trailer CADILLAC ESCALADE EXT 2005 2.G Owner's Guide

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2005, Model line: ESCALADE EXT, Model: CADILLAC ESCALADE EXT 2005 2.GPages: 460, PDF Size: 2.95 MB

Page 326 of 460

If you no longer have the overheat warning, you can

drive. Just to be safe, drive slower for about 10 minutes.

If the warning does not come back on, you can drive

normally.

If the warning continues, pull over, stop, and park your

vehicle right away.

If there is still no sign of steam and your vehicle is

equipped with an engine-driven cooling fan, push down

the accelerator until the engine speed is about twice

as fast as normal idle speed for at least three minutes

while you are parked.

If there is still no sign of steam and your vehicle is

equipped with an electric engine cooling fan, idle the

engine for three minutes while you are parked.

If you still have the warning,turn off the engine and get

everyone out of the vehicleuntil it cools down. Also,

see “Overheated Engine Protection Operating Mode”

later in this section.

You may decide not to lift the hood but to get service

help right away.Overheated Engine Protection

Operating Mode

If an overheated engine condition exists and the

REDUCED ENGINE POWER message is displayed,

an overheat protection mode which alternates �ring

groups of cylinders helps prevent engine damage. In this

mode, you will notice a loss in power and engine

performance. This operating mode allows your vehicle

to be driven to a safe place in an emergency. Driving

extended miles (km) and/or towing a trailer in the

overheat protection mode should be avoided.

Notice:After driving in the overheated engine

protection operating mode, to avoid engine damage,

allow the engine to cool before attempting any

repair. The engine oil will be severely degraded.

Repair the cause of coolant loss, change the oil and

reset the oil life system. SeeEngine Oil on

page 5-13.

5-28

Page 332 of 460

Engine Fan Noise

If your vehicle is equipped with a clutched engine

cooling fan, when the clutch is engaged, the fan spins

faster to provide more air to cool the engine. In

most everyday driving conditions, the fan is spinning

slower and the clutch is not fully engaged. This improves

fuel economy and reduces fan noise. Under heavy

vehicle loading, trailer towing, and/or high outside

temperatures, the fan speed increases as the clutch

more fully engages, so you may hear an increase in fan

noise. This is normal and should not be mistaken as

the transmission slipping or making extra shifts. It

is merely the cooling system functioning properly. The

fan will slow down when additional cooling is not

required and the clutch disengages.

You may also hear this fan noise when you start the

engine. It will go away as the fan clutch partially

disengages.If your vehicle is equipped with electric cooling fans, you

may hear the fans spinning at low speed during most

everyday driving. The fans may turn off if no cooling is

required. Under heavy vehicle loading, trailer towing,

and/or high outside temperatures, or if you are operating

your air conditioning system, the fans change to high

speed and you may hear an increase in fan noise. This

is normal and indicates that the cooling system is

functioning properly. The fans will change to low speed

when additional cooling is no longer required.

5-34

Page 405 of 460

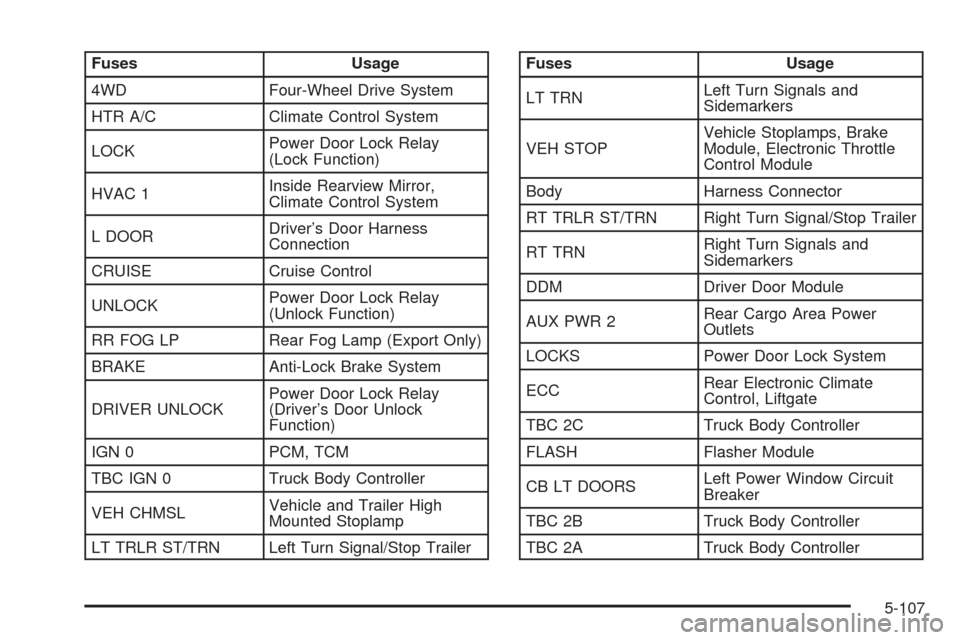

Fuses Usage

4WD Four-Wheel Drive System

HTR A/C Climate Control System

LOCKPower Door Lock Relay

(Lock Function)

HVAC 1Inside Rearview Mirror,

Climate Control System

L DOORDriver’s Door Harness

Connection

CRUISE Cruise Control

UNLOCKPower Door Lock Relay

(Unlock Function)

RR FOG LP Rear Fog Lamp (Export Only)

BRAKE Anti-Lock Brake System

DRIVER UNLOCKPower Door Lock Relay

(Driver’s Door Unlock

Function)

IGN 0 PCM, TCM

TBC IGN 0 Truck Body Controller

VEH CHMSLVehicle and Trailer High

Mounted Stoplamp

LT TRLR ST/TRN Left Turn Signal/Stop TrailerFuses Usage

LT TRNLeft Turn Signals and

Sidemarkers

VEH STOPVehicle Stoplamps, Brake

Module, Electronic Throttle

Control Module

Body Harness Connector

RT TRLR ST/TRN Right Turn Signal/Stop Trailer

RT TRNRight Turn Signals and

Sidemarkers

DDM Driver Door Module

AUX PWR 2Rear Cargo Area Power

Outlets

LOCKS Power Door Lock System

ECCRear Electronic Climate

Control, Liftgate

TBC 2C Truck Body Controller

FLASH Flasher Module

CB LT DOORSLeft Power Window Circuit

Breaker

TBC 2B Truck Body Controller

TBC 2A Truck Body Controller

5-107

Page 406 of 460

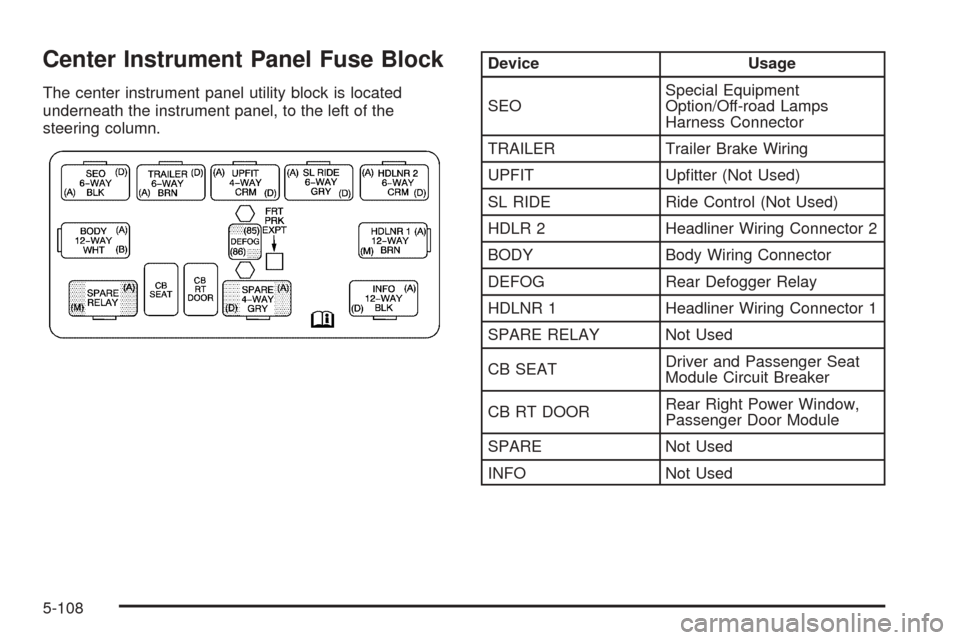

Center Instrument Panel Fuse Block

The center instrument panel utility block is located

underneath the instrument panel, to the left of the

steering column.

Device Usage

SEOSpecial Equipment

Option/Off-road Lamps

Harness Connector

TRAILER Trailer Brake Wiring

UPFIT Up�tter (Not Used)

SL RIDE Ride Control (Not Used)

HDLR 2 Headliner Wiring Connector 2

BODY Body Wiring Connector

DEFOG Rear Defogger Relay

HDLNR 1 Headliner Wiring Connector 1

SPARE RELAY Not Used

CB SEATDriver and Passenger Seat

Module Circuit Breaker

CB RT DOORRear Right Power Window,

Passenger Door Module

SPARE Not Used

INFO Not Used

5-108

Page 409 of 460

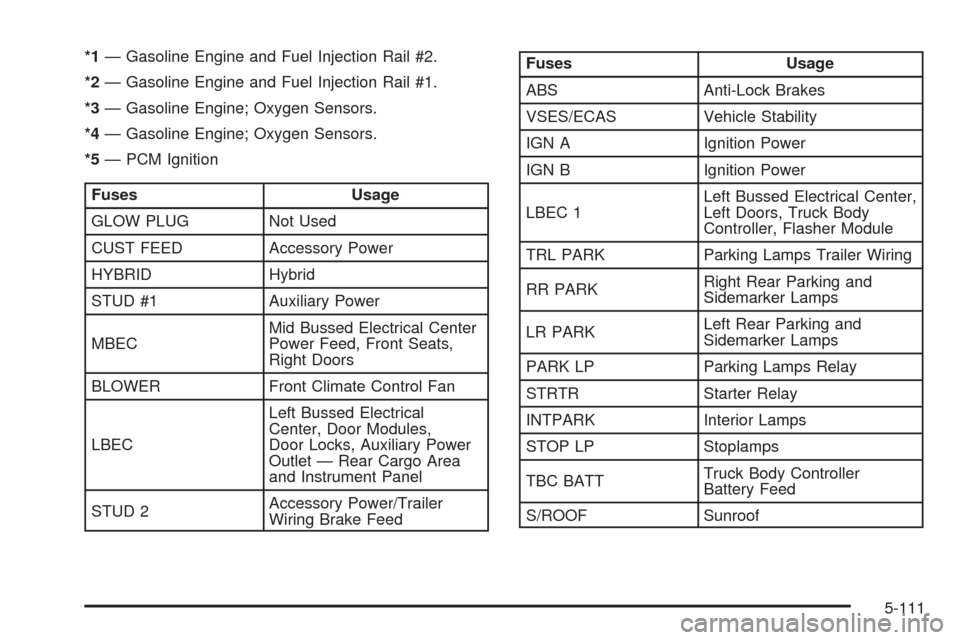

*1— Gasoline Engine and Fuel Injection Rail #2.

*2— Gasoline Engine and Fuel Injection Rail #1.

*3— Gasoline Engine; Oxygen Sensors.

*4— Gasoline Engine; Oxygen Sensors.

*5— PCM Ignition

Fuses Usage

GLOW PLUG Not Used

CUST FEED Accessory Power

HYBRID Hybrid

STUD #1 Auxiliary Power

MBECMid Bussed Electrical Center

Power Feed, Front Seats,

Right Doors

BLOWER Front Climate Control Fan

LBECLeft Bussed Electrical

Center, Door Modules,

Door Locks, Auxiliary Power

Outlet — Rear Cargo Area

and Instrument Panel

STUD 2Accessory Power/Trailer

Wiring Brake Feed

Fuses Usage

ABS Anti-Lock Brakes

VSES/ECAS Vehicle Stability

IGN A Ignition Power

IGN B Ignition Power

LBEC 1Left Bussed Electrical Center,

Left Doors, Truck Body

Controller, Flasher Module

TRL PARK Parking Lamps Trailer Wiring

RR PARKRight Rear Parking and

Sidemarker Lamps

LR PARKLeft Rear Parking and

Sidemarker Lamps

PARK LP Parking Lamps Relay

STRTR Starter Relay

INTPARK Interior Lamps

STOP LP Stoplamps

TBC BATTTruck Body Controller

Battery Feed

S/ROOF Sunroof

5-111

Page 410 of 460

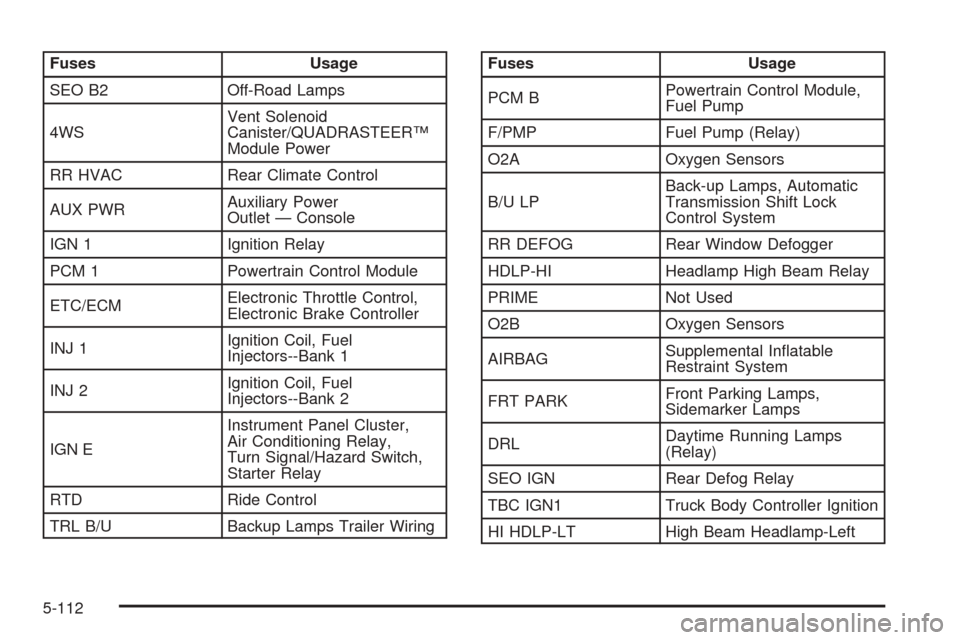

Fuses Usage

SEO B2 Off-Road Lamps

4WSVent Solenoid

Canister/QUADRASTEER™

Module Power

RR HVAC Rear Climate Control

AUX PWRAuxiliary Power

Outlet — Console

IGN 1 Ignition Relay

PCM 1 Powertrain Control Module

ETC/ECMElectronic Throttle Control,

Electronic Brake Controller

INJ 1Ignition Coil, Fuel

Injectors--Bank 1

INJ 2Ignition Coil, Fuel

Injectors--Bank 2

IGN EInstrument Panel Cluster,

Air Conditioning Relay,

Turn Signal/Hazard Switch,

Starter Relay

RTD Ride Control

TRL B/U Backup Lamps Trailer WiringFuses Usage

PCM BPowertrain Control Module,

Fuel Pump

F/PMP Fuel Pump (Relay)

O2A Oxygen Sensors

B/U LPBack-up Lamps, Automatic

Transmission Shift Lock

Control System

RR DEFOG Rear Window Defogger

HDLP-HI Headlamp High Beam Relay

PRIME Not Used

O2B Oxygen Sensors

AIRBAGSupplemental In�atable

Restraint System

FRT PARKFront Parking Lamps,

Sidemarker Lamps

DRLDaytime Running Lamps

(Relay)

SEO IGN Rear Defog Relay

TBC IGN1 Truck Body Controller Ignition

HI HDLP-LT High Beam Headlamp-Left

5-112

Page 422 of 460

(b)Visually inspect front and rear suspension and

steering system for damaged, loose or missing parts,

signs of wear or lack of lubrication. Inspect power

steering lines and hoses for proper hook-up, binding,

leaks, cracks, cha�ng, etc. Visually check constant

velocity joints, rubber boots and axle seals for leaks.

(c)Visually inspect hoses and have them replaced if they

are cracked, swollen or deteriorated. Inspect all pipes,

�ttings and clamps; replace with genuine GM parts as

needed. To help ensure proper operation, a pressure test

of the cooling system and pressure cap and cleaning the

outside of the radiator and air conditioning condenser is

recommended at least once a year.

(d)Visually inspect wiper blades for wear or cracking.

Replace blade inserts that appear worn or damaged

or that streak or miss areas of the windshield.

(e)Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages

are working properly. Look for any other loose or

damaged safety belt system parts. If you see anything

that might keep a safety belt system from doing its

job, have it repaired. Have any torn or frayed safety belts

replaced. Also look for any opened or broken airbag

coverings, and have them repaired or replaced.

(The airbag system does not need regular maintenance.)(f)Lubricate all key lock cylinders, hood latch assembly,

secondary latch, pivots, spring anchor, release pawl, rear

compartment hinges, outer tailgate handle pivot points,

latch bolt, fuel door hinge and folding seat hardware.

More frequent lubrication may be required when exposed

to a corrosive environment. Applying silicone grease on

weatherstrips with a clean cloth will make them last

longer, seal better and not stick or squeak.

(g)Inspect system. Check all fuel and vapor lines and

hoses for proper hook-up, routing and condition. Check

that the purge valve works properly (if equipped).

Replace as needed.

(h)Change automatic transmission �uid and �lter if the

vehicle is mainly driven under one or more of these

conditions:

�In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

�In hilly or mountainous terrain.

�When doing frequent trailer towing.

�Uses such as found in taxi, police or delivery

service.

(i)Drain, �ush and re�ll cooling system. This service can

be complex; you should have your dealer perform this

service. See Engine Coolant on page 5-23 for what to

use. Inspect hoses. Clean radiator, condenser, pressure

cap and �ller neck. Pressure test the cooling system and

pressure cap.

6-8

Page 458 of 460

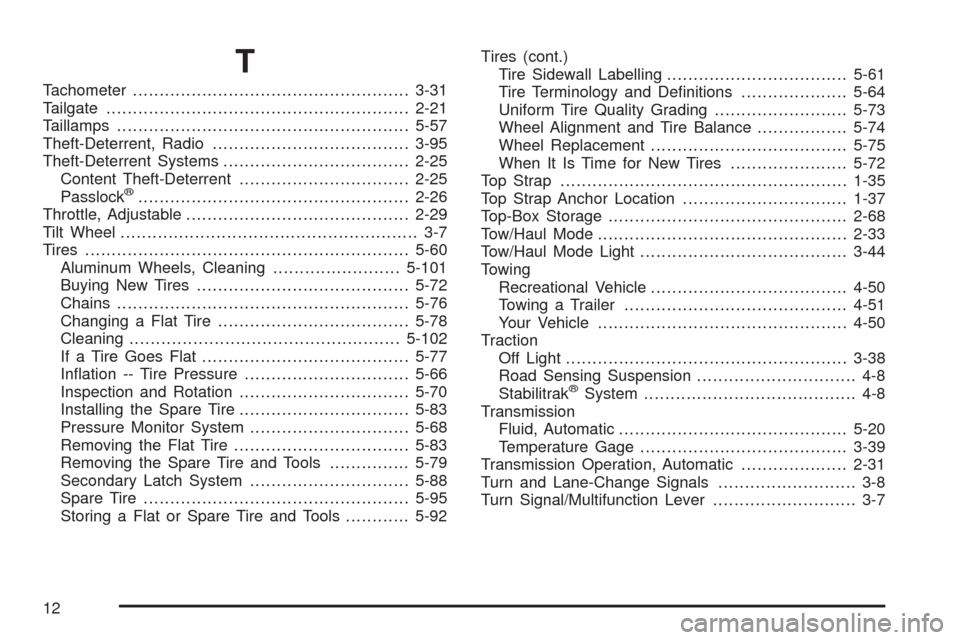

T

Tachometer....................................................3-31

Tailgate.........................................................2-21

Taillamps.......................................................5-57

Theft-Deterrent, Radio.....................................3-95

Theft-Deterrent Systems...................................2-25

Content Theft-Deterrent................................2-25

Passlock

®...................................................2-26

Throttle, Adjustable..........................................2-29

Tilt Wheel........................................................ 3-7

Tires.............................................................5-60

Aluminum Wheels, Cleaning........................5-101

Buying New Tires........................................5-72

Chains.......................................................5-76

Changing a Flat Tire....................................5-78

Cleaning...................................................5-102

If a Tire Goes Flat.......................................5-77

In�ation -- Tire Pressure...............................5-66

Inspection and Rotation................................5-70

Installing the Spare Tire................................5-83

Pressure Monitor System..............................5-68

Removing the Flat Tire.................................5-83

Removing the Spare Tire and Tools...............5-79

Secondary Latch System..............................5-88

Spare Tire..................................................5-95

Storing a Flat or Spare Tire and Tools............5-92Tires (cont.)

Tire Sidewall Labelling..................................5-61

Tire Terminology and De�nitions....................5-64

Uniform Tire Quality Grading.........................5-73

Wheel Alignment and Tire Balance.................5-74

Wheel Replacement.....................................5-75

When It Is Time for New Tires......................5-72

Top Strap......................................................1-35

Top Strap Anchor Location...............................1-37

Top-Box Storage.............................................2-68

Tow/Haul Mode...............................................2-33

Tow/Haul Mode Light.......................................3-44

Towing

Recreational Vehicle.....................................4-50

Towing a Trailer..........................................4-51

Your Vehicle...............................................4-50

Traction

Off Light.....................................................3-38

Road Sensing Suspension.............................. 4-8

Stabilitrak

®System........................................ 4-8

Transmission

Fluid, Automatic...........................................5-20

Temperature Gage.......................................3-39

Transmission Operation, Automatic....................2-31

Turn and Lane-Change Signals.......................... 3-8

Turn Signal/Multifunction Lever........................... 3-7

12