clock BUICK PARK AVENUE 2003 User Guide

[x] Cancel search | Manufacturer: BUICK, Model Year: 2003, Model line: PARK AVENUE, Model: BUICK PARK AVENUE 2003Pages: 372, PDF Size: 2.8 MB

Page 270 of 372

Headlamps

Each headlamp is attached by thumb screws.1. Remove the thumb screws by turning them

counterclockwise.

5-50

Page 271 of 372

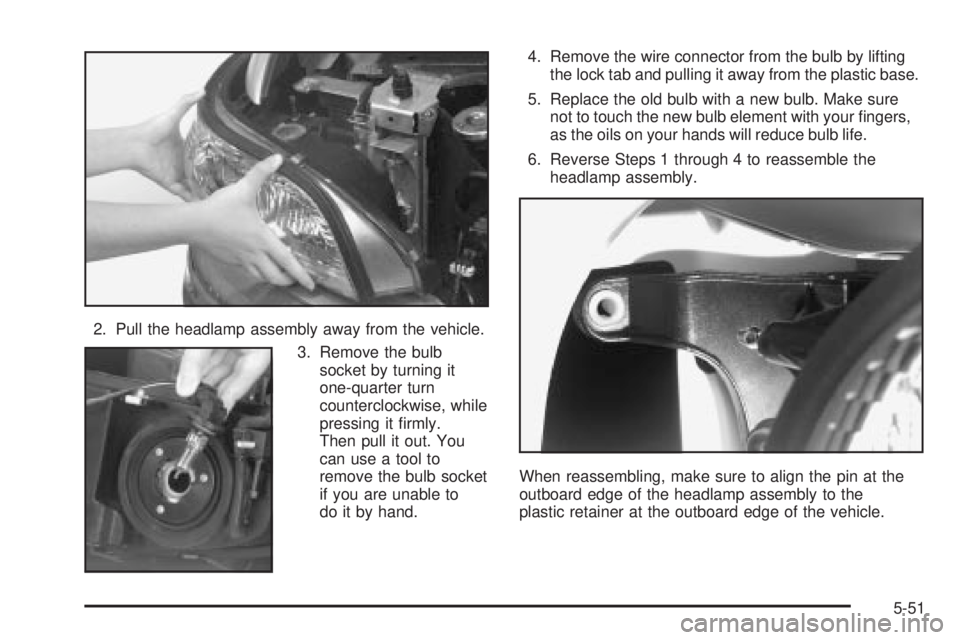

2. Pull the headlamp assembly away from the vehicle.

3. Remove the bulb

socket by turning it

one-quarter turn

counterclockwise, while

pressing it ®rmly.

Then pull it out. You

can use a tool to

remove the bulb socket

if you are unable to

do it by hand.4. Remove the wire connector from the bulb by lifting

the lock tab and pulling it away from the plastic base.

5. Replace the old bulb with a new bulb. Make sure

not to touch the new bulb element with your ®ngers,

as the oils on your hands will reduce bulb life.

6. Reverse Steps 1 through 4 to reassemble the

headlamp assembly.

When reassembling, make sure to align the pin at the

outboard edge of the headlamp assembly to the

plastic retainer at the outboard edge of the vehicle.

5-51

Page 272 of 372

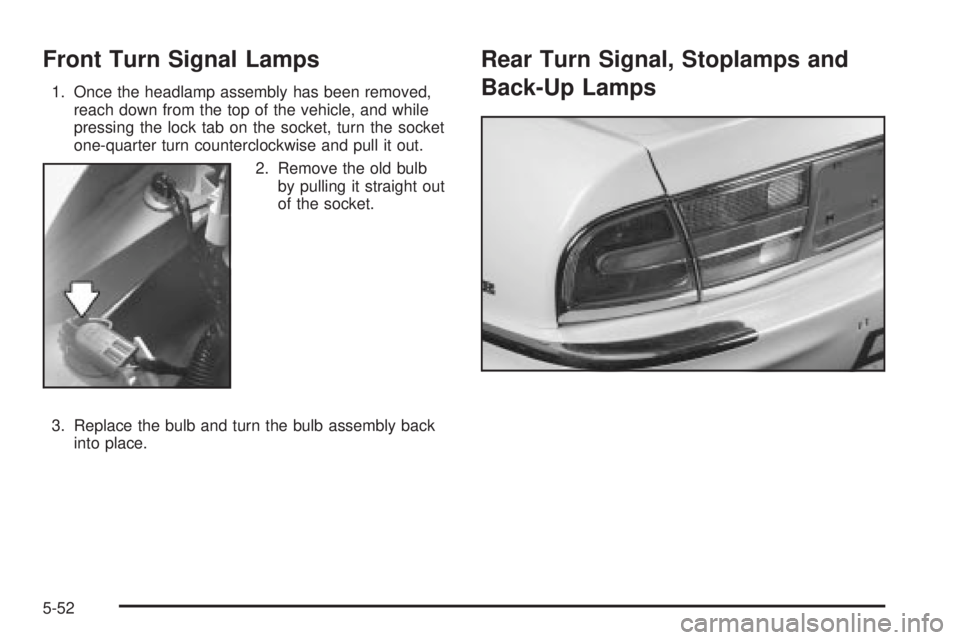

Front Turn Signal Lamps

1. Once the headlamp assembly has been removed,

reach down from the top of the vehicle, and while

pressing the lock tab on the socket, turn the socket

one-quarter turn counterclockwise and pull it out.

2. Remove the old bulb

by pulling it straight out

of the socket.

3. Replace the bulb and turn the bulb assembly back

into place.

Rear Turn Signal, Stoplamps and

Back-Up Lamps

5-52

Page 275 of 372

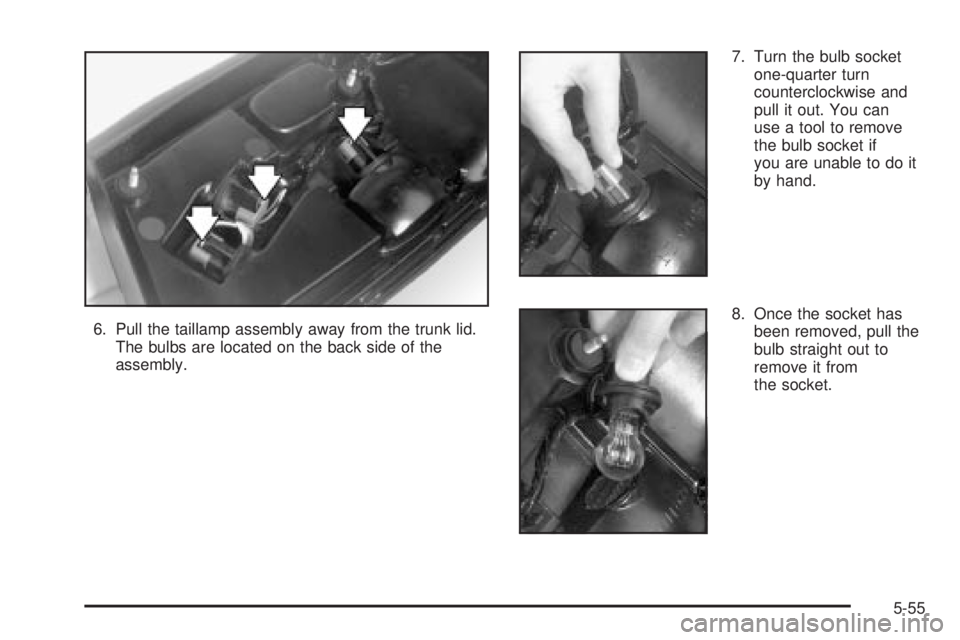

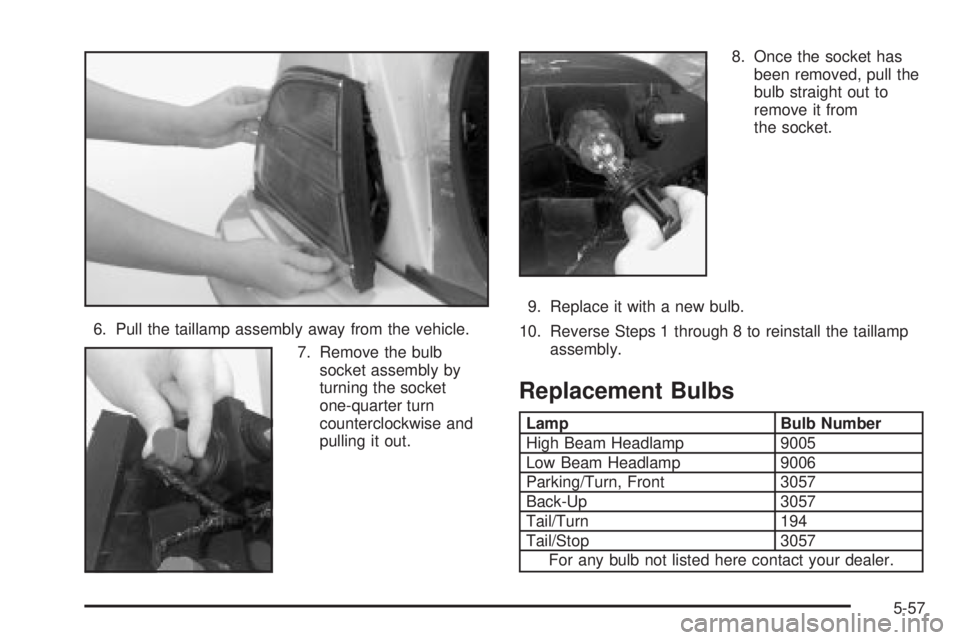

6. Pull the taillamp assembly away from the trunk lid.

The bulbs are located on the back side of the

assembly.7. Turn the bulb socket

one-quarter turn

counterclockwise and

pull it out. You can

use a tool to remove

the bulb socket if

you are unable to do it

by hand.

8. Once the socket has

been removed, pull the

bulb straight out to

remove it from

the socket.

5-55

Page 276 of 372

9. Replace it with a new bulb.

10. Reverse Steps 1 through 8 to reinstall the taillamp

assembly.

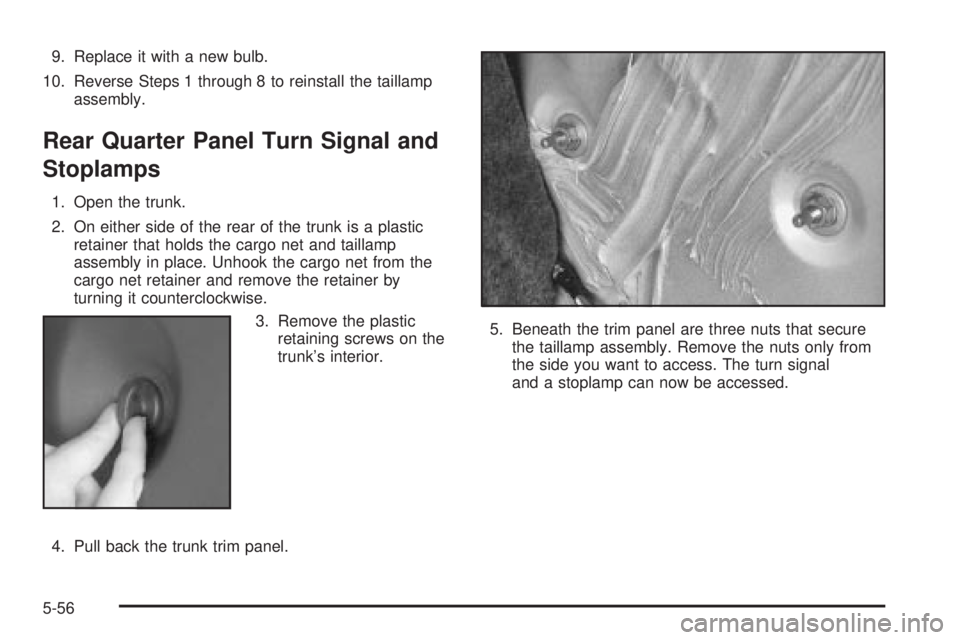

Rear Quarter Panel Turn Signal and

Stoplamps

1. Open the trunk.

2. On either side of the rear of the trunk is a plastic

retainer that holds the cargo net and taillamp

assembly in place. Unhook the cargo net from the

cargo net retainer and remove the retainer by

turning it counterclockwise.

3. Remove the plastic

retaining screws on the

trunk's interior.

4. Pull back the trunk trim panel.5. Beneath the trim panel are three nuts that secure

the taillamp assembly. Remove the nuts only from

the side you want to access. The turn signal

and a stoplamp can now be accessed.

5-56

Page 277 of 372

6. Pull the taillamp assembly away from the vehicle.

7. Remove the bulb

socket assembly by

turning the socket

one-quarter turn

counterclockwise and

pulling it out.8. Once the socket has

been removed, pull the

bulb straight out to

remove it from

the socket.

9. Replace it with a new bulb.

10. Reverse Steps 1 through 8 to reinstall the taillamp

assembly.

Replacement Bulbs

Lamp Bulb Number

High Beam Headlamp 9005

Low Beam Headlamp 9006

Parking/Turn, Front 3057

Back-Up 3057

Tail/Turn 194

Tail/Stop 3057

For any bulb not listed here contact your dealer.

5-57

Page 292 of 372

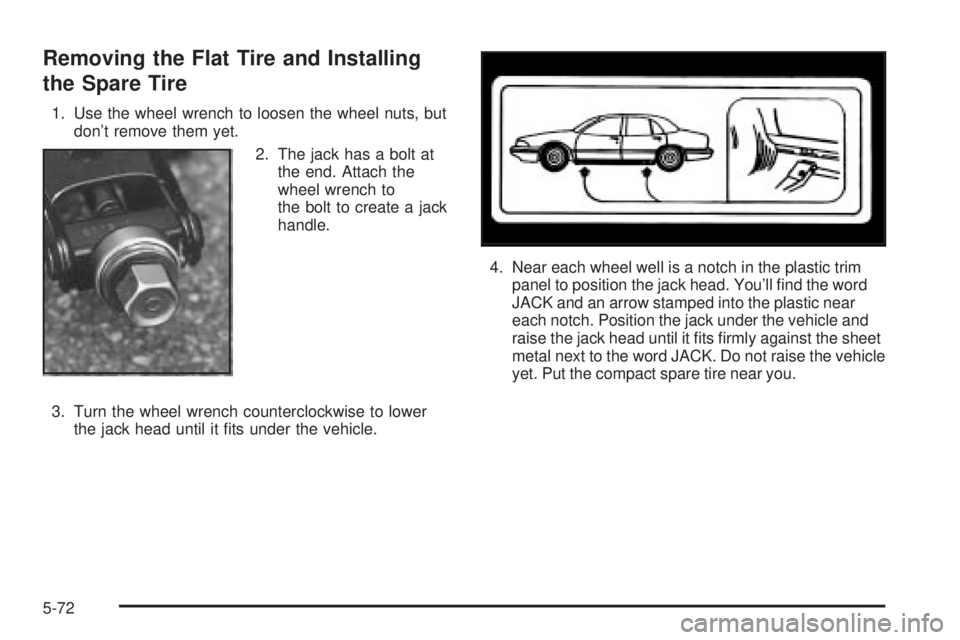

Removing the Flat Tire and Installing

the Spare Tire

1. Use the wheel wrench to loosen the wheel nuts, but

don't remove them yet.

2. The jack has a bolt at

the end. Attach the

wheel wrench to

the bolt to create a jack

handle.

3. Turn the wheel wrench counterclockwise to lower

the jack head until it ®ts under the vehicle.4. Near each wheel well is a notch in the plastic trim

panel to position the jack head. You'll ®nd the word

JACK and an arrow stamped into the plastic near

each notch. Position the jack under the vehicle and

raise the jack head until it ®ts ®rmly against the sheet

metal next to the word JACK. Do not raise the vehicle

yet. Put the compact spare tire near you.

5-72

Page 293 of 372

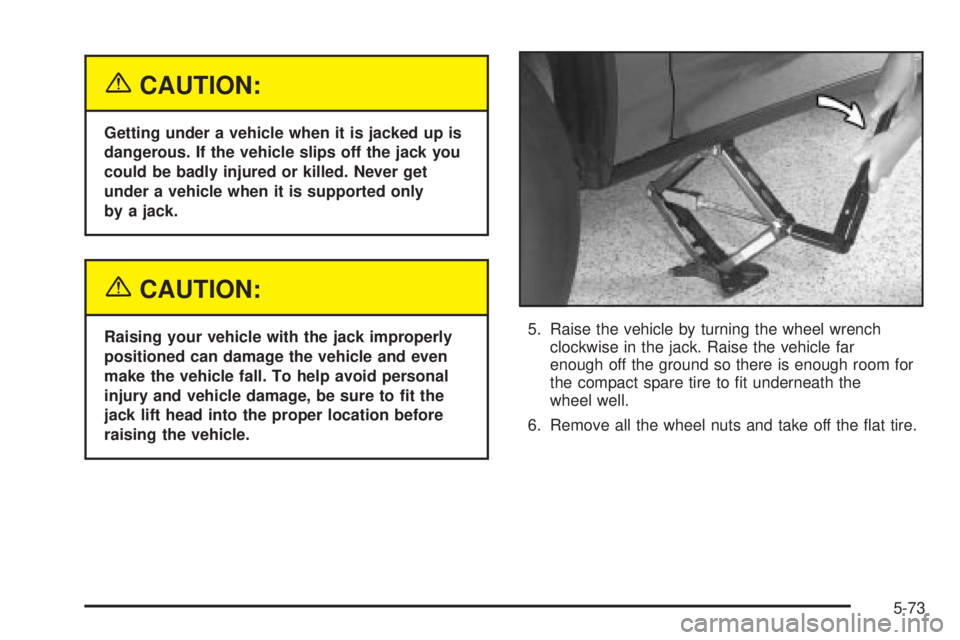

{CAUTION:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack you

could be badly injured or killed. Never get

under a vehicle when it is supported only

by a jack.

{CAUTION:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even

make the vehicle fall. To help avoid personal

injury and vehicle damage, be sure to ®t the

jack lift head into the proper location before

raising the vehicle.5. Raise the vehicle by turning the wheel wrench

clockwise in the jack. Raise the vehicle far

enough off the ground so there is enough room for

the compact spare tire to ®t underneath the

wheel well.

6. Remove all the wheel nuts and take off the ¯at tire.

5-73

Page 295 of 372

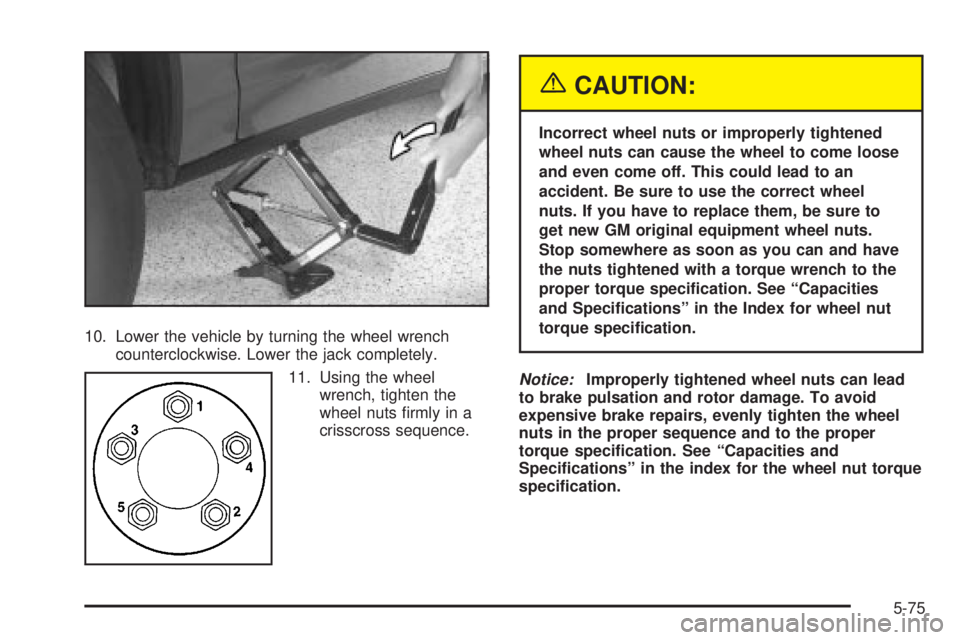

10. Lower the vehicle by turning the wheel wrench

counterclockwise. Lower the jack completely.

11. Using the wheel

wrench, tighten the

wheel nuts ®rmly in a

crisscross sequence.

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci®cation. See ªCapacities

and Speci®cationsº in the Index for wheel nut

torque speci®cation.

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci®cation. See ªCapacities and

Speci®cationsº in the index for the wheel nut torque

speci®cation.

5-75

Page 310 of 372

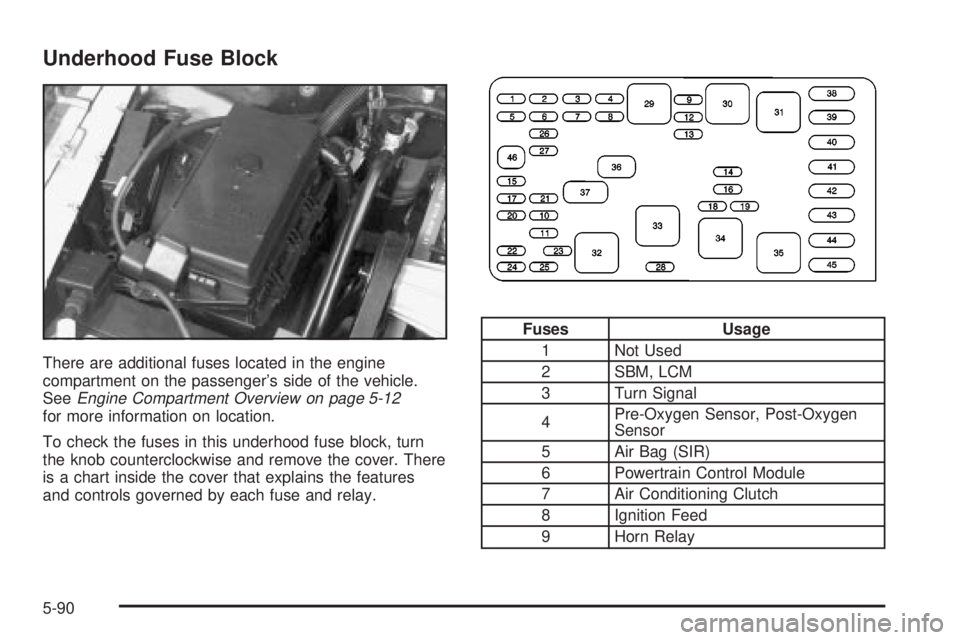

Underhood Fuse Block

There are additional fuses located in the engine

compartment on the passenger's side of the vehicle.

See

Engine Compartment Overview on page 5-12for more information on location.

To check the fuses in this underhood fuse block, turn

the knob counterclockwise and remove the cover. There

is a chart inside the cover that explains the features

and controls governed by each fuse and relay.

Fuses Usage

1 Not Used

2 SBM, LCM

3 Turn Signal

4Pre-Oxygen Sensor, Post-Oxygen

Sensor

5 Air Bag (SIR)

6 Powertrain Control Module

7 Air Conditioning Clutch

8 Ignition Feed

9 Horn Relay

5-90