clock CADILLAC XT5 2020 Owner's Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2020, Model line: XT5, Model: CADILLAC XT5 2020Pages: 384, PDF Size: 6.52 MB

Page 15 of 384

14 KEYS, DOORS, AND WINDOWS

driver door and turn the key

counterclockwise, to the unlock

position, five times within

10 seconds.

The DIC displays READY FOR

REMOTE #2, 3, 4, ETC.

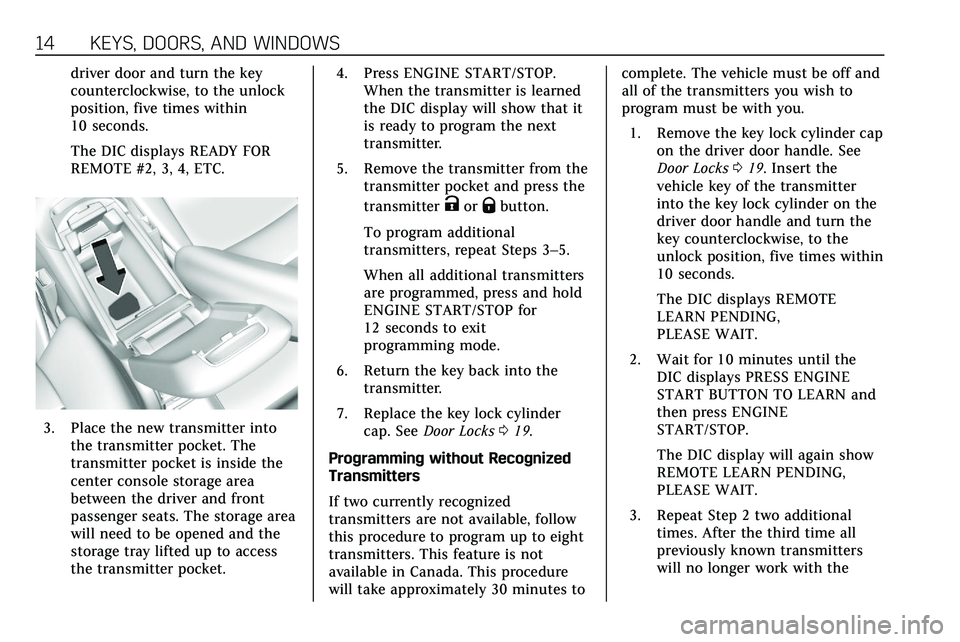

3. Place the new transmitter intothe transmitter pocket. The

transmitter pocket is inside the

center console storage area

between the driver and front

passenger seats. The storage area

will need to be opened and the

storage tray lifted up to access

the transmitter pocket. 4. Press ENGINE START/STOP.

When the transmitter is learned

the DIC display will show that it

is ready to program the next

transmitter.

5. Remove the transmitter from the transmitter pocket and press the

transmitter

KorQbutton.

To program additional

transmitters, repeat Steps 3–5.

When all additional transmitters

are programmed, press and hold

ENGINE START/STOP for

12 seconds to exit

programming mode.

6. Return the key back into the transmitter.

7. Replace the key lock cylinder cap. See Door Locks 019.

Programming without Recognized

Transmitters

If two currently recognized

transmitters are not available, follow

this procedure to program up to eight

transmitters. This feature is not

available in Canada. This procedure

will take approximately 30 minutes to complete. The vehicle must be off and

all of the transmitters you wish to

program must be with you.

1. Remove the key lock cylinder cap on the driver door handle. See

Door Locks 019. Insert the

vehicle key of the transmitter

into the key lock cylinder on the

driver door handle and turn the

key counterclockwise, to the

unlock position, five times within

10 seconds.

The DIC displays REMOTE

LEARN PENDING,

PLEASE WAIT.

2. Wait for 10 minutes until the DIC displays PRESS ENGINE

START BUTTON TO LEARN and

then press ENGINE

START/STOP.

The DIC display will again show

REMOTE LEARN PENDING,

PLEASE WAIT.

3. Repeat Step 2 two additional times. After the third time all

previously known transmitters

will no longer work with the

Page 100 of 384

INSTRUMENTS AND CONTROLS 99

Instruments and

Controls

Controls

Steering Wheel Adjustment . . . . . 100

Steering Wheel Controls . . . . . . . . . 100

Heated Steering Wheel . . . . . . . . . . 100

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Windshield Wiper/Washer . . . . . . . 101

Rear Window Wiper/Washer . . . . 103

Compass . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Power Outlets . . . . . . . . . . . . . . . . . . . . . 104

Wireless Charging . . . . . . . . . . . . . . . . 105

Warning Lights, Gauges, and

Indicators

Warning Lights, Gauges, andIndicators . . . . . . . . . . . . . . . . . . . . . . . 107

Instrument Cluster . . . . . . . . . . . . . . . 108

Speedometer . . . . . . . . . . . . . . . . . . . . . . 111

Odometer . . . . . . . . . . . . . . . . . . . . . . . . . 111

Trip Odometer . . . . . . . . . . . . . . . . . . . . 111

Tachometer . . . . . . . . . . . . . . . . . . . . . . . 111

Fuel Gauge . . . . . . . . . . . . . . . . . . . . . . . . 112

Engine Coolant Temperature Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Seat Belt Reminders . . . . . . . . . . . . . . 113 Airbag Readiness Light . . . . . . . . . . 114

Passenger Airbag Status

Indicator . . . . . . . . . . . . . . . . . . . . . . . . . 114

Charging System Light . . . . . . . . . . . 115

Malfunction Indicator Lamp (Check Engine Light) . . . . . . . . . . . 115

Brake System Warning Light . . . . 117

Electric Parking Brake Light . . . . . 118

Service Electric Parking Brake Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Antilock Brake System (ABS) Warning Light . . . . . . . . . . . . . . . . . . 118

Gear Shifting Light . . . . . . . . . . . . . . . 119

All-Wheel-Drive Light . . . . . . . . . . . . 119

Lane Keep Assist (LKA) Light . . . 119

Vehicle Ahead Indicator . . . . . . . . . 119

Pedestrian Ahead Indicator . . . . . . 120

Traction Off Light . . . . . . . . . . . . . . . . 120

StabiliTrak OFF Light . . . . . . . . . . . . 120

Traction Control System (TCS)/ StabiliTrak Light . . . . . . . . . . . . . . . . 121

Engine Coolant Temperature Warning Light . . . . . . . . . . . . . . . . . . 121

Driver Mode Control Light . . . . . . . 121

Tire Pressure Light . . . . . . . . . . . . . . . 122

Engine Oil Pressure Light . . . . . . . . 122

Low Fuel Warning Light . . . . . . . . . 123

Security Light . . . . . . . . . . . . . . . . . . . . . 123

High-Beam On Light . . . . . . . . . . . . . 123

Lamps On Reminder . . . . . . . . . . . . . 123 Cruise Control Light . . . . . . . . . . . . . . 124

Door Ajar Light . . . . . . . . . . . . . . . . . . . 124

Information Displays

Driver Information

Center (DIC) . . . . . . . . . . . . . . . . . . . . . 124

Head-Up Display (HUD) . . . . . . . . . 127

Vehicle Messages

Vehicle Messages . . . . . . . . . . . . . . . . . 130

Engine Power Messages . . . . . . . . . . 131

Vehicle Speed Messages . . . . . . . . . 131

Vehicle Personalization

Vehicle Personalization . . . . . . . . . . 131

Universal Remote System

Universal Remote System . . . . . . . . 137

Universal Remote System Programming . . . . . . . . . . . . . . . . . . . 137

Universal Remote System Operation . . . . . . . . . . . . . . . . . . . . . . . . 139

Page 105 of 384

104 INSTRUMENTS AND CONTROLS

windshield wiper is performing low or

high speed wipes. If the rear wiper

control is off, the transmission is in

R (Reverse), and the front windshield

wiper is performing INT wipes, then

the rear wiper automatically performs

INT wipes.

This feature can be turned on or off.

SeeVehicle Personalization 0131.

The windshield washer reservoir is

used for the windshield, rear window,

and rear mirror camera, if equipped.

See Rear Camera Mirror 035. Check

the fluid level in the reservoir if either

washer is not working. See Washer

Fluid 0266.

Rear Camera Washer

If equipped, push the windshield

wiper lever forward to spray washer

fluid on the rear camera and the

Night Vision camera lens. The lever

returns to its starting position when

released. See Rear Camera Mirror 035.

Compass

The vehicle may have a compass

display on the Driver Information

Center (DIC). The compass receives its

heading and other information from

the Global Positioning System (GPS)

antenna, StabiliTrak/Electronic

Stability Control (ESC), and vehicle

speed information.

The compass system is designed to

operate for a certain number of miles

or degrees of turn before needing a

signal from the GPS satellites. When

the compass display shows CAL, drive

the vehicle for a short distance in an

open area where it can receive a GPS

signal. The compass system will

automatically determine when a GPS

signal is restored and provide a

heading again.

Clock

The time and date for the clock can be

set using the infotainment system. See

“Time/Date ”in “System ”under

“Settings ”in the infotainment manual.

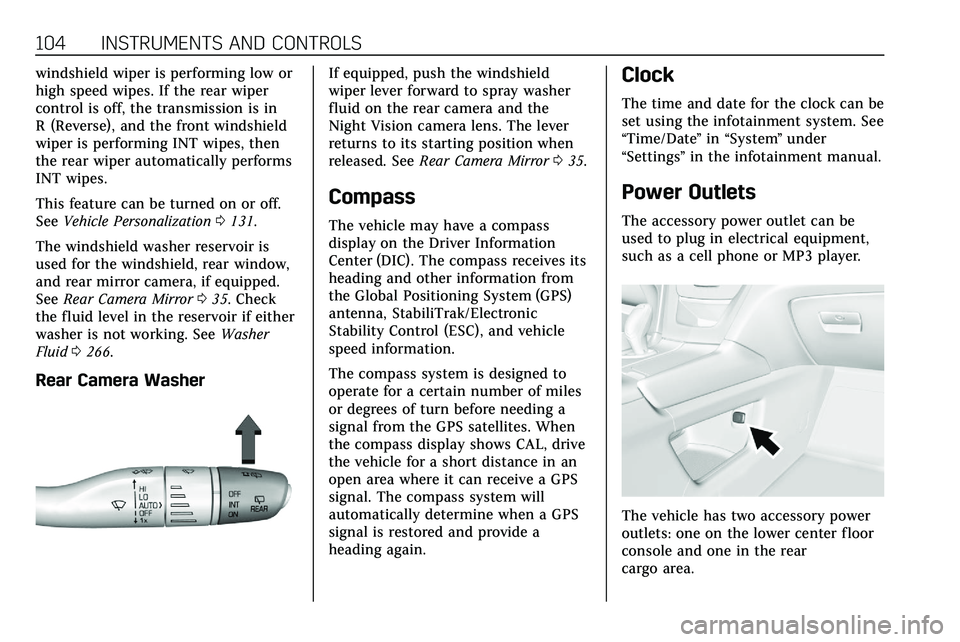

Power Outlets

The accessory power outlet can be

used to plug in electrical equipment,

such as a cell phone or MP3 player.

The vehicle has two accessory power

outlets: one on the lower center floor

console and one in the rear

cargo area.

Page 264 of 384

VEHICLE CARE 263

How to Add Coolant to the

Surge Tank

{Warning

Spilling coolant on hot engine parts

can burn you. Coolant contains

ethylene glycol and it will burn if

the engine parts are hot enough.

{Warning

Steam and scalding liquids from a

hot cooling system are under

pressure. Turning the pressure cap,

even a little, can cause them to

come out at high speed and you

could be burned. Never turn the cap

when the cooling system, including

the pressure cap, is hot. Wait for

the cooling system and pressure

cap to cool.

Caution

Failure to follow the specific

coolant fill procedure could cause

the engine to overheat and could

cause system damage. If coolant is

not visible in the surge tank,

contact your dealer.

The coolant surge tank pressure cap

can be removed when the cooling

system, including the surge tank

pressure cap and upper radiator hose,

is no longer hot.

Coolant Fill Instructions (3.6L

Engine Only)

1. Turn the pressure cap slowly counterclockwise. If a hiss is

heard, wait for that to stop.

A hiss means there is still some

pressure left. 2. Keep turning the pressure cap

slowly and remove it.

3. Fill the coolant surge tank withthe proper mixture to the mark

pointed to on the front of the

coolant surge tank.

4. With the coolant surge tank pressure cap off, start the engine

and let it run until you can feel

the upper radiator hose getting

hot. Watch out for the engine

cooling fans. By this time, the

coolant level inside the coolant

surge tank may be lower. If the

level is lower, add more of the

proper mixture to the coolant

Page 306 of 384

VEHICLE CARE 305

2. Sealant/Air Hose

3. Base of Sealant Canister

4. Tire Sealant Canister

5. On/Off Button

6. Slot on Top of Compressor

7. Pressure Deflation Button

8. Pressure Gauge

9. Power Plug

10. Air Only Hose

Tire Sealant

Read and follow the safe handling

instructions on the label adhered to

the tire sealant canister (4).Check the tire sealant expiration date

on the tire sealant canister. The tire

sealant canister (4) should be replaced

before its expiration date.

Replacement tire sealant canisters are

available at your local dealer.

There is only enough sealant to seal

one tire. After usage, the tire sealant

canister must be replaced.

Using the Tire Sealant and

Compressor Kit to Temporarily

Seal and Inflate a

Punctured Tire

When using the tire sealant and

compressor kit during cold

temperatures, warm the kit in a

heated environment for five minutes.

This will help to inflate the tire faster.

If a tire goes flat, avoid further tire

and wheel damage by driving slowly

to a level place. Turn on the hazard

warning flashers. See

Hazard Warning

Flashers 0143.

See If a Tire Goes Flat 0302 for other

important safety warnings.

Do not remove any objects that have

penetrated the tire. 1. Remove the tire sealant

canister (4) and compressor from

its storage location. See Storing

the Tire Sealant and Compressor

Kit 0310.

2. Remove the air only hose (10) and the power plug (9) from the

bottom of the compressor.

3. Place the compressor on the ground near the flat tire.

4. Attach the air only hose (10) tothe sealant canister inlet

valve (1) by turning it clockwise

until tight.

Page 307 of 384

306 VEHICLE CARE

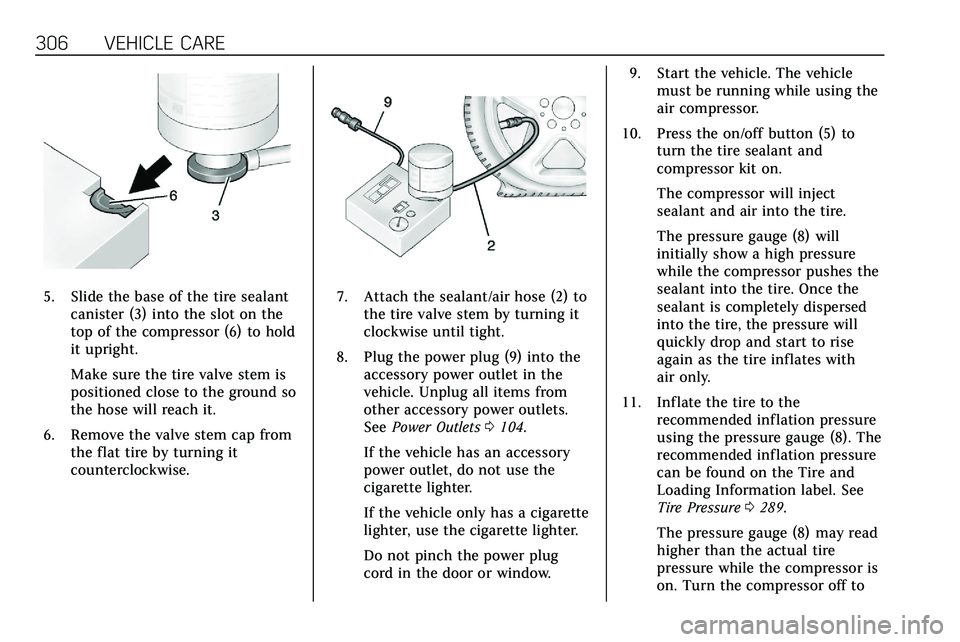

5. Slide the base of the tire sealantcanister (3) into the slot on the

top of the compressor (6) to hold

it upright.

Make sure the tire valve stem is

positioned close to the ground so

the hose will reach it.

6. Remove the valve stem cap from the flat tire by turning it

counterclockwise.7. Attach the sealant/air hose (2) tothe tire valve stem by turning it

clockwise until tight.

8. Plug the power plug (9) into the accessory power outlet in the

vehicle. Unplug all items from

other accessory power outlets.

See Power Outlets 0104.

If the vehicle has an accessory

power outlet, do not use the

cigarette lighter.

If the vehicle only has a cigarette

lighter, use the cigarette lighter.

Do not pinch the power plug

cord in the door or window. 9. Start the vehicle. The vehicle

must be running while using the

air compressor.

10. Press the on/off button (5) to turn the tire sealant and

compressor kit on.

The compressor will inject

sealant and air into the tire.

The pressure gauge (8) will

initially show a high pressure

while the compressor pushes the

sealant into the tire. Once the

sealant is completely dispersed

into the tire, the pressure will

quickly drop and start to rise

again as the tire inflates with

air only.

11. Inflate the tire to the recommended inflation pressure

using the pressure gauge (8). The

recommended inflation pressure

can be found on the Tire and

Loading Information label. See

Tire Pressure 0289.

The pressure gauge (8) may read

higher than the actual tire

pressure while the compressor is

on. Turn the compressor off to

Page 308 of 384

VEHICLE CARE 307

get an accurate pressure reading.

The compressor may be turned

on/off until the correct pressure

is reached.

Caution

If the recommended pressure

cannot be reached after

approximately 25 minutes, the

vehicle should not be driven farther.

The tire is too severely damaged

and the tire sealant and compressor

kit cannot inflate the tire. Remove

the power plug from the accessory

power outlet and unscrew the

inflating hose from the tire valve.

SeeRoadside Service 0353.

12. Press the on/off button (5) to turn the tire sealant and

compressor kit off.

The tire is not sealed and will

continue to leak air until the

vehicle is driven and the sealant

is distributed in the tire.

Therefore, Steps 13–21 must be

done immediately after Step 12. Be careful while handling the tire

sealant and compressor kit as it

could be warm after usage.

13. Unplug the power plug (9) from the accessory power outlet in the

vehicle.

14. Turn the sealant/air hose (2) counterclockwise to remove it

from the tire valve stem.

15. Replace the tire valve stem cap.

16. Remove the tire sealant canister (4) from the slot on top

of the compressor (6).

17. Turn the air only hose (10) counterclockwise to remove it

from the tire sealant canister

inlet valve (1).

18. Turn the sealant/air hose (2) clockwise onto the sealant

canister inlet valve (1) to prevent

sealant leakage.

19. Return the air only hose (10) and power plug (9) back to their

original storage location.20. If the flat tire was able to inflateto the recommended inflation

pressure, remove the maximum

speed label from the sealant

canister and place it in a highly

visible location.

Do not exceed the speed on this

label until the damaged tire is

repaired or replaced.

21. Return the equipment to its original storage location in the

vehicle.

22. Immediately drive the vehicle 8 km (5 mi) to distribute the

sealant in the tire.

23. Stop at a safe location and check the tire pressure. Refer to

Steps 1–10 under “Using the Tire

Sealant and Compressor Kit

without Sealant to Inflate a Tire

(Not Punctured).”

Page 310 of 384

VEHICLE CARE 309

3. Place the compressor on theground near the flat tire.

Make sure the tire valve stem is

positioned close to the ground so

the hose will reach it.

4. Remove the valve stem cap from the flat tire by turning it

counterclockwise.

5. Attach the air only hose (10) to the tire valve stem by turning it

clockwise until tight.

6. Plug the power plug (9) into the accessory power outlet in the

vehicle. Unplug all items from

other accessory power outlets.

See Power Outlets 0104.

If the vehicle has an accessory

power outlet, do not use the

cigarette lighter.

If the vehicle only has a cigarette

lighter, use the cigarette lighter.

Do not pinch the power plug

cord in the door or window.

7. Start the vehicle. The vehicle must be running while using the

air compressor. 8. Press the on/off button (5) to

turn the tire sealant and

compressor kit on.

The compressor will inflate the

tire with air only.

9. Inflate the tire to the recommended inflation pressure

using the pressure gauge (8). The

recommended inflation pressure

can be found on the Tire and

Loading Information label. See

Tire Pressure 0289.

The pressure gauge (8) may read

higher than the actual tire

pressure while the compressor is

on. Turn the compressor off to

get an accurate pressure reading.

The compressor may be turned

on/off until the correct pressure

is reached.

Caution

If the recommended pressure

cannot be reached after

approximately 25 minutes, the

vehicle should not be driven farther. (Continued)

Caution (Continued)

The tire is too severely damaged

and the tire sealant and compressor

kit cannot inflate the tire. Remove

the power plug from the accessory

power outlet and unscrew the

inflating hose from the tire valve.

SeeRoadside Service 0353.

10. Press the on/off button (5) to turn the tire sealant and

compressor kit off.

Be careful while handling the

compressor as it could be warm

after usage.

11. Unplug the power plug (9) from the accessory power outlet in the

vehicle.

12. Turn the air only hose (10) counterclockwise to remove it

from the tire valve stem.

13. Replace the tire valve stem cap.

14. Return the air only hose (10) and power plug (9) back to their

original storage location.

Page 311 of 384

310 VEHICLE CARE

15. Return the equipment to itsoriginal storage location in the

vehicle.

The tire sealant and compressor kit

has accessory adapters located in a

compartment on the bottom of its

housing that can be used to inflate air

mattresses, balls, etc.

Storing the Tire Sealant

and Compressor Kit

The tire sealant and compressor kit is

in a bag in the rear compartment

storage area. 1. Open the liftgate.

2. Remove the cargo management system divider. See Cargo

Management System 096.

3. Lift the load floor. Use the hook to hold the load floor open. See

Rear Storage 093.4. Turn the retainer nut

counterclockwise to remove the

tire sealant and compressor

kit bag.

5. Remove the tire sealant and compressor kit from the bag.

To store the tire sealant and

compressor kit, reverse the steps.

Tire Changing

Removing the Spare Tire and

Tools

To access the spare tire and tools: 1. Open the liftgate. See Liftgate

0 23. 2. Remove the cargo management

system divider. See Cargo

Management System 096.

3. Pull up on the handle to lift the

load floor. Use the hook to hold

the load floor open. See Rear

Storage 093.

Page 312 of 384

VEHICLE CARE 311

4. Turn the wing nut (4)counterclockwise to remove the

jack (1), wheel wrench (2), and

strap (3). Place the tool container

near the tire being changed.5. Remove the nut retaining thespare tire.

6. Remove the spare tire and place it next to the tire being changed.

Removing the Flat Tire and

Installing the Spare Tire

1. Do a safety check beforeproceeding. See If a Tire Goes Flat

0 302.

2. Turn the wheel wrench

counterclockwise to loosen all

the wheel nuts, but do not

remove them yet.

3. Place the jack near the flat tire.

Caution

Make sure that the jack lift head is

in the correct position or you may

damage your vehicle. The repairs

would not be covered by your

warranty.