engine BUICK ENCLAVE 2010 Owners Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2010, Model line: ENCLAVE, Model: BUICK ENCLAVE 2010Pages: 438, PDF Size: 2.47 MB

Page 347 of 438

Vehicle Care 10-49

The TPMS sensors can also be

matched to each tire/wheel position

by increasing or decreasing the

tire's air pressure. If increasing the

tire's air pressure, do not exceed

the maximum inflation pressure

indicated on the tire's sidewall.

To decrease air-pressure out of a

tire you can use the pointed end of

the valve cap, a pencil-style air

pressure gage, or a key.

You have two minutes to match the

first tire/wheel position, and

five minutes overall to match all

four tire/wheel positions. If it takes

longer than two minutes, to match

the first tire and wheel, or more than

five minutes to match all four tire

and wheel positions the matching

process stops and you need to

start over.

The TPMS sensor matching process

is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the engine off. 3. Press the Remote Keyless Entry

(RKE) transmitter's LOCK and

UNLOCK buttons at the same

time for approximately

five seconds. The horn sounds

twice to signal the receiver is in

relearn mode and TIRE

LEARNING ACTIVE message

displays on the DIC screen.

4. Start with the driver side front tire.

5. Remove the valve cap from the valve cap stem. Activate the

TPMS sensor by increasing or

decreasing the tire's air pressure

for five seconds, or until a horn

chirp sounds. The horn chirp,

which may take up to

30 seconds to sound, confirms

that the sensor identification

code has been matched to this

tire and wheel position.

6. Proceed to the passenger side front tire, and repeat the

procedure in Step 5. 7. Proceed to the passenger side

rear tire, and repeat the

procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat the procedure in

Step 5. The horn sounds two

times to indicate the sensor

identification code has been

matched to the driver side rear

tire, and the TPMS sensor

matching process is no longer

active. The TIRE LEARNING

ACTIVE message on the DIC

display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressure

level as indicated on the Tire

and Loading Information label.

11. Put the valve caps back on the valve stems.

Page 357 of 438

Vehicle Care 10-59

{WARNING

Changing a tire can be

dangerous. The vehicle can slip

off the jack and roll over or fall on

you or other people. You and they

could be badly injured or even

killed. Find a level place to

change your tire. To help prevent

the vehicle from moving:1. Set the parking brake firmly.

2. Put an automatic transmission shift lever in

P (Park), or shift a manual

transmission to 1 (First) or

R (Reverse).

3. Turn off the engine and do not restart while the vehicle

is raised.

4. Do not allow passengers to remain in the vehicle.

(Continued)

WARNING (Continued)

To be certain the vehicle will not

move, put blocks at the front and

rear of the tire farthest away from

the one being changed. That

would be the tire on the other

side, at the opposite end of the

vehicle.

This vehicle may come with a jack

and spare tire or a tire sealant and

compressor kit. To use the jacking

equipment to change a spare tire

safely, follow the instructions below.

Then see Tire Changing

on

page 10‑68. To use the tire sealant

and compressor kit, see Tire

Sealant and Compressor Kit

on

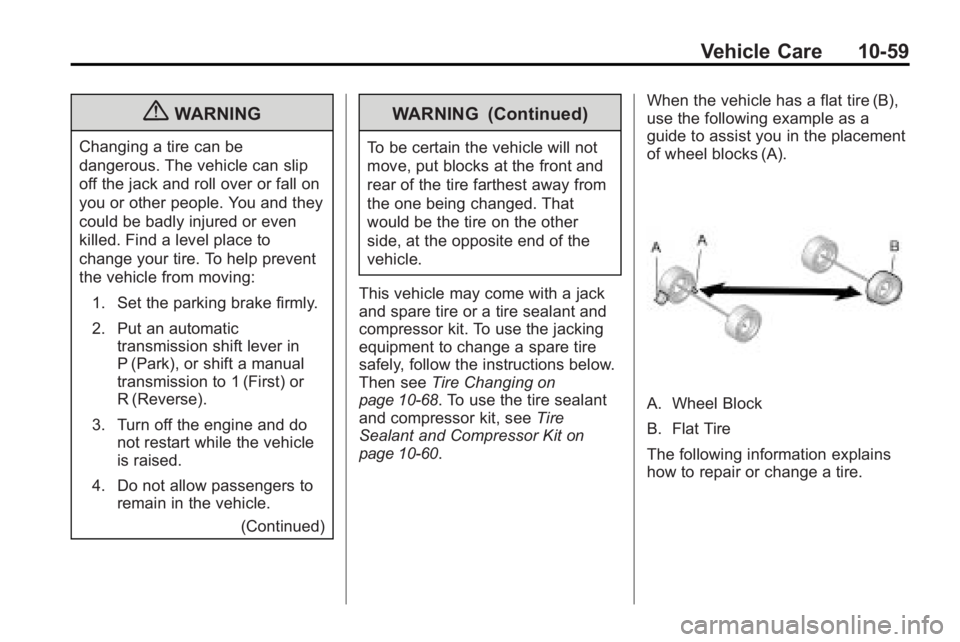

page 10‑60. When the vehicle has a flat tire (B),

use the following example as a

guide to assist you in the placement

of wheel blocks (A).

A. Wheel Block

B. Flat Tire

The following information explains

how to repair or change a tire.

Page 358 of 438

10-60 Vehicle Care

Tire Sealant and

Compressor Kit

{WARNING

Idling a vehicle in an enclosed

area with poor ventilation is

dangerous. Engine exhaust may

enter the vehicle. Engine exhaust

contains Carbon Monoxide (CO)

which cannot be seen or smelled.

It can cause unconsciousness

and even death. Never run the

engine in an enclosed area that

has no fresh air ventilation. For

more information, seeEngine

Exhaust on page 9‑22.

{WARNING

Over-inflating a tire could cause

the tire to rupture and you or

others could be injured. Be sure

to read and follow the tire sealant

and compressor kit instructions

and inflate the tire to its

recommended pressure. Do not

exceed the recommended

pressure.

{WARNING

Storing the tire sealant and

compressor kit or other

equipment in the passenger

compartment of the vehicle could

cause injury. In a sudden stop or

collision, loose equipment could

strike someone. Store the tire

sealant and compressor kit in its

original location. If this vehicle has a tire sealant and

compressor kit, there may not be a

spare tire, tire changing equipment,

and on some vehicles there may not

be a place to store a tire.

The tire sealant and compressor

can be used to temporarily seal

punctures up to ¼ inch (6 mm) in

the tread area of the tire. It can also

be used to inflate an under

inflated tire.

If the tire has been separated from

the wheel, has damaged sidewalls,

or has a large puncture, the tire is

too severely damaged for the tire

sealant and compressor kit to be

effective. See

Roadside Assistance

Program on page 13‑6.

Read and follow all of the tire

sealant and compressor kit

instructions.

Page 380 of 438

10-82 Vehicle Care

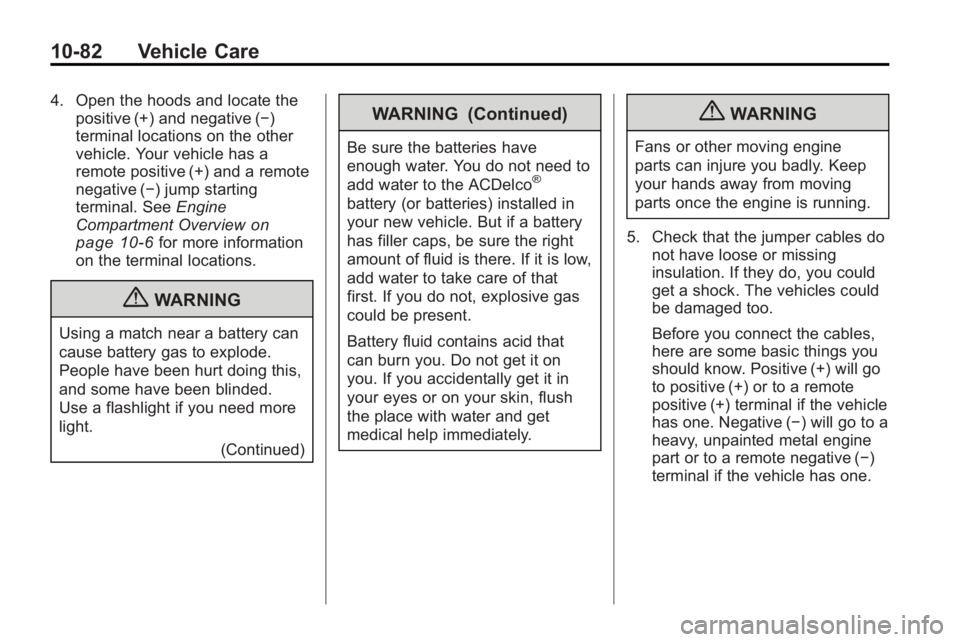

4. Open the hoods and locate thepositive (+) and negative (−)

terminal locations on the other

vehicle. Your vehicle has a

remote positive (+) and a remote

negative (−) jump starting

terminal. See Engine

Compartment Overview

on

page 10‑6for more information

on the terminal locations.

{WARNING

Using a match near a battery can

cause battery gas to explode.

People have been hurt doing this,

and some have been blinded.

Use a flashlight if you need more

light.

(Continued)

WARNING (Continued)

Be sure the batteries have

enough water. You do not need to

add water to the ACDelco

®

battery (or batteries) installed in

your new vehicle. But if a battery

has filler caps, be sure the right

amount of fluid is there. If it is low,

add water to take care of that

first. If you do not, explosive gas

could be present.

Battery fluid contains acid that

can burn you. Do not get it on

you. If you accidentally get it in

your eyes or on your skin, flush

the place with water and get

medical help immediately.

{WARNING

Fans or other moving engine

parts can injure you badly. Keep

your hands away from moving

parts once the engine is running.

5. Check that the jumper cables do not have loose or missing

insulation. If they do, you could

get a shock. The vehicles could

be damaged too.

Before you connect the cables,

here are some basic things you

should know. Positive (+) will go

to positive (+) or to a remote

positive (+) terminal if the vehicle

has one. Negative (−) will go to a

heavy, unpainted metal engine

part or to a remote negative (−)

terminal if the vehicle has one.

Page 381 of 438

Vehicle Care 10-83

Do not connect positive (+) to

negative (−) or you will get a

short that would damage the

battery and maybe other parts

too. And do not connect the

negative (−) cable to the

negative (−) terminal on the dead

battery because this can cause

sparks.

6. Connect the red positive (+)cable to the positive (+) terminal

of the dead battery.

Use a remote positive (+)

terminal if the vehicle has one. 7. Do not let the other end touch

metal. Connect it to the

positive (+) terminal of the good

battery. Use a remote

positive (+) terminal if the vehicle

has one.

8. Now connect the black negative (−) cable to the

negative (−) terminal of the good

battery. Use a remote

negative (−) terminal if the

vehicle has one.

Do not let the other end touch

anything until the next step. The

other end of the negative (−)

cable does not go to the dead

battery. It goes to a heavy,

unpainted metal engine part,

or to a remote negative (−)

terminal on the vehicle with the

dead battery.

9. Connect the other end of thenegative (−) cable at least

18 inches (45 cm) away from the

dead battery, but not near

engine parts that move.

The electrical connection is just

as good there, and the chance

of sparks getting back to the

battery is much less.

Your vehicle has a remote

negative (−) terminal for this

purpose.

Page 382 of 438

10-84 Vehicle Care

10. Now start the vehicle with thegood battery and run the

engine for a while.

11. Try to start the vehicle that had the dead battery. If it will not

start after a few tries, it

probably needs service.

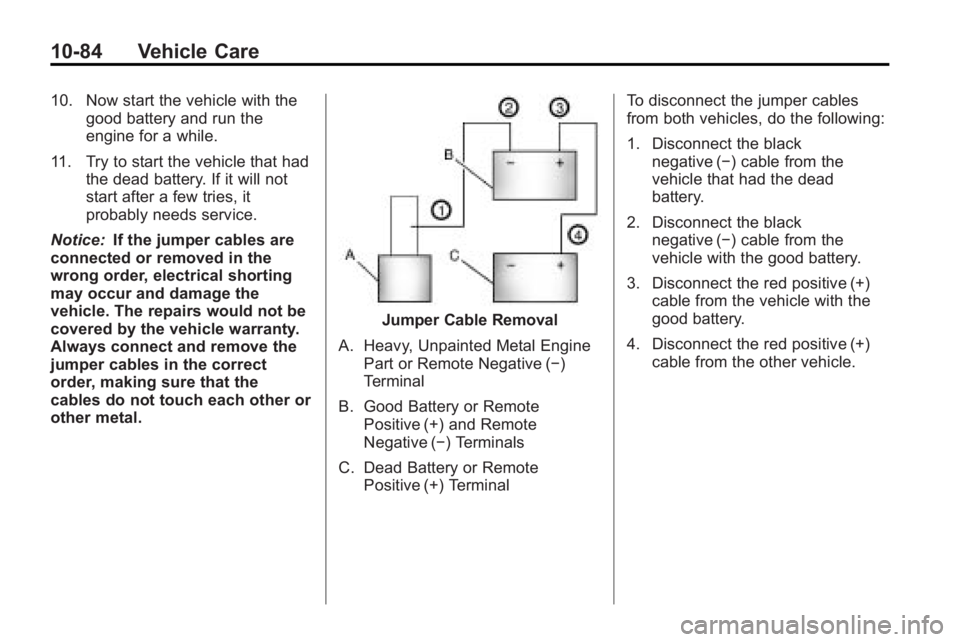

Notice: If the jumper cables are

connected or removed in the

wrong order, electrical shorting

may occur and damage the

vehicle. The repairs would not be

covered by the vehicle warranty.

Always connect and remove the

jumper cables in the correct

order, making sure that the

cables do not touch each other or

other metal.

Jumper Cable Removal

A. Heavy, Unpainted Metal Engine Part or Remote Negative (−)

Terminal

B. Good Battery or Remote Positive (+) and Remote

Negative (−) Terminals

C. Dead Battery or Remote Positive (+) Terminal To disconnect the jumper cables

from both vehicles, do the following:

1. Disconnect the black

negative (−) cable from the

vehicle that had the dead

battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the vehicle with the

good battery.

4. Disconnect the red positive (+) cable from the other vehicle.

Page 384 of 438

10-86 Vehicle Care

Dinghy Towing

If the vehicle is front-wheel-drive, it

can be dinghy towed from the front.

These vehicles may also be towed

by putting the front wheels on a

dolly. See“Dolly Towing” later in this

section.

If the vehicle is all-wheel-drive, it

can be dinghy towed from the front.

These vehicles can also be towed

by placing them on a platform trailer

with all four wheels off of the

ground. These vehicles cannot be

towed using a dolly. For vehicles being dinghy towed,

the vehicle should be run at the

beginning of each day and at each

RV fuel stop for about five minutes.

This will ensure proper lubrication of

transmission components. Re-install

the fuse to start the vehicle.

To tow the vehicle from the front

with all four wheels on the ground:

1. Position the vehicle to be towed,

shift the transmission to

P (Park), and turn the ignition to

LOCK/OFF.

2. Secure the vehicle to the towing vehicle.

3. Set the parking brake.

4. Turn the ignition to ACC/ ACCESSORY.

5. Shift the transmission to N (Neutral). 6. To prevent the battery from

draining while the vehicle is

being towed, remove the 50 amp

BATT1 fuse from the underhood

fuse block and store in a safe

location. See Engine

Compartment Fuse Block

on

page 10‑31.

7. Release the parking brake.

Notice: If the vehicle is towed

without performing each of the

steps listed under “Dinghy

Towing,” the automatic

transmission could be damaged.

Be sure to follow all steps of the

dinghy towing procedure prior to

and after towing the vehicle.

Notice: If 105 km/h (65 mph) is

exceeded while towing the

vehicle, it could be damaged.

Never exceed 105 km/h (65 mph)

while towing the vehicle.

Page 396 of 438

11-2 Service and Maintenance

{WARNING

Performing maintenance work can

be dangerous. Some jobs can

cause serious injury. Perform

maintenance work only if you

have the required know-how and

the proper tools and equipment.

If in doubt, see your dealer/

retailer to have a qualified

technician do the work. See

Doing Your Own Service Work

on

page 10‑4

.

At your General Motors dealer/

retailer, you can be certain that you

will receive the highest level of

service available. Your dealer/

retailer has specially trained service

technicians, uses genuine GM

replacement parts, as well as, up to

date tools and equipment to ensure

fast and accurate diagnostics. The proper replacement parts,

fluids, and lubricants to use are

listed in

Recommended Fluids and

Lubricants

on page 11‑7and

Maintenance Replacement Partson

page 11‑8. We recommend the use

of genuine parts from your dealer/

retailer.

Rotation of New Tires

To maintain ride, handling, and

performance of the vehicle, it is

important that the first rotation

service for new tires be performed

when they have 8 000 to 13 000 km

(5,000 to 8,000 miles). See Tire

Rotation on page 10‑50.

Scheduled

Maintenance

When the Change Engine Oil

Soon Message Displays

Change engine oil and filter.

See Engine Oilon page 10‑8.

An Emission Control Service.

When the Change Engine Oil Soon

message displays, service is

required for the vehicle as soon as

possible, within the next 1 000 km/

600 miles. If driving under the best

conditions, the engine oil life system

might not indicate the need for

vehicle service for more than a year.

The engine oil and filter must be

changed at least once a year and

the oil life system must be reset.

Page 397 of 438

Service and Maintenance 11-3

Your dealer/retailer has trained

service technicians who will perform

this work and reset the system.

If the engine oil life system is reset

accidentally, service the vehicle

within 5 000 km/3,000 miles since

the last service. Reset the oil life

system whenever the oil is changed.

SeeEngine Oil Life System

on

page 10‑10.

When the Change Engine Oil Soon

message displays, certain services,

checks, and inspections are

required. The services described for

Maintenance Ishould be performed

at every engine oil change. The

services described for Maintenance

II should be performed when:

.Maintenance Iwas performed

the last time the engine oil was

changed.

.It has been 10 months or more

since the Change Engine Oil

Soon message has displayed or

since the last service.

Maintenance I

.Change engine oil and filter. See

Engine Oilon page 10‑8.An

Emission Control Service.

.Engine coolant level check. See

Engine Coolant on page 10‑14.

.Windshield washer fluid level

check. See Washer Fluidon

page 10‑21.

.Tire inflation check. See Tire

Pressure on page 10‑44.

.Tire wear inspection. See Tire

Inspection on page 10‑50.

.Rotate tires. See Tire Rotationon page 10‑50.

.Fluids visual leak check (or

every 12 months, whichever

occurs first). A leak in any

system must be repaired and the

fluid level checked.

.Engine air cleaner filter

inspection (vehicles driven in

dusty conditions only). See

Engine Air Cleaner/Filter

on

page 10‑12.

.Brake system inspection (or

every 12 months, whichever

occurs first).

Maintenance II

.Perform all services described in

MaintenanceI.

.Steering and suspension

inspection. Visual inspection for

damaged, loose, or missing

parts or signs of wear.

.Engine cooling system

inspection. Visual inspection of

hoses, pipes, fittings, and

clamps and replacement,

if needed.

.Windshield wiper blade

inspection for wear, cracking,

or contamination and windshield

and wiper blade cleaning,

if contaminated. See Exterior

Care

on page 10‑88. Worn or

damaged wiper blade

replacement. See Wiper Blade

Replacement on page 10‑27.

Page 398 of 438

11-4 Service and Maintenance

.Body hinges and latches, key

lock cylinders, hood latch

assemblies, secondary latches,

pivots, spring anchor and

release pawl, hood and door

hinges, rear folding seats, and

liftgate hinges lubrication. See

Recommended Fluids and

Lubricants

on page 11‑7. More

frequent lubrication may be

required when vehicle is

exposed to a corrosive

environment. Applying silicone

grease on weatherstrips with a

clean cloth makes them last

longer, seal better, and not stick

or squeak.

.Restraint system component

check. See Safety System

Check on page 3‑28.

.Engine air cleaner filter

inspection. See Engine Air

Cleaner/Filter on page 10‑12.

Additional Required Services

At Each Fuel Stop

.Engine oil level check. See

Engine Oil on page 10‑8.

.Engine coolant level check. See

Engine Coolant on page 10‑14.

.Windshield washer fluid level

check. See Washer Fluidon

page 10‑21.

Once a Month

.Tire inflation check. See Tire

Pressure on page 10‑44.

.Tire wear inspection. See Tire

Inspection on page 10‑50.

Once a Year

.See Starter Switch Checkon

page 10‑25.

.See Automatic Transmission

Shift Lock Control System

Check on page 10‑26.

.See Ignition Transmission Lock

Check on page 10‑26.

.See Park Brake and P (Park)

Mechanism Checkon

page 10‑26.

.Engine cooling system and

pressure cap pressure check.

Radiator and air conditioning

condenser outside cleaning. See

Cooling System on page 10‑14.

.Exhaust system and nearby heat

shields inspection for loose or

damaged components.

.Accelerator pedal check for

damage, high effort, or binding.

Replace if needed.

.If the vehicle has a Tire Sealant

and Compressor Kit, check the

sealant expiration date printed

on the instruction label of the kit.

See Tire Sealant and

Compressor Kit on page 10‑60.

First Engine Oil Change After

Every 40 000 km/25,000 Miles

.Fuel system inspection for

damage or leaks.