TPMS reset BUICK LUCERNE 2007 Owner's Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2007, Model line: LUCERNE, Model: BUICK LUCERNE 2007Pages: 496, PDF Size: 2.77 MB

Page 396 of 496

Your vehicle’s TPMS system can warn you about a

low tire pressure condition but it does not replace

normal tire maintenance. SeeTire Inspection and

Rotation on page 398andTires on page 385.

Notice:Do not use a tire sealant if your

vehicle has Tire Pressure Monitors. The liquid

sealant can damage the tire pressure monitor

sensors.

The TPMS will not function properly if one or more

of the TPMS sensors are missing or inoperable.

If the system detects a missing or inoperable

sensor, an error message SERVICE TIRE

MONITOR SYSTEM will be shown on the DIC

display. If you have replaced a tire/wheel assembly

without transferring the TPMS sensors, the error

message will be displayed. Once you re-install the

TPMS sensors, the error message should go

off. See your GM dealer for service if all TPMS

sensors are installed and the error message

comes on and stays on.Resetting the TPMS Sensor

Identi�cation Codes

Each TPMS sensor has a unique identi�cation

code. Any time you replace one or more of

the TPMS sensors or rotate the vehicle’s tires, the

identi�cation codes will need to be matched to

the new tire/wheel position. The sensors are

matched, to the tire/wheel positions, in the

following order: driver’s side front tire, passenger’s

side front tire, passenger’s side rear tire, and

driver’s side rear tire using a TPMS diagnostic tool.

See your GM dealer for service.

The TPMS sensors may also be matched to each

tire/wheel position by increasing or decreasing

the tire’s air pressure. When increasing the tire’s

pressure, do not exceed the maximum in�ation

pressure indicated on the tire’s sidewall.

You will have two minutes to match each tire and

wheel position. If it takes longer than two minutes to

match any tire and wheel position, or more than

�ve minutes to match all four tire and wheel

positions the matching process stops and you will

need to start over.

396

Page 397 of 496

The TPMS matching process is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to RUN with the

engine off.

3. Using the DIC, press the vehicle information

button until the LEARN TIRE POSITIONS

message displays.

4. Press the set/reset button to allow the system

to learn the tire positions. The horn will sound

twice to indicate the receiver is ready, and

the TIRE LEARNING ACTIVE message

will display. The TPMS system is ready for

the sensor matching process to begin.

5. Start with the driver’s side front tire.

6. Remove the valve cap from the tire’s valve

stem. Activate the TPMS sensor by increasing

or decreasing the tire’s air pressure for

�ve seconds, or until a horn chirp sounds.

The horn chirp, which may take up to

30 seconds to sound, con�rms that the

sensor identi�cation code has been matched

to the tire/wheel position. To decrease the

tire’s air-pressure use the pointed end of the

valve cap, a pencil-style air pressure gage,

or a key.7. Proceed to the passenger’s side front tire, and

repeat the procedure in Step 6.

8. Proceed to the passenger’s side rear tire, and

repeat the procedure in Step 6.

9. Proceed to the driver’s side rear tire, and

repeat the procedure in Step 6.

10. After hearing the con�rming horn chirp for the

driver’s side rear tire, the tire learning process

ends. Turn the ignition switch to OFF.

11. Set all four tires to the recommended air

pressure level as indicated on the tire and

loading information label.

12. Put the valve caps back on the valve stems.

The compact spare tire and wheel assembly

does not have a TPMS sensor. If you replace

one of the road tires with the compact spare tire,

the SERVICE TIRE MONITOR SYSTEM

message will be displayed on the DIC display

screen. This message should go off once

you re-install the road tire containing the

TPMS sensor.

397

Page 399 of 496

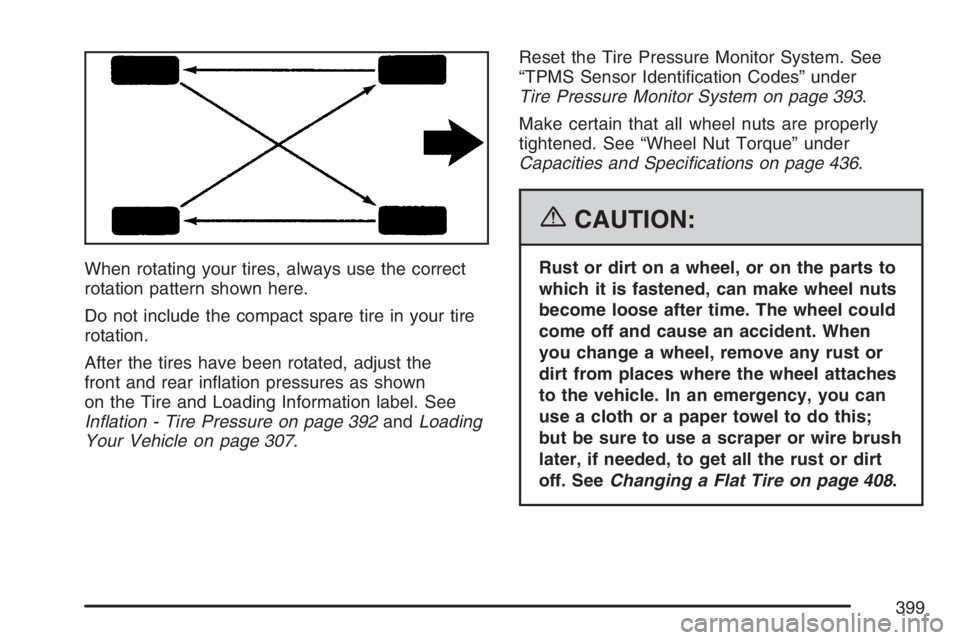

When rotating your tires, always use the correct

rotation pattern shown here.

Do not include the compact spare tire in your tire

rotation.

After the tires have been rotated, adjust the

front and rear in�ation pressures as shown

on the Tire and Loading Information label. See

In�ation - Tire Pressure on page 392andLoading

Your Vehicle on page 307.Reset the Tire Pressure Monitor System. See

“TPMS Sensor Identi�cation Codes” under

Tire Pressure Monitor System on page 393.

Make certain that all wheel nuts are properly

tightened. See “Wheel Nut Torque” under

Capacities and Speci�cations on page 436.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after time. The wheel could

come off and cause an accident. When

you change a wheel, remove any rust or

dirt from places where the wheel attaches

to the vehicle. In an emergency, you can

use a cloth or a paper towel to do this;

but be sure to use a scraper or wire brush

later, if needed, to get all the rust or dirt

off. SeeChanging a Flat Tire on page 408.

399