width CADILLAC XLR V 2007 1.G Owners Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2007, Model line: XLR V, Model: CADILLAC XLR V 2007 1.GPages: 512, PDF Size: 3.84 MB

Page 25 of 512

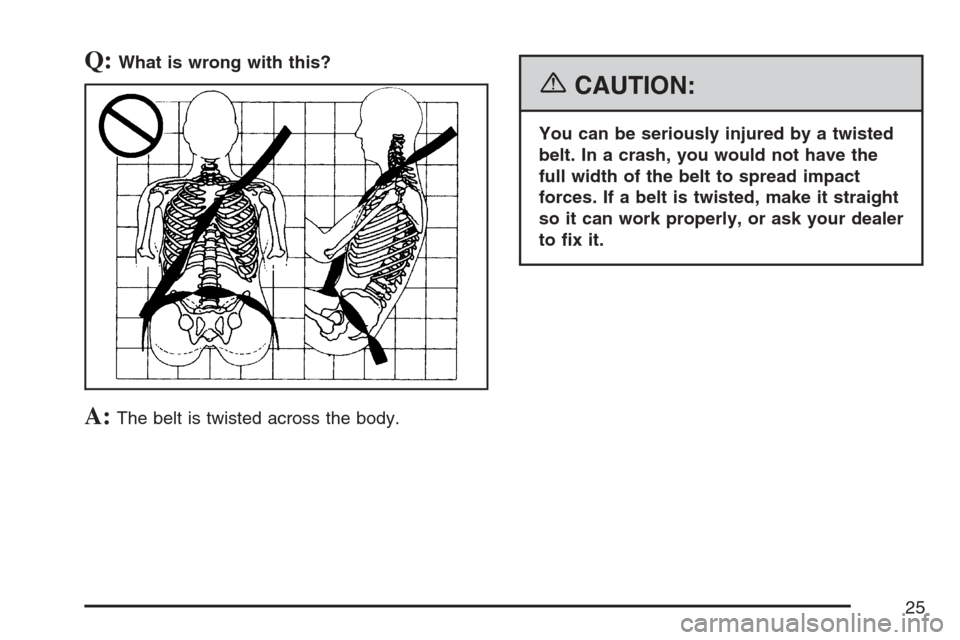

Q:What is wrong with this?

A:The belt is twisted across the body.

{CAUTION:

You can be seriously injured by a twisted

belt. In a crash, you would not have the

full width of the belt to spread impact

forces. If a belt is twisted, make it straight

so it can work properly, or ask your dealer

to �x it.

25

Page 410 of 512

Headlamp Vertical Aiming

To properly prepare the vehicle for vertical

headlamp aiming seeHeadlamp Aiming on

page 408for more information.

To adjust the vertical aim, do the following:

Notice:Horizontal aiming must be performed

before making any adjustments to the

vertical aim. Adjusting the vertical aim �rst will

result in an incorrect headlamp aim.

1. Open the hood. SeeHood Release on

page 373for more information.

2. Locate the aim dot on the inner projector lens

of the low-beam headlamp.

3. Measure the distance from the ground to the

aim dot on each low-beam headlamp. Record

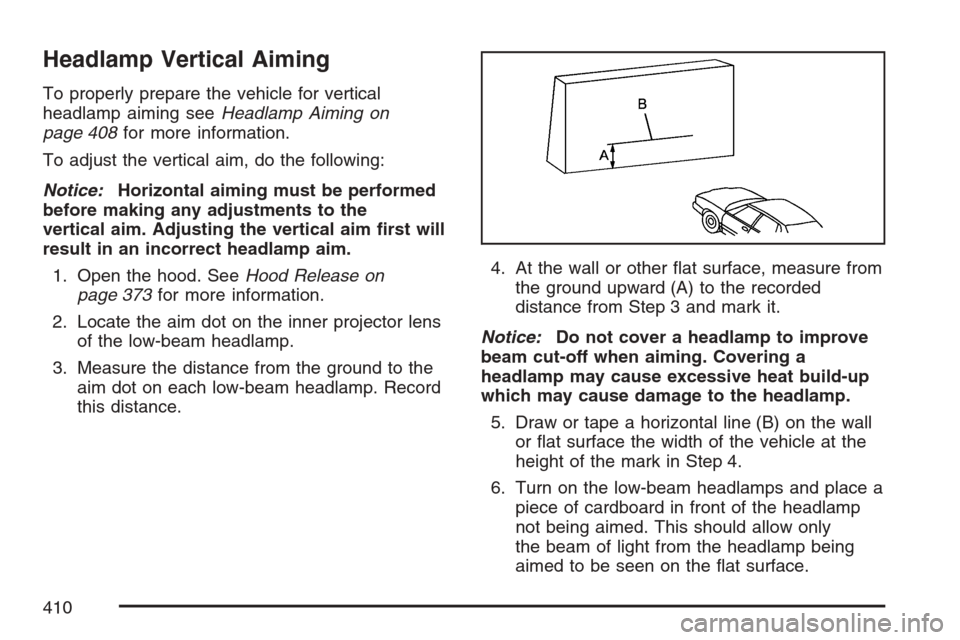

this distance.4. At the wall or other �at surface, measure from

the ground upward (A) to the recorded

distance from Step 3 and mark it.

Notice:Do not cover a headlamp to improve

beam cut-off when aiming. Covering a

headlamp may cause excessive heat build-up

which may cause damage to the headlamp.

5. Draw or tape a horizontal line (B) on the wall

or �at surface the width of the vehicle at the

height of the mark in Step 4.

6. Turn on the low-beam headlamps and place a

piece of cardboard in front of the headlamp

not being aimed. This should allow only

the beam of light from the headlamp being

aimed to be seen on the �at surface.

410

Page 415 of 512

Tire Sidewall Labeling

Useful information about a tire is molded into its

sidewall. The example below shows a typical

passenger (p-metric) tire sidewall.(A) Tire Size:The tire size is a combination of

letters and numbers used to de�ne a particular

tire’s width, height, aspect ratio, construction type,

and service description. See the “Tire Size”

illustration later in this section for more detail.

(B) TPC Spec (Tire Performance Criteria

Speci�cation):Original equipment tires designed

to GM’s speci�c tire performance criteria have

a TPC speci�cation code molded onto the sidewall.

GM’s TPC speci�cations meet or exceed all

federal safety guidelines.

(C) DOT (Department of Transportation):The

Department of Transportation (DOT) code

indicates that the tire is in compliance with the

U.S. Department of Transportation Motor Vehicle

Safety Standards.

(D) Tire Identi�cation Number (TIN):The letters

and numbers following DOT code are the Tire

Identi�cation Number (TIN). The TIN shows

the manufacturer and plant code, tire size, and

date the tire was manufactured. The TIN is molded

onto both sides of the tire, although only one

side may have the date of manufacture.

Passenger (P-Metric) Tire Example

415

Page 416 of 512

(E) Tire Ply Material:The type of cord and

number of plies in the sidewall and under the

tread.

(F) Uniform Tire Quality Grading (UTQG):Tire

manufacturers are required to grade tires

based on three performance factors: treadwear,

traction and temperature resistance. For more

information seeUniform Tire Quality Grading on

page 431.

(G) Maximum Cold In�ation Load Limit:

Maximum load that can be carried and the

maximum pressure needed to support that load.

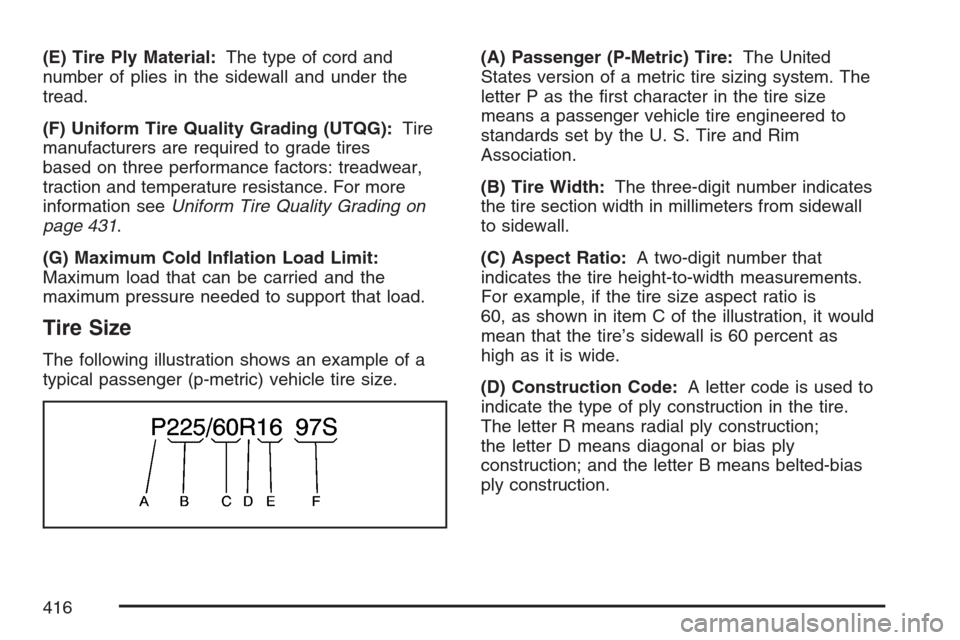

Tire Size

The following illustration shows an example of a

typical passenger (p-metric) vehicle tire size.(A) Passenger (P-Metric) Tire:The United

States version of a metric tire sizing system. The

letter P as the �rst character in the tire size

means a passenger vehicle tire engineered to

standards set by the U. S. Tire and Rim

Association.

(B) Tire Width:The three-digit number indicates

the tire section width in millimeters from sidewall

to sidewall.

(C) Aspect Ratio:A two-digit number that

indicates the tire height-to-width measurements.

For example, if the tire size aspect ratio is

60, as shown in item C of the illustration, it would

mean that the tire’s sidewall is 60 percent as

high as it is wide.

(D) Construction Code:A letter code is used to

indicate the type of ply construction in the tire.

The letter R means radial ply construction;

the letter D means diagonal or bias ply

construction; and the letter B means belted-bias

ply construction.

416

Page 417 of 512

(E) Rim Diameter:Diameter of the wheel in

inches.

(F) Service Description:These characters

represent the load range and speed rating of the

tire. The load index represents the load carry

capacity a tire is certi�ed to carry. The load index

can range from 1 to 279. The speed rating is

the maximum speed a tire is certi�ed to carry a

load. Speed ratings range from A to Z.

Tire Terminology and De�nitions

Air Pressure:The amount of air inside the tire

pressing outward on each square inch of the

tire. Air pressure is expressed in pounds

per square inch (psi) or kilopascal (kPa).

Accessory Weight:This means the combined

weight of optional accessories. Some examples of

optional accessories are, automatic

transmission/transaxle, power steering, power

brakes, power windows, power seats, and

air conditioning.Aspect Ratio:The relationship of a tire’s height

to its width.

Belt:A rubber coated layer of cords that is located

between the plies and the tread. Cords may be

made from steel or other reinforcing materials.

Bead:The tire bead contains steel wires wrapped

by steel cords that hold the tire onto the rim.

Bias Ply Tire:A pneumatic tire in which the plies

are laid at alternate angles less than 90 degrees

to the centerline of the tread.

Cold Tire Pressure:The amount of air pressure

in a tire, measured in pounds per square inch

(psi) or kilopascals (kPa) before a tire has built up

heat from driving. SeeIn�ation - Tire Pressure

on page 422.

Curb Weight:This means the weight of a motor

vehicle with standard and optional equipment

including the maximum capacity of fuel, oil, and

coolant, but without passengers and cargo.

417

Page 431 of 512

Uniform Tire Quality Grading

Quality grades can be found where applicable on

the tire sidewall between tread shoulder and

maximum section width. For example:

Treadwear 200 Traction AA Temperature A

The following information relates to the system

developed by the United States National Highway

Traffic Safety Administration (NHTSA), which

grades tires by treadwear, traction, and

temperature performance. This applies only to

vehicles sold in the United States. The grades are

molded on the sidewalls of most passenger car

tires. The Uniform Tire Quality Grading (UTQG)

system does not apply to deep tread, winter-type

snow tires, space-saver, or temporary use

spare tires, tires with nominal rim diameters of

10 to 12 inches (25 to 30 cm), or to some

limited-production tires.

While the tires available on General Motors

passenger cars and light trucks may vary with

respect to these grades, they must also conform

to federal safety requirements and additional

General Motors Tire Performance Criteria (TPC)

standards.

Treadwear

The treadwear grade is a comparative rating

based on the wear rate of the tire when tested

under controlled conditions on a speci�ed

government test course. For example, a tire

graded 150 would wear one and a half (1.5) times

as well on the government course as a tire

graded 100. The relative performance of tires

depends upon the actual conditions of their use,

however, and may depart signi�cantly from

the norm due to variations in driving habits, service

practices, and differences in road characteristics

and climate.

Traction – AA, A, B, C

The traction grades, from highest to lowest, are

AA, A, B, and C. Those grades represent the tire’s

ability to stop on wet pavement as measured

under controlled conditions on speci�ed

government test surfaces of asphalt and concrete.

A tire marked C may have poor traction

performance.

Warning:The traction grade assigned to this tire

is based on straight-ahead braking traction

tests, and does not include acceleration, cornering,

hydroplaning, or peak traction characteristics.

431

Page 432 of 512

Temperature – A, B, C

The temperature grades are A (the highest), B,

and C, representing the tire’s resistance to

the generation of heat and its ability to dissipate

heat when tested under controlled conditions on a

speci�ed indoor laboratory test wheel. Sustained

high temperature can cause the material of the tire

to degenerate and reduce tire life, and excessive

temperature can lead to sudden tire failure.

The grade C corresponds to a level of performance

which all passenger car tires must meet under

the Federal Motor Vehicle Safety Standard

No. 109. Grades B and A represent higher levels

of performance on the laboratory test wheel

than the minimum required by law.

Warning:The temperature grade for this tire is

established for a tire that is properly in�ated

and not overloaded. Excessive speed,

underin�ation, or excessive loading, either

separately or in combination, can cause heat

buildup and possible tire failure.

Wheel Alignment and Tire Balance

The tires and wheels on your vehicle were aligned

and balanced carefully at the factory to give you

the longest tire life and best overall performance.

Adjustments to wheel alignment and tire

balancing will not be necessary on a regular basis.

However, if you notice unusual tire wear or your

vehicle pulling to one side or the other, the

alignment may need to be checked. If you notice

your vehicle vibrating when driving on a smooth

road, your tires and wheels may need to be

rebalanced. See your dealer for proper diagnosis.

Wheel Replacement

Replace any wheel that is bent, cracked, or badly

rusted or corroded. If wheel nuts keep coming

loose, the wheel, wheel bolts, and wheel

nuts should be replaced. If the wheel leaks air,

replace it (except some aluminum wheels,

which can sometimes be repaired). See your

dealer if any of these conditions exist.

Your dealer will know the kind of wheel you need.

Each new wheel should have the same

load-carrying capacity, diameter, width, offset, and

be mounted the same way as the one it replaces.

432