clock CADILLAC SEVILLE 2003 5.G User Guide

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2003, Model line: SEVILLE, Model: CADILLAC SEVILLE 2003 5.GPages: 408, PDF Size: 2.72 MB

Page 275 of 408

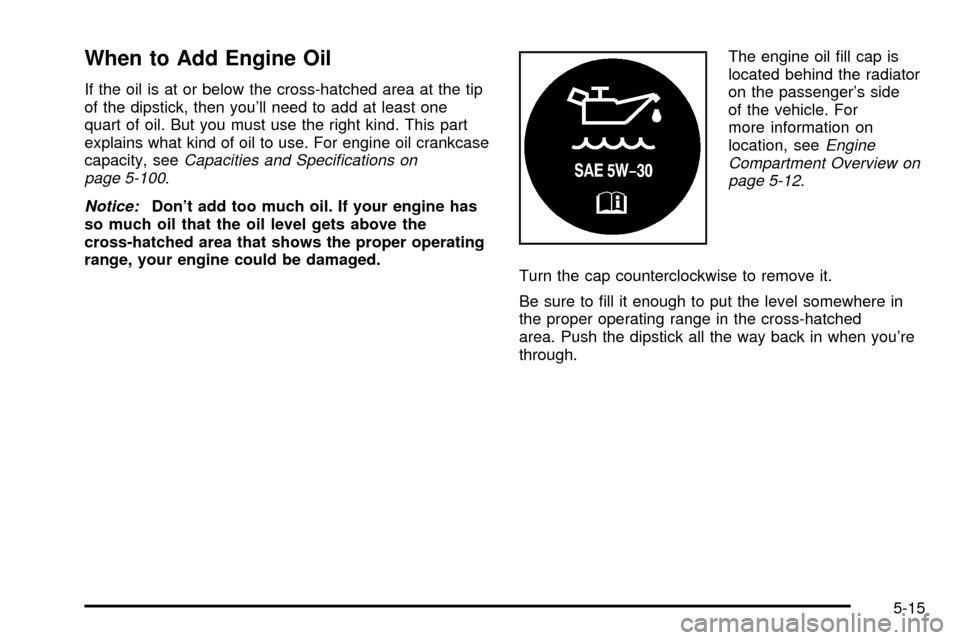

When to Add Engine Oil

If the oil is at or below the cross-hatched area at the tip

of the dipstick, then you'll need to add at least one

quart of oil. But you must use the right kind. This part

explains what kind of oil to use. For engine oil crankcase

capacity, see

Capacities and Speci®cations on

page 5-100.

Notice:Don't add too much oil. If your engine has

so much oil that the oil level gets above the

cross-hatched area that shows the proper operating

range, your engine could be damaged.The engine oil ®ll cap is

located behind the radiator

on the passenger's side

of the vehicle. For

more information on

location, see

Engine

Compartment Overview on

page 5-12

.

Turn the cap counterclockwise to remove it.

Be sure to ®ll it enough to put the level somewhere in

the proper operating range in the cross-hatched

area. Push the dipstick all the way back in when you're

through.

5-15

Page 283 of 408

Then, without shutting off the engine, follow these steps:

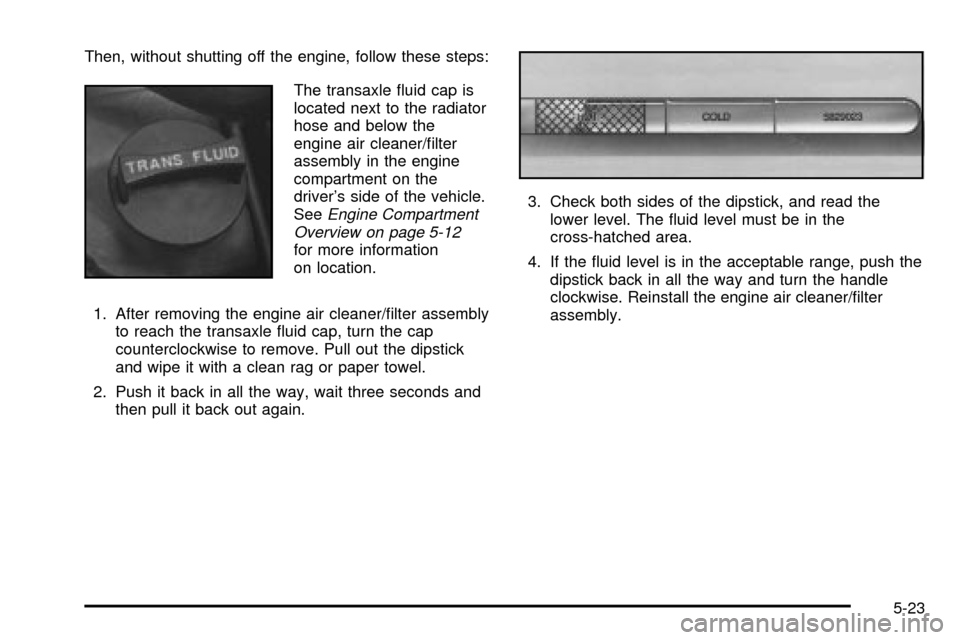

The transaxle ¯uid cap is

located next to the radiator

hose and below the

engine air cleaner/®lter

assembly in the engine

compartment on the

driver's side of the vehicle.

See

Engine Compartment

Overview on page 5-12

for more information

on location.

1. After removing the engine air cleaner/®lter assembly

to reach the transaxle ¯uid cap, turn the cap

counterclockwise to remove. Pull out the dipstick

and wipe it with a clean rag or paper towel.

2. Push it back in all the way, wait three seconds and

then pull it back out again.3. Check both sides of the dipstick, and read the

lower level. The ¯uid level must be in the

cross-hatched area.

4. If the ¯uid level is in the acceptable range, push the

dipstick back in all the way and turn the handle

clockwise. Reinstall the engine air cleaner/®lter

assembly.

5-23

Page 284 of 408

How to Add Fluid

Refer to the Maintenance Schedule to determine what

kind of transaxle ¯uid to use. SeePart D:

Recommended Fluids and Lubricants on page 6-15.

If the ¯uid level is low, add only enough of the proper

¯uid to bring the level into the cross-hatched area on the

dipstick.

1. Pull out the dipstick.

2. Using a long-neck funnel, add enough ¯uid at the

dipstick hole to bring it to the proper level.

It doesn't take much ¯uid, generally less than one

pint (0.5 L). Don't over®ll.

Notice:We recommend you use only ¯uid labeled

DEXRONž±III, because ¯uid with that label is

made especially for your automatic transaxle.

Damage caused by ¯uid other than DEXRON

ž±III is

not covered by your new vehicle warranty.

3. After adding ¯uid, recheck the ¯uid level as

described under

How to Check.

4. When the correct ¯uid level is obtained, push the

dipstick back in all the way and turn the handle

clockwise. Reinstall the engine air cleaner/®lter

assembly.

How to Reset the Transaxle Fluid

Change Indicator

Once the transaxle ¯uid has been changed, the

transaxle ¯uid change indicator must be reset. Use the

following steps to reset the indicator:

1. Press the INFO button on the Driver Information

Center (DIC) until TRANS FLUID LIFE is displayed.

2. Press and hold the INFO RESET button until 100%

is displayed.

The indicator is now reset. The percentage of transaxle

¯uid life remaining may be checked at any time by

pressing the INFO button several times until the TRANS

FLUID LIFE message appears.

5-24

Page 296 of 408

1. Park the vehicle on a level surface. You can

remove the coolant surge tank pressure cap

when the cooling system, including the coolant

surge tank pressure cap and upper radiator hose, is

no longer hot. Turn the pressure cap slowly

counterclockwise (left) until it ®rst stops. Don't press

down while turning the pressure cap.

If you hear a hiss, wait for that to stop. A hiss

means there is still some pressure left.

2. Press down on the pressure cap and keep turning it

slowly. Remove the cap.3. Then ®ll the coolant surge tank with the proper

mixture, to or above the ®ll mark at the forward

edge of the surge tank.

5-36

Page 317 of 408

5. To replace the low-beam bulb, ®rst remove the

rubber housing cover on the rear of the lamp.6. Then, turn the bulb socket counterclockwise to

unlock the socket from the lamp housing.

5-57

Page 319 of 408

9. After reinstalling the bulb and socket, reinstall the

rubber cover. Make sure it fully covers the

headlamp socket.

10. To replace the high-beam bulb, turn the bulb socket

counterclockwise to unlock the socket from the

lamp housing. Follow the instructions in

Step 6 through 8 to install the new bulb.

11. Reinstall the upper ®ller panel by inserting the

grommets, along with the screws, back into

the holes.Front Turn Signal Lamps

1. The turn signal lamps are located on the outboard

side of the headlamps. To access, remove the

headlamp. See Steps 1, 2, 3, and 10 under

Headlamps on page 5-56.

2. Press the bulb socket tab and turn the bulb socket

counterclockwise to unlock the socket from the

lamp housing.

3. To remove the old bulb, grasp the socket ®rmly and

pull the bulb out.

4. Install the new bulb and reverse the steps to

reinstall the lamp housing.

5-59

Page 321 of 408

7. Press the bulb socket tab and turn the socket

counterclockwise to remove it. To remove the

bulb, grasp the socket ®rmly and pull the bulb out.

Once you have replaced the burned-out bulb, reverse

the steps to reassemble the lamp assembly.

Replacement Bulbs

For any bulb not listed here contact your dealer.

Exterior Lamp Bulb Number

Front Turn Signal 2357NA

Headlamps, Composite

High Beam

Low Beam9005HB3

9006HB4

Rear Turn Signal 3057

Stop/Taillamp 3057

5-61

Page 337 of 408

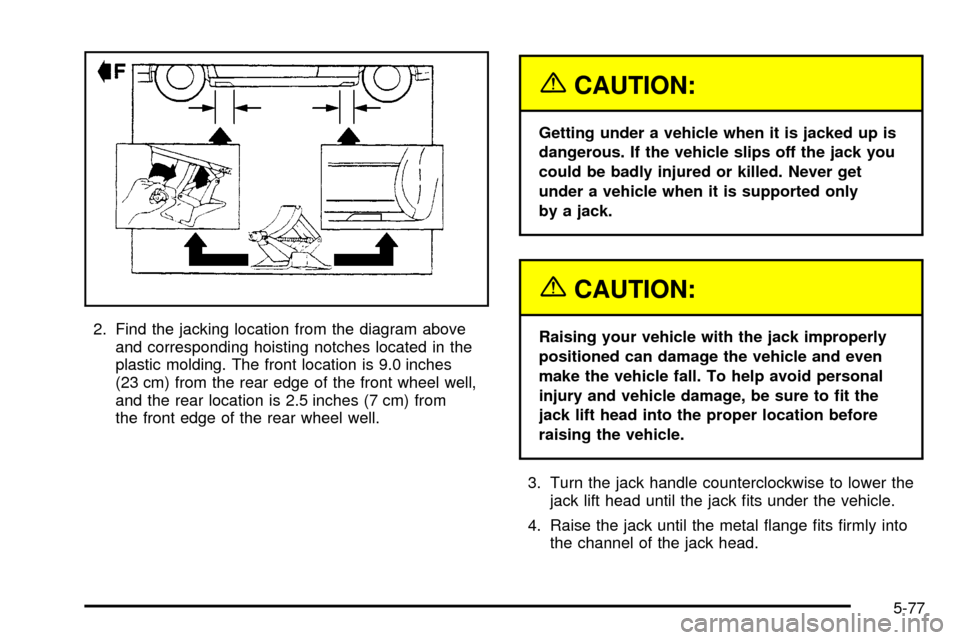

2. Find the jacking location from the diagram above

and corresponding hoisting notches located in the

plastic molding. The front location is 9.0 inches

(23 cm) from the rear edge of the front wheel well,

and the rear location is 2.5 inches (7 cm) from

the front edge of the rear wheel well.

{CAUTION:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack you

could be badly injured or killed. Never get

under a vehicle when it is supported only

by a jack.

{CAUTION:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even

make the vehicle fall. To help avoid personal

injury and vehicle damage, be sure to ®t the

jack lift head into the proper location before

raising the vehicle.

3. Turn the jack handle counterclockwise to lower the

jack lift head until the jack ®ts under the vehicle.

4. Raise the jack until the metal ¯ange ®ts ®rmly into

the channel of the jack head.

5-77

Page 338 of 408

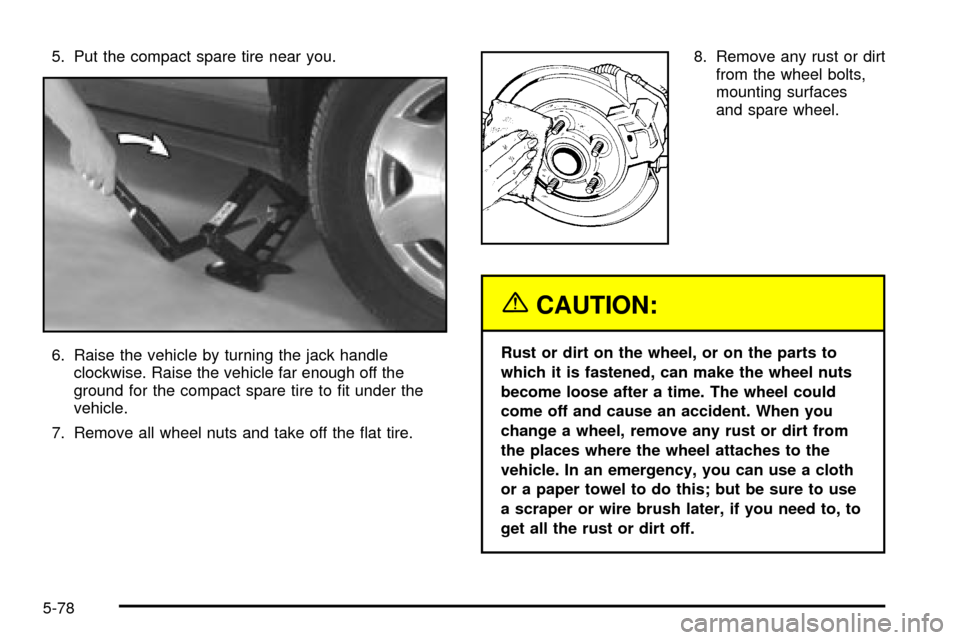

5. Put the compact spare tire near you.

6. Raise the vehicle by turning the jack handle

clockwise. Raise the vehicle far enough off the

ground for the compact spare tire to ®t under the

vehicle.

7. Remove all wheel nuts and take off the ¯at tire.8. Remove any rust or dirt

from the wheel bolts,

mounting surfaces

and spare wheel.

{CAUTION:

Rust or dirt on the wheel, or on the parts to

which it is fastened, can make the wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

the places where the wheel attaches to the

vehicle. In an emergency, you can use a cloth

or a paper towel to do this; but be sure to use

a scraper or wire brush later, if you need to, to

get all the rust or dirt off.

5-78

Page 340 of 408

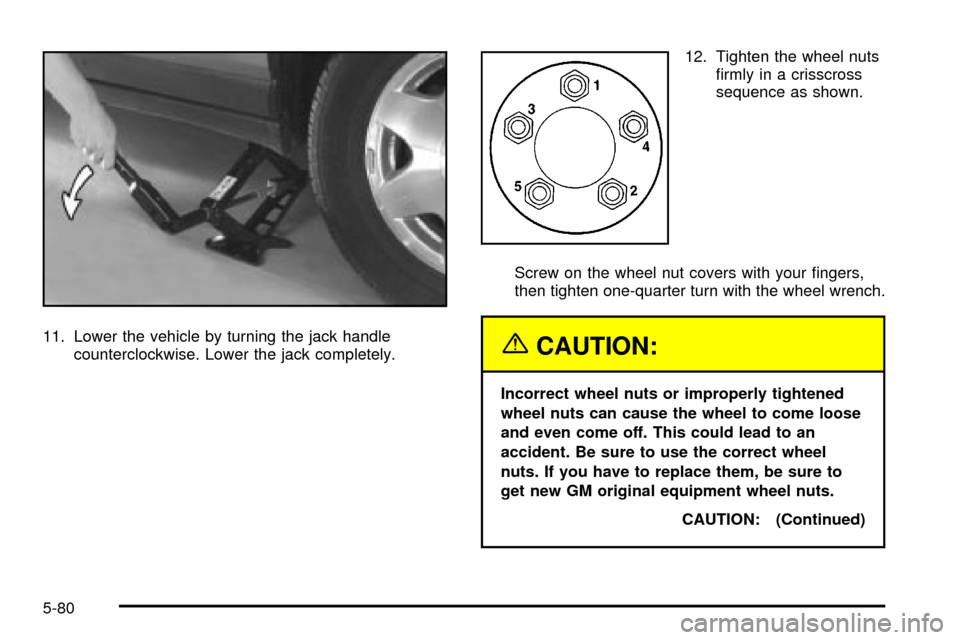

11. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.12. Tighten the wheel nuts

®rmly in a crisscross

sequence as shown.

Screw on the wheel nut covers with your ®ngers,

then tighten one-quarter turn with the wheel wrench.{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

CAUTION: (Continued)

5-80