sensor CADILLAC ESCALADE EXT 2004 2.G User Guide

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2004, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2004 2.GPages: 478, PDF Size: 3.43 MB

Page 202 of 478

DIC Warnings and Messages

Warning messages are displayed on the DIC to notify

the driver that the status of the vehicle has changed and

that some action may be needed by the driver to

correct the condition. If there is more than one message

that needs to be displayed they will appear one after

another. Some messages may not require immediate

action but you should press the select button to

acknowledge that you received the message and clear it

from the display. Some messages cannot be cleared

from the display because they are more urgent;

these messages require action before they can be

removed from the DIC display. The following are the

possible messages that can be displayed and some

information about them.

CHANGE ENGINE OIL

This message is displayed when the engine oil needs to

be changed. SeeGM Oil Life Systempreviously in

this section for information on how to reset the message.

This message will clear itself after 10 seconds until

the next ignition cycle.

OIL LIFE RESET

This message will appear on the display for about

10 seconds after resetting the change engine oil

message.

OIL PRESSURE LOW

If low oil pressure levels occur, this message will be

displayed on the DIC and a chime will sound. Stop the

vehicle as soon as safely possible and do not operate

it until the cause of the low oil pressure has been

corrected. Check your oil as soon as possible and have

your vehicle serviced.

CHECK OIL LEVEL

If the oil level in the vehicle is low, this message will

appear on the DIC. Check the oil level and correct it as

necessary. You may need to let the vehicle cool or

warm up and cycle the ignition to be sure this message

will clear. Once the problem is corrected, pressing

the select button will clear this message from the DIC

display. This message will clear itself after 10 seconds

until the next ignition cycle.

LOW COOLANT LEVEL

If your vehicle has a low coolant sensor and the engine

coolant level is low, this message will appear on the

DIC. Adding coolant will clear the message. This

message will clear itself after 10 seconds until the next

ignition cycle.

3-60

Page 209 of 478

CHECK TIRE PRESSURE

If a low tire pressure is detected in any of the vehicle's

tires, this message will appear on the DIC. Press

the select button to clear it from the DIC display. It will

appear at each ignition cycle until the tires are

in¯ated to the correct in¯ation pressure.

See

Tires on page 5-63for more information on tires

and the correct in¯ation pressures.

SERVICE TIRE MONITOR

This message will be displayed if any of the tire monitor

sensors have malfunctioned, or if the tire monitor

sensors have not been programmed, or if the

recommended tire pressures are not programmed.

Press the select button to clear it from the DIC display.

Audio System(s)

Notice:Before you add any sound equipment to

your vehicle ± like a tape player, CB radio, mobile

telephone or two-way radio ± be sure you can

add what you want. If you can, it's very important to

do it properly. Added sound equipment may

interfere with the operation of your vehicle's engine,

radio or other systems, and even damage them.

Your vehicle's systems may interfere with the

operation of sound equipment that has been added

improperly.

So, before adding sound equipment, check with

your dealer and be sure to check federal rules

covering mobile radio and telephone units.

Your audio system has been designed to operate easily

and to give years of listening pleasure. You will get

the most enjoyment out of it if you acquaint yourself with

it ®rst. Figure out which radio you have in your vehicle,

®nd out what your audio system can do and how to

operate all of its controls to be sure you're getting the

most out of the advanced engineering that went into it.

Your vehicle has a feature called Retained Accessory

Power (RAP). With RAP, you can play your audio

system even after the ignition is turned off. See

ªRetained Accessory Power (RAP)º under

Ignition

Positions on page 2-30.

3-67

Page 382 of 478

Tire Pressure Monitor System

The Tire Pressure Monitor (TPM) system uses radio

and sensor technology to check tire pressure levels. If

your vehicle has this feature, sensors are mounted

on each tire and wheel assembly, except the spare tire.

The TPM sensors transmit tire pressure readings to

a receiver located in the vehicle.

When a low tire pressure condition is detected, the TPM

system will display the CHECK TIRE PRESSURE

warning message on the Driver Information Center

(DIC); and at the same time illuminate the low tire

pressure warning symbol. For additional information and

details about the DIC operation and displays see DIC

Operation and Displays on page 3-49andDIC Warnings

and Messages on page 3-60.

When the tire pressure

monitoring system warning

light is lit, one or more

of your tires is signi®cantly

under-in¯ated.You should stop and check your tires as soon as

possible, and in¯ate them to the proper pressure as

indicated on the vehicle's tire information placard.

Driving on a signi®cantly under-in¯ated tire causes the

tire to overheat and can lead to tire failure.

Under-in¯ation also reduces fuel efficiency and tire tread

life, and may affect the vehicle's handling and stopping

ability. Each tire, including the spare, should be

checked monthly when cold and set to the

recommended in¯ation pressure as speci®ed in the

vehicle placard and owner's manual.

The Certi®cation/Tire label or the Tire and Loading

Information label (tire information placard) shows the

size of your vehicle's original tires and the correct

in¯ation pressure for your vehicle's tires when they are

cold. SeeIn¯ation - Tire Pressure on page 5-71. For

the location of the tire and loading information label, see

Loading Your Vehicle on page 4-47.

Your vehicle's TPM system can alert you about a low

tire pressure condition but it does not replace normal tire

maintenance. See

Tire Inspection and Rotation on

page 5-74andTires on page 5-63.

Notice:Do not use a tire sealant if your vehicle is

equipped with Tire Pressure Monitors. The liquid

sealant can damage the tire pressure monitor

sensors.

5-72

Page 383 of 478

TPM Sensor Identi®cation Codes

Each TPM sensor has a unique identi®cation code. Any

time you rotate your vehicle's tires or replace one or

more of the TPM sensors, the identi®cation codes

will need to be matched to the new tire/wheel position.

Each tire/wheel position is matched to a sensor, by

increasing or decreasing the tire's air pressure.

The sensors are matched to the tire/wheel positions in

the following order: left front (LF); right front (RF);

right rear (RR) and left rear (LR).

You will have one minute to match the ®rst tire/wheel

position, and ®ve minutes overall to match all four

tire/wheel positions. If it takes longer than one minute,

to match the ®rst tire and wheel, or more than ®ve

minutes to match all four tire and wheel positions the

matching process stops and you will need to start over.

The TPM sensor matching process is outlined below:

1. Set the Parking brake.

2. Turn the ignition switch to RUN with the engine off.3. Turn the exterior lamp switch from ªOffº to ªOnº

four times within 3 seconds. A double horn chirp

will sound and the TPM low tire warning light

will begin to ¯ash. The double horn chirp and

¯ashing TPM warning light indicate that the TPM

matching process has started. The TPM warning

light should continue ¯ashing throughout the

matching procedure. The SERVICE TIRE

MONITOR message will be displayed on the Driver

Information Center (DIC).

4. Start with the left (driver's side) front tire.

5. Remove the valve cap from the valve cap stem.

Activate the TPM sensor by increasing or

decreasing the tire's air pressure for 10 seconds,

then stop and listen for a single horn chirp.

The single horn chirp should sound within

15 seconds, con®rming that the sensor identi®cation

code has been matched to this tire and wheel

position. If you do not hear the con®rming single

horn chirp, you will need to start over with step

number one. To let air-pressure out of a tire you can

use the pointy end of the valve cap, a pencil-style

air pressure gage or a key.

5-73

Page 384 of 478

6. Proceed to the right (passenger's side) front tire,

and repeat the procedure in step 5.

7. Proceed to the right (passenger's side) rear tire,

and repeat the procedure in step 5.

8. Proceed to the left (driver's side) rear tire, and

repeat the procedure in step 5.

9. After hearing the con®rming horn chirp for the left

rear tire, check to see if the TPM warning light is

still ¯ashing. If yes, turn the ignition switch to OFF.

10. Set all four tires to the recommended air pressure

level as indicated on the Certi®cation/Tire label or

the Tire and Loading Information label.

11. Put the valve caps back on the valve stems

The spare tire does not have a TPM sensor. If you

replace one of the road tires with the spare, the CHECK

TIRE PRESSURE message will be displayed on the

DIC screen. This message should go off once you

re-install the road tire containing the TPM sensor. The

SERVICE TIRE MONITOR message is displayed

when the TPM system is malfunctioning. One or more

missing or inoperable TPM sensors will cause the

service tire monitor message to be displayed. See your

dealer for service.Federal Communications Commission and

Industry and Science Canada

The TPM system operates on a radio frequency subject

to Federal Communications Commission (FCC) Rules

and with Industry and Science Canada.

This device complies with Part 15 of the FCC Rules and

with RSS-210 of Industry and Science Canada.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and

(2) this device must accept any interference received

including interference that may cause undesired

operation of the device.

Changes or modi®cations to this system by other than

an authorized service facility could void authorization to

use this equipment.

Tire Inspection and Rotation

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km).

Any time you notice unusual wear, rotate your tires as

soon as possible and check wheel alignment. Also

check for damaged tires or wheels. See

When It Is Time

for New Tires on page 5-76andWheel Replacement

on page 5-80for more information.

5-74

Page 385 of 478

Make sure the spare tire is stored securely. Push, pull,

and then try to rotate or turn the tire. If it moves,

use the ratchet/wheel wrench to tighten the cable. See

Changing a Flat Tire on page 5-83.

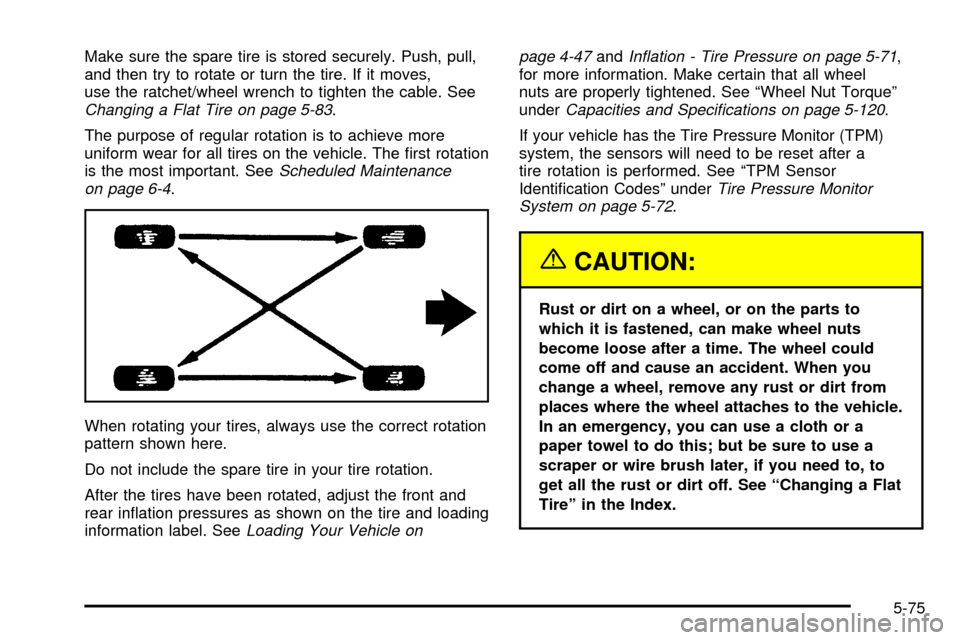

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The ®rst rotation

is the most important. See

Scheduled Maintenance

on page 6-4.

When rotating your tires, always use the correct rotation

pattern shown here.

Do not include the spare tire in your tire rotation.

After the tires have been rotated, adjust the front and

rear in¯ation pressures as shown on the tire and loading

information label. See

Loading Your Vehicle onpage 4-47

andIn¯ation - Tire Pressure on page 5-71,

for more information. Make certain that all wheel

nuts are properly tightened. See ªWheel Nut Torqueº

under

Capacities and Speci®cations on page 5-120.

If your vehicle has the Tire Pressure Monitor (TPM)

system, the sensors will need to be reset after a

tire rotation is performed. See ªTPM Sensor

Identi®cation Codesº under

Tire Pressure Monitor

System on page 5-72.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if you need to, to

get all the rust or dirt off. See ªChanging a Flat

Tireº in the Index.

5-75

Page 427 of 478

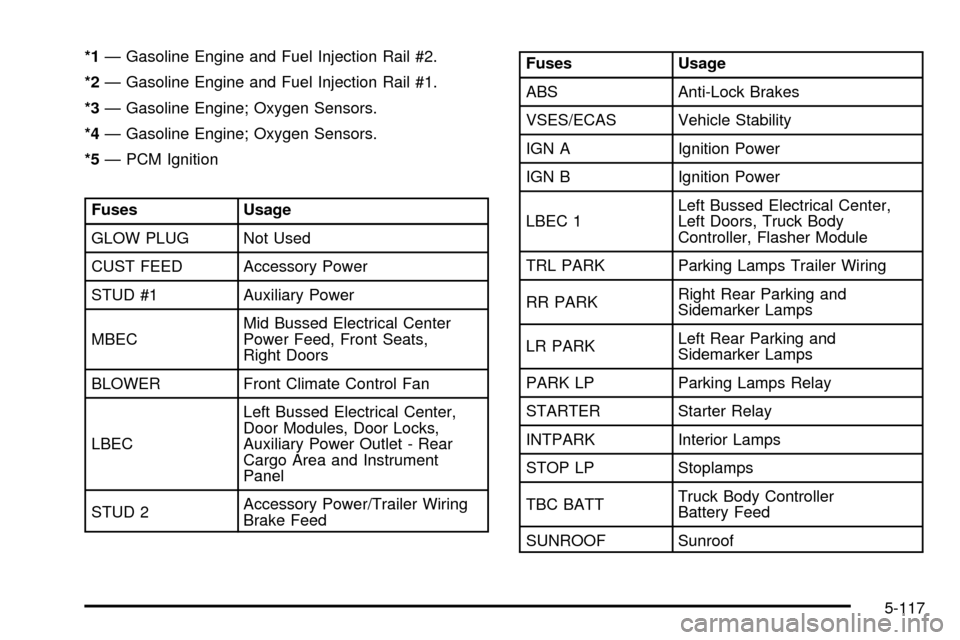

*1Ð Gasoline Engine and Fuel Injection Rail #2.

*2Ð Gasoline Engine and Fuel Injection Rail #1.

*3Ð Gasoline Engine; Oxygen Sensors.

*4Ð Gasoline Engine; Oxygen Sensors.

*5Ð PCM Ignition

Fuses Usage

GLOW PLUG Not Used

CUST FEED Accessory Power

STUD #1 Auxiliary Power

MBECMid Bussed Electrical Center

Power Feed, Front Seats,

Right Doors

BLOWER Front Climate Control Fan

LBECLeft Bussed Electrical Center,

Door Modules, Door Locks,

Auxiliary Power Outlet - Rear

Cargo Area and Instrument

Panel

STUD 2Accessory Power/Trailer Wiring

Brake Feed

Fuses Usage

ABS Anti-Lock Brakes

VSES/ECAS Vehicle Stability

IGN A Ignition Power

IGN B Ignition Power

LBEC 1Left Bussed Electrical Center,

Left Doors, Truck Body

Controller, Flasher Module

TRL PARK Parking Lamps Trailer Wiring

RR PARKRight Rear Parking and

Sidemarker Lamps

LR PARKLeft Rear Parking and

Sidemarker Lamps

PARK LP Parking Lamps Relay

STARTER Starter Relay

INTPARK Interior Lamps

STOP LP Stoplamps

TBC BATTTruck Body Controller

Battery Feed

SUNROOF Sunroof

5-117

Page 428 of 478

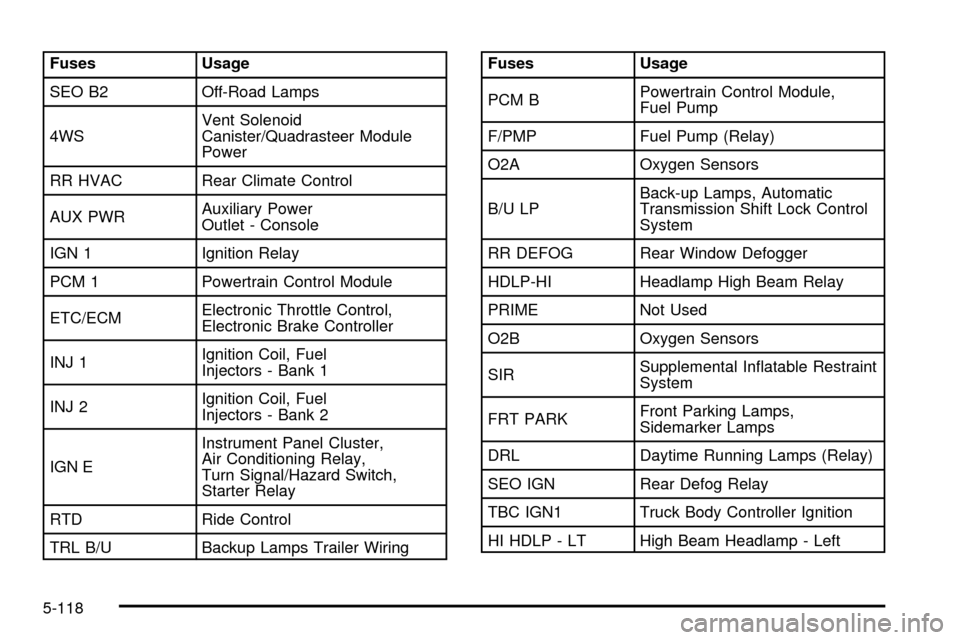

Fuses Usage

SEO B2 Off-Road Lamps

4WSVent Solenoid

Canister/Quadrasteer Module

Power

RR HVAC Rear Climate Control

AUX PWRAuxiliary Power

Outlet - Console

IGN 1 Ignition Relay

PCM 1 Powertrain Control Module

ETC/ECMElectronic Throttle Control,

Electronic Brake Controller

INJ 1Ignition Coil, Fuel

Injectors - Bank 1

INJ 2Ignition Coil, Fuel

Injectors - Bank 2

IGN EInstrument Panel Cluster,

Air Conditioning Relay,

Turn Signal/Hazard Switch,

Starter Relay

RTD Ride Control

TRL B/U Backup Lamps Trailer WiringFuses Usage

PCM BPowertrain Control Module,

Fuel Pump

F/PMP Fuel Pump (Relay)

O2A Oxygen Sensors

B/U LPBack-up Lamps, Automatic

Transmission Shift Lock Control

System

RR DEFOG Rear Window Defogger

HDLP-HI Headlamp High Beam Relay

PRIME Not Used

O2B Oxygen Sensors

SIRSupplemental In¯atable Restraint

System

FRT PARKFront Parking Lamps,

Sidemarker Lamps

DRL Daytime Running Lamps (Relay)

SEO IGN Rear Defog Relay

TBC IGN1 Truck Body Controller Ignition

HI HDLP - LT High Beam Headlamp - Left

5-118