key BUICK LUCERNE 2010 Workshop Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2010, Model line: LUCERNE, Model: BUICK LUCERNE 2010Pages: 474

Page 253 of 474

XM Theftlocked:The XM receiver in the vehicle could

have previously been in another vehicle. For security

purposes, XM receivers cannot be swapped between

vehicles. If this message is received after having the

vehicle serviced, check with your dealer.

XM Radio ID: If tuned to channel 0, this message

alternates with the XM™ Radio 8 digit radio ID label.

This label is needed to activate the service.

Unknown: If this message is received when tuned to

channel 0, there could be a receiver fault. Consult with

your dealer.

Check Antenna: If this message does not clear within

a short period of time, the receiver or antenna could

have a fault. Consult with your dealer.

Check XM Receivr: If this message does not clear

within a short period of time, the receiver could have a

fault. Consult with your dealer.

XM Not Available: If this message does not clear

within a short period of time, the receiver could have a

fault. Consult with your dealer.Navigation/Radio System

For vehicles with a navigation radio system, see the

separate Navigation System manual.

Bluetooth®

Vehicles with a Bluetooth system can use a Bluetooth

capable cell phone with a Hands Free Profile to make

and receive phone calls. The system can be used while

the key is in ON/RUN or ACC/ACCESSORY position.

The range of the Bluetooth system can be up to 9.1 m

(30 ft). Not all phones support all functions, and not all

phones are guaranteed to work with the in-vehicle

Bluetooth system. See www.gm.com/bluetooth for more

information on compatible phones.

Voice Recognition

The Bluetooth system uses voice recognition to

interpret voice commands to dial phone numbers

and name tags.

Noise: Keep interior noise levels to a minimum. The

system may not recognize voice commands if there is

too much background noise.

When to Speak: A short tone sounds after the system

responds indicating when it is waiting for a voice

command. Wait until the tone and then speak.

How to Speak: Speak clearly in a calm and natural

voice.

4-93

Page 262 of 474

Muting a Call

During a call, all sounds from inside the vehicle can be

muted so that the person on the other end of the call

cannot hear them.

To Mute a call

1. Pressbg. The system responds with “Ready”

followed by a tone.

2. Say “Mute Call”. The system responds with “Call

muted”.

To Cancel Mute

1. Pressb g. The system responds with “Ready”

followed by a tone.

2. After the tone, say “Mute Call”. The system

responds with “Resuming call”.

Transferring a Call

Audio can be transferred between the in‐vehicle

Bluetooth system and the cell phone.

To Transfer Audio to the Cell Phone

During a call with the audio in the vehicle:

1. Press

b g. The system responds with “Ready”

followed by a tone.

2. Say “Transfer Call.” The system responds with

“Transferring call” and the audio will switch from

the vehicle to the cell phone.

To Transfer Audio to the In-Vehicle

Bluetooth System

The cellular phone must be paired and connected with

the Bluetooth system before a call can be transferred.

The connection process can take up to two minutes

after the key is turned to the ON/RUN or ACC/

ACCESSORY position.

During a call with the audio on the cell phone,

press

b gfor more than two seconds. The audio

switches from the cell phone to the vehicle.

4-102

Page 294 of 474

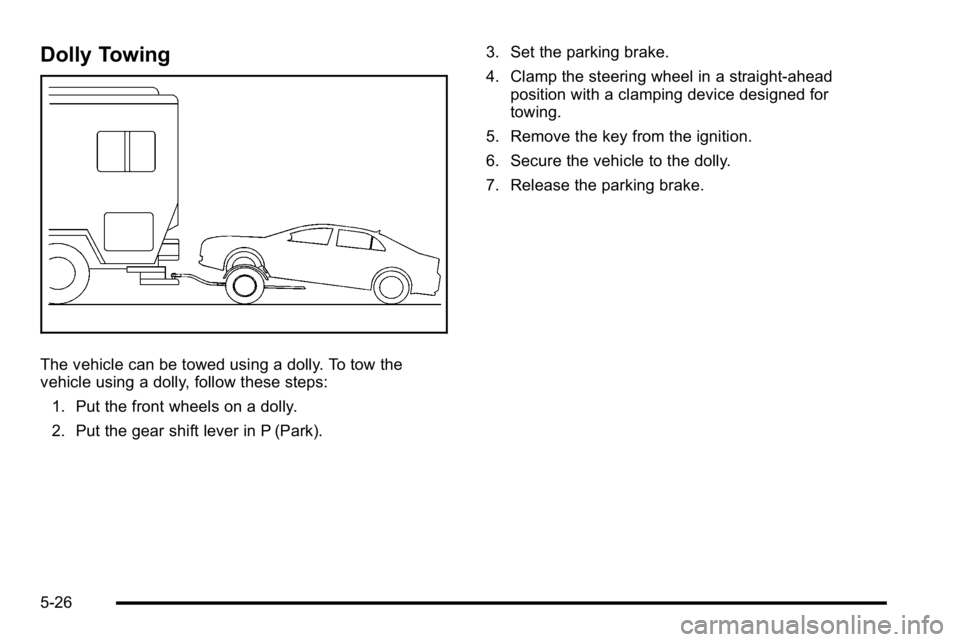

Dolly Towing

The vehicle can be towed using a dolly. To tow the

vehicle using a dolly, follow these steps:1. Put the front wheels on a dolly.

2. Put the gear shift lever in P (Park). 3. Set the parking brake.

4. Clamp the steering wheel in a straight-ahead

position with a clamping device designed for

towing.

5. Remove the key from the ignition.

6. Secure the vehicle to the dolly.

7. Release the parking brake.

5-26

Page 306 of 474

California Proposition 65 Warning

Most motor vehicles, including this one, contain and/or

emit chemicals known to the State of California to

cause cancer and birth defects or other reproductive

harm. Engine exhaust, many parts and systems, many

fluids, and some component wear by-products contain

and/or emit these chemicals.

California Perchlorate Materials

Requirements

Certain types of automotive applications, such as airbag

initiators, seat belt pretensioners, and lithium batteries

contained in remote keyless transmitters, may contain

perchlorate materials. Special handling may be

necessary. For additional information, see

www.dtsc.ca.gov/hazardouswaste/perchlorate.

Doing Your Own Service Work

{WARNING:

You can be injured and the vehicle could be

damaged if you try to do service work on a vehicle

without knowing enough about it.

.Be sure you have sufficient knowledge,

experience, the proper replacement parts, and

tools before attempting any vehicle

maintenance task.

.Be sure to use the proper nuts, bolts, and

other fasteners. English and metric fasteners

can be easily confused. If the wrong fasteners

are used, parts can later break or fall off. You

could be hurt.

If doing some of your own service work, use the proper

service manual. It tells you much more about how to

service the vehicle than this manual can. To order the

proper service manual, see Service Publications

Ordering Information on page 8‑17.

This vehicle has an airbag system. Before attempting to

do your own service work, see Servicing Your

Airbag-Equipped Vehicle on page 2‑72.

6-4

Page 340 of 474

Power Steering Fluid

SeeEngine Compartment

Overviewon page 6‑14for information on the

location of the power

steering fluid reservoir.

When to Check Power Steering Fluid

It is not necessary to regularly check power steering

fluid unless you suspect there is a leak in the system or

you hear an unusual noise. A fluid loss in this system

could indicate a problem. Have the system inspected

and repaired.

How to Check Power Steering Fluid

To check the power steering fluid:

1. Turn the key off and let the engine compartment cool down.

2. Wipe the cap and the top of the reservoir clean.

3. Unscrew the cap and wipe the dipstick with a clean rag.

4. Replace the cap and completely tighten it.

5. Remove the cap again and look at the fluid level on the dipstick.

The level should be at the FULL COLD mark.

If necessary, add only enough fluid to bring the level

up to the mark.

What to Use

To determine what kind of fluid to use, see

Recommended Fluids and Lubricantson page 7‑9.

Always use the proper fluid.

Notice: Use of the incorrect fluid may damage the

vehicle and the damages may not be covered by the

vehicle's warranty. Always use the correct fluid

listed in Recommended Fluids and Lubricants

on

page 7‑9.

6-38

Page 372 of 474

TPMS Sensor Matching Process

Each TPMS sensor has a unique identification code.

Any time you rotate your vehicle's tires or replace one

or more of the TPMS sensors, the identification codes

will need to be matched to the new tire/wheel position.

The sensors are matched to the tire/wheel positions in

the following order: driver side front tire, passenger side

front tire, passenger side rear tire, and driver side rear

tire using a TPMS diagnostic tool. See your dealer/

retailer for service.

The TPMS sensors can also be matched to each tire/

wheel position by increasing or decreasing the tire's air

pressure. If increasing the tire's air pressure, do not

exceed the maximum inflation pressure indicated on the

tire's sidewall.

To decrease air-pressure out of a tire you can use the

pointed end of the valve cap, a pencil-style air pressure

gauge, or a key.

You have two minutes to match the first tire/wheel

position, and five minutes overall to match all four tire/

wheel positions. If it takes longer than two minutes, to

match the first tire and wheel, or more than five minutes

to match all four tire and wheel positions the matching

process stops and you need to start over.The TPMS sensor matching process is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the engine off.

3. Press the Remote Keyless Entry (RKE) transmitter's lock and unlock buttons at the same

time for approximately five seconds. The horn

sounds twice to signal the receiver is in relearn

mode and TIRE LEARNING ACTIVE message

displays on the DIC screen.

4. Start with the driver side front tire.

5. Remove the valve cap from the valve cap stem. Activate the TPMS sensor by increasing or

decreasing the tire's air pressure for five seconds,

or until a horn chirp sounds. The horn chirp, which

may take up to 30 seconds to sound, confirms that

the sensor identification code has been matched to

this tire and wheel position.

6. Proceed to the passenger side front tire, and repeat the procedure in Step 5.

6-70

Page 418 of 474

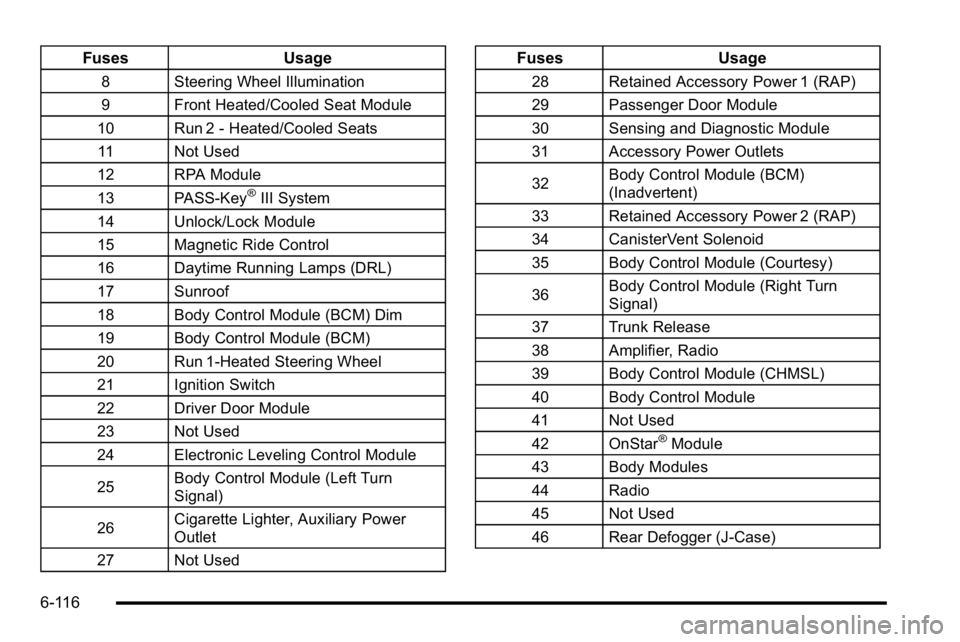

FusesUsage

8 Steering Wheel Illumination

9 Front Heated/Cooled Seat Module

10 Run 2 - Heated/Cooled Seats 11 Not Used

12 RPA Module

13 PASS-Key

®III System

14 Unlock/Lock Module

15 Magnetic Ride Control

16 Daytime Running Lamps (DRL)

17 Sunroof

18 Body Control Module (BCM) Dim

19 Body Control Module (BCM)

20 Run 1-Heated Steering Wheel

21 Ignition Switch

22 Driver Door Module

23 Not Used

24 Electronic Leveling Control Module

25 Body Control Module (Left Turn

Signal)

26 Cigarette Lighter, Auxiliary Power

Outlet

27 Not Used

Fuses Usage

28 Retained Accessory Power 1 (RAP)

29 Passenger Door Module

30 Sensing and Diagnostic Module

31 Accessory Power Outlets

32Body Control Module (BCM)

(Inadvertent)

33 Retained Accessory Power 2 (RAP)

34 CanisterVent Solenoid

35 Body Control Module (Courtesy)

36 Body Control Module (Right Turn

Signal)

37 Trunk Release

38 Amplifier, Radio

39 Body Control Module (CHMSL)

40 Body Control Module

41 Not Used

42 OnStar

®Module

43 Body Modules

44 Radio

45 Not Used

46 Rear Defogger (J-Case)

6-116

Page 426 of 474

.Fluids visual leak check (or every 12 months,

whichever occurs first). A leak in any system must

be repaired and the fluid level checked.

.Engine air cleaner filter inspection (vehicles driven

in dusty conditions only). SeeEngine Air Cleaner/

Filter on page 6‑21.

.Brake system inspection (or every 12 months,

whichever occurs first).

Maintenance II

.Perform all services described in Maintenance I.

.Steering and suspension inspection. Visual

inspection for damaged, loose, or missing parts or

signs of wear.

.Engine cooling system inspection. Visual

inspection of hoses, pipes, fittings, and clamps

and replacement, if needed.

.Windshield wiper blade inspection for wear,

cracking, or contamination and windshield and

wiper blade cleaning, if contaminated. See

Windshield and Wiper Blades

on page 6‑106. Worn

or damaged wiper blade replacement. See

Windshield Wiper Blade Replacement

on

page 6‑55.

.Body hinges and latches, key lock cylinders, and

rear compartment, hood, glove box door, and

console door hinges and latches lubrication. See

Recommended Fluids and Lubricants

on

page 7‑9. More frequent lubrication may be

required when vehicle is exposed to a corrosive

environment. Applying silicone grease on

weatherstrips with a clean cloth makes them last

longer, seal better, and not stick or squeak.

.Restraint system component check. See Checking

the Restraint Systems on page 2‑74.

.Engine air cleaner filter inspection. See Engine Air

Cleaner/Filter on page 6‑21.

.Passenger compartment air filter replacement

(or every 12 months, whichever occurs first). More

frequent replacement may be required if vehicle is

driven regularly under dusty conditions.

7-4

Page 431 of 474

Ignition Transmission Lock Check

While parked, and with the parking brake set, try to turn

the ignition to LOCK/OFF in each shift lever position.

.The ignition should turn to LOCK/OFF only when

the shift lever is in P (Park).

.The ignition key should come out only in

LOCK/OFF.

Contact your dealer if service is required.

Parking Brake and Automatic

Transmission P (Park) Mechanism

Check

{WARNING:

When you are doing this check, the vehicle could

begin to move. You or others could be injured and

property could be damaged. Make sure there is

room in front of the vehicle in case it begins to

roll. Be ready to apply the regular brake at once

should the vehicle begin to move. Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular brake, set the

parking brake.

.To check the parking brake's holding ability:

With the engine running and the transmission in

N (Neutral), slowly remove foot pressure from the

regular brake pedal. Do this until the vehicle is held

by the parking brake only.

.To check the P (Park) mechanism's holding ability:

With the engine running, shift to P (Park). Then

release the parking brake followed by the regular

brake.

Contact your dealer if service is required.

Recommended Fluids and

Lubricants

Fluids and lubricants identified below by name, part

number, or specification can be obtained from your

dealer.

Usage Fluid/Lubricant

Engine Oil Engine oil which meets GM Standard

GM6094M and displays the American

Petroleum Institute Certified for

Gasoline Engines starburst symbol.

To determine the proper viscosity for

your vehicle's engine, see

Engine Oil

on page 6‑17.

7-9

Page 432 of 474

UsageFluid/Lubricant

Engine Coolant50/50 mixture of clean, drinkable

water and use only DEX-COOL

®

Coolant. See

Engine Coolant

(4.6L Engine)on page 6‑27or

Engine Coolant (3.9L Engine)on

page 6‑31.

Hydraulic Brake System DOT 3 Hydraulic Brake Fluid

(GM Part No. U.S. 88862806,

in Canada 88862807).

Windshield Washer Optikleen

®Washer Solvent.

Parking Brake Cable Guides Chassis Lubricant

(GM Part No. U.S. 12377985,

in Canada 88901242) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Power Steering System GM Power Steering Fluid

(GM Part No. U.S. 89021184,

in Canada 89021186).

Usage

Fluid/Lubricant

Automatic

Transmission DEXRON®-VI Automatic Transmission

Fluid.

Key Lock

Cylinders Multi-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Hood Latch Assembly,

Secondary

Latch, Pivots,

Spring Anchor, and

Release Pawl Lubriplate Lubricant Aerosol

(GM Part No. U.S. 12346293,

in Canada 992723) or lubricant

meeting requirements of NLGI #2,

Category LB or GC-LB.

Hood and Door Hinges Multi-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241,

in Canada 10953474).

Weatherstrip Conditioning Weatherstrip Lubricant

(GM Part No. U.S. 3634770,

in Canada 10953518) or

Dielectric Silicone Grease

(GM Part No. U.S. 12345579,

in Canada 992887).

7-10