wheel torque CADILLAC SEVILLE 1993 4.G Owners Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 1993, Model line: SEVILLE, Model: CADILLAC SEVILLE 1993 4.GPages: 407, PDF Size: 22.28 MB

Page 137 of 407

Downloaded from www.Manualslib.com manuals search engine GARAGE DOOR OPENER (OPTION)

This option allows you

to open up to three

garage doors. The

transmitter unit fits the

overhead panel.

Your Cadillac dealer can tell you about the hand held power pack unit

and the installation you’ll need at home to make this work. If your

Cadillac is equipped with an Electriclears heated windshield,

you’ll have

to be closer to the garage door for the transmitter unit to work.

FLOOR MATS

If your Cadillac is equipped with rubber-backed front and rear floor mats,

keep them clean by vacuuming and using a spot cleaner,

if necessary. Do

not machine wash.

TRACTION CONTROL SYSTEM (STS)

Tour traction control system operates only when the system senses that

one or both

of the front wheels is spinning or beginning to lose traction

while driving. This is especially useful

in slippery road conditions. The

traction control system works at all speeds. It limits wheel spin

by using

the antilock and brake systems

to apply the front brakes and by shutting

off furl injectors to reduce engine torque.

You may be able to spin the tires when accelerating from a standstill on

dry

pavement. This is normal. The “Traction Active” message will display on the

drive’s information center when the traction control system is operating.

You may feel the system working through slight movement

of the

accelerator pedal, or you may notice some noise, but this is normal.

Your driver information center is an important source

of information about

your traction control system. See “Driver Information Center” in the Index.

123

Page 221 of 407

Downloaded from www.Manualslib.com manuals search engine F

P

r

I 1

P

c

c

c

c

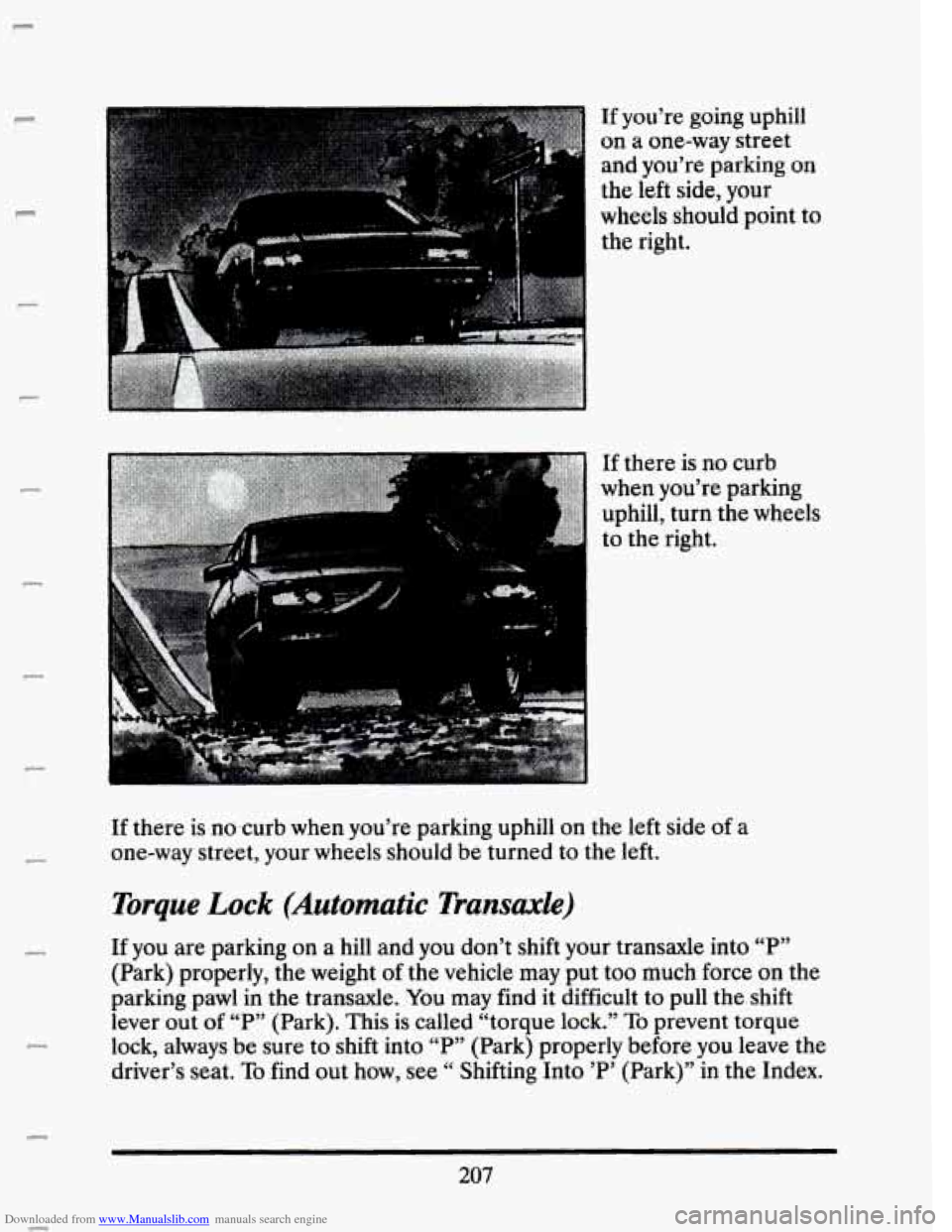

If you’re going uphill

on a one-way street

and you’re parking on

the left side, your

wheels should point to

the right.

.. , . -.

If there is no curb

when you’re parking

uphill, turn the wheels

to the right.

If there is no,curb when you’re parking uphill on the left side

of a

one-way street, your wheels should

be turned to the left.

Torque Lock (Automatic Transaxle)

If you are parking on a hill and you don’t shift your transaxle into “P”

(Park) properly, the weight

of the vehicle may put too much force on the

parking pawl in the transaxle. You may find it difficult to

pull the shift

lever out

of “P” (Park). This is called “torque lock.” To prevent torque

lock, always

be sure to shift into “P” (Park) properly before you leave the

driver’s seat.

To find out how, see “ Shifting Into ’P’ (Park)” in the Index.

c

207

P

Page 271 of 407

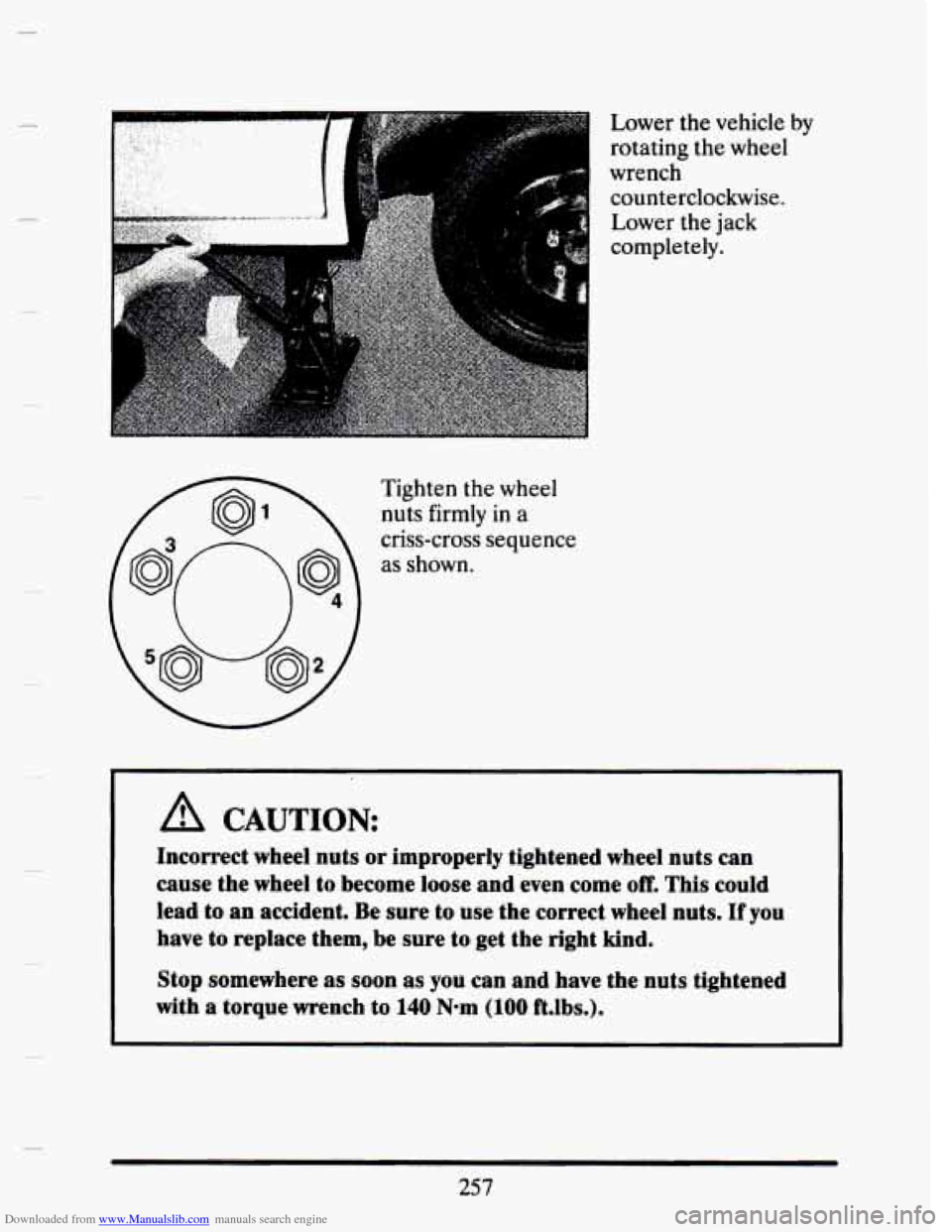

Downloaded from www.Manualslib.com manuals search engine Lower the vehicle by

rotating the wheel

wrench

counterclockwise.

Tighten the wheel nuts

firmly in a

criss-cross sequence as shown. Lower the jack

completely.

1 A CAUTION:

Incorrect wheel nuts or improperly tightened wheel nuts can

cause the wheel to become loose and even come

off. This could

lead to an accident. Be sure to use the correct wheel nuts.

If you

have to replace them, be sure to get the right kind.

Stop somewhere

as soon as you can and have the nuts tightened

with a torque wrench to 140 Nm (100 ft.lbs.).

257

Page 323 of 407

Downloaded from www.Manualslib.com manuals search engine STS recommended tire size is:

GA Performance Blackwall (P225/60ZR 16)

Don’t forget your compact spare tire. It should be at 60 psi (420 kPa).

How to Check Use a good quality pocket-type gage to check tire

pressure. Simply looking at the tires

will not tell you the pressure,

especially if you have radial tires

-- which may look properly inflated even

if they’re underinflated.

If your tires have valve caps, be sure to put them back on. They help

prevent leaks

by keeping out dirt and moisture.

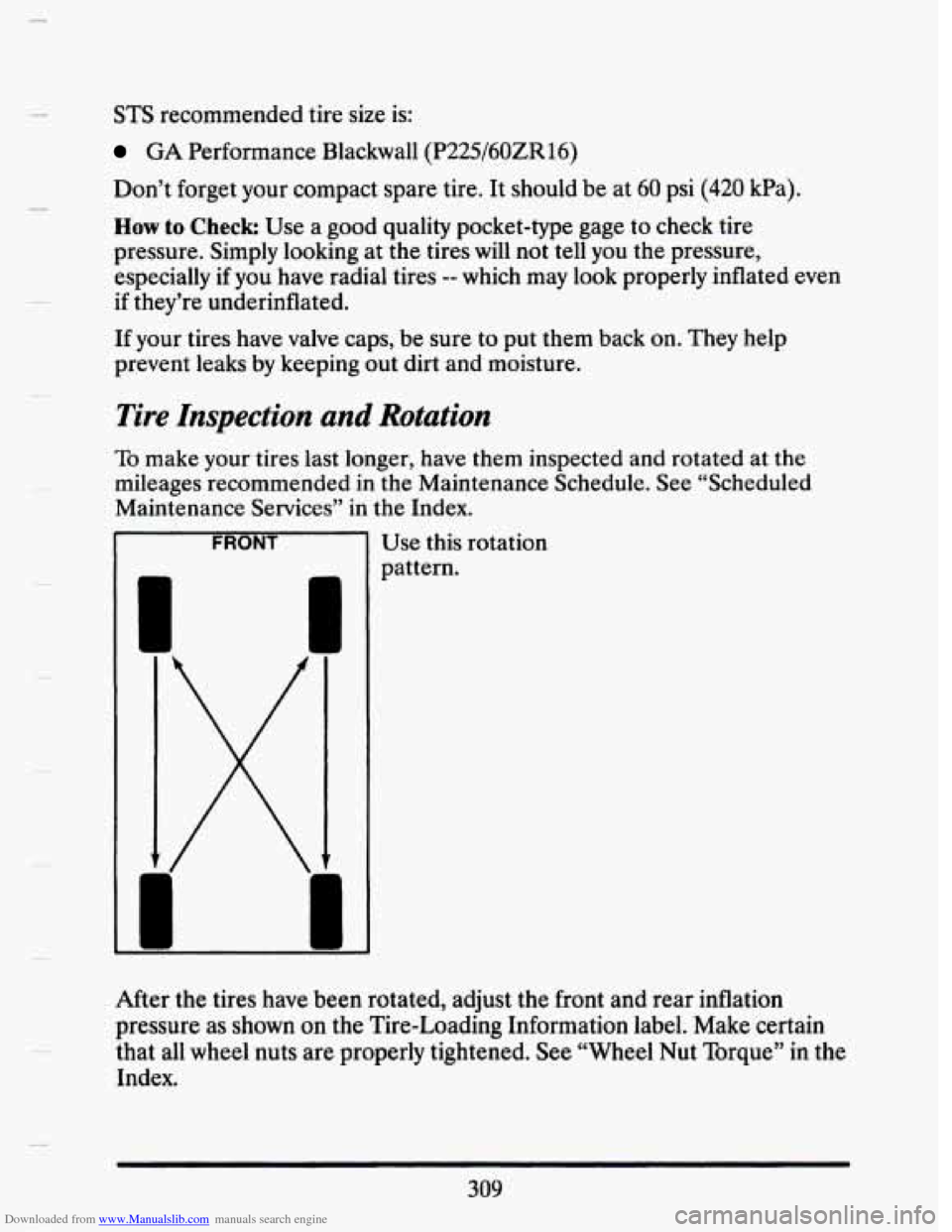

Tire Inspection and Rotation

To make your tires last longer, have them inspected and rotated at the

mileages recommended

in the Maintenance Schedule. See “Scheduled

Maintenance Services”

in the Index.

FRONT Use this rotation

pattern.

After the tires have been rotated, adjust the front and rear inflation

pressure as

shown on the Tire-Loading Information label. Make certain

that

all wheel nuts are properly tightened. See “Wheel Nut Torque’’ in the

Index.

309

Page 354 of 407

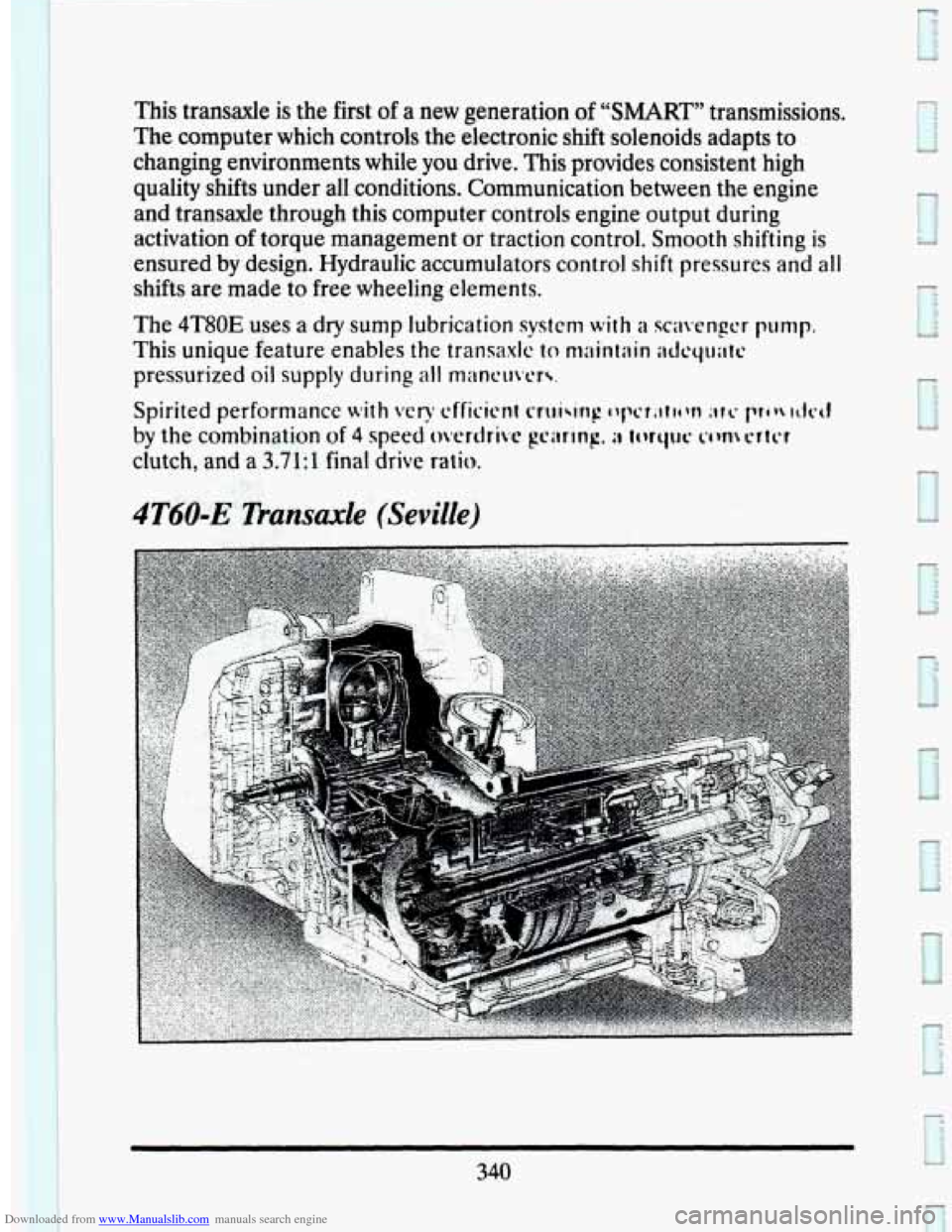

Downloaded from www.Manualslib.com manuals search engine This transaxle is the first of a new generation of “SMART” transmissions.

The computer which controls the electronic shift solenoids adapts to

changing environments while you drive. This provides consistent high

quality shifts under all conditions. Communication between the engine

and transaxle through this computer controls engine output during

activation

of torque management or traction control. Smooth shifting is

ensured by design. Hydraulic accumulators control shift pressures and all

shifts are made to free wheeling elements.

The 4T80E uses a

dry sump lubrication system with a scavenger pump.

This unique feature enables the transaxlc to maintain itdcqlriltt!

pressurized oil supply during all mancl~vcr\.

340

Page 359 of 407

Downloaded from www.Manualslib.com manuals search engine The power rack and pinion steering system has a rotary spool valve which

directs hydraulic fluid coming from the power steering pump to one side

or the other side

of the rack piston. The integral rack piston is attached to

the rack. The rack piston converts hydraulic pressure to a linear force

which moves the rack left or right. The force is then transmitted through

the inner and outer tie rods to the steering knuckles, which turn the

wheels

If hydraulic assist

is not available, manual control is maintained. However

under these conditions more steering effort is required.

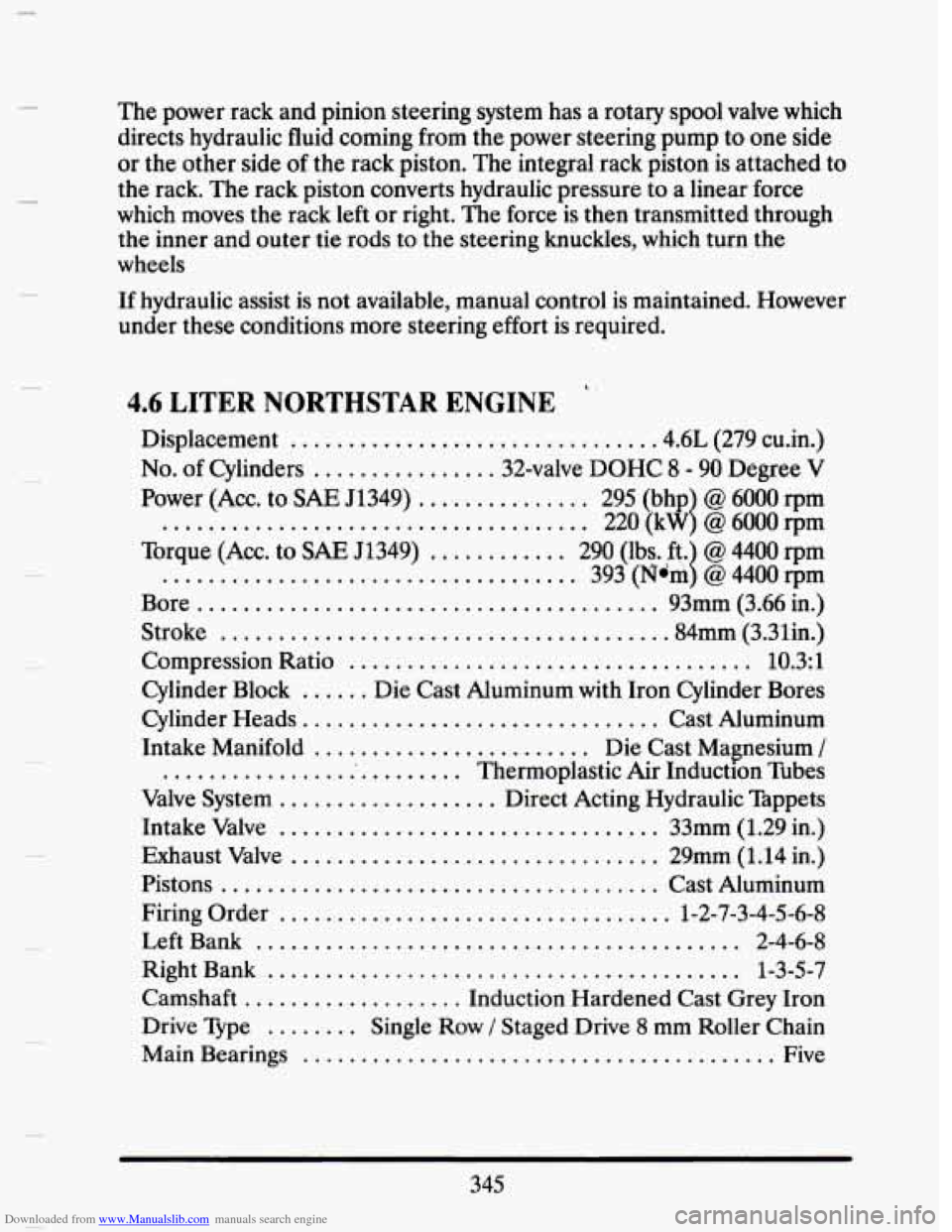

4.6 LITER NORTHSTAR ENGINE

Displacement ............................... .4.6L (279 cu.in.)

No. of Cylinders ................ 32-valve DOHC 8 - 90 Degree V

Power (Acc.

to SAE 51349) ............... 295 (bhp @ 6000 rpm

..................................... 220 (kW @ 6000rpm

Torque (ACC. to

SAE 51349) ............ 290 (lbs. ft. @ 4400 rpm

Bore ........................................ 93mm (3.66 in.)

Stroke

...................................... .84mm (3.31in.)

Compression Ratio

................................... 10.3:l

Cylinder Heads ............................... Cast Aluminum

Intake Manifold

........................ Die Cast Magnesium /

........................... Thermoplastic Air Induction nbes

Valve System

................... Direct Acting Hydraulic Tappets

Intake Valve

................................. 33mm (1.29 in.)

Exhaust Valve

................................ 29mm (1.14 in.)

Pistons

...................................... Cast Aluminum

Firing Order

.................................. 1-2-7-3-4-5-6-8

Left Bank

.......................................... 2-4-6-8

Right Bank

......................................... 1-3-5-7

Camshaft

................... Induction Hardened Cast Grey Iron

Drive Type

........ Single Row / Staged Drive 8 mm Roller Chain

Main Bearings

......................................... Five

1

1 .................................... 393 (Ndm @ 4400 rpm

Cylinder Block

...... Die Cast Aluminum with Iron Cylinder Bores

345

Page 363 of 407

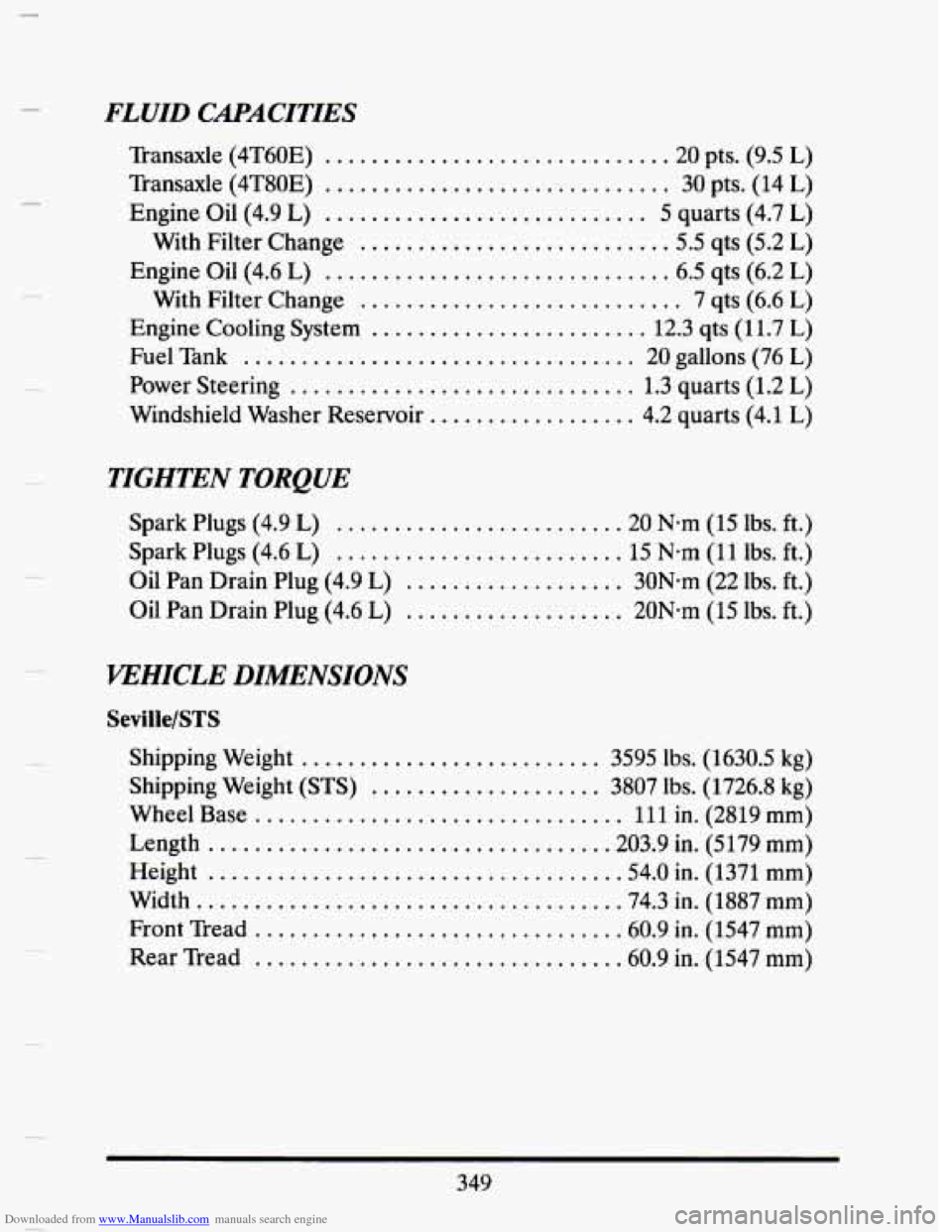

Downloaded from www.Manualslib.com manuals search engine FLUID CAPACITIES

Transaxle (4T6OE) .............................. 20 pts. (9.5 L)

Transaxle (4T80E)

.............................. 30 pts. (14 L)

Engine Oil (4.9 L)

............................ 5 quarts (4.7 L)

With Filter Change ........................... 5.5 qts (5.2 L)

Engine Oil (4.6 L)

.............................. 6.5 qts (6.2 L)

With Filter Change ............................ 7 qts (6.6 L)

Engine Cooling System

........................ 12.3 qts (1 1.7 L)

Fuel Tank .................................. 20 gallons (76 L)

Power Steering .............................. 1.3 quarts (1.2 L)

Windshield Washer Reservoir .................. 4.2 quarts (4.1 L)

TIGHTEN TORQUE

Spark Plugs (4.9 L) ........................ .20 Nqm (15 lbs. ft.)

Spark Plugs (4.6

L) ......................... 15 Nom (11 lbs. ft.)

Oil Pan Drain Plug (4.9 L)

................... 30N-m (22 Ibs. ft.)

Oil Pan Drain Plug (4.6 L) ................... 20N.m (15 lbs. ft.)

KEHICLE DIMENSIONS

Seville/STS

Shipping Weight .......................... 3595 lbs. (1630.5 kg)

Shipping Weight

(STS) .................... 3807 lbs. (1726.8 kg)

Wheel Base

................................ 111 in. (2819 mm)

Length .................................. .203.9 in. (5179 mm)

Height ................................... .54.0 in. (1371 mm)

Width.. .................................. .74.3 in. (1887 mm)

Front Tread ............................... .60.9 in. (1547 mm)

Rear Tread ............................... .60.9 in. (1547 mm)

349

Page 404 of 407

Downloaded from www.Manualslib.com manuals search engine b

p' I

r I

i

f

!

6

I:

r ..

Third Gear. When To Use ............................ 87

Tilt Steering Wheel .................................. 98

Time. Setting The .................................. 162

Tire Chains ........................................ 314

Tire. Flat .......................................... 249

Tire Pressure Inflation .............................. 307

Tire Inspection and Rotation ......................... 309

Tires .. Loading .................................... 306

Tire Quality Grading ................................ 311

Tires ............................................. 306

Tires. When It's Time For New Tires .................. 310

Torn Safety Belts .................................... 62

Torque Lock (Auto Transaxle) ........................ 207

Towing A Qailer ................................... 213

Towing Your Vehicle ................................ 229

Traction Control System (STS) ....................... 123

Trademarks. GM ................................... 261

Traffic Lights ...................................... 172

Traffic Officer ..................................... 174

nailer Towing ..................................... 213

Tkansaxle. Automatic ................................. 83

'Ransaxle Fluid .................................... 278

Transaxle Gear Positions ............................. 83

Travel. Brake Pedal ................................. 184

Trip Odometer ..................................... 126

Trunk Release. Remote .............................. 74

Turn Signal and Lane Change Indicator ................ 100

Tbrn Signalmeadlight Beam ......................... 101

milight Sentinel ................................... 111

'Ilvisted Safety Belts .................................. 29

Two Children Wearing The Same Safety Belt ............. 59

Transaxle Service ................... See Maint . Book. p.22

U

r i

e

r

15

ti

Page 405 of 407

Downloaded from www.Manualslib.com manuals search engine .

.

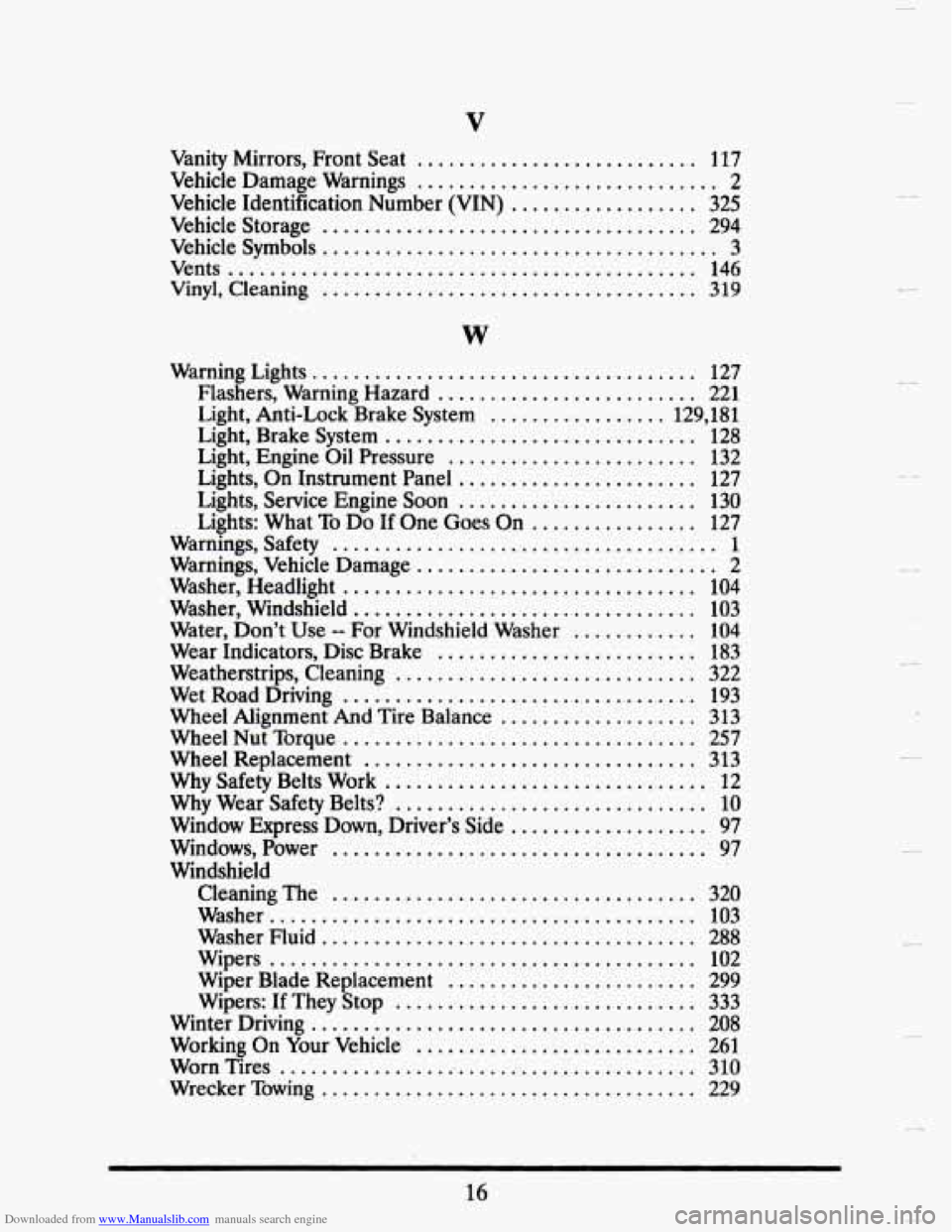

V

Vanity Mirrors. Front Seat ........................... 117

Vehicle Identification Number (VIN) .................. 325

Vehicle Storage .................................... 294

Vehicle Symbols ...................................... 3

Vents ............................................. 146

Vinyl. Cleaning .................................... 319

Vehicle Damage Warnings ............................. 2

W

Warning Lights ..................................... 127

Flashers. Warning Hazard ......................... 221

Light. Anti-Lock Brake System ................. 129. 181

Light. Brake System .............................. 128

Light. Engine Oil Pressure ........................ 132

Lights. On Instrument Panel ....................... 127

Lights. Service Engine Soon ....................... 130

Warnings. Safety ..................................... 1

Warnings. Vehicle Damage ............................. 2

Washer. Headlight .................................. 104

Washer. Windshield ................................. 103

Water. Don’t Use .. For Windshield Washer ............ 104

Wear Indicators. Disc Brake ......................... 183

Weatherstrips. Cleaning ............................. 322

Wet Road Driving .................................. 193

Wheel Alignment And Tire Balance ................... 313

Wheel Replacement ................................ 313

Why Safety Belts Work ............................... 12

Why Wear Safety Belts? .............................. 10

Window Express Down. Driver’s Side ................... 97

Windows. Power .................................... 97

Windshield

Cleaning

The ................................... 320

Washer ......................................... 103

Washer Fluid .................................... 288

Wipers ......................................... 102

Wiper Blade Replacement ........................ 299

Wipers: If They Stop ............................. 333

Winter Driving ..................................... 208

Working On Your Vehicle ........................... 261

Worn Tires ........................................ 310

Wrecker Towing .................................... 229

Lights: What To Do If One Goes On ................ 127

Wheel Nut Torque .................................. 257

16

.

.

.

.

. 4

c

.

.

..

-

.

.