engine CADILLAC ESCALADE EXT 2004 2.G Owners Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2004, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2004 2.GPages: 478, PDF Size: 3.43 MB

Page 355 of 478

5. Check that the jumper cables don't have loose or

missing insulation. If they do, you could get a

shock. The vehicles could be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go to

positive (+) or to a remote positive terminal (+) if

the vehicle has one. Negative (-) will go to a heavy,

unpainted metal engine part or to a remote

negative (-) terminal, if the vehicle has one.

Don't connect positive (+) to negative (-) or you'll

get a short that would damage the battery and

maybe other parts too.

{CAUTION:

Fans or other moving engine parts can injure

you badly. Keep your hands away from moving

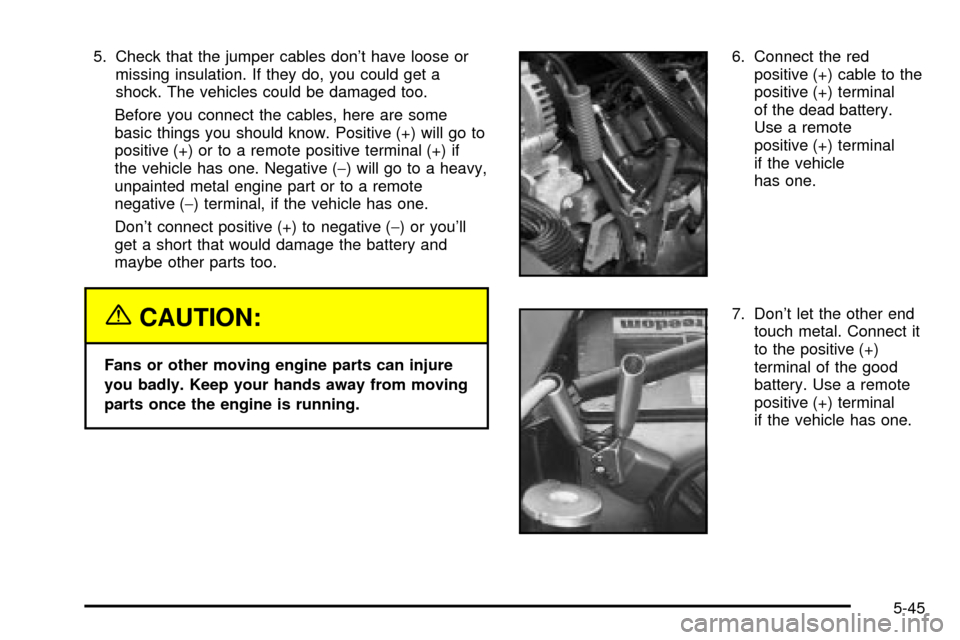

parts once the engine is running.6. Connect the red

positive (+) cable to the

positive (+) terminal

of the dead battery.

Use a remote

positive (+) terminal

if the vehicle

has one.

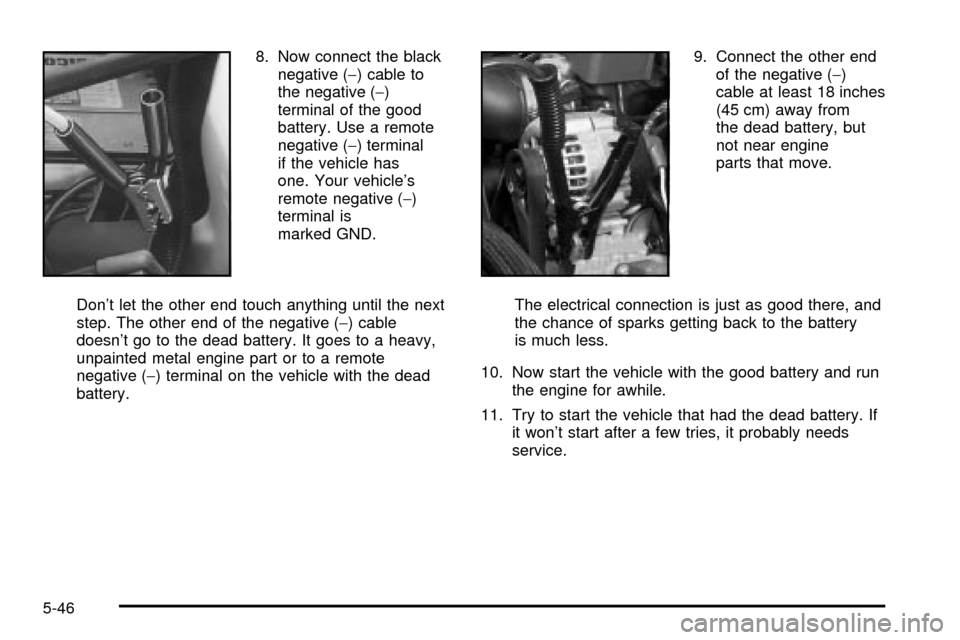

7. Don't let the other end

touch metal. Connect it

to the positive (+)

terminal of the good

battery. Use a remote

positive (+) terminal

if the vehicle has one.

5-45

Page 356 of 478

8. Now connect the black

negative (-) cable to

the negative (-)

terminal of the good

battery. Use a remote

negative (-) terminal

if the vehicle has

one. Your vehicle's

remote negative (-)

terminal is

marked GND.

Don't let the other end touch anything until the next

step. The other end of the negative (-) cable

doesn't go to the dead battery. It goes to a heavy,

unpainted metal engine part or to a remote

negative (-) terminal on the vehicle with the dead

battery.9. Connect the other end

of the negative (-)

cable at least 18 inches

(45 cm) away from

the dead battery, but

not near engine

parts that move.

The electrical connection is just as good there, and

the chance of sparks getting back to the battery

is much less.

10. Now start the vehicle with the good battery and run

the engine for awhile.

11. Try to start the vehicle that had the dead battery. If

it won't start after a few tries, it probably needs

service.

5-46

Page 357 of 478

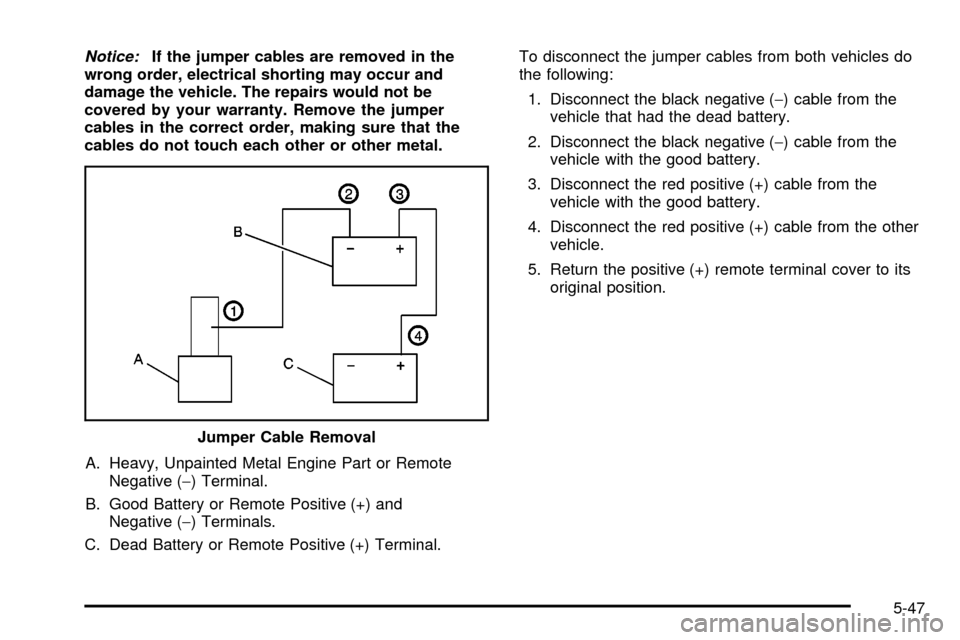

Notice:If the jumper cables are removed in the

wrong order, electrical shorting may occur and

damage the vehicle. The repairs would not be

covered by your warranty. Remove the jumper

cables in the correct order, making sure that the

cables do not touch each other or other metal.

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (-) Terminal.

B. Good Battery or Remote Positive (+) and

Negative (-) Terminals.

C. Dead Battery or Remote Positive (+) Terminal.To disconnect the jumper cables from both vehicles do

the following:

1. Disconnect the black negative (-) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (-) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the positive (+) remote terminal cover to its

original position.

Jumper Cable Removal

5-47

Page 377 of 478

(F) Tire Ply Material:The type of cord and number of

plies in the sidewall and under the tread.

(G) Single Tire Maximum Load:Maximum load

that can be carried and the maximum pressure needed

to support that load when used as a single. For

information on recommended tire pressure see

In¯ation - Tire Pressure on page 5-71andLoading

Your Vehicle on page 4-47.

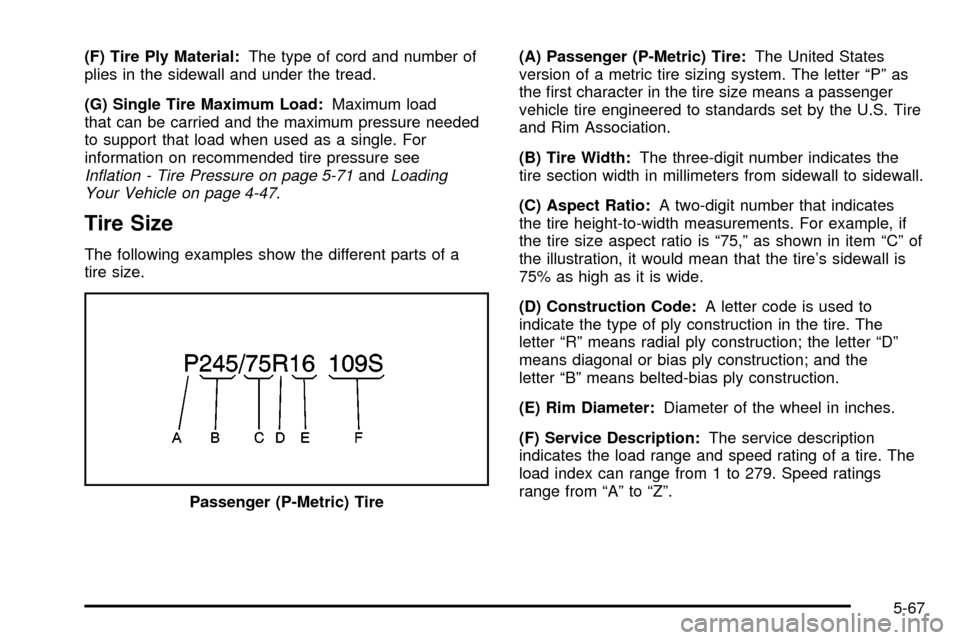

Tire Size

The following examples show the different parts of a

tire size.(A) Passenger (P-Metric) Tire:The United States

version of a metric tire sizing system. The letter ªPº as

the ®rst character in the tire size means a passenger

vehicle tire engineered to standards set by the U.S. Tire

and Rim Association.

(B) Tire Width:The three-digit number indicates the

tire section width in millimeters from sidewall to sidewall.

(C) Aspect Ratio:A two-digit number that indicates

the tire height-to-width measurements. For example, if

the tire size aspect ratio is ª75,º as shown in item ªCº of

the illustration, it would mean that the tire's sidewall is

75% as high as it is wide.

(D) Construction Code:A letter code is used to

indicate the type of ply construction in the tire. The

letter ªRº means radial ply construction; the letter ªDº

means diagonal or bias ply construction; and the

letter ªBº means belted-bias ply construction.

(E) Rim Diameter:Diameter of the wheel in inches.

(F) Service Description:The service description

indicates the load range and speed rating of a tire. The

load index can range from 1 to 279. Speed ratings

range from ªAº to ªZº.

Passenger (P-Metric) Tire

5-67

Page 378 of 478

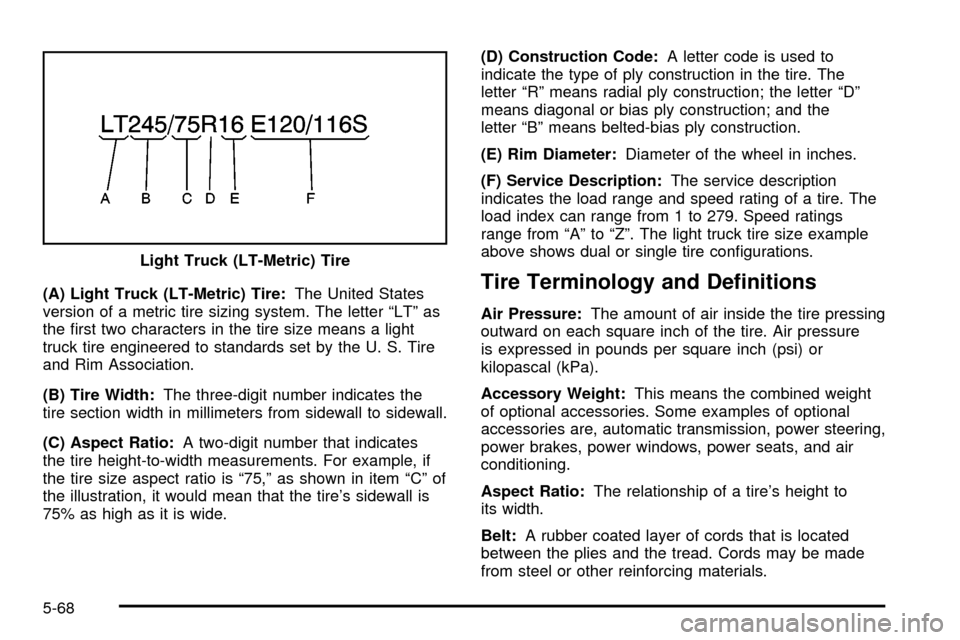

(A) Light Truck (LT-Metric) Tire:The United States

version of a metric tire sizing system. The letter ªLTº as

the ®rst two characters in the tire size means a light

truck tire engineered to standards set by the U. S. Tire

and Rim Association.

(B) Tire Width:The three-digit number indicates the

tire section width in millimeters from sidewall to sidewall.

(C) Aspect Ratio:A two-digit number that indicates

the tire height-to-width measurements. For example, if

the tire size aspect ratio is ª75,º as shown in item ªCº of

the illustration, it would mean that the tire's sidewall is

75% as high as it is wide.(D) Construction Code:A letter code is used to

indicate the type of ply construction in the tire. The

letter ªRº means radial ply construction; the letter ªDº

means diagonal or bias ply construction; and the

letter ªBº means belted-bias ply construction.

(E) Rim Diameter:Diameter of the wheel in inches.

(F) Service Description:The service description

indicates the load range and speed rating of a tire. The

load index can range from 1 to 279. Speed ratings

range from ªAº to ªZº. The light truck tire size example

above shows dual or single tire con®gurations.Tire Terminology and De®nitions

Air Pressure:The amount of air inside the tire pressing

outward on each square inch of the tire. Air pressure

is expressed in pounds per square inch (psi) or

kilopascal (kPa).

Accessory Weight:This means the combined weight

of optional accessories. Some examples of optional

accessories are, automatic transmission, power steering,

power brakes, power windows, power seats, and air

conditioning.

Aspect Ratio:The relationship of a tire's height to

its width.

Belt:A rubber coated layer of cords that is located

between the plies and the tread. Cords may be made

from steel or other reinforcing materials. Light Truck (LT-Metric) Tire

5-68

Page 383 of 478

TPM Sensor Identi®cation Codes

Each TPM sensor has a unique identi®cation code. Any

time you rotate your vehicle's tires or replace one or

more of the TPM sensors, the identi®cation codes

will need to be matched to the new tire/wheel position.

Each tire/wheel position is matched to a sensor, by

increasing or decreasing the tire's air pressure.

The sensors are matched to the tire/wheel positions in

the following order: left front (LF); right front (RF);

right rear (RR) and left rear (LR).

You will have one minute to match the ®rst tire/wheel

position, and ®ve minutes overall to match all four

tire/wheel positions. If it takes longer than one minute,

to match the ®rst tire and wheel, or more than ®ve

minutes to match all four tire and wheel positions the

matching process stops and you will need to start over.

The TPM sensor matching process is outlined below:

1. Set the Parking brake.

2. Turn the ignition switch to RUN with the engine off.3. Turn the exterior lamp switch from ªOffº to ªOnº

four times within 3 seconds. A double horn chirp

will sound and the TPM low tire warning light

will begin to ¯ash. The double horn chirp and

¯ashing TPM warning light indicate that the TPM

matching process has started. The TPM warning

light should continue ¯ashing throughout the

matching procedure. The SERVICE TIRE

MONITOR message will be displayed on the Driver

Information Center (DIC).

4. Start with the left (driver's side) front tire.

5. Remove the valve cap from the valve cap stem.

Activate the TPM sensor by increasing or

decreasing the tire's air pressure for 10 seconds,

then stop and listen for a single horn chirp.

The single horn chirp should sound within

15 seconds, con®rming that the sensor identi®cation

code has been matched to this tire and wheel

position. If you do not hear the con®rming single

horn chirp, you will need to start over with step

number one. To let air-pressure out of a tire you can

use the pointy end of the valve cap, a pencil-style

air pressure gage or a key.

5-73

Page 393 of 478

Changing a Flat Tire

If a tire goes ¯at, avoid further tire and wheel damage

by driving slowly to a level place. Turn on your

hazard warning ¯ashers.

{CAUTION:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you

or other people. You and they could be badly

injured or even killed. Find a level place to

change your tire. To help prevent the vehicle

from moving:

1. Set the parking brake ®rmly.

2. Put the shift lever in PARK (P).

3. Turn off the engine and do not restart

while the vehicle is raised.

4. Do not allow passengers to remain in the

vehicle.

CAUTION: (Continued)

CAUTION: (Continued)

5. Put the wheel blocks at the front and rear

of the tire farthest away from the one

being changed. That would be the tire on

the other side, at the opposite end of the

vehicle.

The following steps will tell you how to use the jack and

change a tire.

5-83

Page 420 of 478

Vehicle Identi®cation

Vehicle Identi®cation Number (VIN)

This is the legal identi®er for your vehicle. It appears on

a plate in the front corner of the instrument panel, on

the driver's side. You can see it if you look through the

windshield from outside your vehicle. The VIN also

appears on the Vehicle Certi®cation and Service Parts

labels and the certi®cates of title and registration.

Engine Identi®cation

The 8th character in your VIN is the engine code. This

code will help you identify your engine, speci®cations

and replacement parts.

Service Parts Identi®cation Label

You'll ®nd this label located in the glove box. It's very

helpful if you ever need to order parts. On this label is:

·your VIN,

·the model designation,

·paint information and

·a list of all production options and special

equipment.

Be sure that this label is not removed from the vehicle.

5-110

Page 425 of 478

Underhood Fuse BlockThe underhood fuse block in the engine compartment

on the driver's side of the vehicle near the battery.

Lift the cover for access to the fuse/relay block.

To remove fuses, hold the end of the fuse between your

thumb and index ®nger and pull straight out.

See

Engine Compartment Overview on page 5-10for

more information on its location.

5-115

Page 427 of 478

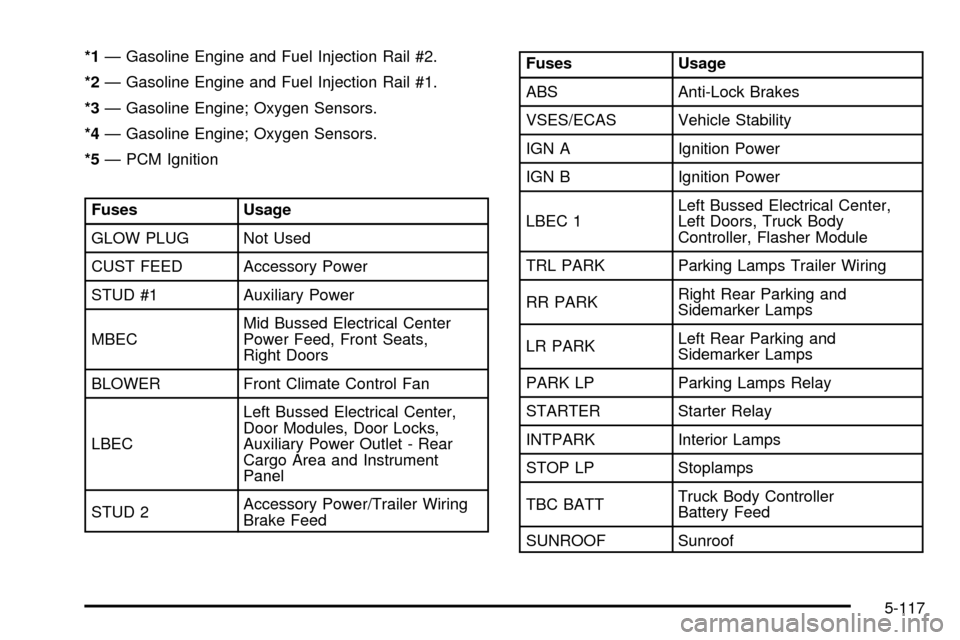

*1Ð Gasoline Engine and Fuel Injection Rail #2.

*2Ð Gasoline Engine and Fuel Injection Rail #1.

*3Ð Gasoline Engine; Oxygen Sensors.

*4Ð Gasoline Engine; Oxygen Sensors.

*5Ð PCM Ignition

Fuses Usage

GLOW PLUG Not Used

CUST FEED Accessory Power

STUD #1 Auxiliary Power

MBECMid Bussed Electrical Center

Power Feed, Front Seats,

Right Doors

BLOWER Front Climate Control Fan

LBECLeft Bussed Electrical Center,

Door Modules, Door Locks,

Auxiliary Power Outlet - Rear

Cargo Area and Instrument

Panel

STUD 2Accessory Power/Trailer Wiring

Brake Feed

Fuses Usage

ABS Anti-Lock Brakes

VSES/ECAS Vehicle Stability

IGN A Ignition Power

IGN B Ignition Power

LBEC 1Left Bussed Electrical Center,

Left Doors, Truck Body

Controller, Flasher Module

TRL PARK Parking Lamps Trailer Wiring

RR PARKRight Rear Parking and

Sidemarker Lamps

LR PARKLeft Rear Parking and

Sidemarker Lamps

PARK LP Parking Lamps Relay

STARTER Starter Relay

INTPARK Interior Lamps

STOP LP Stoplamps

TBC BATTTruck Body Controller

Battery Feed

SUNROOF Sunroof

5-117