CADILLAC ESCALADE EXT 2004 2.G Owners Manual

Manufacturer: CADILLAC, Model Year: 2004, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2004 2.GPages: 478, PDF Size: 3.43 MB

Page 381 of 478

In¯ation - Tire Pressure

The tire and loading information label, shows the correct

in¯ation pressures for your tires when they're cold.

ªColdº means your vehicle has been sitting for at least

three hours or driven no more than 1 mile (1.6 km). See

Loading Your Vehicle on page 4-47, for the location

of your vehicle's tire and loading information label.

Notice:Don't let anyone tell you that underin¯ation

or overin¯ation is all right. It's not. If your tires

don't have enough air (underin¯ation), you can get

the following:

·Too much ¯exing

·Too much heat

·Tire overloading

·Bad wear

·Bad handling

·Bad fuel economy

If your tires have too much air (overin¯ation), you

can get the following:

·Unusual wear

·Bad handling

·Rough ride

·Needless damage from road hazards

When to Check

Check your tires once a month or more.

Also, check the tire pressure of the spare tire.

How to Check

Use a good quality pocket-type gage to check tire

pressure. You can't tell if your tires are properly in¯ated

simply by looking at them. Radial tires may look

properly in¯ated even when they're underin¯ated. Check

the tire's in¯ation pressure when the tires are cold.

cold means your vehicle has been sitting for at least

three hours or driven no more than 1 mile (1.6 km).

Remove the valve cap from the tire valve stem. Press

the tire gage ®rmly onto the valve to get a pressure

measurement. If the cold tire in¯ation pressure matches

the recommended pressure on the tire and loading

information label, no further adjustment is necessary. If

the pressure is low, add air until you reach the

recommended amount.

If you over®ll the tire, release air by pushing on the

metal stem in the center of the tire valve. Recheck the

tire pressure with the tire gage.

Be sure to put the valve caps back on the valve stems.

They help prevent leaks by keeping out dirt and

moisture.

5-71

Page 382 of 478

Tire Pressure Monitor System

The Tire Pressure Monitor (TPM) system uses radio

and sensor technology to check tire pressure levels. If

your vehicle has this feature, sensors are mounted

on each tire and wheel assembly, except the spare tire.

The TPM sensors transmit tire pressure readings to

a receiver located in the vehicle.

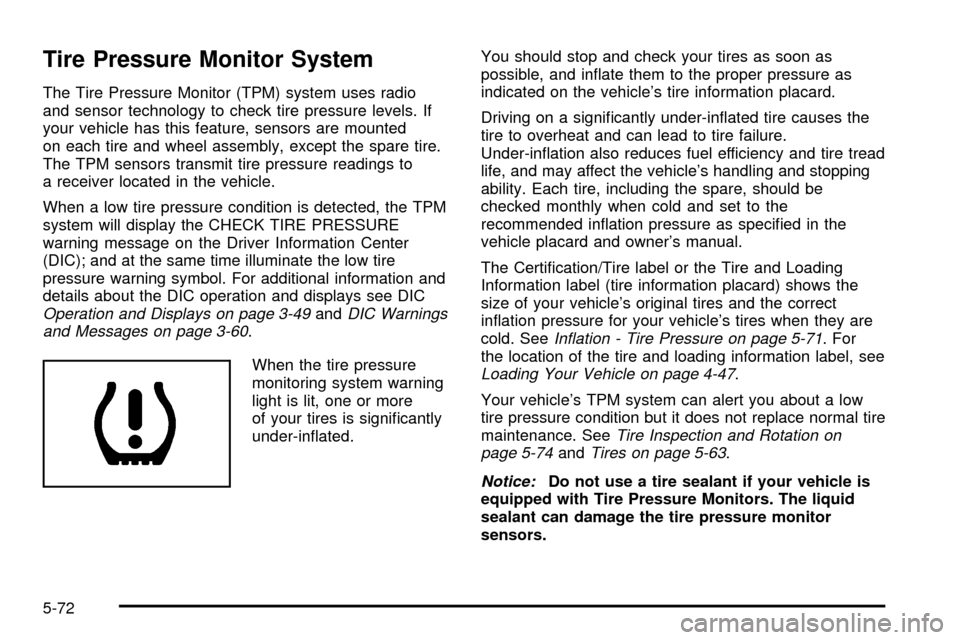

When a low tire pressure condition is detected, the TPM

system will display the CHECK TIRE PRESSURE

warning message on the Driver Information Center

(DIC); and at the same time illuminate the low tire

pressure warning symbol. For additional information and

details about the DIC operation and displays see DIC

Operation and Displays on page 3-49andDIC Warnings

and Messages on page 3-60.

When the tire pressure

monitoring system warning

light is lit, one or more

of your tires is signi®cantly

under-in¯ated.You should stop and check your tires as soon as

possible, and in¯ate them to the proper pressure as

indicated on the vehicle's tire information placard.

Driving on a signi®cantly under-in¯ated tire causes the

tire to overheat and can lead to tire failure.

Under-in¯ation also reduces fuel efficiency and tire tread

life, and may affect the vehicle's handling and stopping

ability. Each tire, including the spare, should be

checked monthly when cold and set to the

recommended in¯ation pressure as speci®ed in the

vehicle placard and owner's manual.

The Certi®cation/Tire label or the Tire and Loading

Information label (tire information placard) shows the

size of your vehicle's original tires and the correct

in¯ation pressure for your vehicle's tires when they are

cold. SeeIn¯ation - Tire Pressure on page 5-71. For

the location of the tire and loading information label, see

Loading Your Vehicle on page 4-47.

Your vehicle's TPM system can alert you about a low

tire pressure condition but it does not replace normal tire

maintenance. See

Tire Inspection and Rotation on

page 5-74andTires on page 5-63.

Notice:Do not use a tire sealant if your vehicle is

equipped with Tire Pressure Monitors. The liquid

sealant can damage the tire pressure monitor

sensors.

5-72

Page 383 of 478

TPM Sensor Identi®cation Codes

Each TPM sensor has a unique identi®cation code. Any

time you rotate your vehicle's tires or replace one or

more of the TPM sensors, the identi®cation codes

will need to be matched to the new tire/wheel position.

Each tire/wheel position is matched to a sensor, by

increasing or decreasing the tire's air pressure.

The sensors are matched to the tire/wheel positions in

the following order: left front (LF); right front (RF);

right rear (RR) and left rear (LR).

You will have one minute to match the ®rst tire/wheel

position, and ®ve minutes overall to match all four

tire/wheel positions. If it takes longer than one minute,

to match the ®rst tire and wheel, or more than ®ve

minutes to match all four tire and wheel positions the

matching process stops and you will need to start over.

The TPM sensor matching process is outlined below:

1. Set the Parking brake.

2. Turn the ignition switch to RUN with the engine off.3. Turn the exterior lamp switch from ªOffº to ªOnº

four times within 3 seconds. A double horn chirp

will sound and the TPM low tire warning light

will begin to ¯ash. The double horn chirp and

¯ashing TPM warning light indicate that the TPM

matching process has started. The TPM warning

light should continue ¯ashing throughout the

matching procedure. The SERVICE TIRE

MONITOR message will be displayed on the Driver

Information Center (DIC).

4. Start with the left (driver's side) front tire.

5. Remove the valve cap from the valve cap stem.

Activate the TPM sensor by increasing or

decreasing the tire's air pressure for 10 seconds,

then stop and listen for a single horn chirp.

The single horn chirp should sound within

15 seconds, con®rming that the sensor identi®cation

code has been matched to this tire and wheel

position. If you do not hear the con®rming single

horn chirp, you will need to start over with step

number one. To let air-pressure out of a tire you can

use the pointy end of the valve cap, a pencil-style

air pressure gage or a key.

5-73

Page 384 of 478

6. Proceed to the right (passenger's side) front tire,

and repeat the procedure in step 5.

7. Proceed to the right (passenger's side) rear tire,

and repeat the procedure in step 5.

8. Proceed to the left (driver's side) rear tire, and

repeat the procedure in step 5.

9. After hearing the con®rming horn chirp for the left

rear tire, check to see if the TPM warning light is

still ¯ashing. If yes, turn the ignition switch to OFF.

10. Set all four tires to the recommended air pressure

level as indicated on the Certi®cation/Tire label or

the Tire and Loading Information label.

11. Put the valve caps back on the valve stems

The spare tire does not have a TPM sensor. If you

replace one of the road tires with the spare, the CHECK

TIRE PRESSURE message will be displayed on the

DIC screen. This message should go off once you

re-install the road tire containing the TPM sensor. The

SERVICE TIRE MONITOR message is displayed

when the TPM system is malfunctioning. One or more

missing or inoperable TPM sensors will cause the

service tire monitor message to be displayed. See your

dealer for service.Federal Communications Commission and

Industry and Science Canada

The TPM system operates on a radio frequency subject

to Federal Communications Commission (FCC) Rules

and with Industry and Science Canada.

This device complies with Part 15 of the FCC Rules and

with RSS-210 of Industry and Science Canada.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and

(2) this device must accept any interference received

including interference that may cause undesired

operation of the device.

Changes or modi®cations to this system by other than

an authorized service facility could void authorization to

use this equipment.

Tire Inspection and Rotation

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km).

Any time you notice unusual wear, rotate your tires as

soon as possible and check wheel alignment. Also

check for damaged tires or wheels. See

When It Is Time

for New Tires on page 5-76andWheel Replacement

on page 5-80for more information.

5-74

Page 385 of 478

Make sure the spare tire is stored securely. Push, pull,

and then try to rotate or turn the tire. If it moves,

use the ratchet/wheel wrench to tighten the cable. See

Changing a Flat Tire on page 5-83.

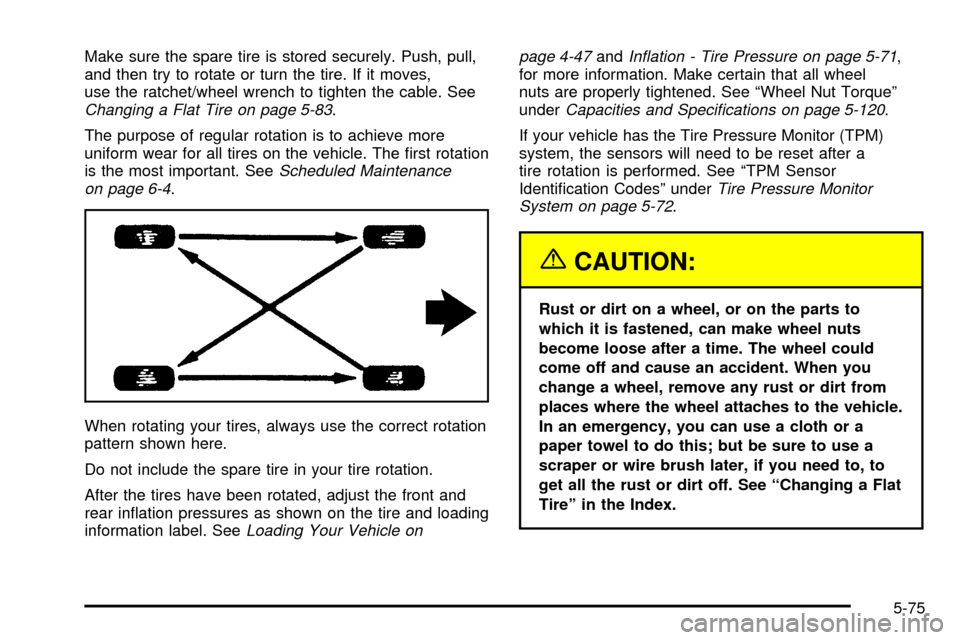

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The ®rst rotation

is the most important. See

Scheduled Maintenance

on page 6-4.

When rotating your tires, always use the correct rotation

pattern shown here.

Do not include the spare tire in your tire rotation.

After the tires have been rotated, adjust the front and

rear in¯ation pressures as shown on the tire and loading

information label. See

Loading Your Vehicle onpage 4-47

andIn¯ation - Tire Pressure on page 5-71,

for more information. Make certain that all wheel

nuts are properly tightened. See ªWheel Nut Torqueº

under

Capacities and Speci®cations on page 5-120.

If your vehicle has the Tire Pressure Monitor (TPM)

system, the sensors will need to be reset after a

tire rotation is performed. See ªTPM Sensor

Identi®cation Codesº under

Tire Pressure Monitor

System on page 5-72.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if you need to, to

get all the rust or dirt off. See ªChanging a Flat

Tireº in the Index.

5-75

Page 386 of 478

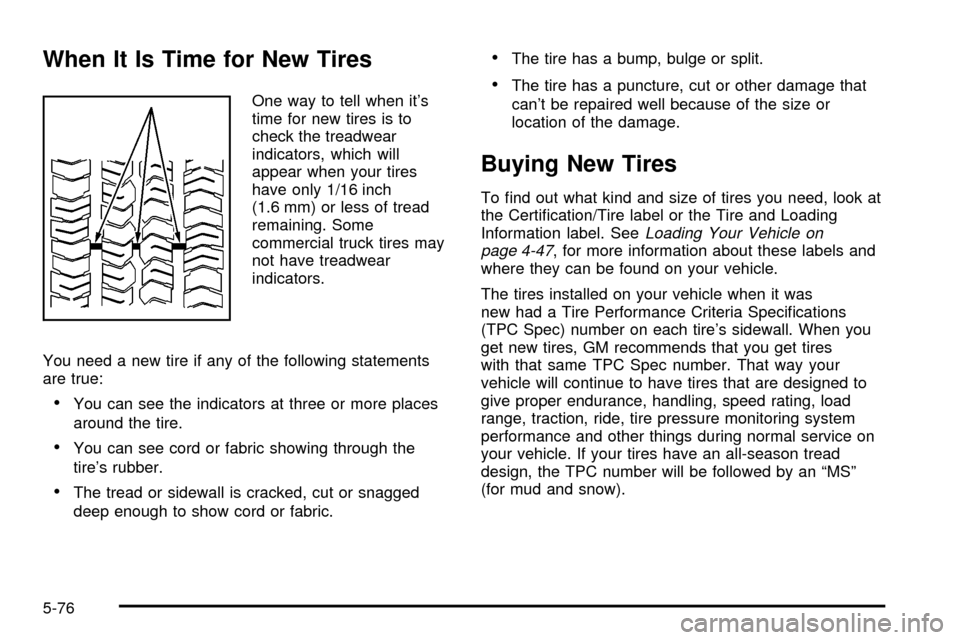

When It Is Time for New Tires

One way to tell when it's

time for new tires is to

check the treadwear

indicators, which will

appear when your tires

have only 1/16 inch

(1.6 mm) or less of tread

remaining. Some

commercial truck tires may

not have treadwear

indicators.

You need a new tire if any of the following statements

are true:

·You can see the indicators at three or more places

around the tire.

·You can see cord or fabric showing through the

tire's rubber.

·The tread or sidewall is cracked, cut or snagged

deep enough to show cord or fabric.

·The tire has a bump, bulge or split.

·The tire has a puncture, cut or other damage that

can't be repaired well because of the size or

location of the damage.

Buying New Tires

To ®nd out what kind and size of tires you need, look at

the Certi®cation/Tire label or the Tire and Loading

Information label. See

Loading Your Vehicle on

page 4-47, for more information about these labels and

where they can be found on your vehicle.

The tires installed on your vehicle when it was

new had a Tire Performance Criteria Speci®cations

(TPC Spec) number on each tire's sidewall. When you

get new tires, GM recommends that you get tires

with that same TPC Spec number. That way your

vehicle will continue to have tires that are designed to

give proper endurance, handling, speed rating, load

range, traction, ride, tire pressure monitoring system

performance and other things during normal service on

your vehicle. If your tires have an all-season tread

design, the TPC number will be followed by an ªMSº

(for mud and snow).

5-76

Page 387 of 478

When ever you replace your tires with those not having

a TPC Spec number, make sure they are the same

size, load range, speed rating and construction

type (bias, bias-belted or radial) as your original tires.

If you replace your vehicle's tires with those not having a

TPC Spec number, the tire pressure monitoring

system may give an inaccurate low pressure warning.

Non-TPC Spec tires may give a low pressure warning

that is higher or lower than the proper warning level you

would get with TPC Spec numbered tires.

{CAUTION:

Mixing tires could cause you to lose control

while driving. If you mix tires of different sizes

or types (radial and bias-belted tires), the

vehicle may not handle properly, and you

could have a crash. Using tires of different

sizes may also cause damage to your vehicle.

Be sure to use the same size and type tires on

all wheels.

CAUTION: (Continued)

CAUTION: (Continued)

Your vehicle may be equipped with a different

size spare than the road tires (those originally

installed on your vehicle). When new, your

vehicle included a spare tire and wheel

assembly with a similar overall diameter as

your vehicle's road tires and wheels, so it is all

right to drive on it. Because this spare was

developed for use on your vehicle, it will not

affect vehicle handling.

{CAUTION:

If you use bias-ply tires on your vehicle, the

wheel rim ¯anges could develop cracks after

many miles of driving. A tire and/or wheel

could fail suddenly, causing a crash. Use only

radial-ply tires with the wheels on your vehicle.

5-77

Page 388 of 478

Uniform Tire Quality Grading

Quality grades can be found where applicable on the

tire sidewall between tread shoulder and maximum

section width. For example:

Treadwear 200 Traction AA Temperature A

The following information relates to the system

developed by the United States National Highway

Traffic Safety Administration, which grades tires by

treadwear, traction and temperature performance. (This

applies only to vehicles sold in the United States.)

The grades are molded on the sidewalls of most

passenger car tires. The Uniform Tire Quality Grading

system does not apply to deep tread, winter-type

snow tires, space-saver or temporary use spare tires,

tires with nominal rim diameters of 10 to 12 inches

(25 to 30 cm), or to some limited-production tires.

While the tires available on General Motors passenger

cars and light trucks may vary with respect to these

grades, they must also conform to federal safety

requirements and additional General Motors Tire

Performance Criteria (TPC) standards.

Treadwear

The treadwear grade is a comparative rating based on

the wear rate of the tire when tested under controlled

conditions on a speci®ed government test course.

For example, a tire graded 150 would wear one and

a half (1.5) times as well on the government course as

a tire graded 100. The relative performance of tires

depends upon the actual conditions of their use,

however, and may depart signi®cantly from the norm

due to variations in driving habits, service practices and

differences in road characteristics and climate.

Traction ± AA, A, B, C

The traction grades, from highest to lowest, are AA, A,

B, and C. Those grades represent the tire's ability

to stop on wet pavement as measured under controlled

conditions on speci®ed government test surfaces of

asphalt and concrete. A tire marked C may have poor

traction performance. Warning: The traction grade

assigned to this tire is based on straight-ahead braking

traction tests, and does not include acceleration,

cornering, hydroplaning, or peak traction characteristics.

5-78

Page 389 of 478

Temperature ± A, B, C

The temperature grades are A (the highest), B, and C,

representing the tire's resistance to the generation

of heat and its ability to dissipate heat when tested

under controlled conditions on a speci®ed indoor

laboratory test wheel. Sustained high temperature can

cause the material of the tire to degenerate and

reduce tire life, and excessive temperature can lead to

sudden tire failure. The grade C corresponds to a

level of performance which all passenger car tires must

meet under the Federal Motor Vehicle Safety Standard

No. 109. Grades B and A represent higher levels of

performance on the laboratory test wheel than the

minimum required by law.

Warning: The temperature grade for this tire is

established for a tire that is properly in¯ated and not

overloaded. Excessive speed, underin¯ation, or

excessive loading, either separately or in combination,

can cause heat buildup and possible tire failure.

Wheel Alignment and Tire Balance

The wheels on your vehicle were aligned and balanced

carefully at the factory to give you the longest tire life

and best overall performance.

Scheduled wheel alignment and wheel balancing are

not needed. However, if you notice unusual tire wear or

your vehicle pulling one way or the other, the alignment

may need to be reset. If you notice your vehicle

vibrating when driving on a smooth road, your wheels

may need to be rebalanced.

5-79

Page 390 of 478

Wheel Replacement

Replace any wheel that is bent, cracked, or badly rusted

or corroded. If wheel nuts keep coming loose, the

wheel, wheel bolts and wheel nuts should be replaced.

If the wheel leaks air, replace it (except some

aluminum wheels, which can sometimes be repaired).

See your dealer if any of these conditions exist.

Your dealer will know the kind of wheel you need.

Each new wheel should have the same load-carrying

capacity, diameter, width, offset and be mounted

the same way as the one it replaces.

If you need to replace any of your wheels, wheel bolts

or wheel nuts, replace them only with new GM

original equipment parts. This way, you will be sure to

have the right wheel, wheel bolts and wheel nuts

for your vehicle.{CAUTION:

Using the wrong replacement wheels, wheel

bolts or wheel nuts on your vehicle can be

dangerous. It could affect the braking and

handling of your vehicle, make your tires lose

air and make you lose control. You could have

a collision in which you or others could be

injured. Always use the correct wheel, wheel

bolts and wheel nuts for replacement.

Notice:The wrong wheel can also cause problems

with bearing life, brake cooling, speedometer or

odometer calibration, headlamp aim, bumper height,

vehicle ground clearance and tire clearance to the

body and chassis.

See

Changing a Flat Tire on page 5-83for more

information.

5-80