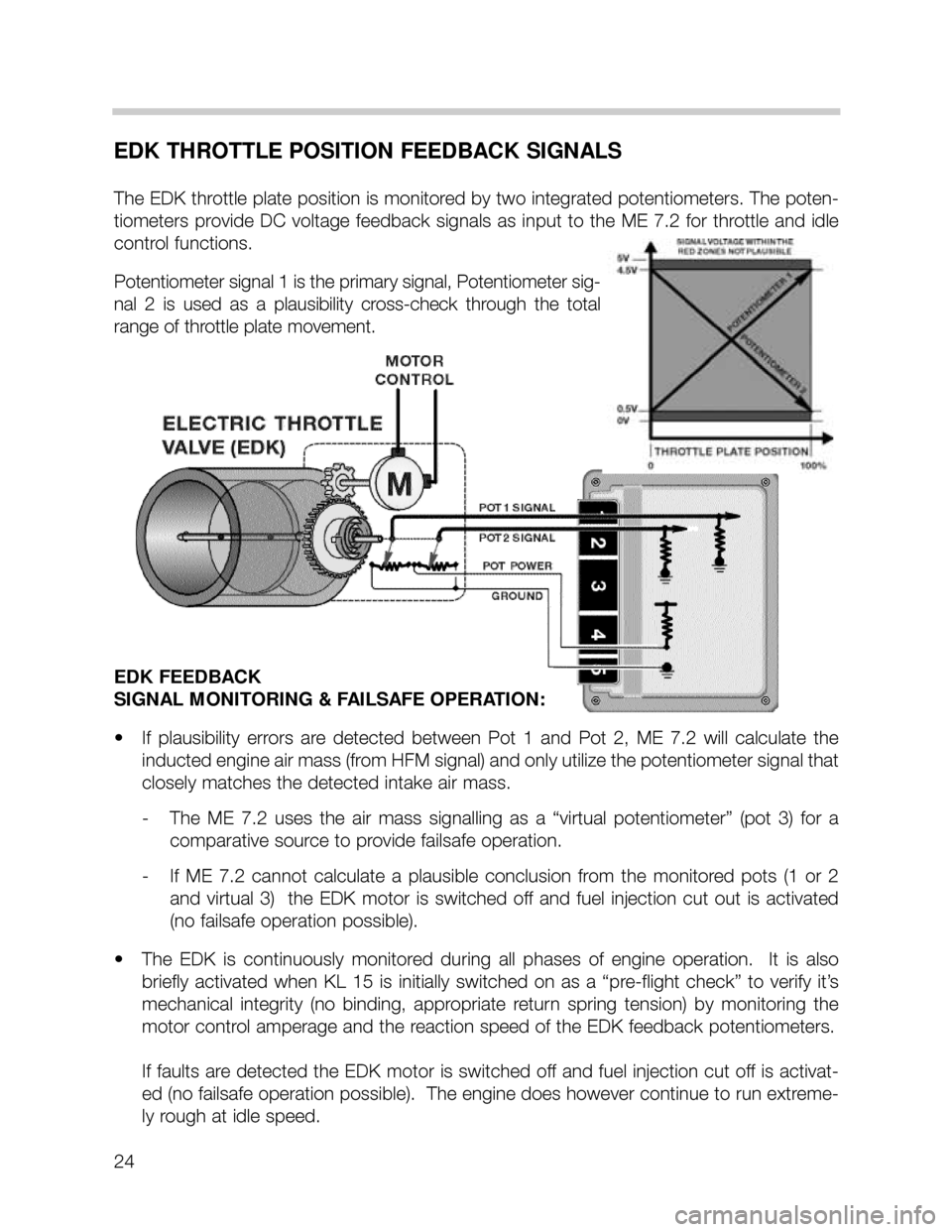

EDK THROTTLE POSITION FEEDBACK SIGNALS

The EDK throttle plate position is monitored by two integrated potentiometers. The poten-

tiometers provide DC voltage feedback signals as input to the ME 7.2 for throttle and idle

control functions.

Potentiometer signal 1 is the primary signal, Potentiometer sig-

nal 2 is used as a plausibility cross-check through the total

range of throttle plate movement.

EDK FEEDBACK

SIGNAL MONITORING & FAILSAFE OPERATION:

• If plausibility errors are detected between Pot 1 and Pot 2, ME 7.2 will calculate the

inducted engine air mass (from HFM signal) and only utilize the potentiometer signal that

closely matches the detected intake air mass.

- The ME 7.2 uses the air mass signalling as a “virtual potentiometer” (pot 3) for a

comparative source to provide failsafe operation.

- If ME 7.2 cannot calculate a plausible conclusion from the monitored pots (1 or 2

and virtual 3) the EDK motor is switched off and fuel injection cut out is activated

(no failsafe operation possible).

• The EDK is continuously monitored during all phases of engine operation. It is also

briefly activated when KL 15 is initially switched on as a “pre-flight check” to verify it’s

mechanical integrity (no binding, appropriate return spring tension) by monitoring the

motor control amperage and the reaction speed of the EDK feedback potentiometers.

If faults are detected the EDK motor is switched off and fuel injection cut off is activat-

ed (no failsafe operation possible). The engine does however continue to run extreme-

ly rough at idle speed.

Page 25 of 37

25

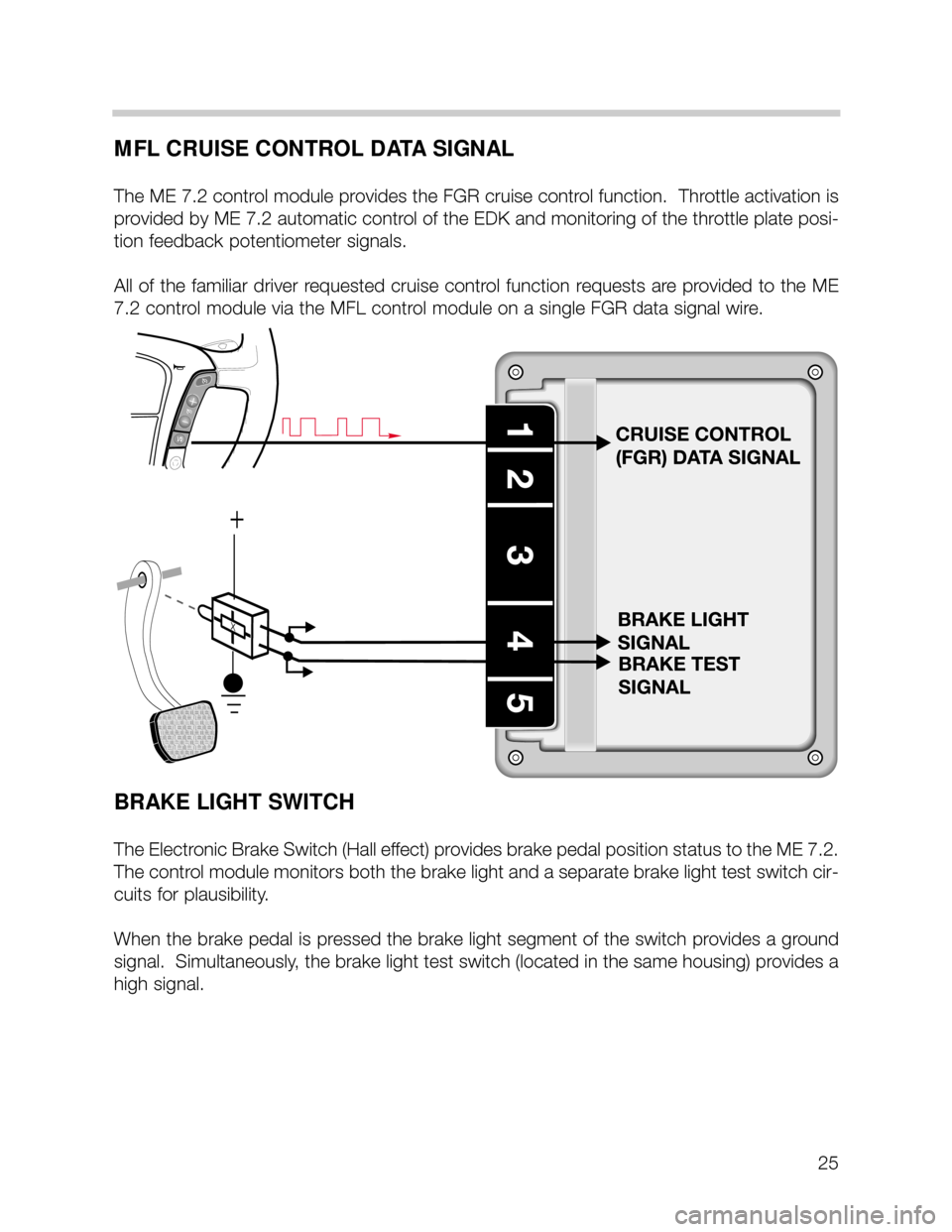

MFL CRUISE CONTROL DATA SIGNAL

The ME 7.2 control module provides the FGR cruise control function. Throttle activation is

provided by ME 7.2 automatic control of the EDK and monitoring of the throttle plate posi-

tion feedback potentiometer signals.

All of the familiar driver requested cruise control function requests are provided to the ME

7.2 control module via the MFL control module on a single FGR data signal wire.

BRAKE LIGHT SWITCH

The Electronic Brake Switch (Hall effect) provides brake pedal position status to the ME 7.2.

The control module monitors both the brake light and a separate brake light test switch cir-

cuits for plausibility.

When the brake pedal is pressed the brake light segment of the switch provides a ground

signal. Simultaneously, the brake light test switch (located in the same housing) provides a

high signal.

Page 26 of 37

26

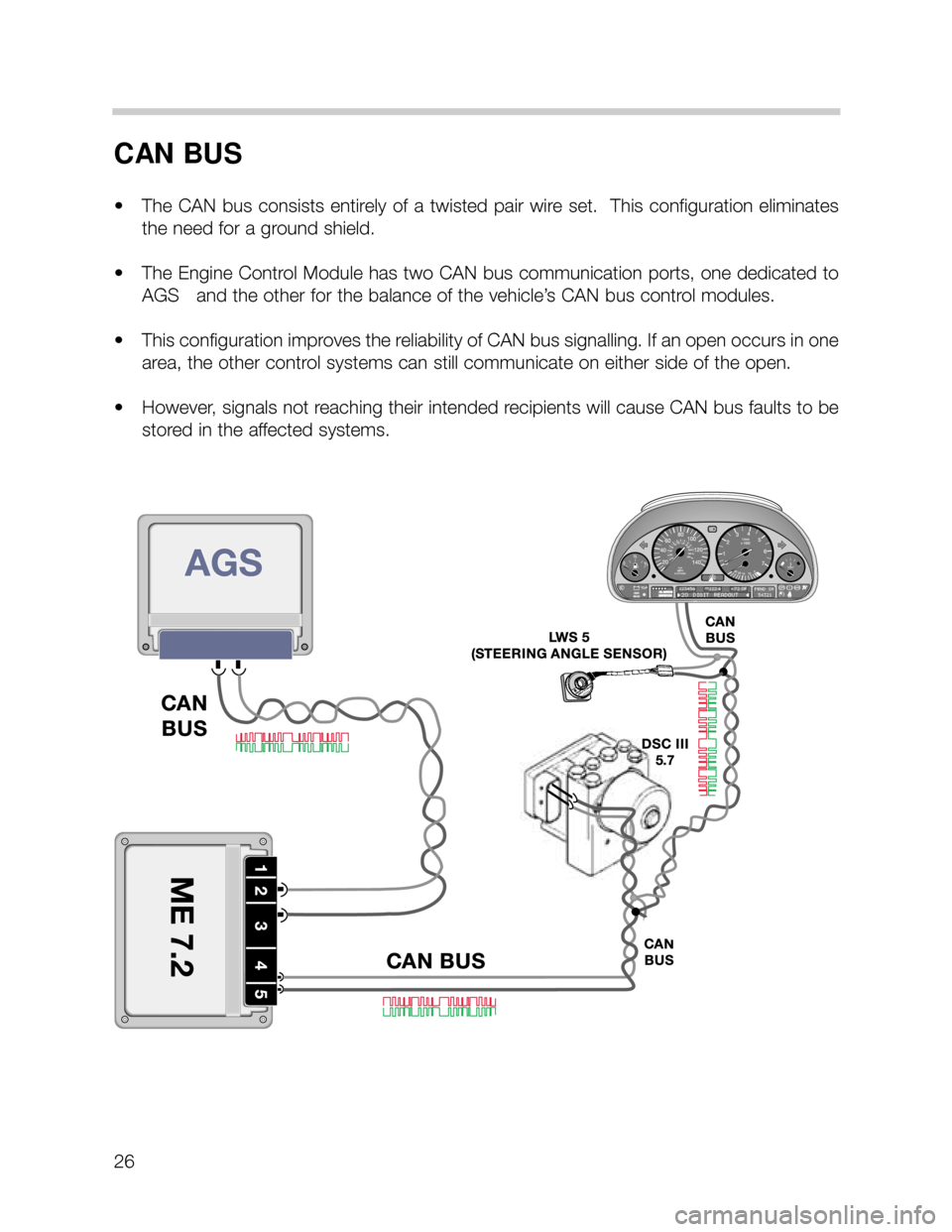

CAN BUS

• The CAN bus consists entirely of a twisted pair wire set. This configuration eliminates

the need for a ground shield.

• The Engine Control Module has two CAN bus communication ports, one dedicated to

AGS and the other for the balance of the vehicle’s CAN bus control modules.

• This configuration improves the reliability of CAN bus signalling. If an open occurs in one

area, the other control systems can still communicate on either side of the open.

• However, signals not reaching their intended recipients will cause CAN bus faults to be

stored in the affected systems.

Page 27 of 37

27

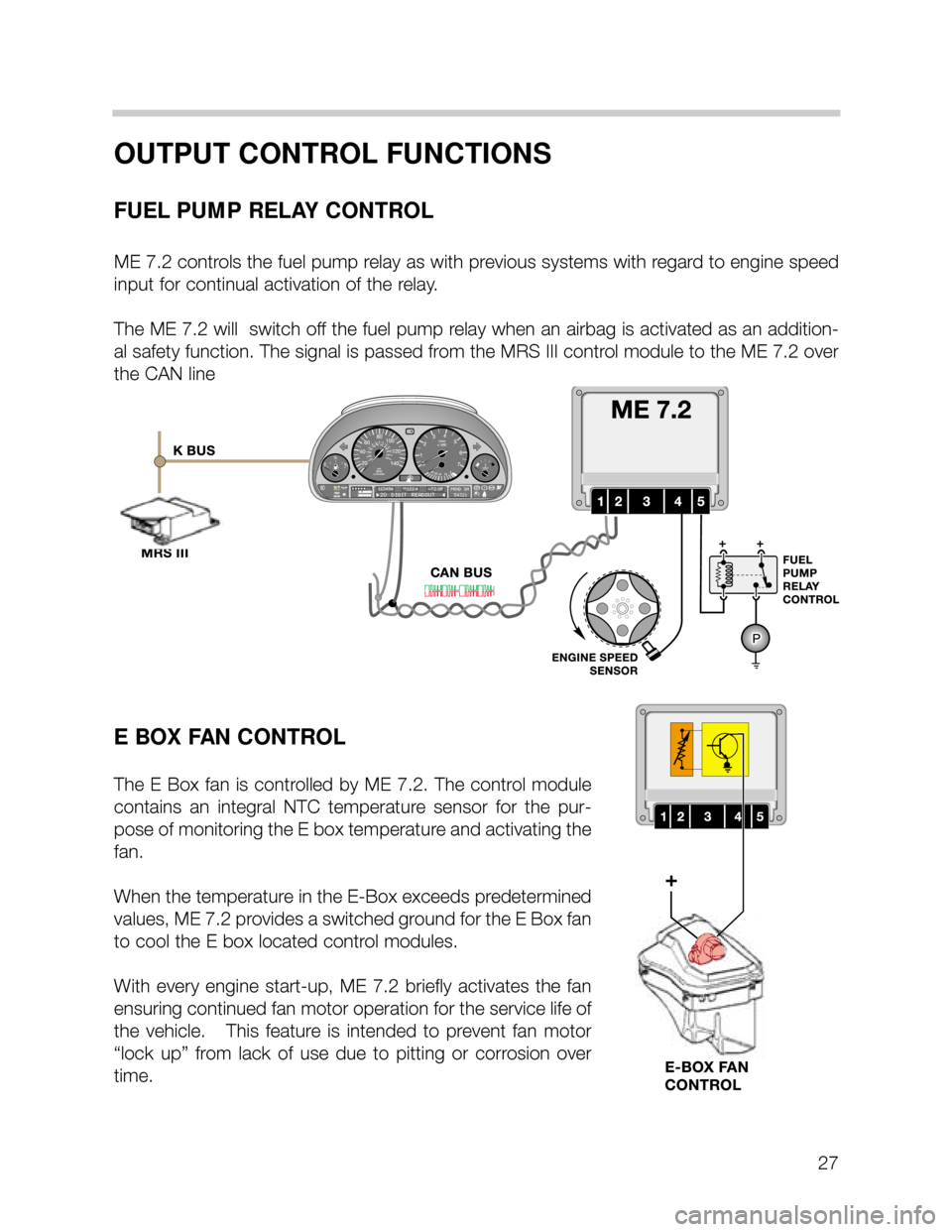

OUTPUT CONTROL FUNCTIONS

FUEL PUMP RELAY CONTROL

ME 7.2 controls the fuel pump relay as with previous systems with regard to engine speed

input for continual activation of the relay.

The ME 7.2 will switch off the fuel pump relay when an airbag is activated as an addition-

al safety function. The signal is passed from the MRS III control module to the ME 7.2 over

the CAN line

E BOX FAN CONTROL

The E Box fan is controlled by ME 7.2. The control module

contains an integral NTC temperature sensor for the pur-

pose of monitoring the E box temperature and activating the

fan.

When the temperature in the E-Box exceeds predetermined

values, ME 7.2 provides a switched ground for the E Box fan

to cool the E box located control modules.

With every engine start-up, ME 7.2 briefly activates the fan

ensuring continued fan motor operation for the service life of

the vehicle. This feature is intended to prevent fan motor

“lock up” from lack of use due to pitting or corrosion over

time.

Page 28 of 37

28

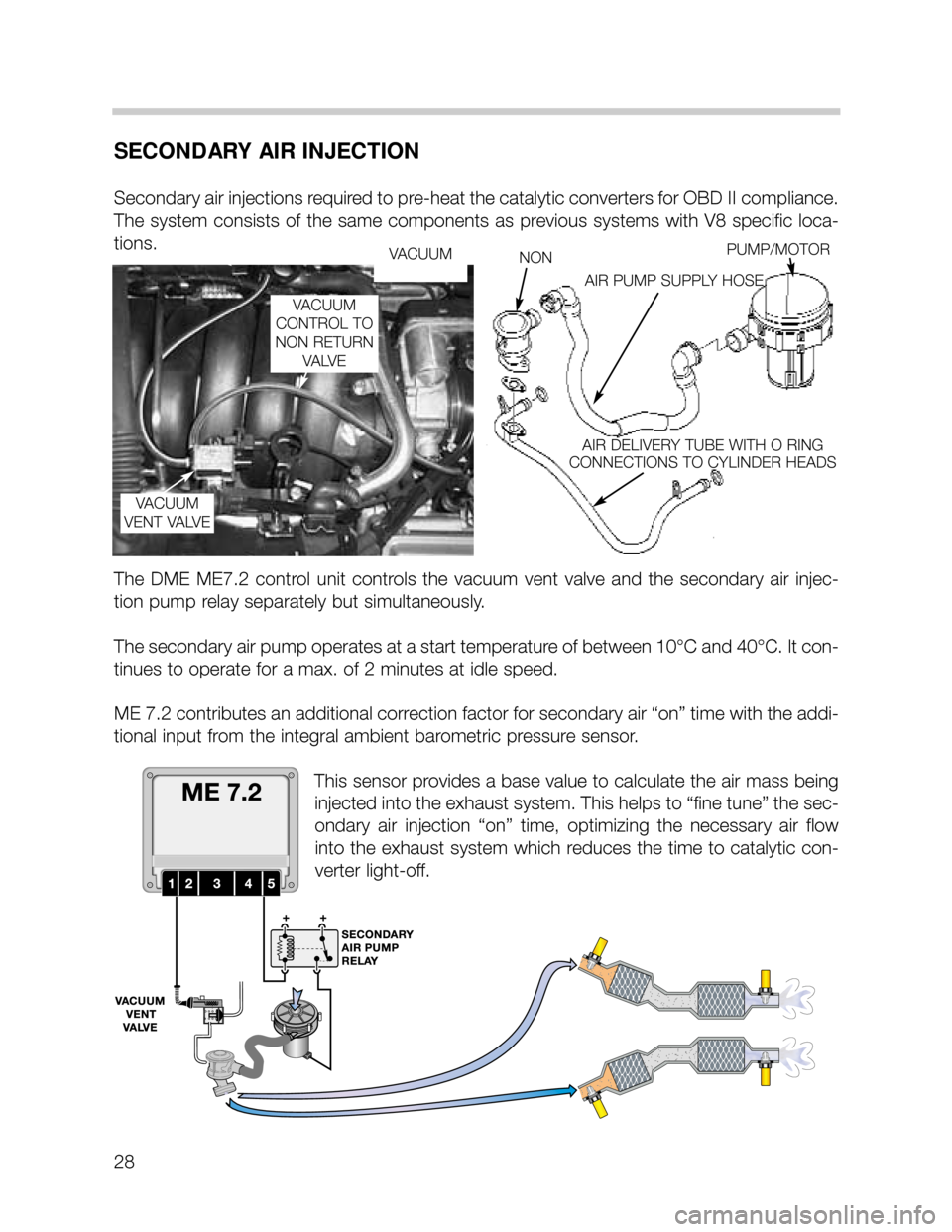

SECONDARY AIR INJECTION

Secondary air injections required to pre-heat the catalytic converters for OBD II compliance.

The system consists of the same components as previous systems with V8 specific loca-

tions.

The DME ME7.2 control unit controls the vacuum vent valve and the secondary air injec-

tion pump relay separately but simultaneously.

The secondary air pump operates at a start temperature of between 10°C and 40°C. It con-

tinues to operate for a max. of 2 minutes at idle speed.

ME 7.2 contributes an additional correction factor for secondary air “on” time with the addi-

tional input from the integral ambient barometric pressure sensor.

This sensor provides a base value to calculate the air mass being

injected into the exhaust system. This helps to “fine tune” the sec-

ondary air injection “on” time, optimizing the necessary air flow

into the exhaust system which reduces the time to catalytic con-

verter light-off.

VACUUM

VACUUM

VENT VALVENONPUMP/MOTOR

AIR PUMP SUPPLY HOSE

AIR DELIVERY TUBE WITH O RING

CONNECTIONS TO CYLINDER HEADS

VACUUM

CONTROL TO

NON RETURN

VA LV E

Page 29 of 37

29

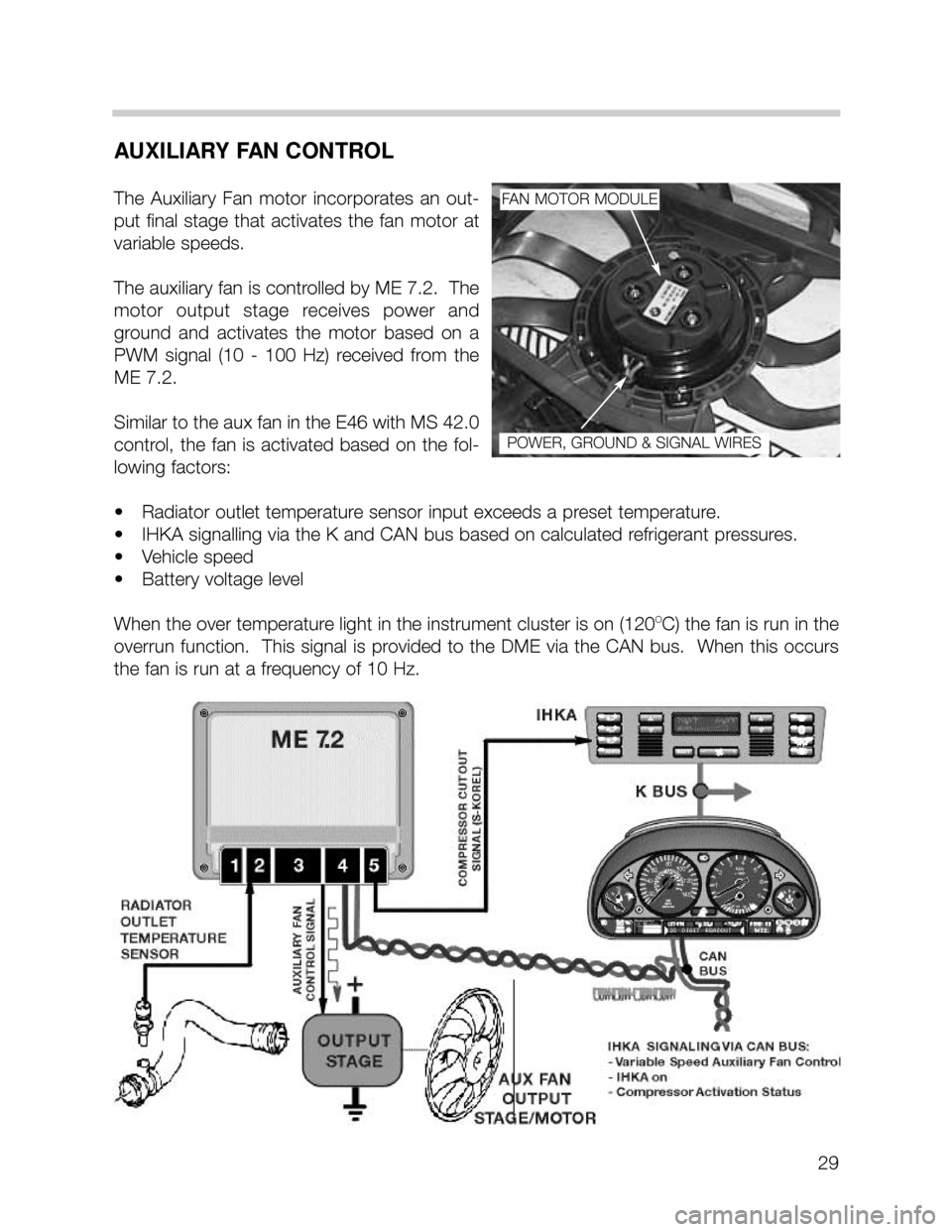

AUXILIARY FAN CONTROL

The Auxiliary Fan motor incorporates an out-

put final stage that activates the fan motor at

variable speeds.

The auxiliary fan is controlled by ME 7.2. The

motor output stage receives power and

ground and activates the motor based on a

PWM signal (10 - 100 Hz) received from the

ME 7.2.

Similar to the aux fan in the E46 with MS 42.0

control, the fan is activated based on the fol-

lowing factors:

• Radiator outlet temperature sensor input exceeds a preset temperature.

• IHKA signalling via the K and CAN bus based on calculated refrigerant pressures.

• Vehicle speed

• Battery voltage level

When the over temperature light in the instrument cluster is on (120

OC) the fan is run in the

overrun function. This signal is provided to the DME via the CAN bus. When this occurs

the fan is run at a frequency of 10 Hz.

FAN MOTOR MODULE

POWER, GROUND & SIGNAL WIRES

Page 30 of 37

30

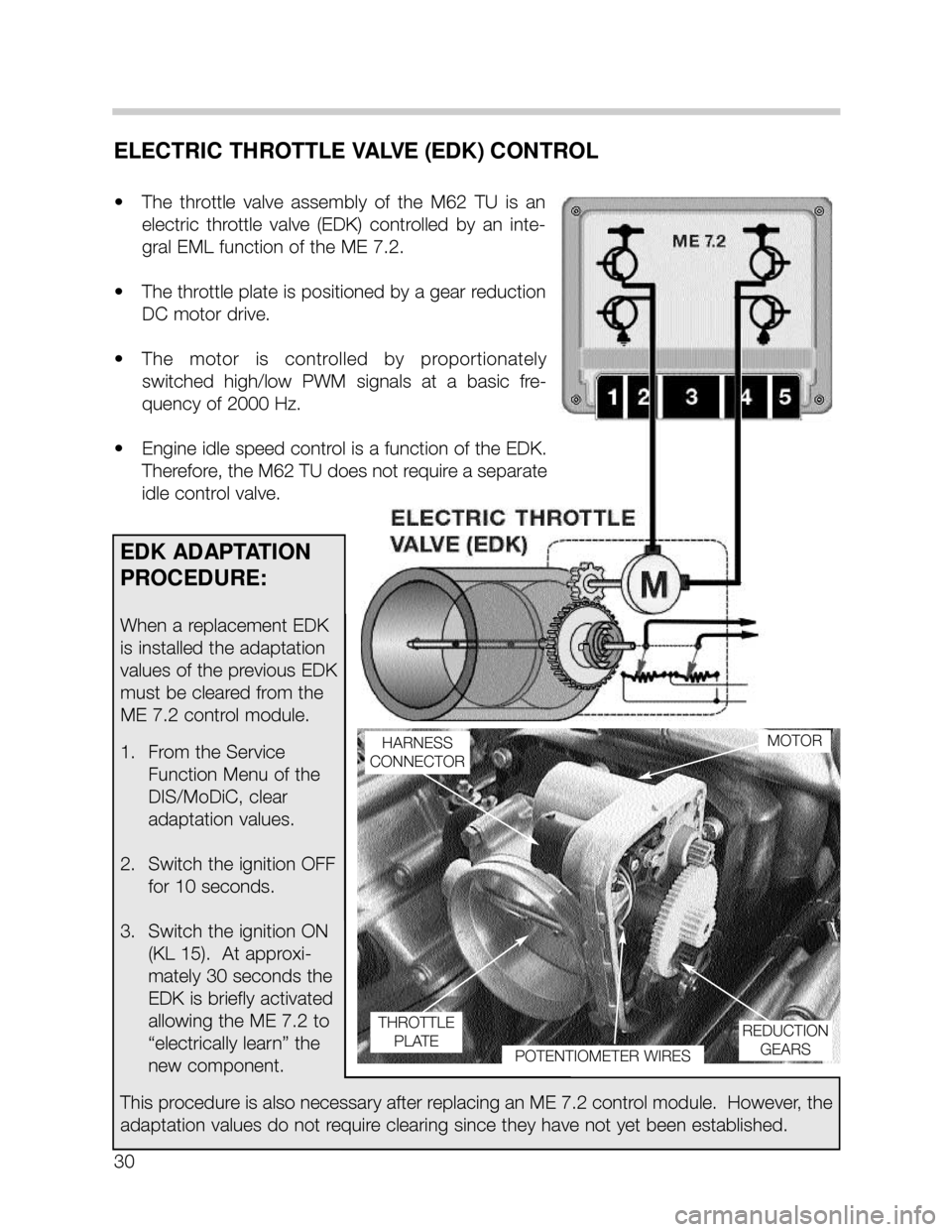

ELECTRIC THROTTLE VALVE (EDK) CONTROL

• The throttle valve assembly of the M62 TU is an

electric throttle valve (EDK) controlled by an inte-

gral EML function of the ME 7.2.

• The throttle plate is positioned by a gear reduction

DC motor drive.

• The motor is controlled by proportionately

switched high/low PWM signals at a basic fre-

quency of 2000 Hz.

• Engine idle speed control is a function of the EDK.

Therefore, the M62 TU does not require a separate

idle control valve.

HARNESS

CONNECTORMOTOR

REDUCTION

GEARS

POTENTIOMETER WIRES

THROTTLE

PLATE

EDK ADAPTATION

PROCEDURE:

When a replacement EDK

is installed the adaptation

values of the previous EDK

must be cleared from the

ME 7.2 control module.

1. From the Service

Function Menu of the

DIS/MoDiC, clear

adaptation values.

2. Switch the ignition OFF

for 10 seconds.

3. Switch the ignition ON

(KL 15). At approxi-

mately 30 seconds the

EDK is briefly activated

allowing the ME 7.2 to

“electrically learn” the

new component.

This procedure is also necessary after replacing an ME 7.2 control module. However, the

adaptation values do not require clearing since they have not yet been established.