light BUICK ENCORE 2021 Repair Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2021, Model line: ENCORE, Model: BUICK ENCORE 2021Pages: 313, PDF Size: 11.21 MB

Page 202 of 313

Buick Encore Owner Manual (GMNA-Localizing-U.S./Canada-14607636) -

2021 - CRC - 8/18/20

Vehicle Care 201

Vehicle Care

General Information

General Information . . . . . . . . . . . . . . . . . . . 202

California Proposition 65 Warning . . . . . 202

California Perchlorate MaterialsRequirements . . . . . . . . . . . . . . . . . . . . . . . . 202

Accessories and Modifications . . . . . . . . . 202

Vehicle Checks

Doing Your Own Service Work . . . . . . . . 203

Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Engine Compartment Overview . . . . . . . . 205

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Engine Oil Life System . . . . . . . . . . . . . . . . . 210

Automatic Transmission Fluid . . . . . . . . . . 210

Engine Air Cleaner/Filter . . . . . . . . . . . . . . . 211

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . 212

Engine Overheating . . . . . . . . . . . . . . . . . . . . 215

Washer Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Battery - North America . . . . . . . . . . . . . . . 219

All-Wheel Drive . . . . . . . . . . . . . . . . . . . . . . . . 219

Starter Switch Check . . . . . . . . . . . . . . . . . . . 219

Automatic Transmission Shift Lock Control Function Check . . . . . . . . . . . . . . 220

Park Brake and P (Park) Mechanism Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Wiper Blade Replacement . . . . . . . . . . . . . 220 Windshield Replacement . . . . . . . . . . . . . . . 221

Gas Strut(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Headlamp Aiming

Front Headlamp Aiming . . . . . . . . . . . . . . . 223

Bulb Replacement

Bulb Replacement . . . . . . . . . . . . . . . . . . . . . 223

Halogen Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . 223

LED Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Headlamps, Front Turn Signal and

Parking Lamps . . . . . . . . . . . . . . . . . . . . . . . 223

Taillamps, Turn Signal, Sidemarker, Stoplamps, and Back-Up Lamps . . . . . . 224

License Plate Lamp . . . . . . . . . . . . . . . . . . . . 225

Electrical System

Electrical System Overload . . . . . . . . . . . . 226

Fuses and Circuit Breakers . . . . . . . . . . . . . 226

Engine Compartment Fuse Block . . . . . . . 227

Instrument Panel Fuse Block . . . . . . . . . . 230

Rear Compartment Fuse Block . . . . . . . . . 231

Wheels and Tires

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

All-Season Tires . . . . . . . . . . . . . . . . . . . . . . . . 233

Winter Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Tire Sidewall Labeling . . . . . . . . . . . . . . . . . 234

Tire Designations . . . . . . . . . . . . . . . . . . . . . . 235

Tire Terminology and Definitions . . . . . . 236

Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Tire Pressure Monitor System . . . . . . . . . 239 Tire Pressure Monitor Operation . . . . . . 240

Tire Inspection . . . . . . . . . . . . . . . . . . . . . . . . 242

Tire Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . 242

When It Is Time for New Tires . . . . . . . . 243

Buying New Tires . . . . . . . . . . . . . . . . . . . . . 244

Different Size Tires and Wheels . . . . . . . 245

Uniform Tire Quality Grading . . . . . . . . . 245

Wheel Alignment and Tire Balance . . . . 247

Wheel Replacement . . . . . . . . . . . . . . . . . . . 247

Tire Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

If a Tire Goes Flat . . . . . . . . . . . . . . . . . . . . . 248

Tire Changing . . . . . . . . . . . . . . . . . . . . . . . . . 249

Compact Spare Tire . . . . . . . . . . . . . . . . . . . . 252

Jump Starting

Jump Starting - North America . . . . . . . . 253

Towing the Vehicle

Towing the Vehicle . . . . . . . . . . . . . . . . . . . . 255

Recreational Vehicle Towing . . . . . . . . . . . 256

Appearance Care

Exterior Care . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Interior Care . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Floor Mats . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Page 212 of 313

Buick Encore Owner Manual (GMNA-Localizing-U.S./Canada-14607636) -

2021 - CRC - 8/18/20

Vehicle Care 211

Caution

Use of the incorrect automatic

transmission fluid may damage the

vehicle, and the damage may not be

covered by the vehicle warranty. Always

use the correct automatic transmission

fluid. SeeRecommended Fluids and

Lubricants 0275.

Change the fluid at the intervals listed in

Maintenance Schedule 0267, and be sure to

use the fluid listed in Recommended Fluids

and Lubricants 0275.

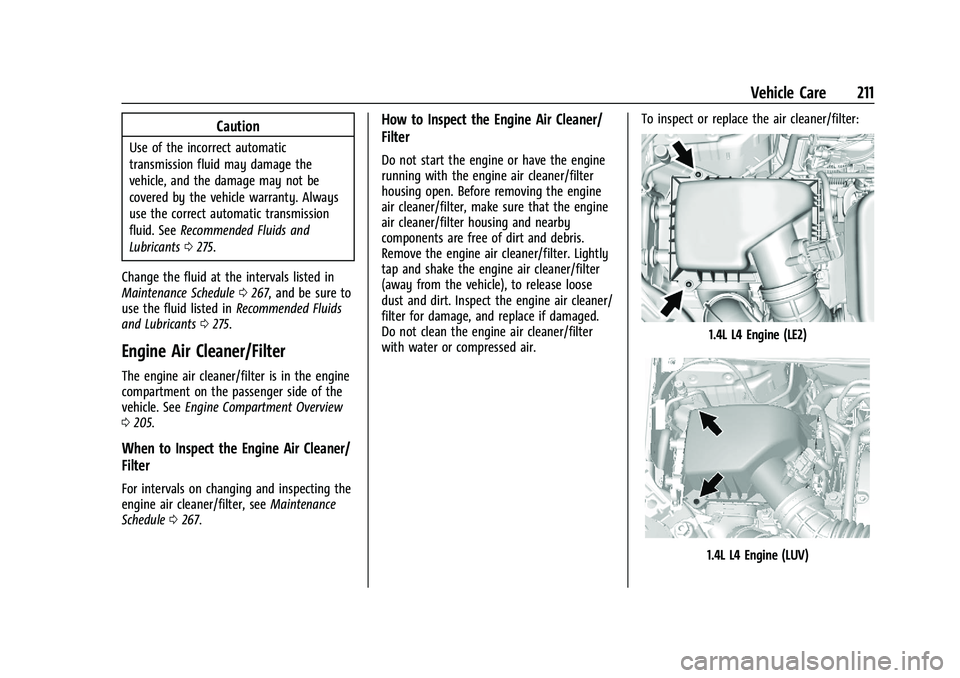

Engine Air Cleaner/Filter

The engine air cleaner/filter is in the engine

compartment on the passenger side of the

vehicle. See Engine Compartment Overview

0 205.

When to Inspect the Engine Air Cleaner/

Filter

For intervals on changing and inspecting the

engine air cleaner/filter, see Maintenance

Schedule 0267.

How to Inspect the Engine Air Cleaner/

Filter

Do not start the engine or have the engine

running with the engine air cleaner/filter

housing open. Before removing the engine

air cleaner/filter, make sure that the engine

air cleaner/filter housing and nearby

components are free of dirt and debris.

Remove the engine air cleaner/filter. Lightly

tap and shake the engine air cleaner/filter

(away from the vehicle), to release loose

dust and dirt. Inspect the engine air cleaner/

filter for damage, and replace if damaged.

Do not clean the engine air cleaner/filter

with water or compressed air. To inspect or replace the air cleaner/filter:

1.4L L4 Engine (LE2)

1.4L L4 Engine (LUV)

Page 219 of 313

Buick Encore Owner Manual (GMNA-Localizing-U.S./Canada-14607636) -

2021 - CRC - 8/18/20

218 Vehicle Care

Replacing Brake System Parts

Always replace brake system parts with

new, approved replacement parts. If this is

not done, the brakes may not work

properly. The braking performance can

change in many ways if the wrong brake

parts are installed or if parts are improperly

installed.

Brake Fluid

The brake master cylinder reservoir is filled

with GM approved DOT 4 brake fluid as

indicated on the reservoir cap. SeeEngine

Compartment Overview 0205 for the

location of the reservoir.

Checking Brake Fluid

With the vehicle in P (Park) on a level

surface, the brake fluid level should be

between the minimum and maximum marks

on the brake fluid reservoir. There are only two reasons why the brake

fluid level in the reservoir may go down:

.Normal brake lining wear. When new

linings are installed, the fluid level goes

back up.

.A fluid leak in the brake hydraulic system.

Have the brake hydraulic system fixed.

With a leak, the brakes will not

work well.

Always clean the brake fluid reservoir cap

and the area around the cap before

removing it.

Do not top off the brake fluid. Adding fluid

does not correct a leak. If fluid is added

when the linings are worn, there will be too

much fluid when new brake linings are

installed. Add or remove fluid, as necessary,

only when work is done on the brake

hydraulic system.

{Warning

If too much brake fluid is added, it can

spill on the engine and burn, if the

engine is hot enough. You or others could

be burned, and the vehicle could be

damaged. Add brake fluid only when

work is done on the brake hydraulic

system. When the brake fluid falls to a low level,

the brake warning light comes on. See

Brake

System Warning Light 082.

Brake fluid absorbs water over time which

degrades the effectiveness of the brake fluid.

Replace brake fluid at the specified intervals

to prevent increased stopping distance. See

Maintenance Schedule 0267.

What to Add

Use only GM approved DOT 4 brake fluid

from a clean, sealed container. See

Recommended Fluids and Lubricants 0275.

{Warning

The wrong or contaminated brake fluid

could result in damage to the brake

system. This could result in the loss of

braking leading to a possible injury.

Always use the proper GM approved

brake fluid.

Caution

If brake fluid is spilled on the vehicle's

painted surfaces, the paint finish can be

damaged. Immediately wash off any

painted surface.

Page 224 of 313

Buick Encore Owner Manual (GMNA-Localizing-U.S./Canada-14607636) -

2021 - CRC - 8/18/20

Vehicle Care 223

Headlamp Aiming

Front Headlamp Aiming

Headlamp aim has been preset and should

need no further adjustment.

If the vehicle is damaged in a crash, the

headlamp aim may be affected.

If adjustment to the headlamps is necessary,

see your dealer.

Bulb Replacement

For the proper type of replacement bulbs,

or any bulb changing procedure not listed in

this section, contact your dealer.

Caution

Do not replace incandescent bulbs with

aftermarket LED replacement bulbs. This

can cause damage to the vehicle electrical

system.

Halogen Bulbs

{Warning

Halogen bulbs have pressurized gas inside

and can burst if you drop or scratch the

bulb. You or others could be injured. Be

sure to read and follow the instructions

on the bulb package.

LED Lighting

This vehicle has several LED lamps. For

replacement of any LED lighting assembly,

contact your dealer.

Headlamps, Front Turn Signal and

Parking Lamps

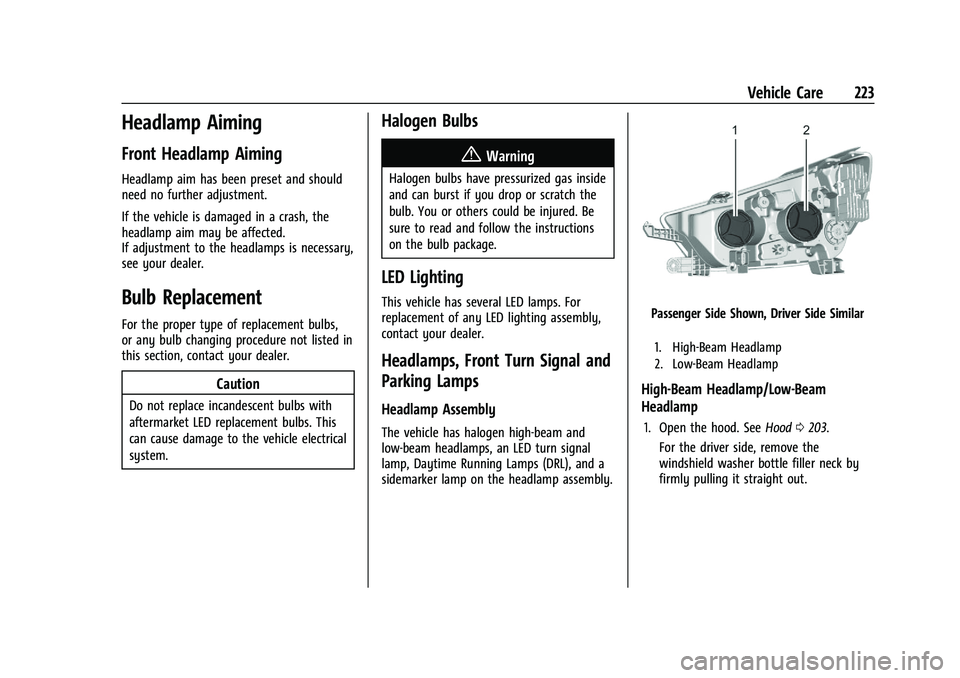

Headlamp Assembly

The vehicle has halogen high-beam and

low-beam headlamps, an LED turn signal

lamp, Daytime Running Lamps (DRL), and a

sidemarker lamp on the headlamp assembly.

Passenger Side Shown, Driver Side Similar

1. High-Beam Headlamp

2. Low-Beam Headlamp

High-Beam Headlamp/Low-Beam

Headlamp

1. Open the hood. SeeHood0203.

For the driver side, remove the

windshield washer bottle filler neck by

firmly pulling it straight out.

Page 238 of 313

Buick Encore Owner Manual (GMNA-Localizing-U.S./Canada-14607636) -

2021 - CRC - 8/18/20

Vehicle Care 237

GAWR FRT:Gross Axle Weight Rating

for the front axle. See Vehicle Load

Limits 0170.

GAWR RR

:Gross Axle Weight Rating

for the rear axle. See Vehicle Load

Limits 0170.

Intended Outboard Sidewall

:The side

of an asymmetrical tire that must

always face outward when mounted on

a vehicle.

Kilopascal (kPa)

:The metric unit for air

pressure.

Light Truck (LT-Metric) Tire

:A tire used

on light duty trucks and some

multipurpose passenger vehicles.

Load Index

:An assigned number

ranging from 1 to 279 that corresponds

to the load carrying capacity of a tire.

Maximum Inflation Pressure

:The

maximum air pressure to which a cold

tire can be inflated. The maximum air

pressure is molded onto the sidewall.

Maximum Load Rating

:The load rating

for a tire at the maximum permissible

inflation pressure for that tire. Maximum Loaded Vehicle Weight

:The

sum of curb weight, accessory weight,

vehicle capacity weight, and production

options weight.

Normal Occupant Weight

:The number

of occupants a vehicle is designed to

seat multiplied by 68 kg (150 lb). See

Vehicle Load Limits 0170.

Occupant Distribution

:Designated

seating positions.

Outward Facing Sidewall

:The side of

an asymmetrical tire that has a

particular side that faces outward when

mounted on a vehicle. The side of the

tire that contains a whitewall, bears

white lettering, or bears manufacturer,

brand, and/or model name molding

that is higher or deeper than the same

moldings on the other sidewall of

the tire.

Passenger (P-Metric) Tire

:A tire used

on passenger cars and some light duty

trucks and multipurpose vehicles. Recommended Inflation Pressure

:

Vehicle manufacturer's recommended

tire inflation pressure as shown on the

tire placard. See

Tire Pressure0238 and

Vehicle Load Limits 0170.

Radial Ply Tire

:A pneumatic tire in

which the ply cords that extend to the

beads are laid at 90 degrees to the

centerline of the tread.

Rim

:A metal support for a tire and

upon which the tire beads are seated.

Sidewall

:The portion of a tire between

the tread and the bead.

Speed Rating

:An alphanumeric code

assigned to a tire indicating the

maximum speed at which a tire can

operate.

Traction

:The friction between the tire

and the road surface. The amount of

grip provided.

Tread

:The portion of a tire that comes

into contact with the road.

Page 241 of 313

Buick Encore Owner Manual (GMNA-Localizing-U.S./Canada-14607636) -

2021 - CRC - 8/18/20

240 Vehicle Care

sequence will continue upon subsequent

vehicle start-ups as long as the malfunction

exists.

When the malfunction indicator is

illuminated, the system may not be able to

detect or signal low tire pressure as

intended. TPMS malfunctions may occur for

a variety of reasons, including the

installation of replacement or alternate tires

or wheels on the vehicle that prevent the

TPMS from functioning properly. Always

check the TPMS malfunction telltale after

replacing one or more tires or wheels on

your vehicle to ensure that the replacement

or alternate tires and wheels allow the

TPMS to continue to function properly.

SeeTire Pressure Monitor Operation 0240.

See Radio Frequency Statement 0290.

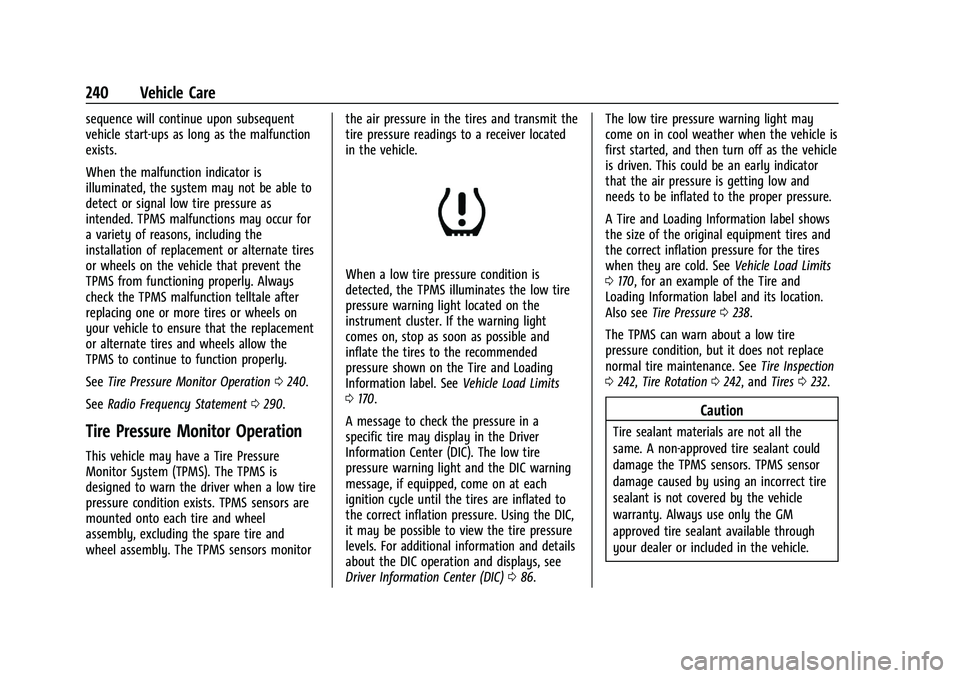

Tire Pressure Monitor Operation

This vehicle may have a Tire Pressure

Monitor System (TPMS). The TPMS is

designed to warn the driver when a low tire

pressure condition exists. TPMS sensors are

mounted onto each tire and wheel

assembly, excluding the spare tire and

wheel assembly. The TPMS sensors monitor the air pressure in the tires and transmit the

tire pressure readings to a receiver located

in the vehicle.

When a low tire pressure condition is

detected, the TPMS illuminates the low tire

pressure warning light located on the

instrument cluster. If the warning light

comes on, stop as soon as possible and

inflate the tires to the recommended

pressure shown on the Tire and Loading

Information label. See

Vehicle Load Limits

0 170.

A message to check the pressure in a

specific tire may display in the Driver

Information Center (DIC). The low tire

pressure warning light and the DIC warning

message, if equipped, come on at each

ignition cycle until the tires are inflated to

the correct inflation pressure. Using the DIC,

it may be possible to view the tire pressure

levels. For additional information and details

about the DIC operation and displays, see

Driver Information Center (DIC) 086. The low tire pressure warning light may

come on in cool weather when the vehicle is

first started, and then turn off as the vehicle

is driven. This could be an early indicator

that the air pressure is getting low and

needs to be inflated to the proper pressure.

A Tire and Loading Information label shows

the size of the original equipment tires and

the correct inflation pressure for the tires

when they are cold. See

Vehicle Load Limits

0 170, for an example of the Tire and

Loading Information label and its location.

Also see Tire Pressure 0238.

The TPMS can warn about a low tire

pressure condition, but it does not replace

normal tire maintenance. See Tire Inspection

0 242, Tire Rotation 0242, and Tires0232.

Caution

Tire sealant materials are not all the

same. A non-approved tire sealant could

damage the TPMS sensors. TPMS sensor

damage caused by using an incorrect tire

sealant is not covered by the vehicle

warranty. Always use only the GM

approved tire sealant available through

your dealer or included in the vehicle.

Page 242 of 313

Buick Encore Owner Manual (GMNA-Localizing-U.S./Canada-14607636) -

2021 - CRC - 8/18/20

Vehicle Care 241

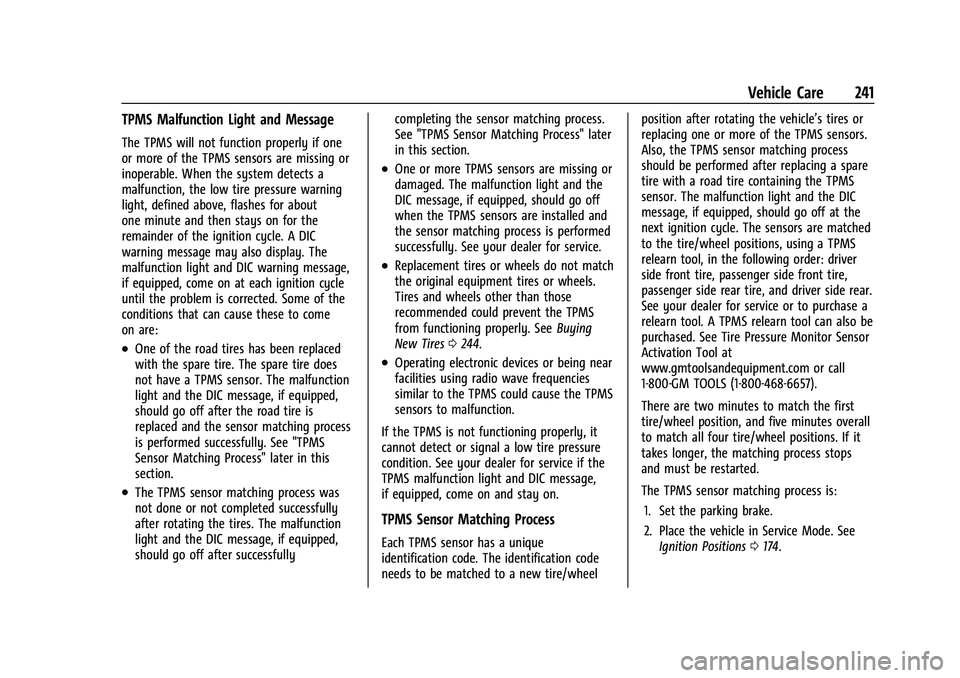

TPMS Malfunction Light and Message

The TPMS will not function properly if one

or more of the TPMS sensors are missing or

inoperable. When the system detects a

malfunction, the low tire pressure warning

light, defined above, flashes for about

one minute and then stays on for the

remainder of the ignition cycle. A DIC

warning message may also display. The

malfunction light and DIC warning message,

if equipped, come on at each ignition cycle

until the problem is corrected. Some of the

conditions that can cause these to come

on are:

.One of the road tires has been replaced

with the spare tire. The spare tire does

not have a TPMS sensor. The malfunction

light and the DIC message, if equipped,

should go off after the road tire is

replaced and the sensor matching process

is performed successfully. See "TPMS

Sensor Matching Process" later in this

section.

.The TPMS sensor matching process was

not done or not completed successfully

after rotating the tires. The malfunction

light and the DIC message, if equipped,

should go off after successfullycompleting the sensor matching process.

See "TPMS Sensor Matching Process" later

in this section.

.One or more TPMS sensors are missing or

damaged. The malfunction light and the

DIC message, if equipped, should go off

when the TPMS sensors are installed and

the sensor matching process is performed

successfully. See your dealer for service.

.Replacement tires or wheels do not match

the original equipment tires or wheels.

Tires and wheels other than those

recommended could prevent the TPMS

from functioning properly. See

Buying

New Tires 0244.

.Operating electronic devices or being near

facilities using radio wave frequencies

similar to the TPMS could cause the TPMS

sensors to malfunction.

If the TPMS is not functioning properly, it

cannot detect or signal a low tire pressure

condition. See your dealer for service if the

TPMS malfunction light and DIC message,

if equipped, come on and stay on.

TPMS Sensor Matching Process

Each TPMS sensor has a unique

identification code. The identification code

needs to be matched to a new tire/wheel position after rotating the vehicle’s tires or

replacing one or more of the TPMS sensors.

Also, the TPMS sensor matching process

should be performed after replacing a spare

tire with a road tire containing the TPMS

sensor. The malfunction light and the DIC

message, if equipped, should go off at the

next ignition cycle. The sensors are matched

to the tire/wheel positions, using a TPMS

relearn tool, in the following order: driver

side front tire, passenger side front tire,

passenger side rear tire, and driver side rear.

See your dealer for service or to purchase a

relearn tool. A TPMS relearn tool can also be

purchased. See Tire Pressure Monitor Sensor

Activation Tool at

www.gmtoolsandequipment.com or call

1-800-GM TOOLS (1-800-468-6657).

There are two minutes to match the first

tire/wheel position, and five minutes overall

to match all four tire/wheel positions. If it

takes longer, the matching process stops

and must be restarted.

The TPMS sensor matching process is:

1. Set the parking brake.

2. Place the vehicle in Service Mode. See Ignition Positions 0174.

Page 244 of 313

Buick Encore Owner Manual (GMNA-Localizing-U.S./Canada-14607636) -

2021 - CRC - 8/18/20

Vehicle Care 243

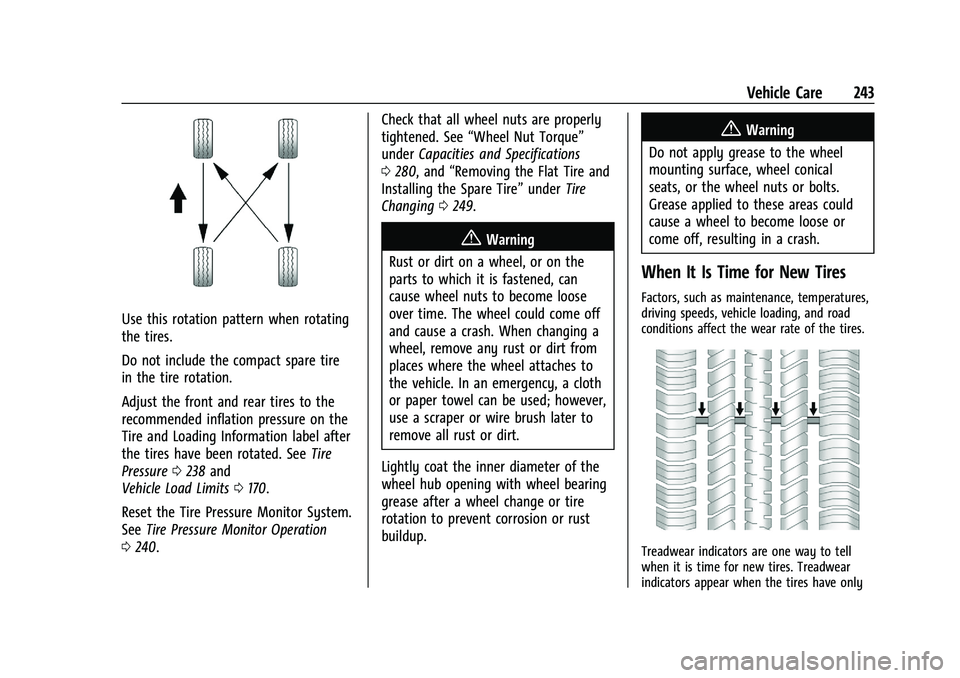

Use this rotation pattern when rotating

the tires.

Do not include the compact spare tire

in the tire rotation.

Adjust the front and rear tires to the

recommended inflation pressure on the

Tire and Loading Information label after

the tires have been rotated. SeeTire

Pressure 0238 and

Vehicle Load Limits 0170.

Reset the Tire Pressure Monitor System.

See Tire Pressure Monitor Operation

0 240. Check that all wheel nuts are properly

tightened. See

“Wheel Nut Torque”

under Capacities and Specifications

0 280, and “Removing the Flat Tire and

Installing the Spare Tire” underTire

Changing 0249.

{Warning

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

cause wheel nuts to become loose

over time. The wheel could come off

and cause a crash. When changing a

wheel, remove any rust or dirt from

places where the wheel attaches to

the vehicle. In an emergency, a cloth

or paper towel can be used; however,

use a scraper or wire brush later to

remove all rust or dirt.

Lightly coat the inner diameter of the

wheel hub opening with wheel bearing

grease after a wheel change or tire

rotation to prevent corrosion or rust

buildup.

{Warning

Do not apply grease to the wheel

mounting surface, wheel conical

seats, or the wheel nuts or bolts.

Grease applied to these areas could

cause a wheel to become loose or

come off, resulting in a crash.

When It Is Time for New Tires

Factors, such as maintenance, temperatures,

driving speeds, vehicle loading, and road

conditions affect the wear rate of the tires.

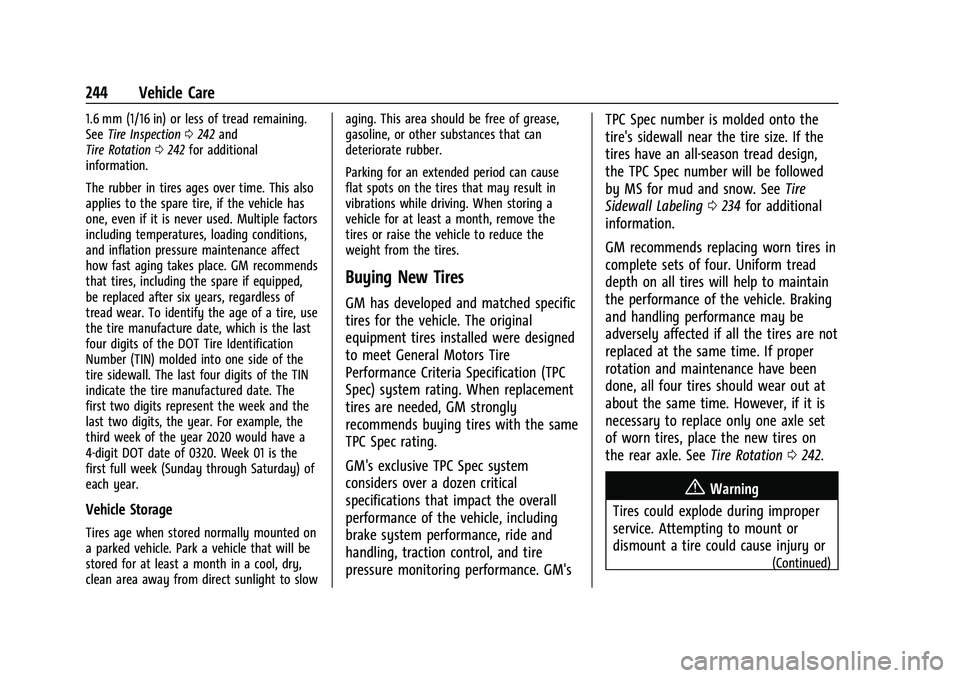

Treadwear indicators are one way to tell

when it is time for new tires. Treadwear

indicators appear when the tires have only

Page 245 of 313

Buick Encore Owner Manual (GMNA-Localizing-U.S./Canada-14607636) -

2021 - CRC - 8/18/20

244 Vehicle Care

1.6 mm (1/16 in) or less of tread remaining.

SeeTire Inspection 0242 and

Tire Rotation 0242 for additional

information.

The rubber in tires ages over time. This also

applies to the spare tire, if the vehicle has

one, even if it is never used. Multiple factors

including temperatures, loading conditions,

and inflation pressure maintenance affect

how fast aging takes place. GM recommends

that tires, including the spare if equipped,

be replaced after six years, regardless of

tread wear. To identify the age of a tire, use

the tire manufacture date, which is the last

four digits of the DOT Tire Identification

Number (TIN) molded into one side of the

tire sidewall. The last four digits of the TIN

indicate the tire manufactured date. The

first two digits represent the week and the

last two digits, the year. For example, the

third week of the year 2020 would have a

4-digit DOT date of 0320. Week 01 is the

first full week (Sunday through Saturday) of

each year.

Vehicle Storage

Tires age when stored normally mounted on

a parked vehicle. Park a vehicle that will be

stored for at least a month in a cool, dry,

clean area away from direct sunlight to slow aging. This area should be free of grease,

gasoline, or other substances that can

deteriorate rubber.

Parking for an extended period can cause

flat spots on the tires that may result in

vibrations while driving. When storing a

vehicle for at least a month, remove the

tires or raise the vehicle to reduce the

weight from the tires.

Buying New Tires

GM has developed and matched specific

tires for the vehicle. The original

equipment tires installed were designed

to meet General Motors Tire

Performance Criteria Specification (TPC

Spec) system rating. When replacement

tires are needed, GM strongly

recommends buying tires with the same

TPC Spec rating.

GM's exclusive TPC Spec system

considers over a dozen critical

specifications that impact the overall

performance of the vehicle, including

brake system performance, ride and

handling, traction control, and tire

pressure monitoring performance. GM's

TPC Spec number is molded onto the

tire's sidewall near the tire size. If the

tires have an all-season tread design,

the TPC Spec number will be followed

by MS for mud and snow. See

Tire

Sidewall Labeling 0234 for additional

information.

GM recommends replacing worn tires in

complete sets of four. Uniform tread

depth on all tires will help to maintain

the performance of the vehicle. Braking

and handling performance may be

adversely affected if all the tires are not

replaced at the same time. If proper

rotation and maintenance have been

done, all four tires should wear out at

about the same time. However, if it is

necessary to replace only one axle set

of worn tires, place the new tires on

the rear axle. See Tire Rotation0242.

{Warning

Tires could explode during improper

service. Attempting to mount or

dismount a tire could cause injury or

(Continued)

Page 247 of 313

Buick Encore Owner Manual (GMNA-Localizing-U.S./Canada-14607636) -

2021 - CRC - 8/18/20

246 Vehicle Care

The Uniform Tire Quality Grading

(UTQG) system does not apply to deep

tread, winter tires, compact spare tires,

tires with nominal rim diameters of

10 to 12 inches (25 to 30 cm), or to some

limited-production tires.

While the tires available on General

Motors passenger cars and light trucks

may vary with respect to these grades,

they must also conform to federal

safety requirements and additional

General Motors Tire Performance

Criteria (TPC) standards.

Quality grades can be found where

applicable on the tire sidewall between

tread shoulder and maximum section

width. For example:

Treadwear 200 Traction AA Temperature A

All Passenger Car Tires Must Conform to

Federal Safety Requirements In Addition

To These Grades.

Treadwear

The treadwear grade is a comparative

rating based on the wear rate of the

tire when tested under controlledconditions on a specified government

test course. For example, a tire graded

150 would wear one and one-half (1½)

times as well on the government course

as a tire graded 100. The relative

performance of tires depends upon the

actual conditions of their use, however,

and may depart significantly from the

norm due to variations in driving habits,

service practices and differences in road

characteristics and climate.

Traction

The traction grades, from highest to

lowest, are AA, A, B, and C. Those

grades represent the tire's ability to

stop on wet pavement as measured

under controlled conditions on specified

government test surfaces of asphalt and

concrete. A tire marked C may have

poor traction performance. Warning:

The traction grade assigned to this tire

is based on straight-ahead braking

traction tests, and does not include

acceleration, cornering, hydroplaning,

or peak traction characteristics.

Temperature

The temperature grades are A (the

highest), B, and C, representing the

tire's resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled conditions

on a specified indoor laboratory test

wheel. Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. The grade C

corresponds to a level of performance

which all passenger car tires must meet

under the Federal Motor Safety

Standard No. 109. Grades B and A

represent higher levels of performance

on the laboratory test wheel than the

minimum required by law. Warning:

The temperature grade for this tire is

established for a tire that is properly

inflated and not overloaded. Excessive

speed, underinflation, or excessive

loading, either separately or in

combination, can cause heat buildup

and possible tire failure.