spare tire CADILLAC SEVILLE 2003 5.G Owners Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2003, Model line: SEVILLE, Model: CADILLAC SEVILLE 2003 5.GPages: 408, PDF Size: 2.72 MB

Page 262 of 408

Buying New Tires.........................................5-68

Uniform Tire Quality Grading..........................5-69

Wheel Alignment and Tire Balance..................5-71

Wheel Replacement......................................5-71

Tire Chains..................................................5-72

If a Tire Goes Flat........................................5-73

Changing a Flat Tire.....................................5-74

Compact Spare Tire......................................5-83

Appearance Care............................................5-83

Cleaning the Inside of Your Vehicle.................5-84

Care of Safety Belts......................................5-86

Weatherstrips...............................................5-86

Cleaning the Outside of Your Vehicle..............5-86

Sheet Metal Damage.....................................5-88

Finish Damage.............................................5-89

Underbody Maintenance................................5-89Chemical Paint Spotting.................................5-89

Vehicle Care/Appearance Materials..................5-90

Vehicle Identi®cation......................................5-91

Vehicle Identi®cation Number (VIN).................5-91

Service Parts Identi®cation Label.....................5-92

Electrical System............................................5-92

Add-On Electrical Equipment..........................5-92

Headlamp Wiring..........................................5-92

Windshield Wiper Fuses................................5-92

Power Windows and Other Power Options.......5-92

Fuses and Circuit Breakers............................5-93

Removing the Rear Seat Cushion...................5-96

Capacities and Speci®cations........................5-100

Normal Maintenance Replacement Parts.........5-101

Section 5 Service and Appearance Care

5-2

Page 320 of 408

Center High-Mounted

Stoplamp (CHMSL)

It is recommended that this component be replaced as

a unit. See your dealer.

Taillamps and Turn Signal Lamps

1. Open the trunk to gain access to the lamp housing.

2. Remove the rear

compartment sill plate

by removing the

upper convenience net

retainers, located at

each end, as shown.

3. Move the spare tire cover out of the way.

4. Pull the trunk trim away to access the wing nuts.5. Remove the three wing nuts that fasten the taillamp

to the body.

6. Gently remove the taillamp from the body. The

taillamp is on the bottom of the housing and the

rear turn signal lamp is on the upper part of

the housing.

5-60

Page 325 of 408

When to Check

Check your tires once a month or more.

Don't forget your compact spare tire. It should be at

60 psi (420 kPa).

How to Check

Use a good quality pocket-type gage to check tire

pressure. You can't tell if your tires are properly in¯ated

simply by looking at them. Radial tires may look

properly in¯ated even when they're underin¯ated.

Be sure to put the valve caps back on the valve stems.

They help prevent leaks by keeping out dirt and

moisture.

Tire Pressure Monitor System

Your vehicle may have a Tire Pressure Monitor System

(TPM). The TPM system uses radio and sensor

technology to check tire pressure levels. Sensors,

mounted on each road wheel, transmit tire pressure

readings to a receiver located in the trunk. Tire pressure

status and tire pressure warnings are shown on the

Driver Information Center (DIC) display. See

Driver

Information Center (DIC) on page 3-53, for details

regarding DIC controls and displays.The system operates on a radio frequency subject to

Federal Communications Commission (FCC) Rules and

with Industry and Science Canada.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired

operation.

This device complies with RSS-210 of Industry and

Science Canada. Operation is subject to the following

two conditions: (1) this device may not cause

interference, and (2) this device must accept any

interference received, including interference that may

cause undesired operation of the device.

Changes or modi®cations to this system by anyone

other than an authorized service facility could void

authorization to use this equipment.

5-65

Page 326 of 408

If the TPM system detects low tire pressure, below

25 psi (172 kPa), or high tire pressure, above 38 psi

(262 kPa), a message, CHECK TIRE PRESSURE, will

appear on the Driver Information Center (DIC)

display. By pressing the INFO button, the DIC screen

will show which tire(s) has the low or high pressure

condition. See

In¯ation -- Tire Pressure on page 5-64for

information regarding correct tire in¯ation. If a tire is

low, you should stop as soon as possible and check all

your tires for damage. If a tire is ¯at, see

If a Tire

Goes Flat on page 5-73.

Notice:Do not use a tire sealant if your vehicle is

equipped with Tire Pressure Monitors. The liquid

sealant can damage the tire pressure monitor

sensors.

Once a low or high tire pressure condition is detected,

the TPM system will display the CHECK TIRE

MESSAGE each time the engine is started, until the

tire(s) are set to the correct in¯ation pressure.

The Tire-Loading Information Label, which is located on

the rear edge of the driver's door, shows the correct

in¯ation pressure for the tires on your vehicle.

The TPM system also allows the driver to check the air

pressure status of each road tire using the Driver

Information Center (DIC). Each tire's air pressure will belisted individually, in the following order: LF (left front or

driver's side front tire), RF (right front or passenger's

side front tire), RR (right rear or passenger's side

rear tire) and LR (left rear or driver's side rear tire). See

In¯ation -- Tire Pressure on page 5-64for information

regarding correct tire in¯ation. Also, seeDriver

Information Center (DIC) on page 3-53for information

on the DIC controls and displays.

If the DIC display doesn't show tire pressures or the

SERVICE TPM SYSTEM message appears, see

your dealer for service. The TPM system may not work

properly while the compact spare tire is installed.

Anytime you replace one or more tires or rotate your

tires, the TPM system will need to be reset. A special

tool is needed to reset the sensor identi®cation

codes. See your dealer for service.

Your vehicle was delivered from the factory with

aluminum valve stem caps. If you ever have to replace

the valve stem caps on your vehicle, you should

replace them with aluminum or plastic caps.

The TPM system can alert you about a low or high tire

pressure condition, but it doesn't replace normal tire

maintenance. See

Tires on page 5-63.

5-66

Page 327 of 408

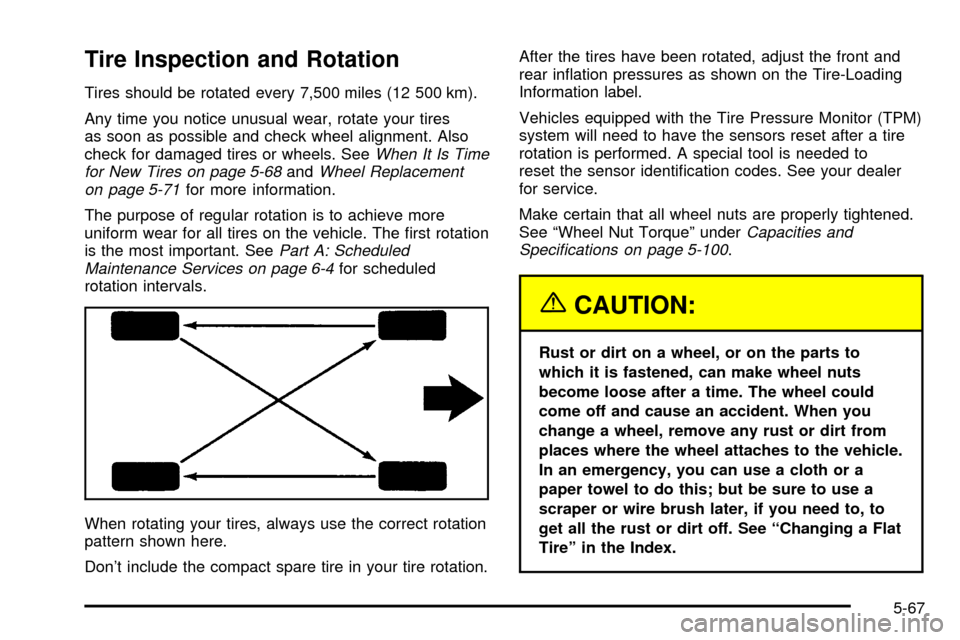

Tire Inspection and Rotation

Tires should be rotated every 7,500 miles (12 500 km).

Any time you notice unusual wear, rotate your tires

as soon as possible and check wheel alignment. Also

check for damaged tires or wheels. See

When It Is Time

for New Tires on page 5-68andWheel Replacement

on page 5-71for more information.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The ®rst rotation

is the most important. See

Part A: Scheduled

Maintenance Services on page 6-4for scheduled

rotation intervals.

When rotating your tires, always use the correct rotation

pattern shown here.

Don't include the compact spare tire in your tire rotation.After the tires have been rotated, adjust the front and

rear in¯ation pressures as shown on the Tire-Loading

Information label.

Vehicles equipped with the Tire Pressure Monitor (TPM)

system will need to have the sensors reset after a tire

rotation is performed. A special tool is needed to

reset the sensor identi®cation codes. See your dealer

for service.

Make certain that all wheel nuts are properly tightened.

See ªWheel Nut Torqueº under

Capacities and

Speci®cations on page 5-100.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if you need to, to

get all the rust or dirt off. See ªChanging a Flat

Tireº in the Index.

5-67

Page 329 of 408

{CAUTION:

Mixing tires could cause you to lose control

while driving. If you mix tires of different sizes

or types (radial and bias-belted tires), the

vehicle may not handle properly, and you

could have a crash. Using tires of different

sizes may also cause damage to your vehicle.

Be sure to use the same size and type tires on

all wheels. It's all right to drive with your

compact spare temporarily, it was developed

for use on your vehicle. See ªCompact Spare

Tireº in the index.

{CAUTION:

If you use bias-ply tires on your vehicle, the

wheel rim ¯anges could develop cracks after

many miles of driving. A tire and/or wheel

could fail suddenly, causing a crash. Use only

radial-ply tires with the wheels on your vehicle.

Uniform Tire Quality Grading

Quality grades can be found where applicable on the

tire sidewall between tread shoulder and maximum

section width. For example:

Treadwear 200 Traction AA Temperature A

The following information relates to the system

developed by the United States National Highway

Traffic Safety Administration, which grades tires by

treadwear, traction and temperature performance. (This

applies only to vehicles sold in the United States.)

The grades are molded on the sidewalls of most

passenger car tires. The Uniform Tire Quality Grading

system does not apply to deep tread, winter-type

snow tires, space-saver or temporary use spare tires,

tires with nominal rim diameters of 10 to 12 inches

(25 to 30 cm), or to some limited-production tires.

While the tires available on General Motors passenger

cars and light trucks may vary with respect to these

grades, they must also conform to federal safety

requirements and additional General Motors Tire

Performance Criteria (TPC) standards.

5-69

Page 335 of 408

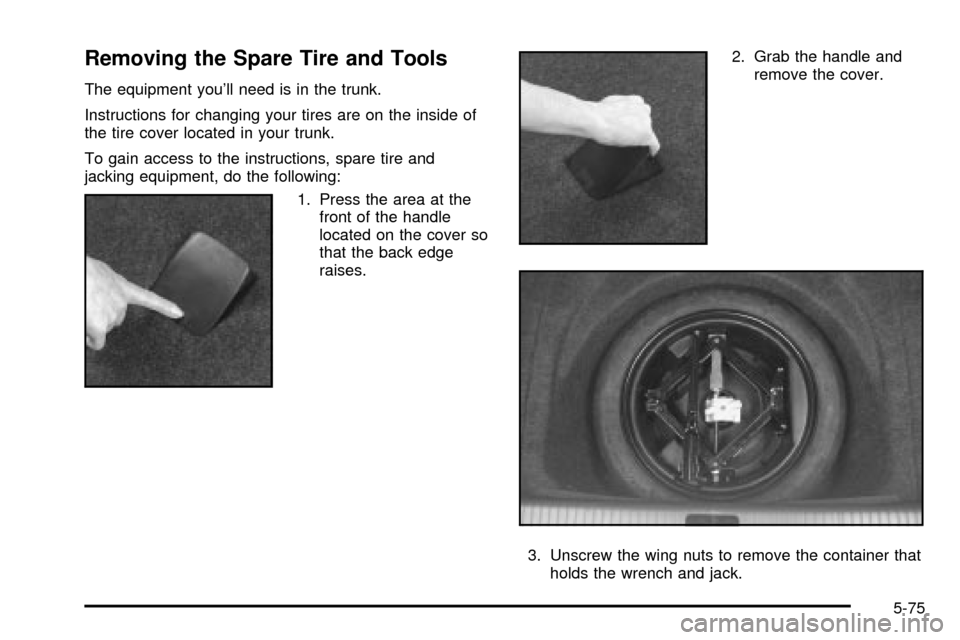

Removing the Spare Tire and Tools

The equipment you'll need is in the trunk.

Instructions for changing your tires are on the inside of

the tire cover located in your trunk.

To gain access to the instructions, spare tire and

jacking equipment, do the following:

1. Press the area at the

front of the handle

located on the cover so

that the back edge

raises.2. Grab the handle and

remove the cover.

3. Unscrew the wing nuts to remove the container that

holds the wrench and jack.

5-75

Page 336 of 408

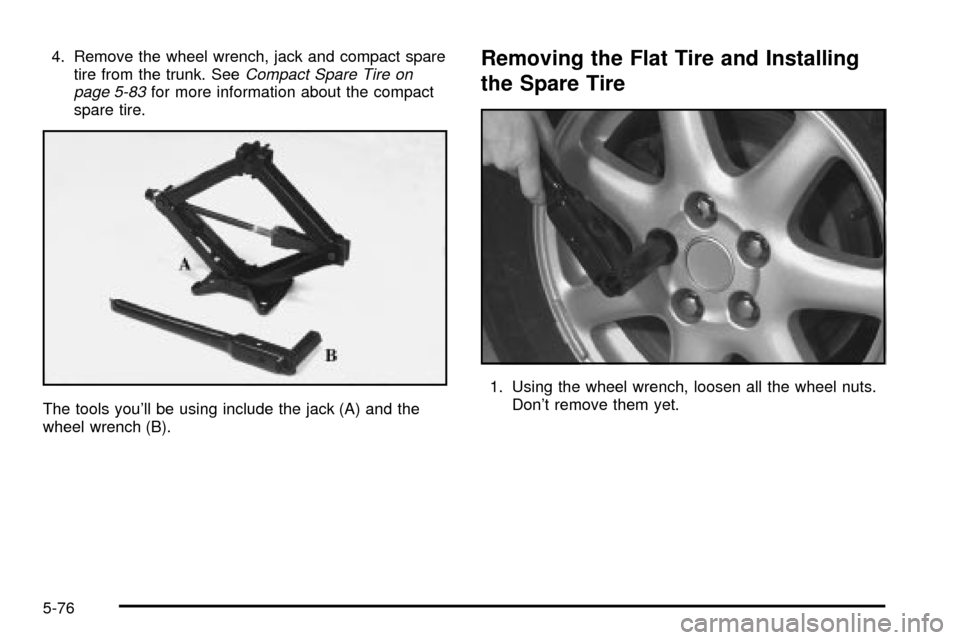

4. Remove the wheel wrench, jack and compact spare

tire from the trunk. SeeCompact Spare Tire on

page 5-83for more information about the compact

spare tire.

The tools you'll be using include the jack (A) and the

wheel wrench (B).

Removing the Flat Tire and Installing

the Spare Tire

1. Using the wheel wrench, loosen all the wheel nuts.

Don't remove them yet.

5-76

Page 338 of 408

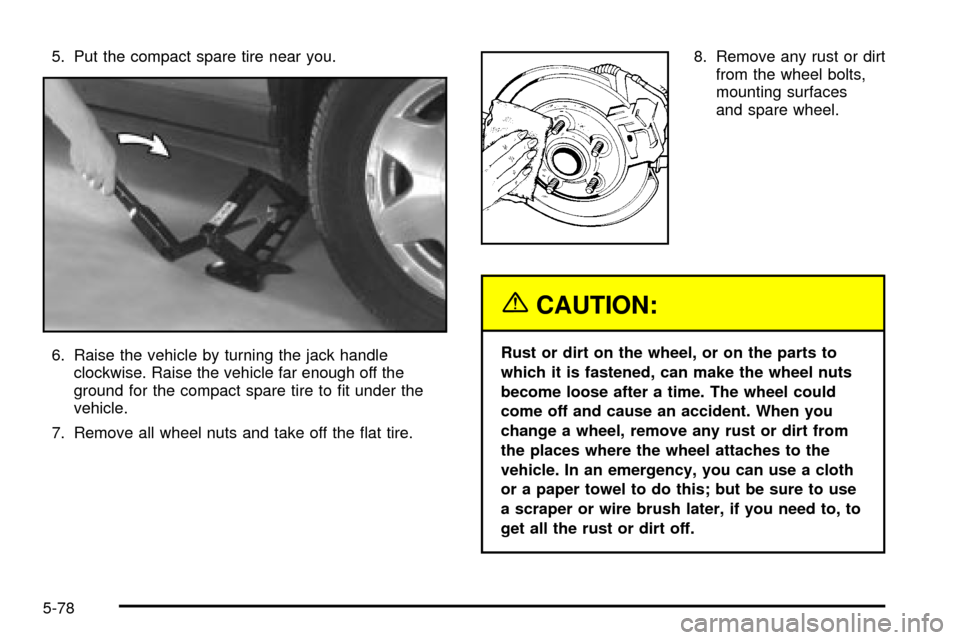

5. Put the compact spare tire near you.

6. Raise the vehicle by turning the jack handle

clockwise. Raise the vehicle far enough off the

ground for the compact spare tire to ®t under the

vehicle.

7. Remove all wheel nuts and take off the ¯at tire.8. Remove any rust or dirt

from the wheel bolts,

mounting surfaces

and spare wheel.

{CAUTION:

Rust or dirt on the wheel, or on the parts to

which it is fastened, can make the wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

the places where the wheel attaches to the

vehicle. In an emergency, you can use a cloth

or a paper towel to do this; but be sure to use

a scraper or wire brush later, if you need to, to

get all the rust or dirt off.

5-78

Page 339 of 408

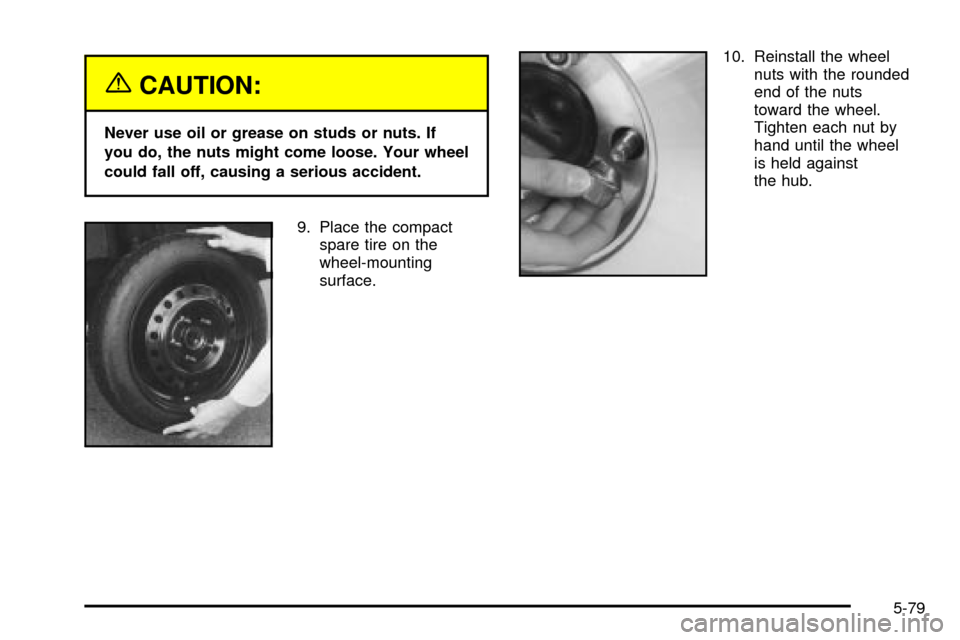

{CAUTION:

Never use oil or grease on studs or nuts. If

you do, the nuts might come loose. Your wheel

could fall off, causing a serious accident.

9. Place the compact

spare tire on the

wheel-mounting

surface.10. Reinstall the wheel

nuts with the rounded

end of the nuts

toward the wheel.

Tighten each nut by

hand until the wheel

is held against

the hub.

5-79