ECU BUICK RAINIER 2006 Workshop Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2006, Model line: RAINIER, Model: BUICK RAINIER 2006Pages: 470, PDF Size: 2.72 MB

Page 376 of 470

Tire Inspection and Rotation

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km).

Any time you notice unusual wear, rotate your tires

as soon as possible and check wheel alignment. Also

check for damaged tires or wheels. SeeWhen It Is Time

for New Tires on page 5-61andWheel Replacement

on page 5-66for more information.

Make sure the spare tire is stored securely. Push, pull,

and then try to rotate or turn the tire. If it moves, use the

wheel wrench to tighten the cable. For information on

storing or removing the spare tire, seeChanging a Flat

Tire on page 5-70.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The �rst rotation

is the most important. SeeScheduled Maintenance

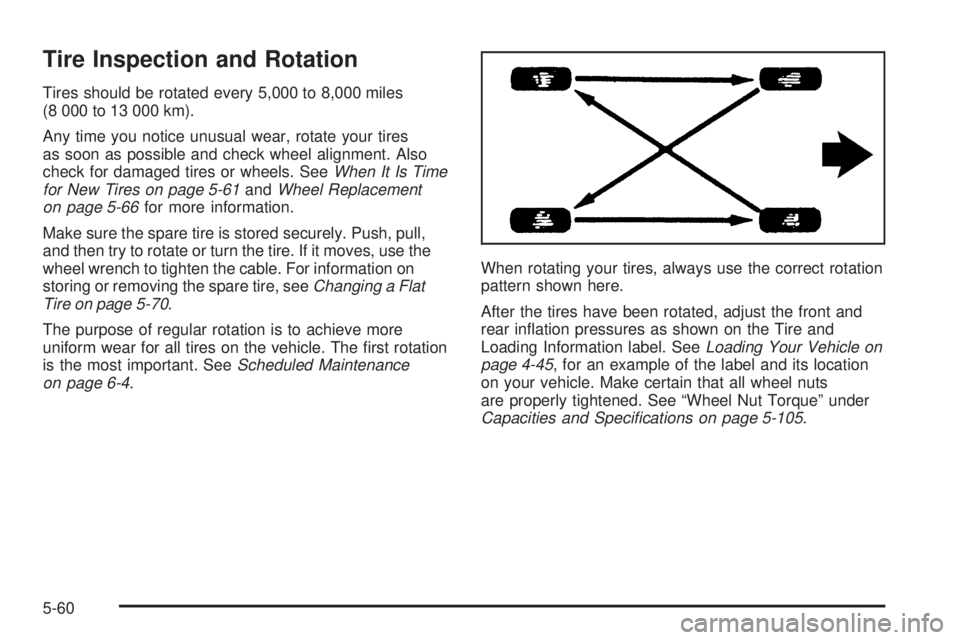

on page 6-4.When rotating your tires, always use the correct rotation

pattern shown here.

After the tires have been rotated, adjust the front and

rear in�ation pressures as shown on the Tire and

Loading Information label. SeeLoading Your Vehicle on

page 4-45, for an example of the label and its location

on your vehicle. Make certain that all wheel nuts

are properly tightened. See “Wheel Nut Torque” under

Capacities and Speci�cations on page 5-105.

5-60

Page 400 of 470

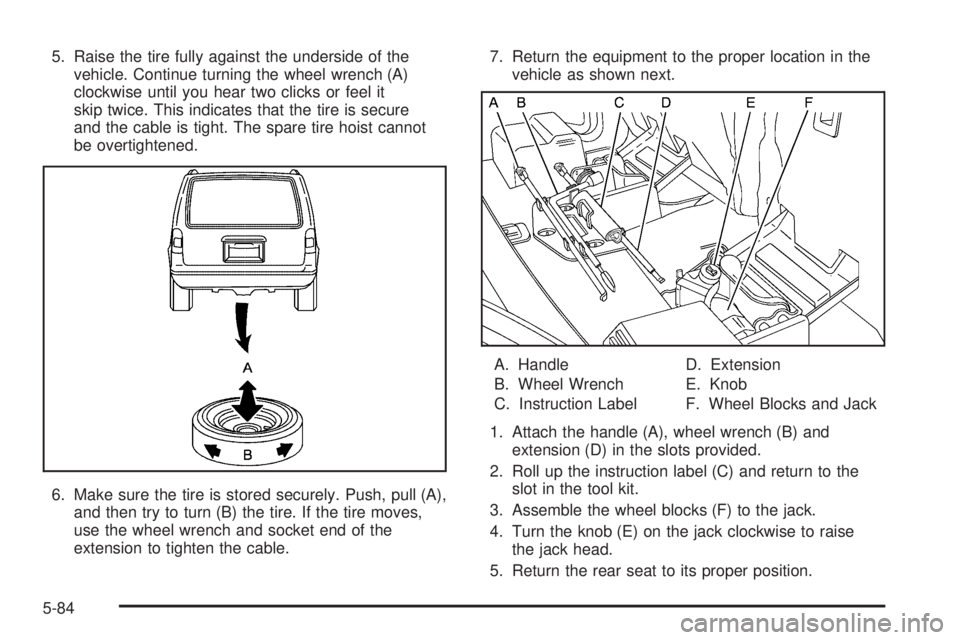

5. Raise the tire fully against the underside of the

vehicle. Continue turning the wheel wrench (A)

clockwise until you hear two clicks or feel it

skip twice. This indicates that the tire is secure

and the cable is tight. The spare tire hoist cannot

be overtightened.

6. Make sure the tire is stored securely. Push, pull (A),

and then try to turn (B) the tire. If the tire moves,

use the wheel wrench and socket end of the

extension to tighten the cable.7. Return the equipment to the proper location in the

vehicle as shown next.

A. Handle

B. Wheel Wrench

C. Instruction LabelD. Extension

E. Knob

F. Wheel Blocks and Jack

1. Attach the handle (A), wheel wrench (B) and

extension (D) in the slots provided.

2. Roll up the instruction label (C) and return to the

slot in the tool kit.

3. Assemble the wheel blocks (F) to the jack.

4. Turn the knob (E) on the jack clockwise to raise

the jack head.

5. Return the rear seat to its proper position.

5-84

Page 431 of 470

Owner Checks and Services

These owner checks and services should be performed

at the intervals speci�ed to help ensure the safety,

dependability, and emission control performance of your

vehicle. Your GM Goodwrench

®dealer can assist you

with these checks and services.

Be sure any necessary repairs are completed at once.

Whenever any �uids or lubricants are added to your

vehicle, make sure they are the proper ones, as shown

inRecommended Fluids and Lubricants on page 6-12.

At Each Fuel Fill

It is important to perform these underhood checks at

each fuel �ll.

Engine Oil Level Check

Check the engine oil level and add the proper oil if

necessary. SeeEngine Oil on page 5-15for further

details.

Notice:It is important to check your oil regularly

and keep it at the proper level. Failure to keep your

engine oil at the proper level can cause damage

to your engine not covered by your warranty.

Engine Coolant Level Check

Check the engine coolant level and add

DEX-COOL®coolant mixture if necessary.

SeeEngine Coolant on page 5-24for further details.

Windshield Washer Fluid Level Check

Check the windshield washer �uid level in the

windshield washer �uid reservoir and add the

proper �uid if necessary.

At Least Once a Month

Tire In�ation Check

Visually inspect your vehicle’s tires and make sure they

are in�ated to the correct pressures. Do not forget to

check the spare tire. SeeTires on page 5-52for further

details. Check to make sure the spare tire is stored

securely. SeeChanging a Flat Tire on page 5-70.

Tire Wear Inspection

Tire rotation may be required for high mileage highway

drivers prior to the Engine Oil Life System service

noti�cation. Check the tires for wear and, if necessary,

rotate the tires. SeeTire Inspection and Rotation

on page 5-60.

6-9

Page 447 of 470

While we hope you never have the occasion to use

our service, it is added security while traveling for you

and your family. Remember, we are only a phone

call away. Buick Roadside Assistance:1-800-252-1112,

text telephone (TTY) users, call1-888-889-2438.

Buick reserves the right to limit services or

reimbursement to an owner or driver when, in Buick’s

judgement, the claims become excessive in frequency

or type of occurrence.

Roadside Assistance is not part of or included in the

coverage provided by the New Vehicle Limited Warranty.

Buick reserves the right to make any changes or

discontinue the Roadside Assistance program at any

time without noti�cation.

Canadian Roadside Assistance

Vehicles purchased in Canada have an extensive

roadside assistance program accessible from anywhere

in Canada or the United States. Please refer to the

Warranty and Owner Assistance Information book.

Courtesy Transportation

To enhance your ownership experience, we and

our participating dealers are proud to offer Courtesy

Transportation, a customer support program for

new vehicles.

The Courtesy Transportation program is offered to

customers in conjunction with the Bumper-to-Bumper

coverage provided by the New Vehicle Limited Warranty.

Several transportation options are available when

warranty repairs are required. This will reduce your

inconvenience during warranty repairs.

Scheduling Service Appointments

When your vehicle requires warranty service, you

should contact your dealer and request an appointment.

By scheduling a service appointment and advising

your service consultant of your transportation needs,

your dealer can help minimize your inconvenience.

If your vehicle cannot be scheduled into the service

department immediately, keep driving it until it can be

scheduled for service, unless, of course, the problem

is safety-related. If it is, please call your dealership,

let them know this, and ask for instructions.

If the dealer requests that you simply drop the vehicle

off for service, you are urged to do so as early in the

work day as possible to allow for the same day repair.

7-7

Page 459 of 470

Charging System Light....................................3-32

Check

Engine Light...............................................3-36

Gages Warning Light...................................3-41

Check Gas Cap Light......................................3-42

Checking Things Under the Hood......................5-10

Chemical Paint Spotting...................................5-92

Child Restraints

Child Restraint Systems...............................1-32

Infants and Young Children...........................1-29

Lower Anchors and Tethers for Children..........1-37

Older Children.............................................1-26

Securing a Child Restraint in a Rear

Outside Seat Position...............................1-42

Securing a Child Restraint in the Center

Rear Seat Position...................................1-44

Securing a Child Restraint in the Right

Front Seat Position...................................1-44

Where to Put the Restraint...........................1-36

Chime Level Adjustment.................................3-130

Cigarette Lighter.............................................3-18

Cleaning

Aluminum Wheels........................................5-90

Exterior Lamps/Lenses.................................5-89

Fabric/Carpet..............................................5-87

Finish Care.................................................5-89

Inside of Your Vehicle..................................5-85

Instrument Panel, Vinyl, and Other

Plastic Surfaces.......................................5-88Cleaning (cont.)

Leather......................................................5-87

Tires..........................................................5-91

Underbody Maintenance...............................5-92

Washing Your Vehicle...................................5-88

Windshield, Backglass, and Wiper Blades.......5-90

Climate Control System

Dual Automatic............................................3-19

Outlet Adjustment........................................3-23

Rear..........................................................3-24

Collision Damage Repair..................................7-10

Comfort Guides, Rear Safety Belt.....................1-23

Content Theft-Deterrent....................................2-15

Control of a Vehicle.......................................... 4-5

Convenience Net............................................2-49

Coolant

Engine Temperature Gage............................3-35

Heater, Engine............................................2-20

Cooling System..............................................5-28

Cruise Control................................................3-11

Cruise Control Light........................................3-39

Customer Assistance Information

Courtesy Transportation.................................. 7-7

Customer Assistance for Text

Telephone (TTY) Users............................... 7-4

Customer Assistance Offices........................... 7-4

Customer Satisfaction Procedure..................... 7-2

GM Mobility Reimbursement Program............... 7-5

Reporting Safety Defects to General Motors....7-14

3

Page 460 of 470

Customer Assistance Information (cont.)

Reporting Safety Defects to the

Canadian Government..............................7-14

Reporting Safety Defects to the

United States Government.........................7-13

Roadside Assistance Program......................... 7-6

Service Publications Ordering Information........7-14

D

Daytime Running Lamps..................................3-14

Defensive Driving............................................. 4-2

Delayed Locking............................................... 2-8

Displacement on Demand™ (DoD™).................2-21

Doing Your Own Service Work........................... 5-4

Dome Lamp Override......................................3-16

Dome Lamps.................................................3-16

Door

Delayed Locking........................................... 2-8

Locks.......................................................... 2-7

Power Door Locks......................................... 2-8

Programmable Automatic Door Locks............... 2-9

Rear Door Security Locks.............................2-11

Driver

Position, Safety Belt.....................................1-13

Driver Information Center (DIC).........................3-43

DIC Operation and Displays..........................3-44

DIC Vehicle Customization............................3-52

DIC Warnings and Messages........................3-47Driving

At Night.....................................................4-30

City...........................................................4-34

Defensive..................................................... 4-2

Drunken....................................................... 4-3

Freeway.....................................................4-35

Hill and Mountain Roads..............................4-38

In Rain and on Wet Roads...........................4-31

Off-Road....................................................4-18

Rocking Your Vehicle to Get it Out.................4-44

Winter........................................................4-40

Dual Automatic Climate Control System.............3-19

DVD

Rear Seat Entertainment System..................3-113

E

Electrical System

Add-On Equipment......................................5-94

Engine Compartment Fuse Block...................5-96

Fuses and Circuit Breakers...........................5-95

Headlamps.................................................5-95

Power Windows and Other Power Options......5-95

Rear Underseat Fuse Block.........................5-102

Windshield Wiper Fuses...............................5-95

Electronically Controlled Air Suspension

System......................................................4-50

4

Page 463 of 470

J

Jump Starting.................................................5-40

K

Keyless Entry System....................................... 2-4

Keys............................................................... 2-3

L

Labeling, Tire Sidewall.....................................5-53

Lamps

Battery Run-Down Protection.........................3-17

Dome........................................................3-16

Dome Lamp Override...................................3-16

Fog ...........................................................3-15

Reading.....................................................3-17

LATCH System

Child Restraints...........................................1-37

Liftgate/Liftglass..............................................2-12

Liftglass/Liftgate..............................................2-12

Light

Airbag Readiness........................................3-29

Anti-Lock Brake System Warning...................3-34

Brake System Warning.................................3-33

Charging System.........................................3-32

Check Gages Warning.................................3-41Light (cont.)

Check Gas Cap..........................................3-42

Cruise Control.............................................3-39

Gate Ajar...................................................3-41

Highbeam On.............................................3-40

Low Fuel Warning.......................................3-42

Malfunction Indicator....................................3-36

Passenger Airbag Status Indicator..................3-30

Passenger Safety Belt Reminder....................3-28

Reduced Engine Power................................3-40

Safety Belt Reminder...................................3-28

Security.....................................................3-39

Service All-Wheel-Drive................................3-41

StabiliTrak

®Indicator....................................3-35

StabiliTrak®Service......................................3-34

Lighting

Entry.........................................................3-17

Exit...........................................................3-17

Loading Your Vehicle.......................................4-45

Locking Rear Axle............................................ 4-8

Lockout Protection..........................................2-11

Locks

Delayed Locking........................................... 2-8

Door........................................................... 2-7

Lockout Protection.......................................2-11

Power Door.................................................. 2-8

Programmable Automatic Door Locks............... 2-9

Rear Door Security Locks.............................2-11

7

Page 466 of 470

Q

Questions and Answers About Safety Belts.........1-12

R

Radiator Pressure Cap....................................5-26

Radios..........................................................3-58

Care of Your Cassette Tape Player...............3-128

Care of Your CD and DVD Player................3-129

Care of Your CDs and DVDs.......................3-129

Navigation/Radio System, see Navigation

Manual.................................................3-113

Radio with Cassette and CD.........................3-85

Radio with CD....................................3-60, 3-70

Radio with Six-Disc CD................................3-99

Rear Seat Audio........................................3-124

Setting the Time..........................................3-59

Theft-Deterrent..........................................3-126

Understanding Reception............................3-127

Rainsense™ Wipers.......................................... 3-9

Reading Lamps..............................................3-17

Rear Axle......................................................5-45

Locking........................................................ 4-8

Rear Climate Control System............................3-24

Rear Door Security Locks................................2-11

Rear Floor Storage Lid....................................2-48

Rear Safety Belt Comfort Guides......................1-23Rear Seat Audio (RSA)..................................3-124

Rear Seat Entertainment System.....................3-113

Rear Seat Operation......................................... 1-6

Rear Seat Passengers, Safety Belts..................1-20

Rear Windshield Washer/Wiper.........................3-10

Rearview Mirror, Automatic Dimming with

Compass....................................................2-35

Rearview Mirror, Automatic Dimming with

Compass and Temperature Display................2-37

Rearview Mirror, Automatic Dimming with

OnStar

®and Compass.................................2-31

Rearview Mirror, Automatic Dimming with

OnStar

®, Compass and Temperature Display . . . 2-33

Rearview Mirror with OnStar®...........................2-29

Rearview Mirror with OnStar®, Compass,

and Temperature Display..............................2-29

Rearview Mirrors.............................................2-29

Reclining Seatbacks, Power............................... 1-4

Recommended Fluids and Lubricants.................6-12

Recreational Vehicle Towing.............................4-50

Reduced Engine Power Light............................3-40

Remote Keyless Entry System............................ 2-4

Remote Keyless Entry System, Operation............ 2-5

Removing the Flat Tire and Installing the

Spare Tire..................................................5-74

Removing the Spare Tire and Tools...................5-72

Replacement Bulbs.........................................5-49

Replacement, Windshield.................................5-50

10

Page 467 of 470

Reporting Safety Defects

Canadian Government..................................7-14

General Motors...........................................7-14

United States Government............................7-13

Restraint System Check

Checking the Restraint Systems....................1-62

Replacing Restraint System Parts

After a Crash..........................................1-62

Retained Accessory Power (RAP)......................2-18

Right Front Passenger Position, Safety Belts......1-20

Roadside

Assistance Program....................................... 7-6

Rocking Your Vehicle to Get it Out....................4-44

Running the Engine While Parked.....................2-28

S

Safety Belt

Passenger Reminder Light............................3-28

Pretensioners..............................................1-25

Reminder Light............................................3-28

Safety Belts

Care of......................................................5-88

Driver Position............................................1-13

How to Wear Safety Belts Properly................1-13

Questions and Answers About Safety Belts.....1-12

Rear Safety Belt Comfort Guides...................1-23Safety Belts (cont.)

Rear Seat Passengers.................................1-20

Right Front Passenger Position......................1-20

Safety Belt Extender....................................1-25

Safety Belt Use During Pregnancy.................1-19

Safety Belts Are for Everyone......................... 1-8

Safety Warnings and Symbols.............................. iii

Scheduled Maintenance..................................... 6-4

Seats

Head Restraints............................................ 1-5

Heated Seats............................................... 1-3

Memory.....................................................2-51

Power Lumbar.............................................. 1-3

Power Reclining Seatbacks............................. 1-4

Power Seats................................................. 1-2

Rear Seat Operation...................................... 1-6

Secondary Latch System.................................5-80

Securing a Child Restraint

Center Rear Seat Position............................1-44

Rear Outside Seat Position...........................1-42

Right Front Seat Position..............................1-44

Security Light.................................................3-39

Service........................................................... 5-3

Accessories and Modi�cations......................... 5-3

Adding Equipment to the Outside of

Your Vehicle.............................................. 5-5

All-Wheel-Drive Light....................................3-41

11