Trunk BMW X6 2016 F16 User Guide

[x] Cancel search | Manufacturer: BMW, Model Year: 2016, Model line: X6, Model: BMW X6 2016 F16Pages: 265, PDF Size: 6.17 MB

Page 193 of 265

Load

The maximum load is the sum of the weight of

the occupants and the cargo.

The greater the weight of the occupants, the

less cargo that can be transported.

Stowing cargo

▷Cover sharp edges and corners on the

cargo.▷Heavy cargo: stow as far forward as possi‐

ble, directly behind and at the bottom of

the rear passenger seat backrests.▷Very heavy cargo: when the rear seat is not

occupied, secure each of the outer safety

belts in the opposite buckle.▷If necessary, fold down the rear backrests

to stow cargo.▷Do not stack cargo above the top edge of

the backrests.Securing cargo

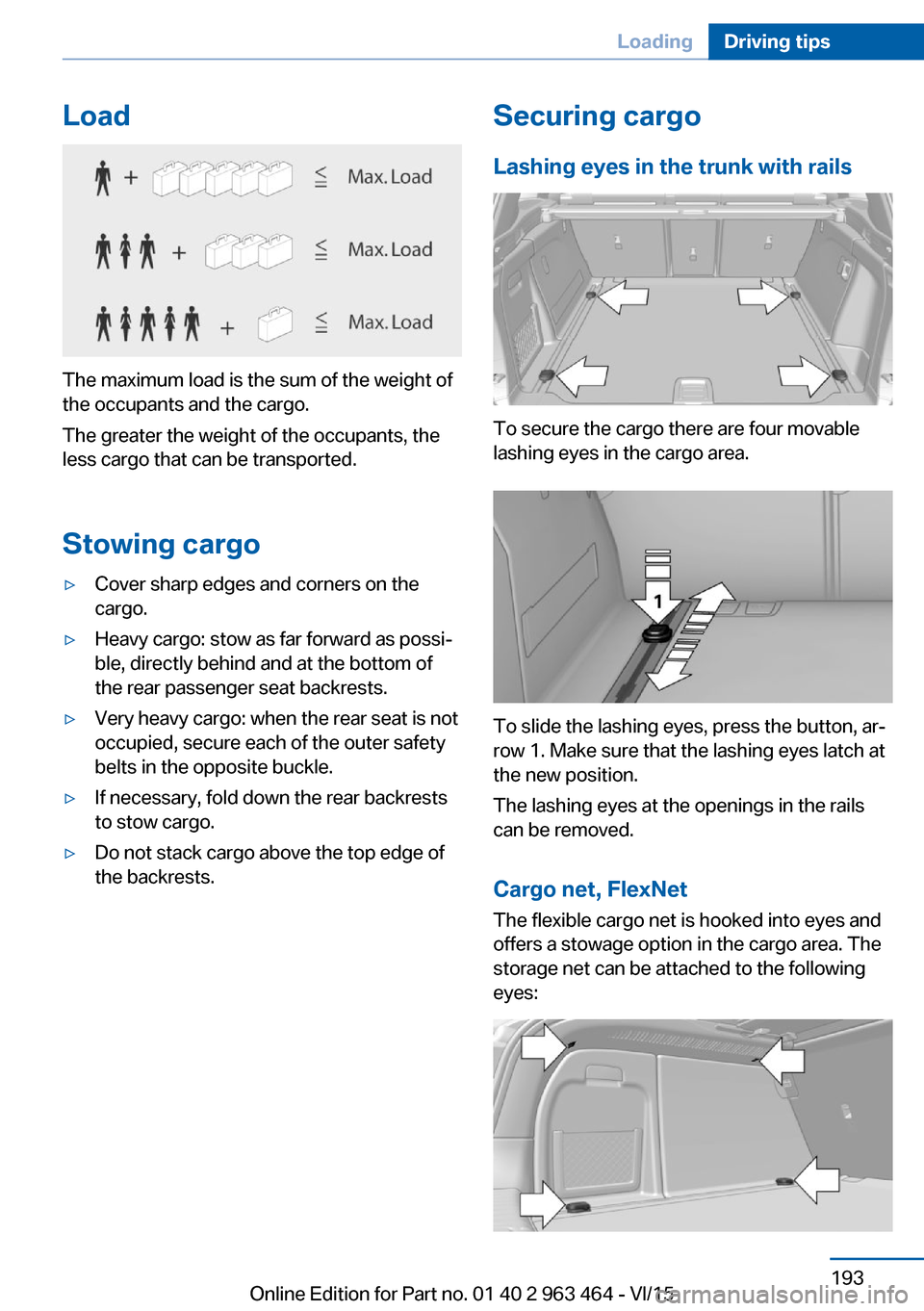

Lashing eyes in the trunk with rails

To secure the cargo there are four movable

lashing eyes in the cargo area.

To slide the lashing eyes, press the button, ar‐

row 1. Make sure that the lashing eyes latch at

the new position.

The lashing eyes at the openings in the rails

can be removed.

Cargo net, FlexNet The flexible cargo net is hooked into eyes and

offers a stowage option in the cargo area. The

storage net can be attached to the following

eyes:

Seite 193LoadingDriving tips193

Online Edition for Part no. 01 40 2 963 464 - VI/15

Page 194 of 265

▷Lashing eyes in the rails.▷Eyes on the trunk wall.

The eyes are located on both sides of the

trunk.

Securing cargo WARNING

Improperly stowed objects can shift and

be thrown into the car's interior, e.g. in the

event of an accident or during braking and eva‐

sive maneuvers. Vehicle occupants can be hit

and injured. There is risk of injuries. Stow and

secure objects and cargo properly.◀

▷Smaller and lighter items: secure with re‐

taining straps or with a cargo net or draw

straps.▷Larger and heavy objects: secure with

cargo straps.

Cargo straps, cargo netting, retaining

straps or draw straps on the lashing eyes in

the trunk.

Roof-mounted luggage rack

Information

Installation only possible with roof rack.

Roof racks are available as special accessories.

Securing

Follow the installation instructions of the roof

rack.

Loading Because roof racks raise the vehicle's center

of gravity when loaded, they have a major ef‐

fect on vehicle handling and steering re‐

sponse.

Therefore, note the following when loading

and driving:

▷Do not exceed the approved roof/axle

loads and the approved gross vehicle

weight.▷Be sure that adequate clearance is main‐

tained for tilting and opening the glass

sunroof.▷Distribute the roof load uniformly.▷The roof load should not extend past the

loading area.▷Always place the heaviest pieces on the

bottom.▷Secure the roof luggage firmly, e.g., tie

with ratchet straps.▷Do not let objects project into the opening

path of the tailgate.▷Drive cautiously and avoid sudden acceler‐

ation and braking maneuvers. Take corners

gently.Seite 194Driving tipsLoading194

Online Edition for Part no. 01 40 2 963 464 - VI/15

Page 204 of 265

RefuelingVehicle features and options

This chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and

systems. The respectively applicable country

provisions must be observed when using the

respective features and systems.

Information Observe the fuel recommendation, refer to

page 206, prior to refueling.

CAUTION

With a range of less than 30 miles/50 km

it is possible that the engine will no longer have

sufficient fuel. Engine functions are no longer

ensured. There is risk of property damage. Re‐

fuel promptly.◀

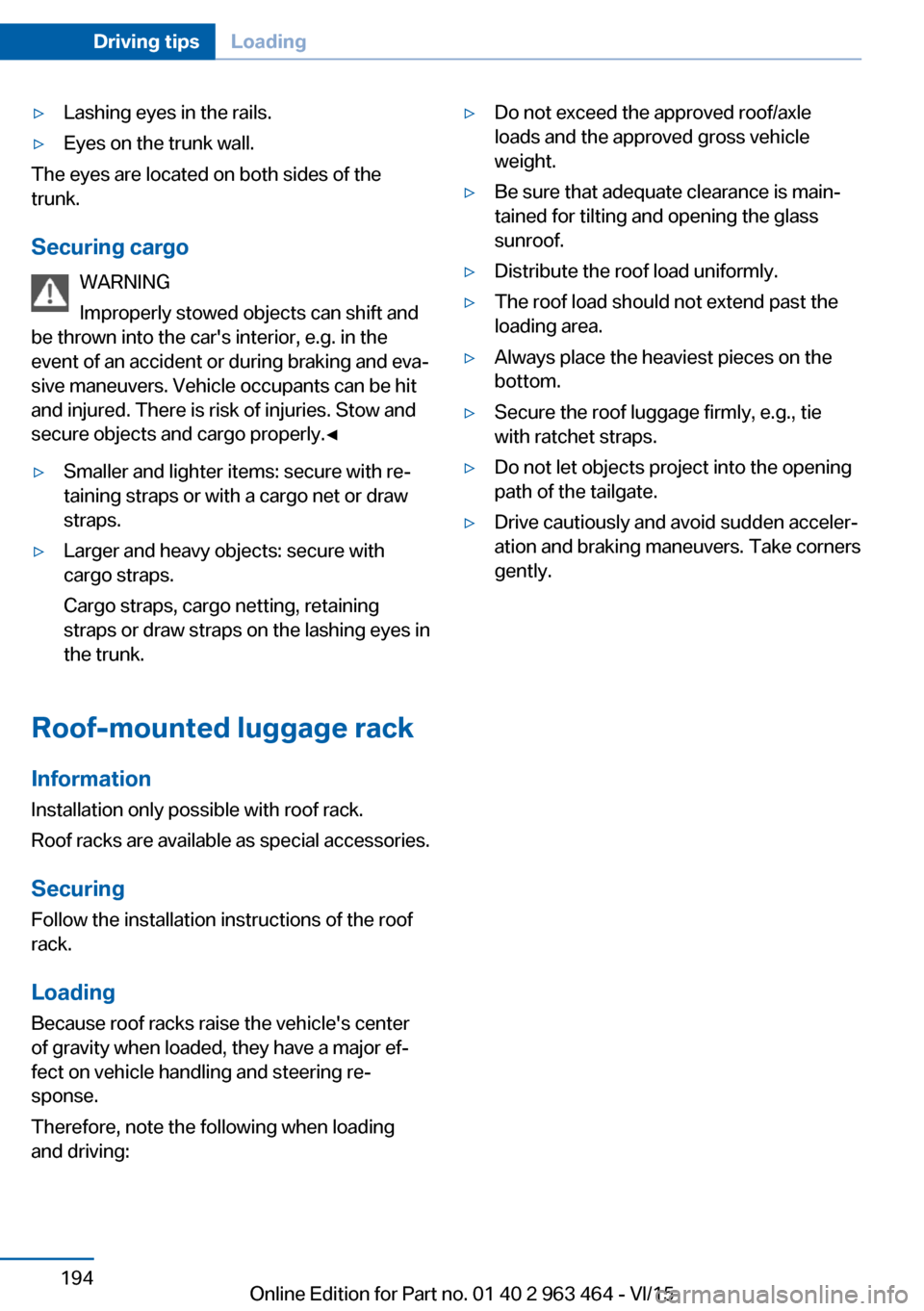

Fuel lidOpening1.Briefly press the rear edge of the fuel filler

flap.2.Turn the tank lid counterclockwise.3.Place the tank lid in the bracket attached to

the fuel filler flap.

Closing

1.Fit the lid and turn it clockwise until you

clearly hear a click.2.Close the fuel filler flap.

WARNING

The retaining strap of the fuel cap be

jammed and crushed during closing. In this

case, the lid cannot be correctly closed and

fuel vapors or fuel can escape. There is risk of

injuries or risk of property damage. Pay atten‐

tion that the retaining strap is not jammed or

crushed when closing the lid.◀

Manually unlocking fuel filler flapE. g. in the event of an electrical malfunction.

The release is located in the trunk.

Seite 204MobilityRefueling204

Online Edition for Part no. 01 40 2 963 464 - VI/15

Page 208 of 265

Wheels and tiresVehicle features and options

This chapter describes all standard, country-

specific and optional features offered with the

series. It also describes features that are not

necessarily available in your car, e. g., due to

the selected options or country versions. This

also applies to safety-related functions and

systems. The respectively applicable country

provisions must be observed when using the

respective features and systems.

Tire inflation pressure Safety information

The tire characteristics and tire inflation pres‐

sure influence the following:▷The service life of the tires.▷Road safety.▷Driving comfort.

Checking the tire inflation pressure

WARNING

A tire with low or missing tire inflation

pressure impacts handling, such as steering

and braking response. There is risk of an acci‐

dent. Regularly check the tire inflation pres‐

sure, and correct it as needed, e.g. twice a

month and before a long trip.◀

Also check the tire inflation pressure of the

emergency wheel in the trunk regularly, and

correct it as needed.

Tires have a natural, consistent loss of tire in‐

flation pressure.

Tires heat up while driving, and the tire infla‐

tion pressure increases along with the tire's

temperature. The tire inflation pressure speci‐

fications relate to cold tires or tires with the

ambient temperature.

Only check the tire inflation pressure when the

tires are cold. This means after driving no more

than 1.25 miles/2 km or when the vehicle has

been parked for at least 2 hours.

The displays of inflation devices may under-

read by up to 0.1 bar, 2 psi.

For Flat Tire Monitor: after correcting the tire

inflation pressure, reinitialize the Flat Tire

Monitor.

For Tire Pressure Monitor: after correcting the

tire inflation pressure, reset the Tire Pressure

Monitor.

Tire inflation pressure specifications

The tire inflation pressure table, refer to

page 209, contains all tire inflation pressure

specifications for the specified tire sizes at the

ambient temperature. The tire inflation pres‐

sure values apply to tire sizes approved by the

manufacturer of the vehicle for the vehicle

type.

To identify the correct tire inflation pressure,

please note the following:▷Tire sizes of your vehicle.▷Maximum permitted driving speed.

Tire inflation pressures up to

100 mph/160 km/h

For speeds of up to 100 mph/160 km/h and for

optimum driving comfort, note the pressure

values in the tire inflation pressure table, refer

to page 209, and adjust as necessary.

Seite 208MobilityWheels and tires208

Online Edition for Part no. 01 40 2 963 464 - VI/15

Page 217 of 265

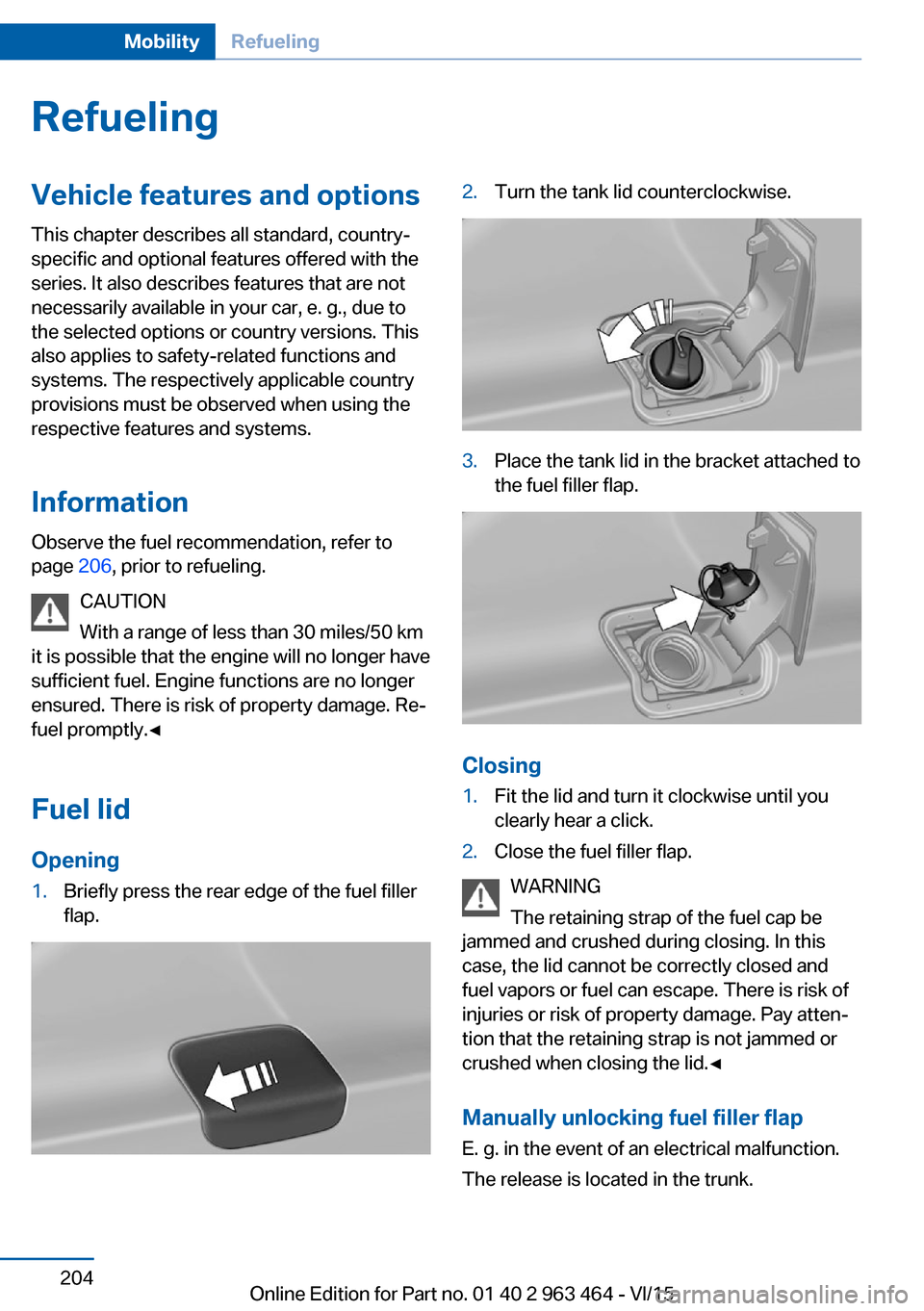

7.With the ignition turned on or the engine

running, switch on the compressor.

CAUTION

The compressor can overheat during ex‐

tended operation. There is risk of property

damage. Do not run the compressor for more

than 10 min.◀

Let the compressor run for approx. 3 to 8 mi‐

nutes to fill the tire with sealant and achieve a

tire inflation pressure of approx. 2.5 bar.

While the tire is being filled with sealant, the

tire inflation pressure may sporadically reach

approx. 5 bar. Do not switch off the compres‐

sor at this point.

If a tire inflation pressure of 2 bar is not

reached:

1.Switch off the compressor.2.Unscrew the filling hose from the wheel.3.Drive 33 ft/10 m forward and back to dis‐

tribute the sealant in the tire.4.Inflate the tire again using the compressor.

If a tire inflation pressure of 2 bar cannot be

reached, contact your dealer’s service cen‐

ter or another qualified service center or

repair shop.

Stowing the Mobility System

1.Unscrew the filling hose of the sealant con‐

tainer from the wheel.2.Unscrew the connection hose of the com‐

pressor from the sealant container.3.Connect the filling hose of the sealant con‐

tainer previously connected to the tirevalve with the available connector on the

sealant container.

This prevents leftover sealant from escap‐

ing from the container.4.Wrap the empty sealant container in suita‐

ble material to avoid dirtying the trunk.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive approx. 5 miles/10 km to en‐

sure that the sealant is evenly distributed in the

tire.

Do not exceed a speed of 50 mph/80 km/h.

If possible, do not drive at speeds less than

12 mph/20 km/h.

To correct the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose of the com‐

pressor directly onto the tire valve stem.3.Insert the connector into the power socket

inside the vehicle.4.Correct the tire inflation pressure to

2.5 bar.▷Increase pressure: with the ignition

turned on or the engine running, switch

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

Continuing the trip

Do not exceed the maximum permissible

speed of 50 mph/80 km/h.

Reinitialize the Flat Tire Monitor.

Reinitialize the Tire Pressure Monitor.

Replace the nonworking tire and the sealant

container of the Mobility System as soon as

possible.

Seite 217Wheels and tiresMobility217

Online Edition for Part no. 01 40 2 963 464 - VI/15

Page 234 of 265

LED front fog lights

These front fog lights are made using LED

technology. Contact a dealer’s service center

or another qualified service center or repair

shop in the event of a malfunction.

Tail lights, bulb replacement

LED tail lights

These tail lights are made using LED technol‐

ogy. Contact a dealer’s service center or an‐

other qualified service center or repair shop in

the event of a malfunction.

Changing wheels

Information When using run-flat tires or sealants, a tire

does not need to be changed immediately in

the event of pressure loss due to a flat tire.

The tools for changing wheels are available as

accessories from your dealer’s service center

or another qualified service center or repair

shop.

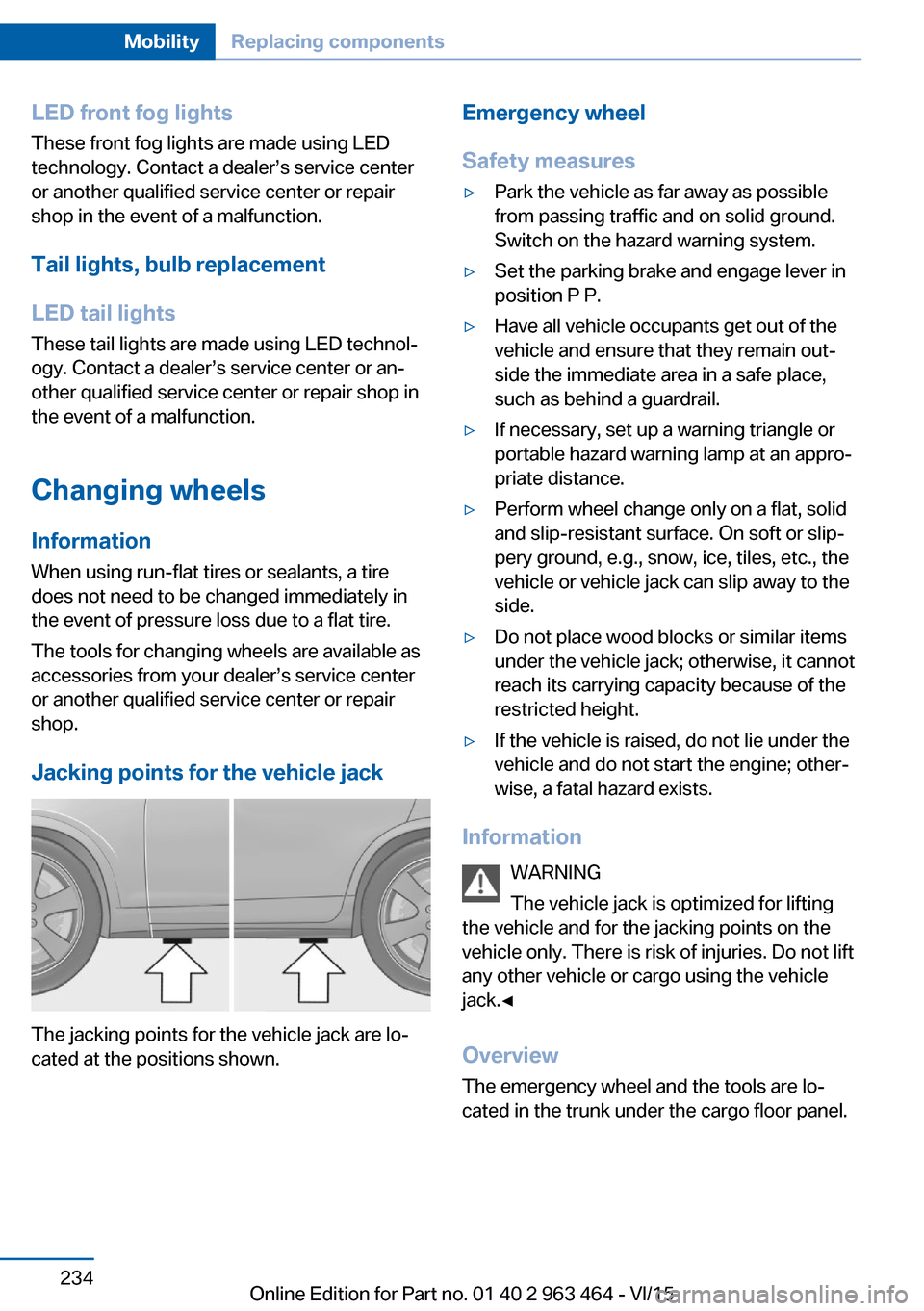

Jacking points for the vehicle jack

The jacking points for the vehicle jack are lo‐

cated at the positions shown.

Emergency wheel

Safety measures▷Park the vehicle as far away as possible

from passing traffic and on solid ground.

Switch on the hazard warning system.▷Set the parking brake and engage lever in

position P P.▷Have all vehicle occupants get out of the

vehicle and ensure that they remain out‐

side the immediate area in a safe place,

such as behind a guardrail.▷If necessary, set up a warning triangle or

portable hazard warning lamp at an appro‐

priate distance.▷Perform wheel change only on a flat, solid

and slip-resistant surface. On soft or slip‐

pery ground, e.g., snow, ice, tiles, etc., the

vehicle or vehicle jack can slip away to the

side.▷Do not place wood blocks or similar items

under the vehicle jack; otherwise, it cannot

reach its carrying capacity because of the

restricted height.▷If the vehicle is raised, do not lie under the

vehicle and do not start the engine; other‐

wise, a fatal hazard exists.

Information

WARNING

The vehicle jack is optimized for lifting

the vehicle and for the jacking points on the

vehicle only. There is risk of injuries. Do not lift

any other vehicle or cargo using the vehicle

jack.◀

Overview

The emergency wheel and the tools are lo‐ cated in the trunk under the cargo floor panel.

Seite 234MobilityReplacing components234

Online Edition for Part no. 01 40 2 963 464 - VI/15

Page 235 of 265

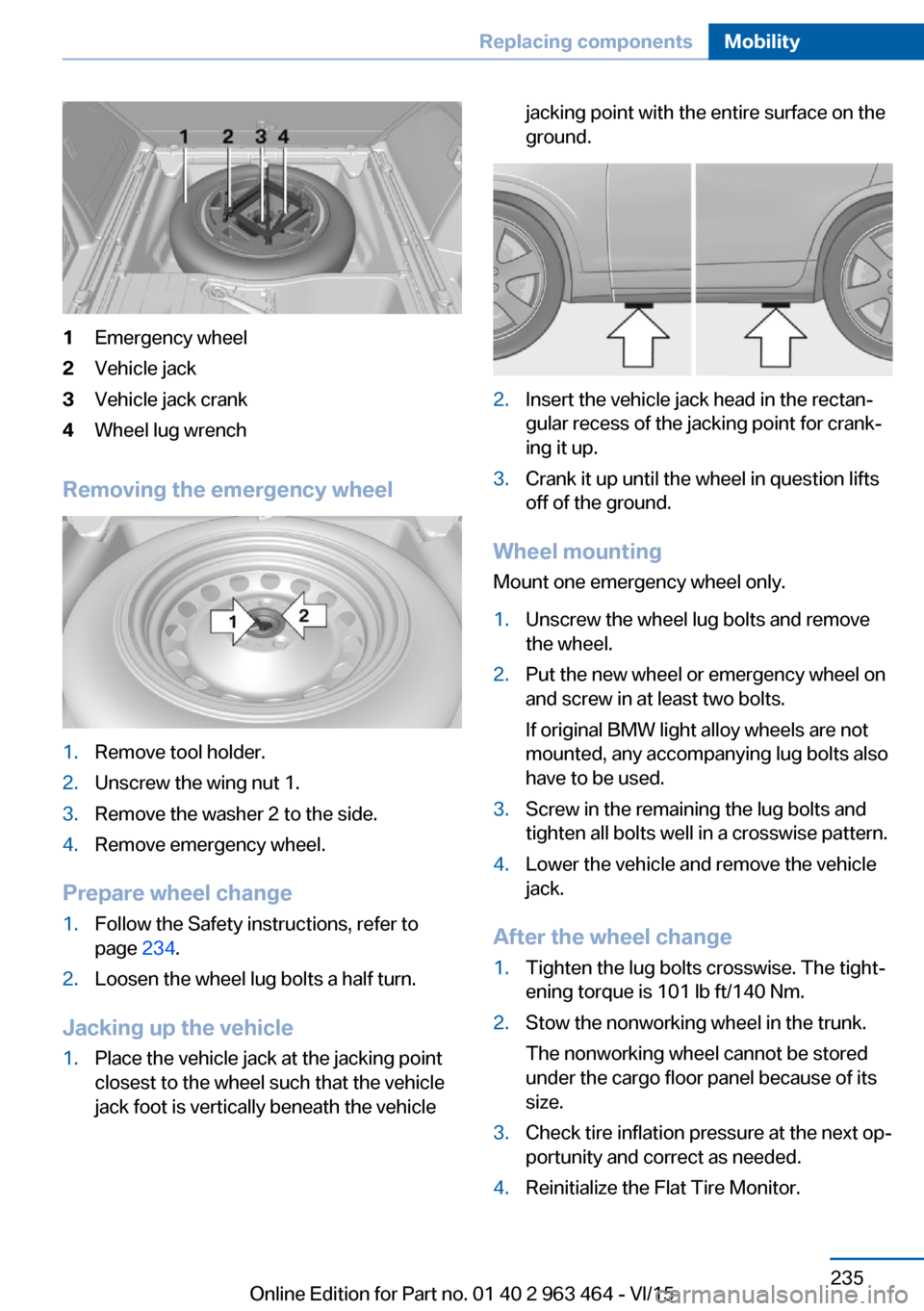

1Emergency wheel2Vehicle jack3Vehicle jack crank4Wheel lug wrench

Removing the emergency wheel

1.Remove tool holder.2.Unscrew the wing nut 1.3.Remove the washer 2 to the side.4.Remove emergency wheel.

Prepare wheel change

1.Follow the Safety instructions, refer to

page 234.2.Loosen the wheel lug bolts a half turn.

Jacking up the vehicle

1.Place the vehicle jack at the jacking point

closest to the wheel such that the vehicle

jack foot is vertically beneath the vehiclejacking point with the entire surface on the

ground.2.Insert the vehicle jack head in the rectan‐

gular recess of the jacking point for crank‐

ing it up.3.Crank it up until the wheel in question lifts

off of the ground.

Wheel mounting

Mount one emergency wheel only.

1.Unscrew the wheel lug bolts and remove

the wheel.2.Put the new wheel or emergency wheel on

and screw in at least two bolts.

If original BMW light alloy wheels are not

mounted, any accompanying lug bolts also

have to be used.3.Screw in the remaining the lug bolts and

tighten all bolts well in a crosswise pattern.4.Lower the vehicle and remove the vehicle

jack.

After the wheel change

1.Tighten the lug bolts crosswise. The tight‐

ening torque is 101 lb ft/140 Nm.2.Stow the nonworking wheel in the trunk.

The nonworking wheel cannot be stored

under the cargo floor panel because of its

size.3.Check tire inflation pressure at the next op‐

portunity and correct as needed.4.Reinitialize the Flat Tire Monitor.Seite 235Replacing componentsMobility235

Online Edition for Part no. 01 40 2 963 464 - VI/15

Page 237 of 265

Disposing of old batteriesHave old batteries disposed of by a

dealer’s service center or another

qualified service center or repair shop

or take them to a collection point.

Maintain the battery in an upright position for

transport and storage. Secure the battery so

that it does not tip over during transport.

Fuses Information WARNING

Incorrect and repaired fuses can overload

electrical lines and components. There is risk

of fire. Never attempt to repair a blown fuse

and do not replace a nonworking fuse with a

substitute of another color or amperage rat‐

ing.◀

Plastic tweezers and information on the fuse

types and locations are stored in the fuse box

in the trunk.

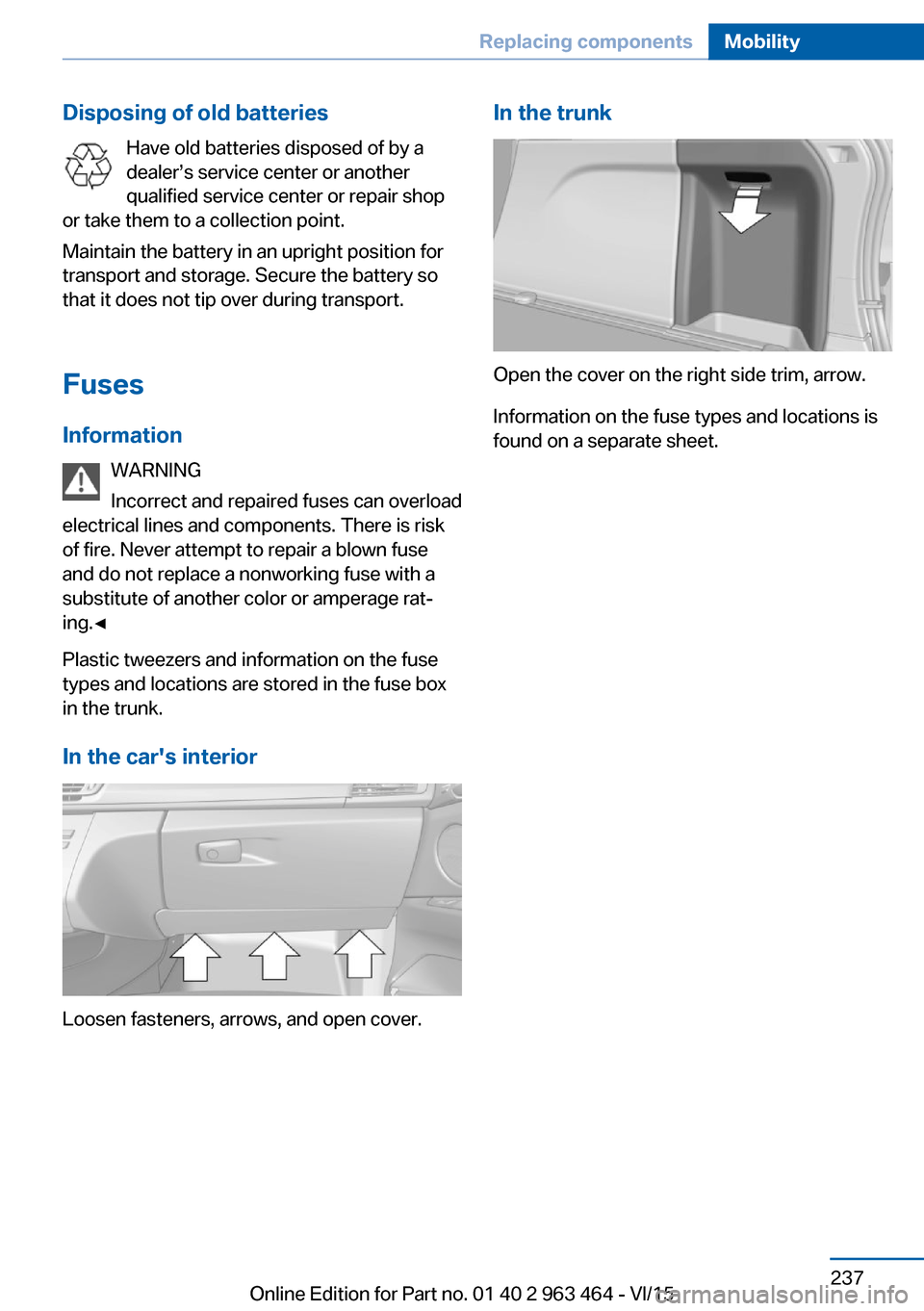

In the car's interior

Loosen fasteners, arrows, and open cover.

In the trunk

Open the cover on the right side trim, arrow.

Information on the fuse types and locations is

found on a separate sheet.

Seite 237Replacing componentsMobility237

Online Edition for Part no. 01 40 2 963 464 - VI/15

Page 251 of 265

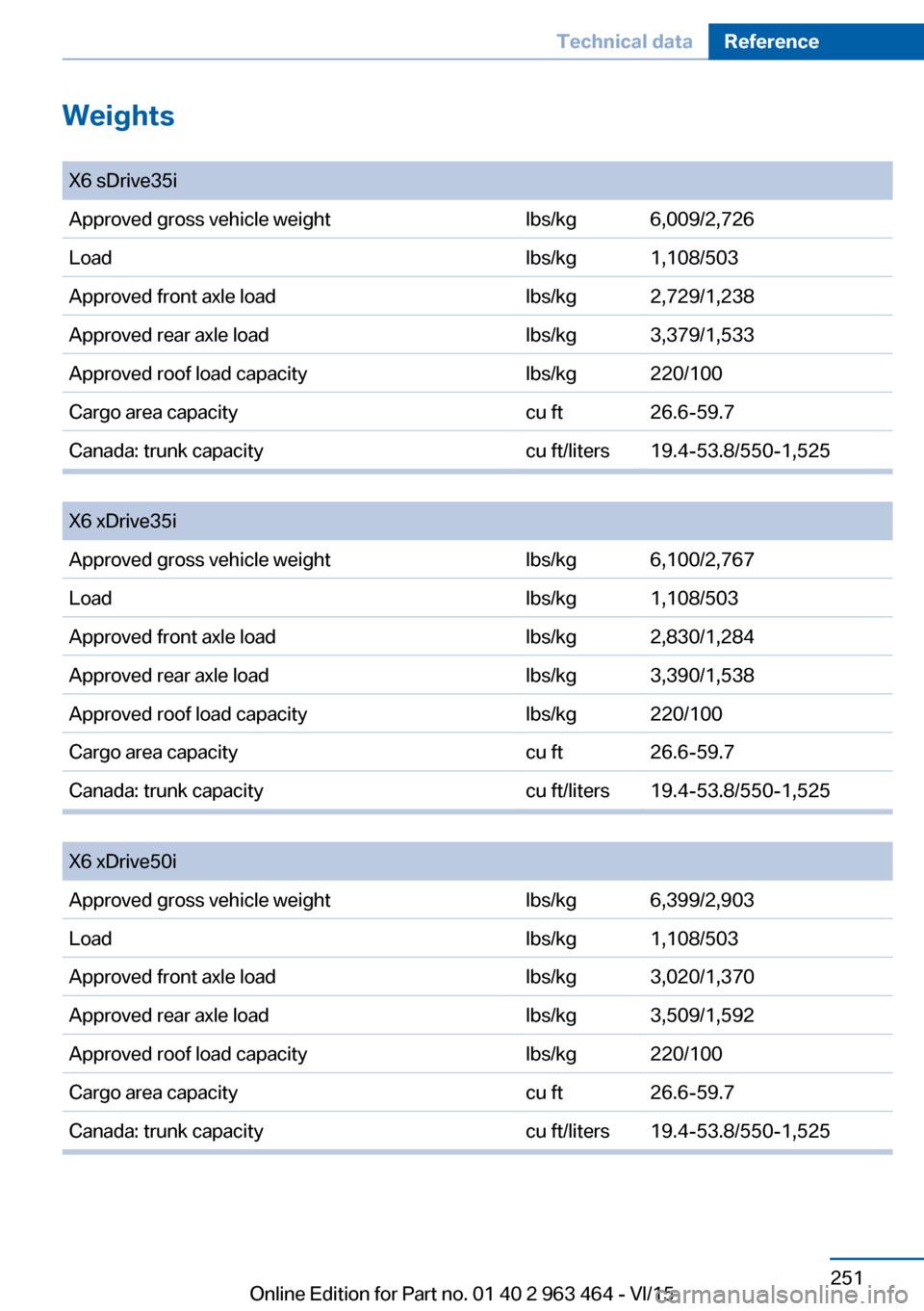

Weights

Seite 251Technical dataReference251

Online Edition for Part no. 01 40 2 963 464 - VI/15

X6 sDrive35iApproved gross vehicle weightlbs/kg6,009/2,726Loadlbs/kg1,108/503Approved front axle loadlbs/kg2,729/1,238Approved rear axle loadlbs/kg3,379/1,533Approved roof load capacitylbs/kg220/100Cargo area capacitycu ft26.6-59.7Canada: trunk capacity19.4-53.8/550-1,525X6 xDrive35iApproved gross vehicle weightlbs/kg6,100/2,767Loadlbs/kg1,108/503Approved front axle loadlbs/kg2,830/1,284Approved rear axle loadlbs/kg3,390/1,538Approved roof load capacitylbs/kg220/100Cargo area capacitycu ft26.6-59.7Canada: trunk capacity19.4-53.8/550-1,525X6 xDrive50iApproved gross vehicle weightlbs/kg6,399/2,903Loadlbs/kg1,108/503Approved front axle loadlbs/kg3,020/1,370Approved rear axle loadlbs/kg3,509/1,592Approved roof load capacitylbs/kg220/100Cargo area capacitycu ft26.6-59.7Canada: trunk capacity19.4-53.8/550-1,525cu ft/literscu ft/literscu ft/liters