wheel bolt torque BUICK LACROSSE 2012 Owner's Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2012, Model line: LACROSSE, Model: BUICK LACROSSE 2012Pages: 512, PDF Size: 6.21 MB

Page 400 of 512

Black plate (62,1)Buick LaCrosse Owner Manual - 2012

10-62 Vehicle Care

Check that all wheel nuts are

properly tightened. See“Wheel

Nut Torque” underCapacities

and Specifications on

page 12‑2.

{WARNING

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

make wheel nuts become loose

after time. The wheel could come

off and cause an accident. When

changing a wheel, remove any

rust or dirt from places where the

wheel attaches to the vehicle. In

an emergency, a cloth or a paper

towel can be used; however, use

a scraper or wire brush later to

remove all rust or dirt.

Lightly coat the center of the

wheel hub with wheel bearing

grease after a wheel change or

tire rotation to prevent corrosion

or rust build-up. Do not get

grease on the flat wheel

mounting surface or on the

wheel nuts or bolts.

When It Is Time for New

Tires

Factors such as maintenance,

temperatures, driving speeds,

vehicle loading, and road conditions

affect the wear rate of the tires.Treadwear indicators are one way to

tell when it is time for new tires.

Treadwear indicators appear when

the tires have only 1.6 mm (1/16 in)

or less of tread remaining. See Tire

Inspection on page 10‑60 andTire

Rotation on page 10‑61 for more

information.

Page 429 of 512

Black plate (91,1)Buick LaCrosse Owner Manual - 2012

Vehicle Care 10-91

{WARNING

Never use oil or grease on bolts

or nuts because the nuts might

come loose. The vehicle's wheel

could fall off, causing a crash.

11. Put the wheel nuts back on with the rounded end of the

nuts toward the wheel. Turn

each nut clockwise by hand

until the wheel is held against

the hub.

12. Lower the vehicle by turning the jack handle

counterclockwise. Lower the

jack completely.

{WARNING

Wheel nuts that are improperly or

incorrectly tightened can cause

the wheels to become loose or

come off. The wheel nuts should

be tightened with a torque wrench

to the proper torque specification

after replacing. Follow the torque

specification supplied by the

aftermarket manufacturer when

using accessory locking wheel

nuts. See Capacities and

Specifications on page 12‑2 for

original equipment wheel nut

torque specifications.

Notice: Improperly tightened

wheel nuts can lead to brake

pulsation and rotor damage. To

avoid expensive brake repairs,

evenly tighten the wheel nuts in

the proper sequence and to the

proper torque specification. See

Capacities and Specifications on

page 12‑2 for the wheel nut

torque specification.

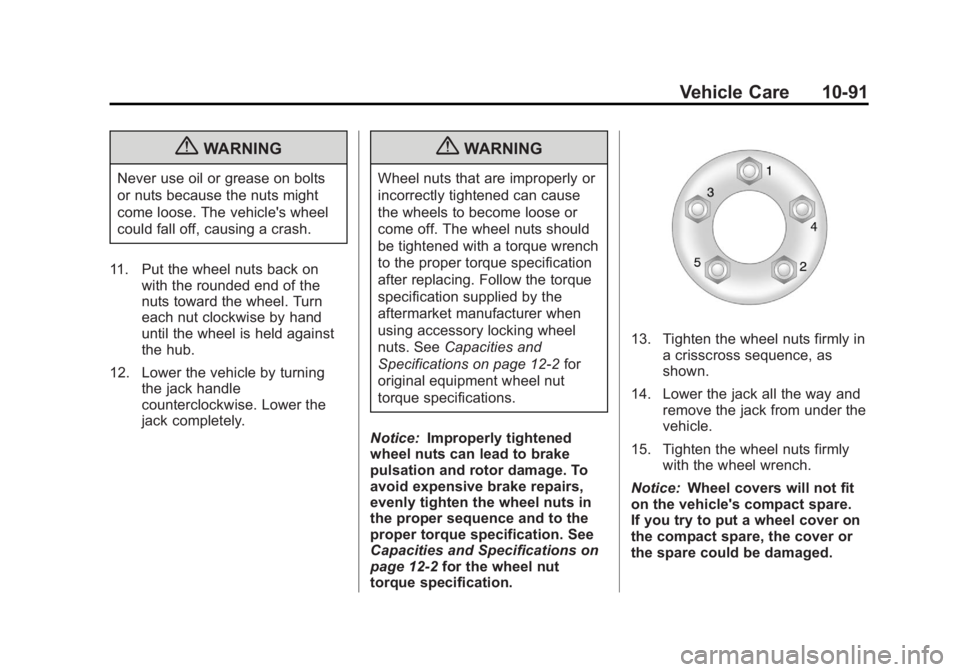

13. Tighten the wheel nuts firmly in a crisscross sequence, as

shown.

14. Lower the jack all the way and remove the jack from under the

vehicle.

15. Tighten the wheel nuts firmly with the wheel wrench.

Notice: Wheel covers will not fit

on the vehicle's compact spare.

If you try to put a wheel cover on

the compact spare, the cover or

the spare could be damaged.