maintenance BUICK LUCERNE 2010 Owner's Guide

[x] Cancel search | Manufacturer: BUICK, Model Year: 2010, Model line: LUCERNE, Model: BUICK LUCERNE 2010Pages: 474

Page 325 of 474

Automatic Transmission Fluid

When to Check and Change Automatic

Transmission Fluid

A good time to check the automatic transmission fluid

level is when the engine oil is changed.

Change the fluid and filter at the intervals listed in

Scheduled Maintenance

on page 7‑3and be sure to

use the transmission fluid listed in Recommended

Fluids and Lubricants on page 7‑9.

How to Check Automatic Transmission

Fluid (3.9L Engine)

Because this operation can be a little difficult, you

may choose to have this done at the dealer service

department.

If you do it yourself, be sure to follow all the instructions

here, or you could get a false reading on the dipstick.

Notice: Too much or too little fluid can damage the

transmission. Too much can mean that some of the

fluid could come out and fall on hot engine parts

or exhaust system parts, starting a fire. Too little

fluid could cause the transmission to overheat.

Be sure to get an accurate reading if checking the

transmission fluid. Wait at least 30 minutes before checking the

transmission fluid level if you have been driving:

.When outside temperatures are above

90°F (32°C).

.At high speed for quite a while.

.In heavy traffic

—especially in hot weather.

.While pulling a trailer.

To get the right reading, the fluid should be at normal

operating temperature, which is 180°F to 200°F

(82°C to 93°C).

Get the vehicle warmed up by driving about 15 miles

(24 km) when outside temperatures are above 50°F

(10°C). If it is colder than 50°F (10°C), you may have to

drive longer.

Checking the Fluid Level

Prepare the vehicle as follows: 1. Park the vehicle on a level place. Keep the engine running.

2. With the parking brake applied, place the shift lever in P (Park).

3. With your foot on the brake pedal, move the shift lever through each gear range, pausing for about

three seconds in each range. Then, position the

shift lever in P (Park).

4. Let the engine run at idle for three to five minutes.

6-23

Page 327 of 474

How to Add Automatic Transmission

Fluid

Refer to the Maintenance Schedule to determine what

kind of transmission fluid to use. SeeRecommended

Fluids and Lubricants on page 7‑9.

If the fluid level is low, add only enough of the proper

fluid to bring the level into the cross-hatched area on

the dipstick.

1. Pull out the dipstick.

2. Using a long-neck funnel, add enough fluid at the dipstick hole to bring it to the proper level.

It does not take much fluid, generally less than

one pint (0.5 L). Do not overfill. Notice:

Use of the incorrect automatic transmission

fluid may damage the vehicle, and the damages may

not be covered by the vehicle's warranty. Always

use the automatic transmission fluid listed in

Recommended Fluids and Lubricants on page 7‑9.

3. After adding fluid, recheck the fluid level as described under “How to Check Automatic

Transmission Fluid” earlier in this section.

4. When the correct fluid level is obtained, push the dipstick back in all the way.

How to Check Automatic Transmission

Fluid (4.6L Engine)

For the 4.6L V8 engine, it is not necessary to check the

transmission fluid level. A transmission fluid leak is the

only reason for fluid loss. If a leak occurs, take the

vehicle to your dealer service department and have it

repaired as soon as possible.

6-25

Page 357 of 474

License Plate Lamp

To replace one of these bulbs:1. Remove the license plate.

2. Reach up through the opening above the license plate to access the two license plate lamps.

3. Turn the socket counterclockwise to remove.

4. Grasp the bulb in the socket and pull straight out.

5. Push the bulb straight into the socket until it clicks to secure it.

6. Push the socket in and turn it clockwise to secure it.

7. Reinstall the license plate in its original location.

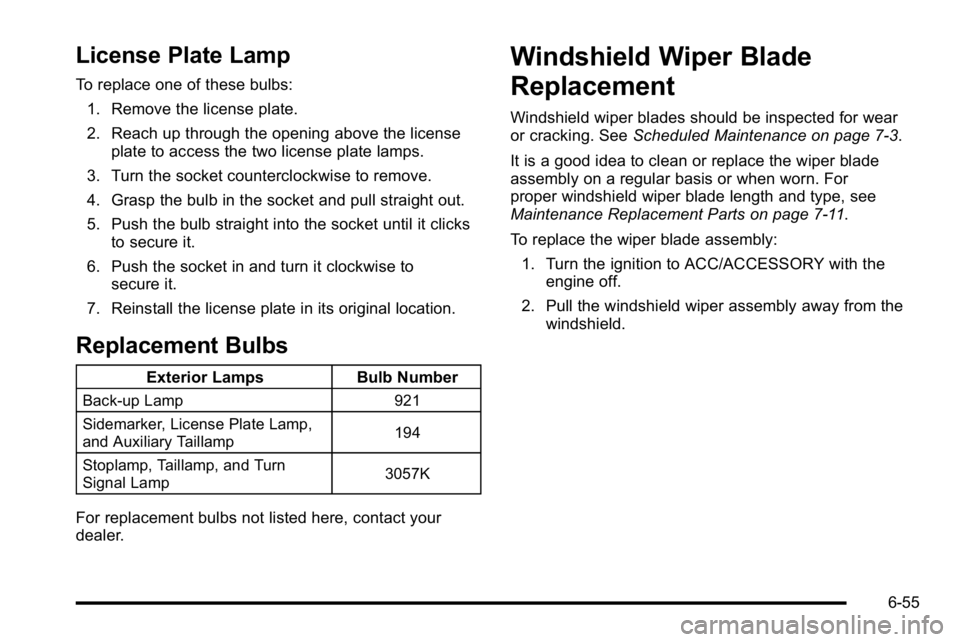

Replacement Bulbs

Exterior Lamps Bulb Number

Back-up Lamp 921

Sidemarker, License Plate Lamp,

and Auxiliary Taillamp 194

Stoplamp, Taillamp, and Turn

Signal Lamp 3057K

For replacement bulbs not listed here, contact your

dealer.

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for wear

or cracking. See

Scheduled Maintenance on page 7‑3.

It is a good idea to clean or replace the wiper blade

assembly on a regular basis or when worn. For

proper windshield wiper blade length and type, see

Maintenance Replacement Parts on page 7‑11.

To replace the wiper blade assembly: 1. Turn the ignition to ACC/ACCESSORY with the engine off.

2. Pull the windshield wiper assembly away from the windshield.

6-55

Page 369 of 474

Please note that the TPMS is not a substitute for proper

tire maintenance, and it is the driver's responsibility to

maintain correct tire pressure, even if under‐inflation

has not reached the level to trigger illumination of the

TPMS low tire pressure telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is not

operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the

system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously

illuminated. This sequence will continue upon

subsequent vehicle start‐ups as long as the malfunction

exists.

When the malfunction indicator is illuminated, the

system may not be able to detect or signal low tire

pressure as intended. TPMS malfunctions may occur

for a variety of reasons, including the installation of

replacement or alternate tires or wheels on the vehicle

that prevent the TPMS from functioning properly.

Always check the TPMS malfunction telltale after

replacing one or more tires or wheels on your vehicle to

ensure that the replacement or alternate tires and

wheels allow the TPMS to continue to function properly.

SeeTire Pressure Monitor Operation

on page 6‑67for

additional information.

Federal Communications Commission

(FCC) and Industry Canada

See Radio Frequency Statementon page 8‑20for

information regarding Part 15 of the Federal

Communications Commission (FCC) Rules and

RSS-210/211 of Industry Canada.

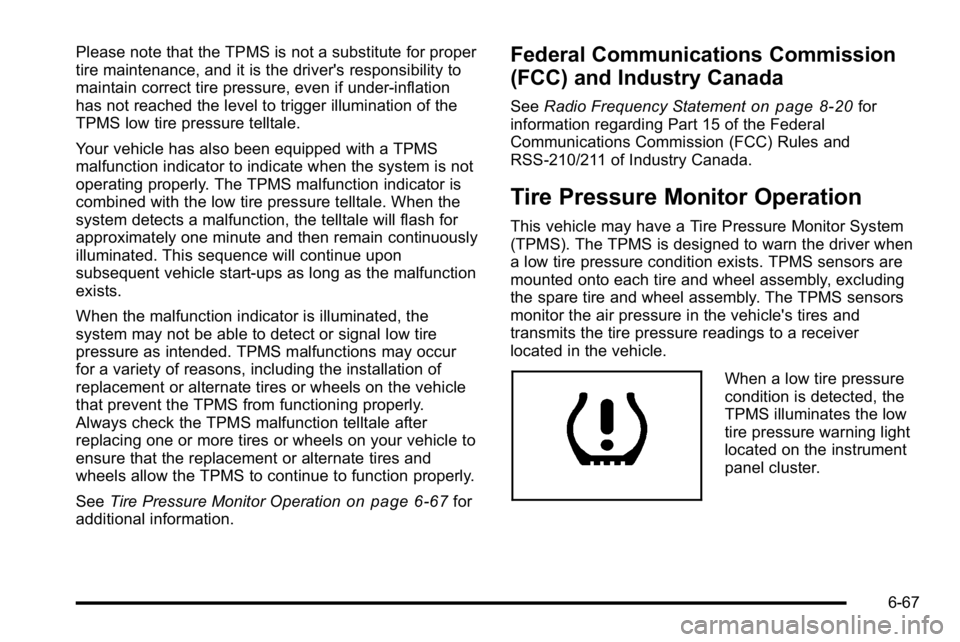

Tire Pressure Monitor Operation

This vehicle may have a Tire Pressure Monitor System

(TPMS). The TPMS is designed to warn the driver when

a low tire pressure condition exists. TPMS sensors are

mounted onto each tire and wheel assembly, excluding

the spare tire and wheel assembly. The TPMS sensors

monitor the air pressure in the vehicle's tires and

transmits the tire pressure readings to a receiver

located in the vehicle.

When a low tire pressure

condition is detected, the

TPMS illuminates the low

tire pressure warning light

located on the instrument

panel cluster.

6-67

Page 370 of 474

If the warning light comes on, stop as soon as possible

and inflate the tires to the recommended pressure

shown on the tire loading information label. See

Loading the Vehicle on page 5‑19.

At the same time a message to check the pressure in a

specific tire appears on the Driver Information Center

(DIC) display. The low tire pressure warning light and

the DIC warning message come on at each ignition

cycle until the tires are inflated to the correct inflation

pressure. Using the DIC, tire pressure levels can be

viewed by the driver. For additional information and

details about the DIC operation and displays seeDIC

Operation and Displays

on page 4‑47and DIC

Warnings and Messages on page 4‑55.

The low tire pressure warning light may come on in cool

weather when the vehicle is first started, and then turn

off as you start to drive. This could be an early indicator

that the air pressure in the tire(s) are getting low and

need to be inflated to the proper pressure. A Tire and Loading Information label, attached to your

vehicle, shows the size of your vehicle's original

equipment tires and the correct inflation pressure for

your vehicle's tires when they are cold. See

Loading the

Vehicle

on page 5‑19, for an example of the Tire and

Loading Information label and its location on your

vehicle. Also see Inflation - Tire Pressure on page 6‑65.

Your vehicle's TPMS can warn you about a low tire

pressure condition but it does not replace normal tire

maintenance. See Tire Inspection and Rotation

on

page 6‑71and Tires on page 6‑57.

Notice: Using non‐approved tire sealants could

damage the Tire Pressure Monitor System (TPMS)

sensors. TPMS sensor damage caused by using an

incorrect tire sealant is not covered by the vehicle

warranty. Always use the GM approved tire sealant

available through your dealer.

Factory-installed Tire Inflator Kits use a GM approved

liquid tire sealant. Using non-approved tire sealants

could damage the TPMS sensors. See Tire Sealant and

Compressor Kit

on page 6‑82for information regarding

the inflator kit materials and instructions.

6-68

Page 373 of 474

7. Proceed to the passenger side rear tire, and repeatthe procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat the procedure in Step 5. The horn sounds two times to

indicate the sensor identification code has been

matched to the driver side rear tire, and the TPMS

sensor matching process is no longer active. The

TIRE LEARNING ACTIVE message on the DIC

display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressure level as indicated on the Tire and Loading

Information label.

11. Put the valve caps back on the valve stems.Tire Inspection and Rotation

We recommend that you regularly inspect your

vehicle's tires, including the spare tire, for signs of

wear or damage. See When It Is Time for New

Tires

on page 6‑73for more information.

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km). See Scheduled Maintenance

on page 7‑3.

The purpose of a regular tire rotation is to achieve

a uniform wear for all tires on the vehicle. This will

ensure that your vehicle continues to perform

most like it did when the tires were new.

6-71

Page 375 of 474

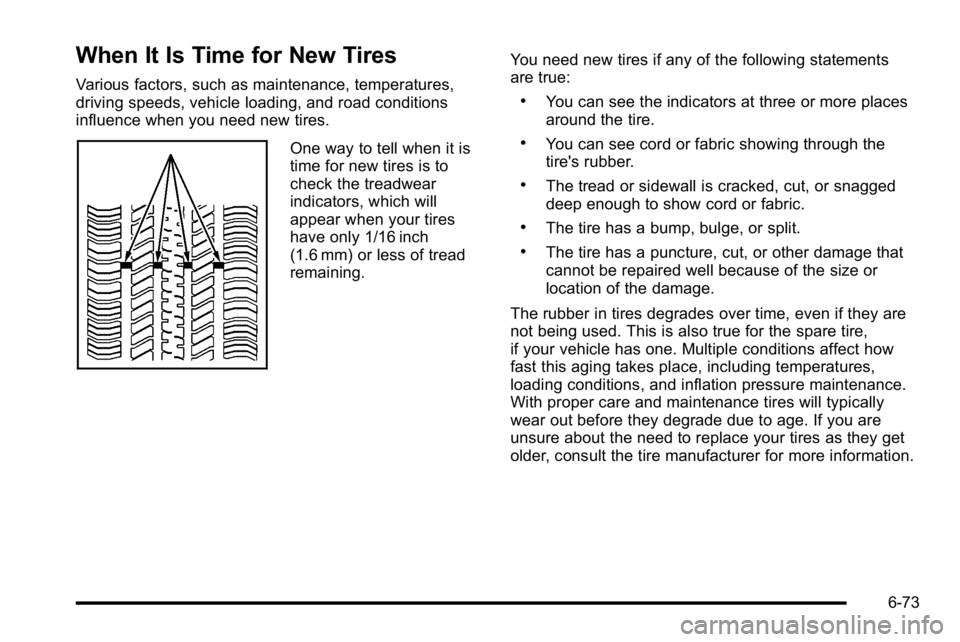

When It Is Time for New Tires

Various factors, such as maintenance, temperatures,

driving speeds, vehicle loading, and road conditions

influence when you need new tires.

One way to tell when it is

time for new tires is to

check the treadwear

indicators, which will

appear when your tires

have only 1/16 inch

(1.6 mm) or less of tread

remaining.You need new tires if any of the following statements

are true:

.You can see the indicators at three or more places

around the tire.

.You can see cord or fabric showing through the

tire's rubber.

.The tread or sidewall is cracked, cut, or snagged

deep enough to show cord or fabric.

.The tire has a bump, bulge, or split.

.The tire has a puncture, cut, or other damage that

cannot be repaired well because of the size or

location of the damage.

The rubber in tires degrades over time, even if they are

not being used. This is also true for the spare tire,

if your vehicle has one. Multiple conditions affect how

fast this aging takes place, including temperatures,

loading conditions, and inflation pressure maintenance.

With proper care and maintenance tires will typically

wear out before they degrade due to age. If you are

unsure about the need to replace your tires as they get

older, consult the tire manufacturer for more information.

6-73

Page 383 of 474

If a Tire Goes Flat

It is unusual for a tire to blowout while you are driving,

especially if you maintain your vehicle's tires properly.

If air goes out of a tire, it is much more likely to leak out

slowly. But if you should ever have a blowout, here are

a few tips about what to expect and what to do:

If a front tire fails, the flat tire creates a drag that pulls

the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you would

use in a skid. In any rear blowout remove your foot from

the accelerator pedal. Get the vehicle under control by

steering the way you want the vehicle to go. It may be

very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.{WARNING:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without the

appropriate safety equipment and training. If a

jack is provided with the vehicle, it is designed

only for changing a flat tire. If it is used for

anything else, you or others could be badly

injured or killed if the vehicle slips off the jack. If a

jack is provided with the vehicle, only use it for

changing a flat tire.

This vehicle may come with a jack and spare tire or a

tire sealant and compressor kit. To use the jack and

spare tire, follow the instructions below. To use the tire

sealant and compressor kit, see Tire Sealant and

Compressor Kit

on page 6‑82.

6-81

Page 410 of 474

Finish Damage

Any stone chips, fractures or deep scratches in the

finish should be repaired right away. Bare metal will

corrode quickly and may develop into major repair

expense.

Minor chips and scratches can be repaired with

touch-up materials available from your dealer.

Larger areas of finish damage can be corrected

in your dealer's/retailer's body and paint shop.

Underbody Maintenance

Chemicals used for ice and snow removal and dust

control can collect on the underbody. If these are not

removed, corrosion and rust can develop on the

underbody parts such as fuel lines, frame, floor pan,

and exhaust system even though they have corrosion

protection.At least every spring, flush these materials from the

underbody with plain water. Clean any areas where

mud and debris can collect. Dirt packed in close areas

of the frame should be loosened before being flushed.

Your dealer or an underbody car washing system can

do this.

Chemical Paint Spotting

Some weather and atmospheric conditions can create a

chemical fallout. Airborne pollutants can fall upon and

attack painted surfaces on the vehicle. This damage

can take two forms: blotchy, ring-shaped discolorations,

and small, irregular dark spots etched into the paint

surface.

Although no defect in the paint job causes this, we will

repair, at no charge to the owner, the surfaces of new

vehicles damaged by this fallout condition within

12 months or 12,000 miles (20 000 km) of purchase,

whichever occurs first.

6-108

Page 423 of 474

Section 7 Maintenance Schedule

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Owner Checks and Services . . . . . . . . . . . . . . . . . . . . 7-8 Recommended Fluids and Lubricants . . . . . . . . . . . 7-9

Maintenance Replacement Parts . . . . . . . . . . . . . . . 7-11

Engine Drive Belt Routing . . . . . . . . . . . . . . . . . . . . . 7-12

Maintenance Record . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7-1