service BUICK LESABRE 2005 Workshop Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2005, Model line: LESABRE, Model: BUICK LESABRE 2005Pages: 392, PDF Size: 2.45 MB

Page 283 of 392

6. Connect the red positive (+) cable to the positive (+)

terminal of the dead battery. Use a remote

positive (+) terminal if the vehicle has one.

7. Do not let the other end touch metal. Connect it to

the positive (+) terminal of the good battery. Use a

remote positive (+) terminal if the vehicle has one.

8. Now connect the black negative (−) cable to the

negative (−) terminal of the good battery. Use a

remote negative (−) terminal if the vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (−) cable

does notgo to the dead battery. It goes to a

heavy, unpainted metal engine part or to a remote

negative (−) terminal on the vehicle with the

dead battery.9. Connect the other end of the negative (−) cable at

least 18 inches (45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is just as good there, and the chance

of sparks getting back to the battery is much less.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery.

If it will not start after a few tries, it probably

needs service.

5-43

Page 285 of 392

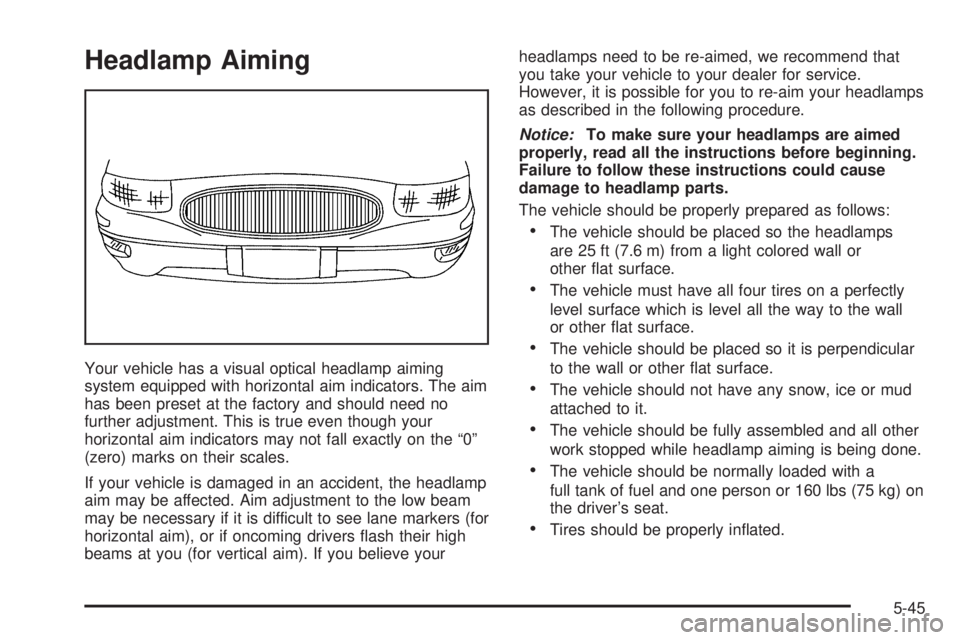

Headlamp Aiming

Your vehicle has a visual optical headlamp aiming

system equipped with horizontal aim indicators. The aim

has been preset at the factory and should need no

further adjustment. This is true even though your

horizontal aim indicators may not fall exactly on the “0”

(zero) marks on their scales.

If your vehicle is damaged in an accident, the headlamp

aim may be affected. Aim adjustment to the low beam

may be necessary if it is difficult to see lane markers (for

horizontal aim), or if oncoming drivers �ash their high

beams at you (for vertical aim). If you believe yourheadlamps need to be re-aimed, we recommend that

you take your vehicle to your dealer for service.

However, it is possible for you to re-aim your headlamps

as described in the following procedure.

Notice:To make sure your headlamps are aimed

properly, read all the instructions before beginning.

Failure to follow these instructions could cause

damage to headlamp parts.

The vehicle should be properly prepared as follows:

The vehicle should be placed so the headlamps

are 25 ft (7.6 m) from a light colored wall or

other �at surface.

The vehicle must have all four tires on a perfectly

level surface which is level all the way to the wall

or other �at surface.

The vehicle should be placed so it is perpendicular

to the wall or other �at surface.

The vehicle should not have any snow, ice or mud

attached to it.

The vehicle should be fully assembled and all other

work stopped while headlamp aiming is being done.

The vehicle should be normally loaded with a

full tank of fuel and one person or 160 lbs (75 kg) on

the driver’s seat.

Tires should be properly in�ated.

5-45

Page 293 of 392

Replacement Bulbs

Exterior Lamp Bulb Number

Front Turn Signals 3157

Headlamps

High-Beam 9005

Low-Beam 9006

Trunk-Mounted Back-Up Lamps 3057

Trunk-Mounted Taillamps 194

Tail/Stop/Turn Signal Lamps 3357

For replacement bulbs not listed here, contact

your dealer.

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected at least

twice a year for wear or cracking. See “Wiper Blade

Check” underPart B: Owner Checks and Services on

page 6-18for more information.

Replacement blades come in different types and are

removed in different ways.

To replace the wiper blade assembly, do the following:

1. Lift the windshield wiper arm away from

the windshield.2. Push the tab on the wiper blade assembly and pull

the assembly down enough to release it from the

U-hooked end of the wiper arm. Slide the assembly

away from the arm.

3. Remove the blade.

4. To reinstall the wiper blade assembly, slide it over

the wiper arm to engage the U-hooked end on the

wiper blade assembly. Pull up on the assembly

to lock it into place.

For the proper windshield wiper blade replacement

length and type, seeNormal Maintenance Replacement

Parts on page 5-97.

5-53

Page 294 of 392

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer. If you ever have questions

about your tire warranty and where to obtain service,

see your GM Warranty booklet for details. For additional

information refer to the tire manufacturer’s booklet

included with your vehicle’s Owner’s Manual.

{CAUTION:

Poorly maintained and improperly used tires

are dangerous.

Overloading your tires can cause

overheating as a result of too much

friction. You could have an air-out and a

serious accident. SeeLoading Your

Vehicle on page 4-31.

CAUTION: (Continued)

CAUTION: (Continued)

Underin�ated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be

checked when your tires are cold. See

Inflation - Tire Pressure on page 5-60.

Overin�ated tires are more likely to be

cut, punctured or broken by a sudden

impact — such as when you hit a pothole.

Keep tires at the recommended pressure.

Worn, old tires can cause accidents. If

your tread is badly worn, or if your tires

have been damaged, replace them.

5-54

Page 295 of 392

Tire Sidewall Labelling

Useful information about a tire is molded into its

sidewall. The examples below show a typical passenger

vehicle tire and a compact spare tire sidewall.

(A) Tire Size:The tire size is a combination of letters

and numbers used to de�ne a particular tire’s width,

height, aspect ratio, construction type and service

description. See the “Tire Size” illustration later in this

section for more detail.(B) TPC Spec (Tire Performance Criteria

Speci�cation):Original equipment tires designed to

GM’s speci�c tire performance criteria have a TPC

speci�cation code molded onto the sidewall. GM’s TPC

speci�cations meet or exceed all federal safety

guidelines.

(C) DOT (Department of Transportation):The

Department of Transportation (DOT) code indicates that

the tire is in compliance with the U.S. Department of

Transportation Motor Vehicle Safety Standards.

(D) Tire Identi�cation Number (TIN):The letters and

numbers following DOT (Department of Transportation)

code is the Tire Identi�cation Number (TIN). The

TIN shows the manufacturer and plant code, tire size,

and date the tire was manufactured. The TIN is molded

onto both sides of the tire, although only one side

may have the date of manufacture.

(E) Tire Ply Material:The type of cord and number of

plies in the sidewall and under the tread.

(F) Uniform Tire Quality Grading (UTQG):Tire

manufacturers are required to grade tires based on three

performance factors: treadwear, traction and

temperature resistance. For more information see

Uniform Tire Quality Grading on page 5-66.

(G) Maximum Cold In�ation Load Limit:Maximum

load that can be carried and the maximum pressure

needed to support that load. Passenger (P-Metric) Tire Example

5-55

Page 296 of 392

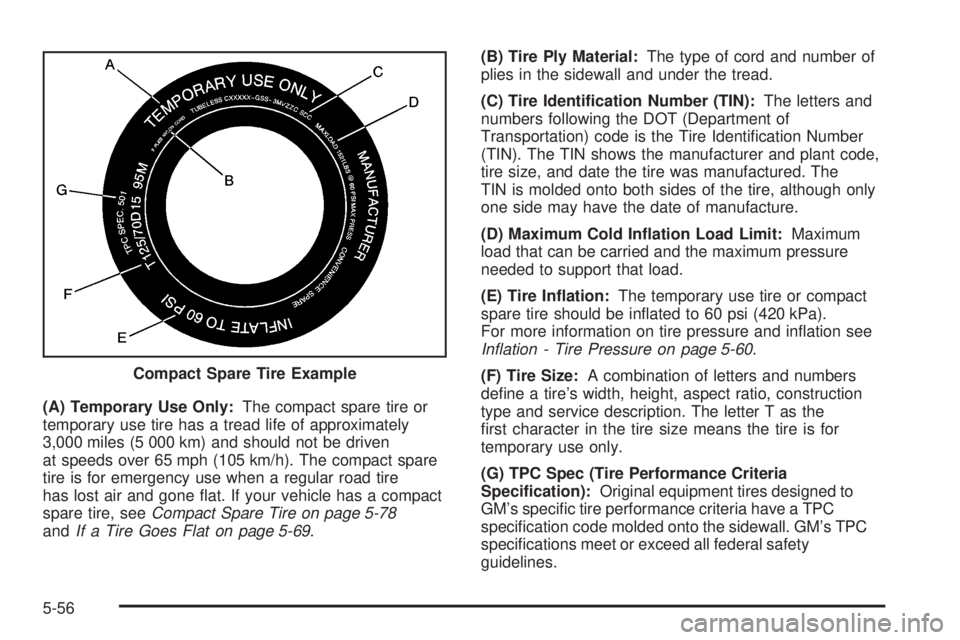

(A) Temporary Use Only:The compact spare tire or

temporary use tire has a tread life of approximately

3,000 miles (5 000 km) and should not be driven

at speeds over 65 mph (105 km/h). The compact spare

tire is for emergency use when a regular road tire

has lost air and gone �at. If your vehicle has a compact

spare tire, seeCompact Spare Tire on page 5-78

andIf a Tire Goes Flat on page 5-69.(B) Tire Ply Material:The type of cord and number of

plies in the sidewall and under the tread.

(C) Tire Identi�cation Number (TIN):The letters and

numbers following the DOT (Department of

Transportation) code is the Tire Identi�cation Number

(TIN). The TIN shows the manufacturer and plant code,

tire size, and date the tire was manufactured. The

TIN is molded onto both sides of the tire, although only

one side may have the date of manufacture.

(D) Maximum Cold In�ation Load Limit:Maximum

load that can be carried and the maximum pressure

needed to support that load.

(E) Tire In�ation:The temporary use tire or compact

spare tire should be in�ated to 60 psi (420 kPa).

For more information on tire pressure and in�ation see

In�ation - Tire Pressure on page 5-60.

(F) Tire Size:A combination of letters and numbers

de�ne a tire’s width, height, aspect ratio, construction

type and service description. The letter T as the

�rst character in the tire size means the tire is for

temporary use only.

(G) TPC Spec (Tire Performance Criteria

Speci�cation):Original equipment tires designed to

GM’s speci�c tire performance criteria have a TPC

speci�cation code molded onto the sidewall. GM’s TPC

speci�cations meet or exceed all federal safety

guidelines. Compact Spare Tire Example

5-56

Page 297 of 392

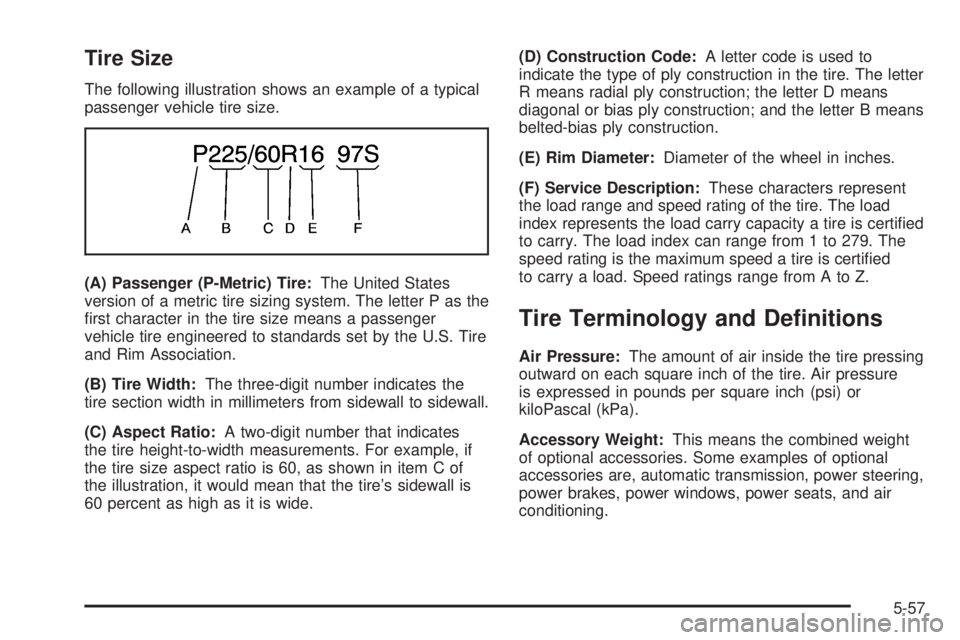

Tire Size

The following illustration shows an example of a typical

passenger vehicle tire size.

(A) Passenger (P-Metric) Tire:The United States

version of a metric tire sizing system. The letter P as the

�rst character in the tire size means a passenger

vehicle tire engineered to standards set by the U.S. Tire

and Rim Association.

(B) Tire Width:The three-digit number indicates the

tire section width in millimeters from sidewall to sidewall.

(C) Aspect Ratio:A two-digit number that indicates

the tire height-to-width measurements. For example, if

the tire size aspect ratio is 60, as shown in item C of

the illustration, it would mean that the tire’s sidewall is

60 percent as high as it is wide.(D) Construction Code:A letter code is used to

indicate the type of ply construction in the tire. The letter

R means radial ply construction; the letter D means

diagonal or bias ply construction; and the letter B means

belted-bias ply construction.

(E) Rim Diameter:Diameter of the wheel in inches.

(F) Service Description:These characters represent

the load range and speed rating of the tire. The load

index represents the load carry capacity a tire is certi�ed

to carry. The load index can range from 1 to 279. The

speed rating is the maximum speed a tire is certi�ed

to carry a load. Speed ratings range from A to Z.

Tire Terminology and De�nitions

Air Pressure:The amount of air inside the tire pressing

outward on each square inch of the tire. Air pressure

is expressed in pounds per square inch (psi) or

kiloPascal (kPa).

Accessory Weight:This means the combined weight

of optional accessories. Some examples of optional

accessories are, automatic transmission, power steering,

power brakes, power windows, power seats, and air

conditioning.

5-57

Page 302 of 392

Check Tire Pressure System

If your vehicle has the check tire pressure system, it

can alert you to a large change in the pressure of one

tire. The system will not alert you before you drive

that a tire is low or �at. You must begin driving before

the system will work properly.

The CHECK TIRE PRESSURE message will appear on

the Driver Information Center (DIC) if pressure

difference (low pressure) is detected in one tire. The

check tire pressure system may not alert you if:

More than one tire is low.

The vehicle is moving faster than

65 mph (105 km/h).

The system is not yet calibrated.

The tire treadwear is uneven.

The compact spare tire is installed.

Tire chains are being used.

The vehicle is being driven on a rough or

frozen road.

If the anti-lock brake system warning light comes on,

the check tire pressure system may not be working

properly. See your dealer for service. Also, see

Anti-Lock Brake System Warning Light on page 3-39.The check tire pressure system detects differences in

tire rotation speeds that are caused by changes in

tire pressure. The system can alert you about a

low tire — but it does not replace normal tire

maintenance. SeeTires on page 5-54.

When the CHECK TIRE PRESSURE message appears

on the Driver Information Center, you should stop as

soon as you can and check all your tires for damage. If

a tire is �at, seeIf a Tire Goes Flat on page 5-69.

Also check the tire pressure in all four tires as soon as

you can. SeeIn�ation - Tire Pressure on page 5-60.

Any time you adjust a tire’s pressure or have one

or more tires repaired or replaced, you will need to reset

(calibrate) the check tire pressure system. You will

also need to reset the system whenever you rotate the

tires, buy new tires and install or remove the compact

spare tire.

Do not reset the check tire pressure system without �rst

correcting the cause of the problem and checking

and adjusting the pressure in all four tires. If you reset

the system when the tire pressures are incorrect,

the check tire pressure system will not work properly

and may not alert you when a tire is low or high.

5-62

Page 303 of 392

To reset (calibrate) the system:

1. Turn the ignition switch to RUN.

2. Press the GAGE INFO button on the DIC until TIRE

PRESSURE appears on the display.

3. Press and hold the DIC RESET button for about

�ve seconds. After �ve seconds, the display will

show TIRE PRESSURE RESET. If TIRE

PRESSURE RESET does not appear in the display

after about �ve seconds repeat the procedure. If it

does not work after two tries, see your dealer for

service. After you release the DIC RESET button,

TIRE PRESSURE NORMAL will appear in the

display.

The system completes the calibration process during

driving. Calibration time can take 45 to 90 minutes,

depending on your driving habits. After the system has

been calibrated, the system will alert the driver that

a tire is low, up to a maximum speed of 65 mph

(105 km/h).

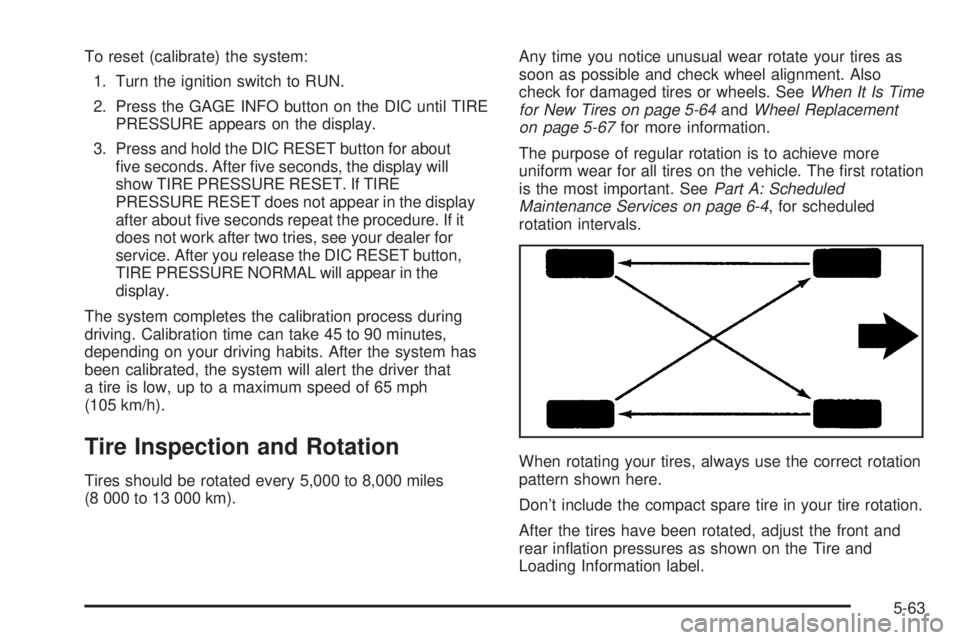

Tire Inspection and Rotation

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km).Any time you notice unusual wear rotate your tires as

soon as possible and check wheel alignment. Also

check for damaged tires or wheels. SeeWhen It Is Time

for New Tires on page 5-64andWheel Replacement

on page 5-67for more information.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The �rst rotation

is the most important. SeePart A: Scheduled

Maintenance Services on page 6-4, for scheduled

rotation intervals.

When rotating your tires, always use the correct rotation

pattern shown here.

Don’t include the compact spare tire in your tire rotation.

After the tires have been rotated, adjust the front and

rear in�ation pressures as shown on the Tire and

Loading Information label.

5-63

Page 305 of 392

Buying New Tires

To �nd out what kind and size of tires your vehicle

needs, look at the tire and loading information label. For

more information about this label and its location on

your vehicle, seeLoading Your Vehicle on page 4-31.

The tires installed on your vehicle when it was new had

a Tire Performance Criteria Speci�cation (TPC Spec)

number on each tire’s sidewall. When you get new tires,

GM recommends that you get tires with that same

TPC Spec number. That way your vehicle will continue

to have tires that are designed to give proper

endurance, handling, speed rating, load range, traction,

ride and other things during normal service on your

vehicle. If your tires have an all-season tread design,

the TPC number will be followed by an “MS” (for mud

and snow).

If you ever replace your tires with those not having a

TPC Spec number, make sure they are the same size,

load range, speed rating and construction type (bias,

bias-belted or radial) as your original tires.{CAUTION:

Mixing tires could cause you to lose control

while driving. If you mix tires of different sizes

or types (radial and bias-belted tires), the

vehicle may not handle properly, and you

could have a crash. Using tires of different

sizes may also cause damage to your vehicle.

Be sure to use the same size and type tires on

all wheels. It’s all right to drive with your

compact spare temporarily, it was developed

for use on your vehicle. SeeCompact Spare

Tire on page 5-78.

{CAUTION:

If you use bias-ply tires on your vehicle, the

wheel rim �anges could develop cracks after

many miles of driving. A tire and/or wheel

could fail suddenly, causing a crash. Use only

radial-ply tires with the wheels on your vehicle.

5-65