ECU CADILLAC ESCALADE 2006 2.G Workshop Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2006, Model line: ESCALADE, Model: CADILLAC ESCALADE 2006 2.GPages: 484, PDF Size: 2.84 MB

Page 313 of 484

Towing a trailer requires a certain amount of experience.

Before setting out for the open road, you’ll want to get

to know your rig. Acquaint yourself with the feel of

handling and braking with the added weight of the trailer.

And always keep in mind that the vehicle you are

driving is now a good deal longer and not nearly as

responsive as your vehicle is by itself.

Before you start, check all trailer hitch parts and

attachments, safety chains, electrical connector, lamps,

tires and mirror adjustment. If the trailer has electric

brakes, start your vehicle and trailer moving and then

apply the trailer brake controller by hand to be sure

the brakes are working. This lets you check your

electrical connection at the same time.

During your trip, check occasionally to be sure that the

load is secure, and that the lamps and any trailer

brakes are still working.

Following Distance

Stay at least twice as far behind the vehicle ahead as

you would when driving your vehicle without a trailer.

This can help you avoid situations that require

heavy braking and sudden turns.

Passing

You’ll need more passing distance up ahead when

you’re towing a trailer. And, because you’re a good deal

longer, you’ll need to go much farther beyond the

passed vehicle before you can return to your lane.

Backing Up

Hold the bottom of the steering wheel with one hand.

Then, to move the trailer to the left, just move that hand

to the left. To move the trailer to the right, move your

hand to the right. Always back up slowly and, if possible,

have someone guide you.

Making Turns

Notice:Making very sharp turns while trailering

could cause the trailer to come in contact with the

vehicle. Your vehicle could be damaged. Avoid

making very sharp turns while trailering.

When you’re turning with a trailer, make wider turns

than normal. Do this so your trailer won’t strike

soft shoulders, curbs, road signs, trees or other objects.

Avoid jerky or sudden maneuvers. Signal well in

advance.

4-63

Page 342 of 484

Adding Coolant

If you need more coolant, add the proper DEX-COOL®

coolant mixture at the surge tank, but only when the

engine is cool.

{CAUTION:

You can be burned if you spill coolant on hot

engine parts. Coolant contains ethylene glycol,

and it will burn if the engine parts are hot

enough. Do not spill coolant on a hot engine.

When replacing the pressure cap, make sure it is

hand-tight and fully seated.

Coolant Surge Tank Pressure Cap

Notice:If the pressure cap is not tightly installed,

coolant loss and possible engine damage may

occur. Be sure the cap is properly and tightly

secured.

The coolant surge tank pressure cap must be fully

installed on the coolant surge tank. SeeEngine

Compartment Overview on page 5-10for more

information on location.

Engine Overheating

You will �nd a coolant temperature gage on your

vehicle’s instrument panel cluster. SeeEngine Coolant

Temperature Gage on page 3-42.

In addition, you will �nd an ENGINE COOLANT HOT,

ENGINE OVERHEATED and a REDUCED ENGINE

POWER message in the Driver Information Center (DIC)

on the instrument panel. SeeDIC Warnings and

Messages on page 3-54.

5-24

Page 375 of 484

2. Push the release lever (B) to disengage the hook

and push the wiper arm (A) out of the blade (C).

3. Push the new wiper blade securely on the wiper arm

until you hear the release lever click into place.

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer. If you ever have questions

about your tire warranty and where to obtain service,

see your GM Warranty booklet for details. For additional

information refer to the tire manufacturer’s booklet

included with your vehicle’s Owner Manual.

{CAUTION:

Poorly maintained and improperly used tires

are dangerous.

Overloading your tires can cause

overheating as a result of too much

friction. You could have an air-out and a

serious accident. SeeLoading Your

Vehicle on page 4-47.

Underin�ated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be

checked when your tires are cold. See

Inflation - Tire Pressure on page 5-64.

Overin�ated tires are more likely to be

cut, punctured, or broken by a sudden

impact — such as when you hit a pothole.

Keep tires at the recommended pressure.

Worn, old tires can cause accidents.

If your tread is badly worn, or if your tires

have been damaged, replace them.

5-57

Page 388 of 484

The Tire Pressure Monitor System (TPMS) operates

on a radio frequency and complies with RSS-210

of Industry and Science Canada. Operation is subject to

the following two conditions:

1. This device may not cause interference.

2. This device must accept any interference received,

including interference that may cause undesired

operation of the device.

Changes or modi�cations to this system by other than

an authorized service facility could void authorization to

use this equipment.

Tire Inspection and Rotation

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km).

Any time you notice unusual wear, rotate your tires as

soon as possible and check wheel alignment. Also

check for damaged tires or wheels. SeeWhen It Is Time

for New Tires on page 5-71andWheel Replacement

on page 5-76for more information.

Make sure the spare tire is stored securely. Push,

pull, and then try to rotate or turn the tire. If it moves,

use the ratchet/wheel wrench to tighten the cable.

SeeChanging a Flat Tire on page 5-78.The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The �rst rotation

is the most important. SeeScheduled Maintenance

on page 6-4.

When rotating your vehicle’s tires, always use the

correct rotation pattern shown here.

Do not include the spare tire in the tire rotation.

After the tires have been rotated, adjust the front and

rear in�ation pressures as shown on the tire and loading

information label. SeeLoading Your Vehicle on

page 4-47andIn�ation - Tire Pressure on page 5-64,

for more information.

5-70

Page 408 of 484

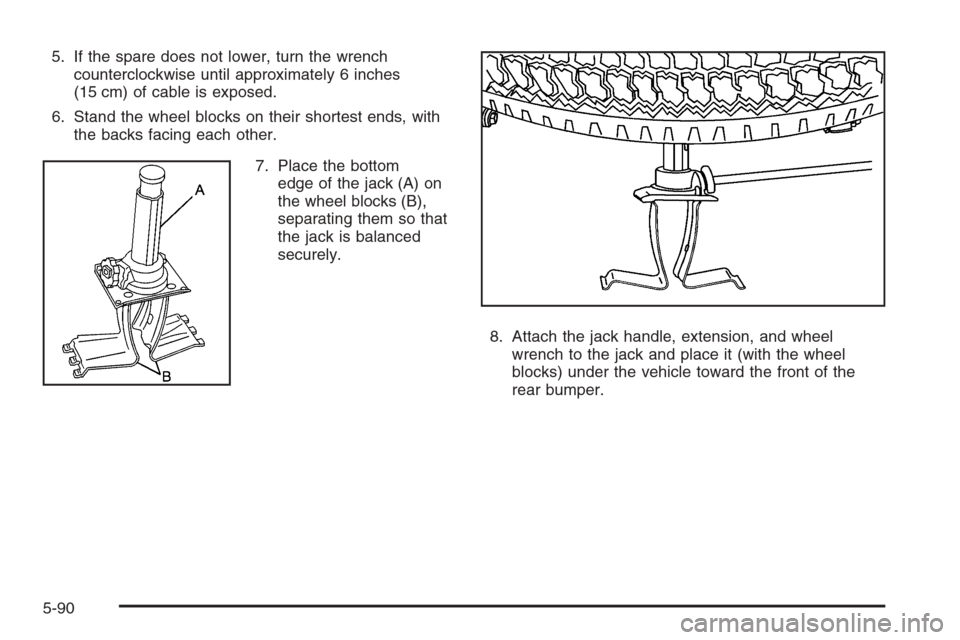

5. If the spare does not lower, turn the wrench

counterclockwise until approximately 6 inches

(15 cm) of cable is exposed.

6. Stand the wheel blocks on their shortest ends, with

the backs facing each other.

7. Place the bottom

edge of the jack (A) on

the wheel blocks (B),

separating them so that

the jack is balanced

securely.

8. Attach the jack handle, extension, and wheel

wrench to the jack and place it (with the wheel

blocks) under the vehicle toward the front of the

rear bumper.

5-90

Page 412 of 484

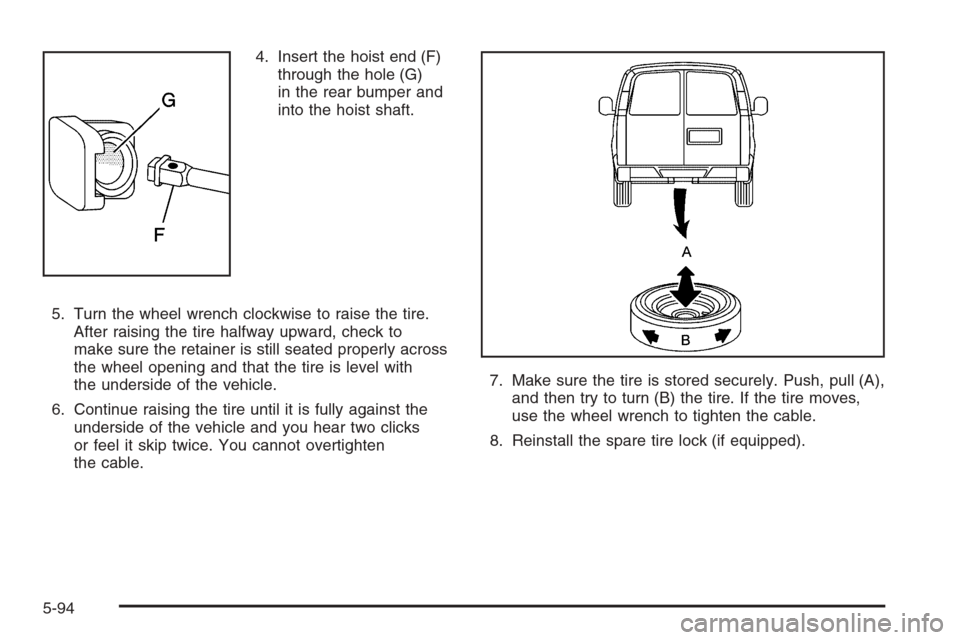

4. Insert the hoist end (F)

through the hole (G)

in the rear bumper and

into the hoist shaft.

5. Turn the wheel wrench clockwise to raise the tire.

After raising the tire halfway upward, check to

make sure the retainer is still seated properly across

the wheel opening and that the tire is level with

the underside of the vehicle.

6. Continue raising the tire until it is fully against the

underside of the vehicle and you hear two clicks

or feel it skip twice. You cannot overtighten

the cable.7. Make sure the tire is stored securely. Push, pull (A),

and then try to turn (B) the tire. If the tire moves,

use the wheel wrench to tighten the cable.

8. Reinstall the spare tire lock (if equipped).

5-94

Page 413 of 484

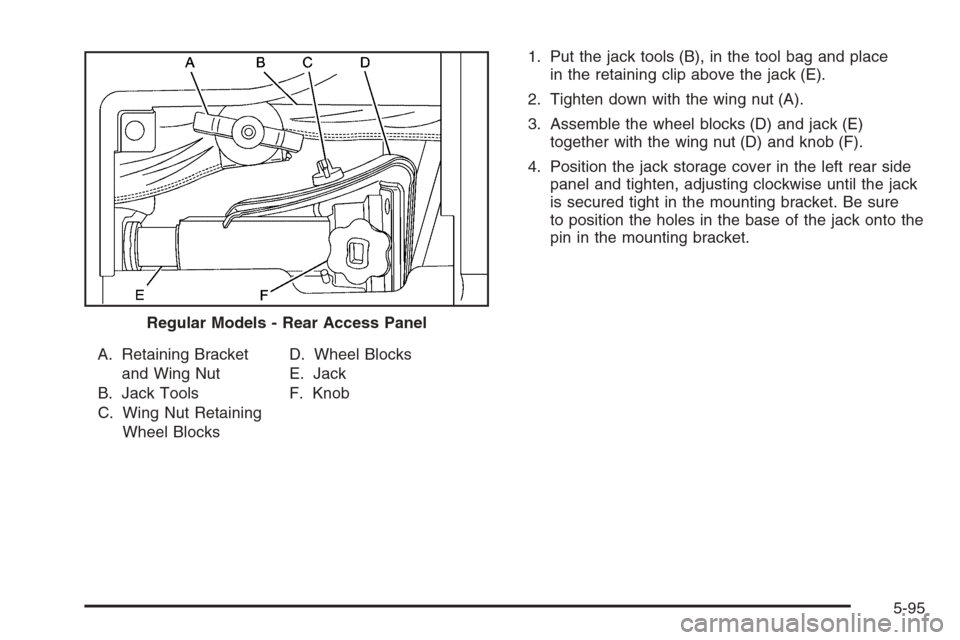

A. Retaining Bracket

and Wing Nut

B. Jack Tools

C. Wing Nut Retaining

Wheel BlocksD. Wheel Blocks

E. Jack

F. Knob1. Put the jack tools (B), in the tool bag and place

in the retaining clip above the jack (E).

2. Tighten down with the wing nut (A).

3. Assemble the wheel blocks (D) and jack (E)

together with the wing nut (D) and knob (F).

4. Position the jack storage cover in the left rear side

panel and tighten, adjusting clockwise until the jack

is secured tight in the mounting bracket. Be sure

to position the holes in the base of the jack onto the

pin in the mounting bracket.

Regular Models - Rear Access Panel

5-95

Page 414 of 484

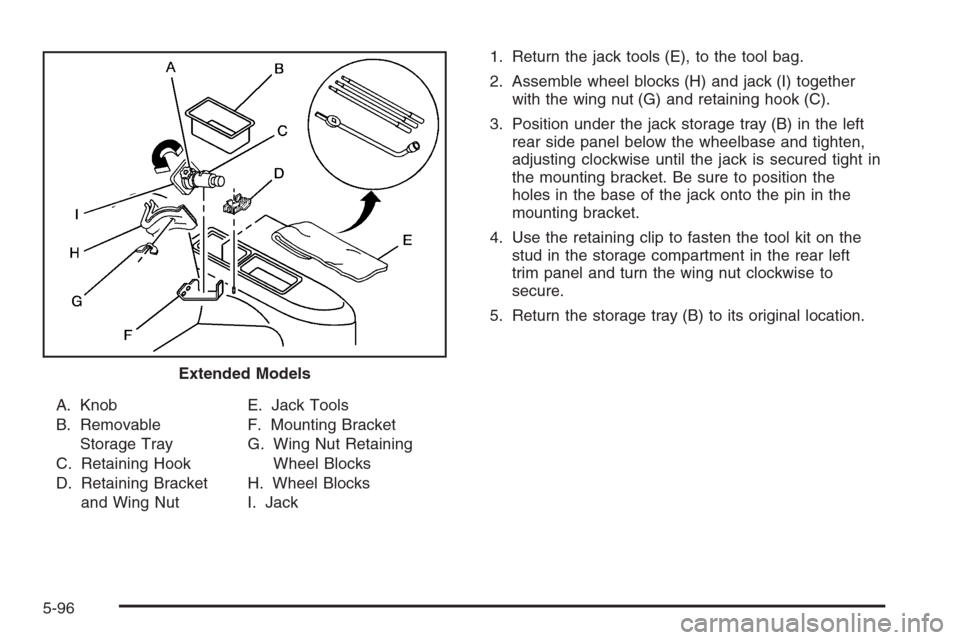

A. Knob

B. Removable

Storage Tray

C. Retaining Hook

D. Retaining Bracket

and Wing NutE. Jack Tools

F. Mounting Bracket

G. Wing Nut Retaining

Wheel Blocks

H. Wheel Blocks

I. Jack1. Return the jack tools (E), to the tool bag.

2. Assemble wheel blocks (H) and jack (I) together

with the wing nut (G) and retaining hook (C).

3. Position under the jack storage tray (B) in the left

rear side panel below the wheelbase and tighten,

adjusting clockwise until the jack is secured tight in

the mounting bracket. Be sure to position the

holes in the base of the jack onto the pin in the

mounting bracket.

4. Use the retaining clip to fasten the tool kit on the

stud in the storage compartment in the rear left

trim panel and turn the wing nut clockwise to

secure.

5. Return the storage tray (B) to its original location.

Extended Models

5-96

Page 444 of 484

At Least Once a Month

Tire In�ation Check

Visually inspect your vehicle’s tires and make sure they

are in�ated to the correct pressures. Do not forget to

check the spare tire. SeeTires on page 5-57for further

details. Check to make sure the spare tire is stored

securely. SeeChanging a Flat Tire on page 5-78.

Tire Wear Inspection

Tire rotation may be required for high mileage highway

drivers prior to the Engine Oil Life System service

noti�cation. Check the tires for wear and, if necessary,

rotate the tires. SeeTire Inspection and Rotation on

page 5-70.

At Least Once a Year

Starter Switch Check

{CAUTION:

When you are doing this inspection, the

vehicle could move suddenly. If the vehicle

moves, you or others could be injured.

1. Before you start, be sure you have enough room

around the vehicle.

2. Firmly apply both the parking brake and the regular

brake. SeeParking Brake on page 2-23.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. Try to start the engine in each gear. The vehicle

should start only in PARK (P) or NEUTRAL (N).

If the vehicle starts in any other position, contact

your GM Goodwrench

®dealer for service.

6-10

Page 473 of 484

C

California Fuel.................................................. 5-5

California Proposition 65 Warning....................... 5-3

Canadian Owners................................................ ii

Capacities and Speci�cations..........................5-116

Carbon Monoxide...................2-11, 2-26, 4-41, 4-54

Care of

Safety Belts..............................................5-100

Your Cassette Tape Player..........................3-104

Your CD and DVD Player...........................3-105

Your CDs and DVDs ..................................3-105

Cargo Cover..................................................2-45

CD Changer...................................................3-99

Center Console Storage Area...........................2-43

Center Rear Passenger Position, Safety Belts.....1-45

Chains, Tire...................................................5-77

Charging System Light....................................3-38

Check

Engine Light...............................................3-44

Checking Things Under the Hood....................... 5-8

Chemical Paint Spotting.................................5-104

Child Restraints

Child Restraint Systems...............................1-55

Infants and Young Children...........................1-52

Lower Anchors and Tethers for Children..........1-61

Older Children.............................................1-49

Securing a Child Restraint in a Rear Outside

Seat Position...........................................1-68Child Restraints (cont.)

Securing a Child Restraint in the Center Rear

Seat Position...........................................1-70

Securing a Child Restraint in the Right Front

Seat Position...........................................1-72

Where to Put the Restraint...........................1-60

Chime Level Adjustment.................................3-106

Cigarette Lighter.............................................3-23

Cleaning

Aluminum or Chrome-Plated Wheels.............5-102

Exterior Lamps/Lenses................................5-101

Fabric/Carpet..............................................5-99

Finish Care...............................................5-101

Inside of Your Vehicle..................................5-97

Instrument Panel, Vinyl, and Other Plastic

Surfaces...............................................5-100

Leather......................................................5-99

Speaker Covers.........................................5-100

Tires........................................................5-103

Underbody Maintenance.............................5-104

Washing Your Vehicle.................................5-101

Weatherstrips............................................5-100

Windshield, Backglass, and Wiper Blades......5-102

Wood Panels............................................5-100

Climate Control System

Dual Automatic............................................3-24

Outlet Adjustment........................................3-29

Rear ..........................................................3-30

Clock............................................................3-23

Collision Damage Repair..................................7-10

3