tow CHERY TIGGO 2009 Service User Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1306 of 1903

Downloaded from www.Manualslib.com manuals search engine DESCRIPTIONTORQUE (N·m)

Longitudinal Beam And Flat Gasket Of Vehicle (Front)

Body 74-86

One On Each Side To Connect Upper Link With Towing

Arm 100 - 120

One On Each Side To Connect Lower Control Arm With

Towing Arm 100 - 120

Steering Knuckle And Suspension Strut 110 - 130

Soft Gasket And Bracket Of Front Suspension 75 - 85

Steering Knuckle Tie Rod And Steering Knuckle 32 - 38

Sub-Frame And Gasket Of Vehicle (Front) Body 170 - 190

Sub-Frame And Longitudinal Beam Welding Assembly 75 - 85

Steering Gear And Sub-Frame 75 - 85

Wheel Mounting Nut \

\

110

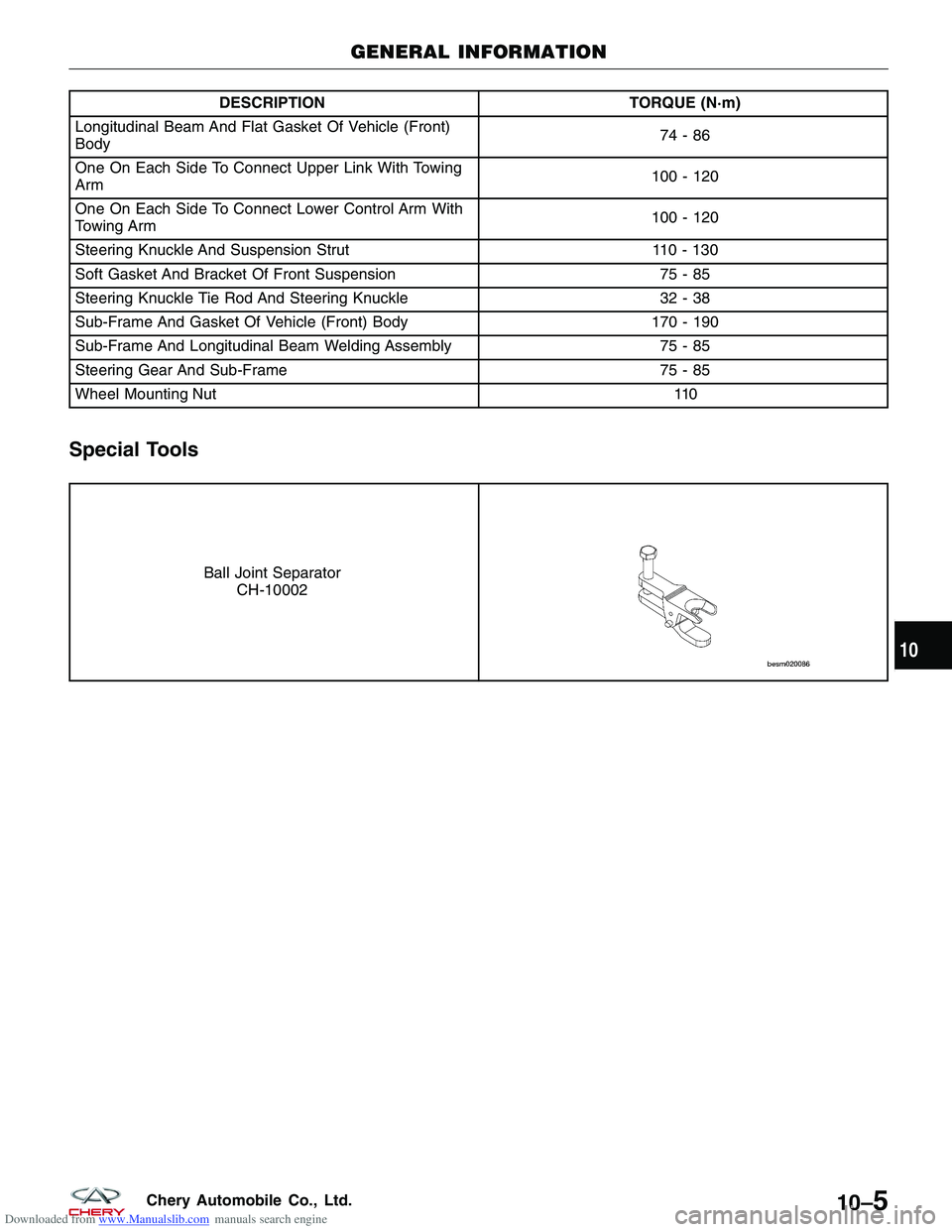

Special Tools

Ball Joint Separator

CH-10002

GENERAL INFORMATION

10

10–5Chery Automobile Co., Ltd.

Page 1314 of 1903

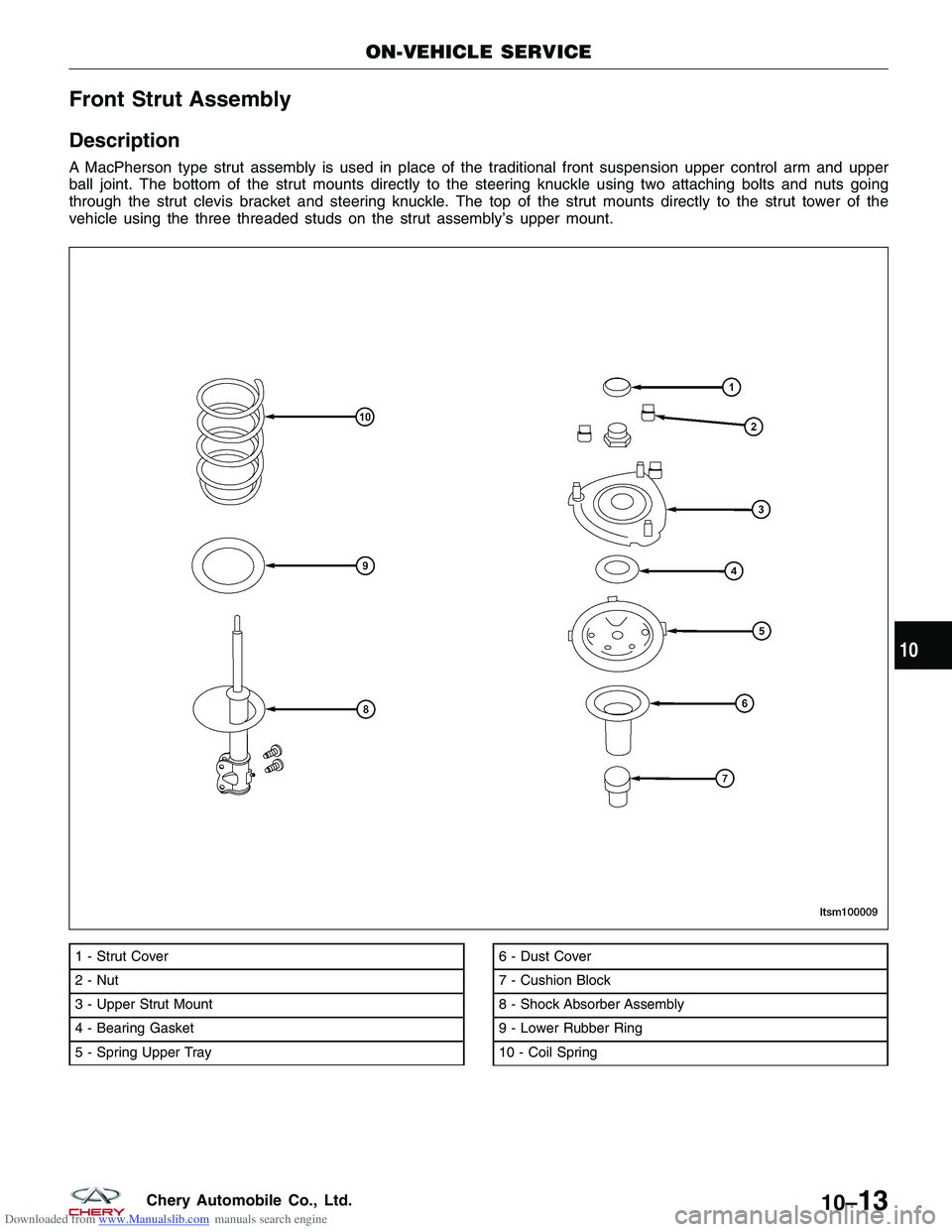

Downloaded from www.Manualslib.com manuals search engine Front Strut Assembly

Description

A MacPherson type strut assembly is used in place of the traditional front suspension upper control arm and upper

ball joint. The bottom of the strut mounts directly to the steering knuckle using two attaching bolts and nuts going

through the strut clevis bracket and steering knuckle. The top of the strut mounts directly to the strut tower of the

vehicle using the three threaded studs on the strut assembly’s upper mount.

1 - Strut Cover

2 - Nut

3 - Upper Strut Mount

4 - Bearing Gasket

5 - Spring Upper Tray6 - Dust Cover

7 - Cushion Block

8 - Shock Absorber Assembly

9 - Lower Rubber Ring

10 - Coil Spring

ON-VEHICLE SERVICE

LTSM100009

10

10–13Chery Automobile Co., Ltd.

Page 1316 of 1903

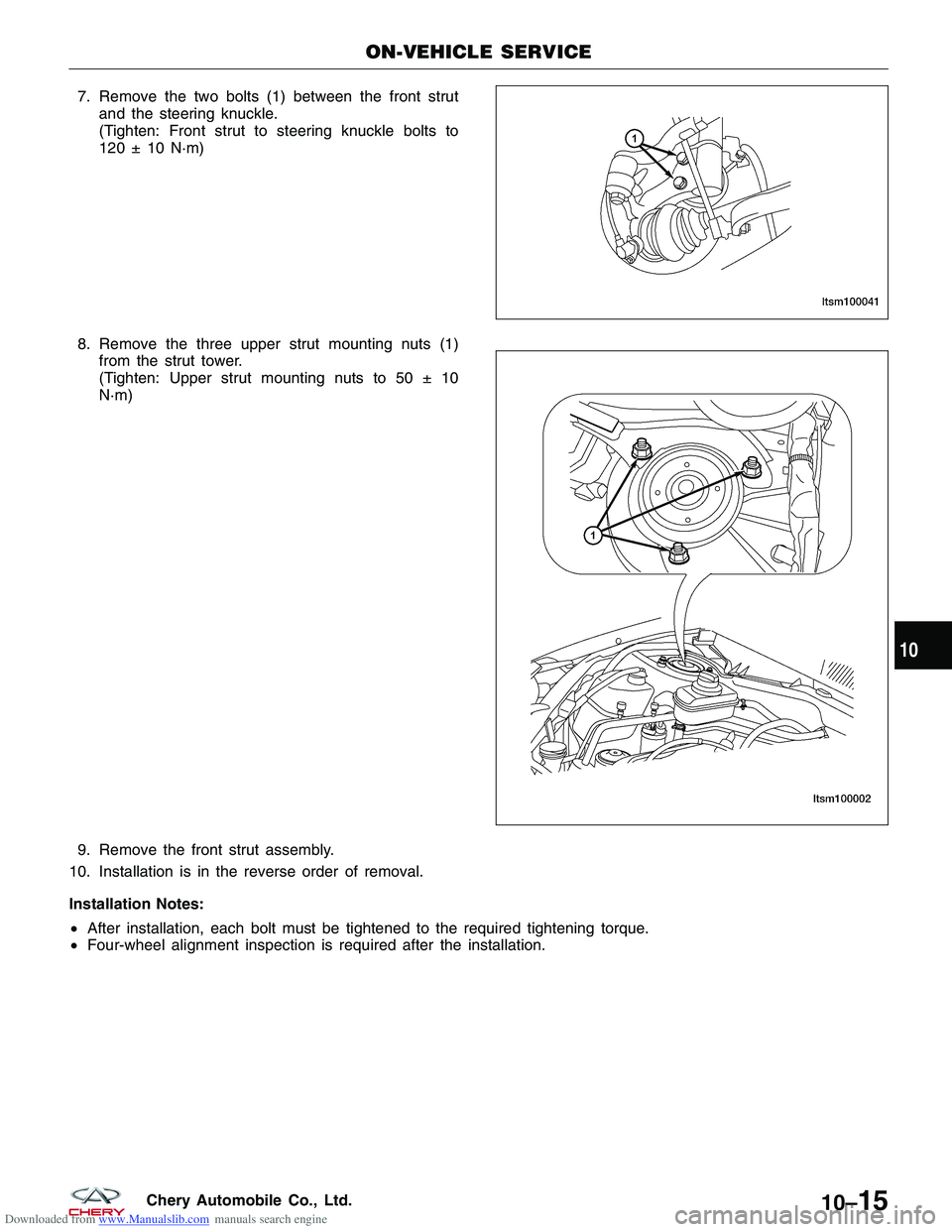

Downloaded from www.Manualslib.com manuals search engine 7. Remove the two bolts (1) between the front strutand the steering knuckle.

(Tighten: Front strut to steering knuckle bolts to

120 ± 10 N·m)

8. Remove the three upper strut mounting nuts (1) from the strut tower.

(Tighten: Upper strut mounting nuts to 50 ± 10

N·m)

9. Remove the front strut assembly.

10. Installation is in the reverse order of removal.

Installation Notes:

• After installation, each bolt must be tightened to the required tightening torque.

• Four-wheel alignment inspection is required after the installation.

ON-VEHICLE SERVICE

LTSM100041

LTSM100002

10

10–15Chery Automobile Co., Ltd.

Page 1317 of 1903

Downloaded from www.Manualslib.com manuals search engine Front Coil Spring

Description

A coil-over front strut assembly supports each front coil spring. The top of the strut assembly mounts to the strut

tower.

Operation

Coil springs are designed to store energy and subsequently release it and to absorb shock and maintain a force

between contacting surfaces. Coil springs are rated for specific vehicle applications.

NOTE :

Each component is serviced by removing the strut assembly from the vehicle and disassembling it. Coil springs are

rated separately for each corner or side of the vehicle depending on optional equipment and type of vehicle service.

If a coil spring requires replacement, be sure that it is replaced with a spring meeting the correct load rating for the

vehicle and its specific options.

Removal & Installation

CAUTION:

At no time when servicing a vehicle can a sheet metal screw, bolt or other metal fastener be

installed into the strut tower to take the place of an original plastic clamp. Also, do not drill holes

into the front strut tower for the installation of any metal fasteners into the strut tower area indi-

cated.

1. Raise and support the vehicle.

2. Remove the front strut assembly (See Front Strut Removal & Installation in Section 10 Suspension).

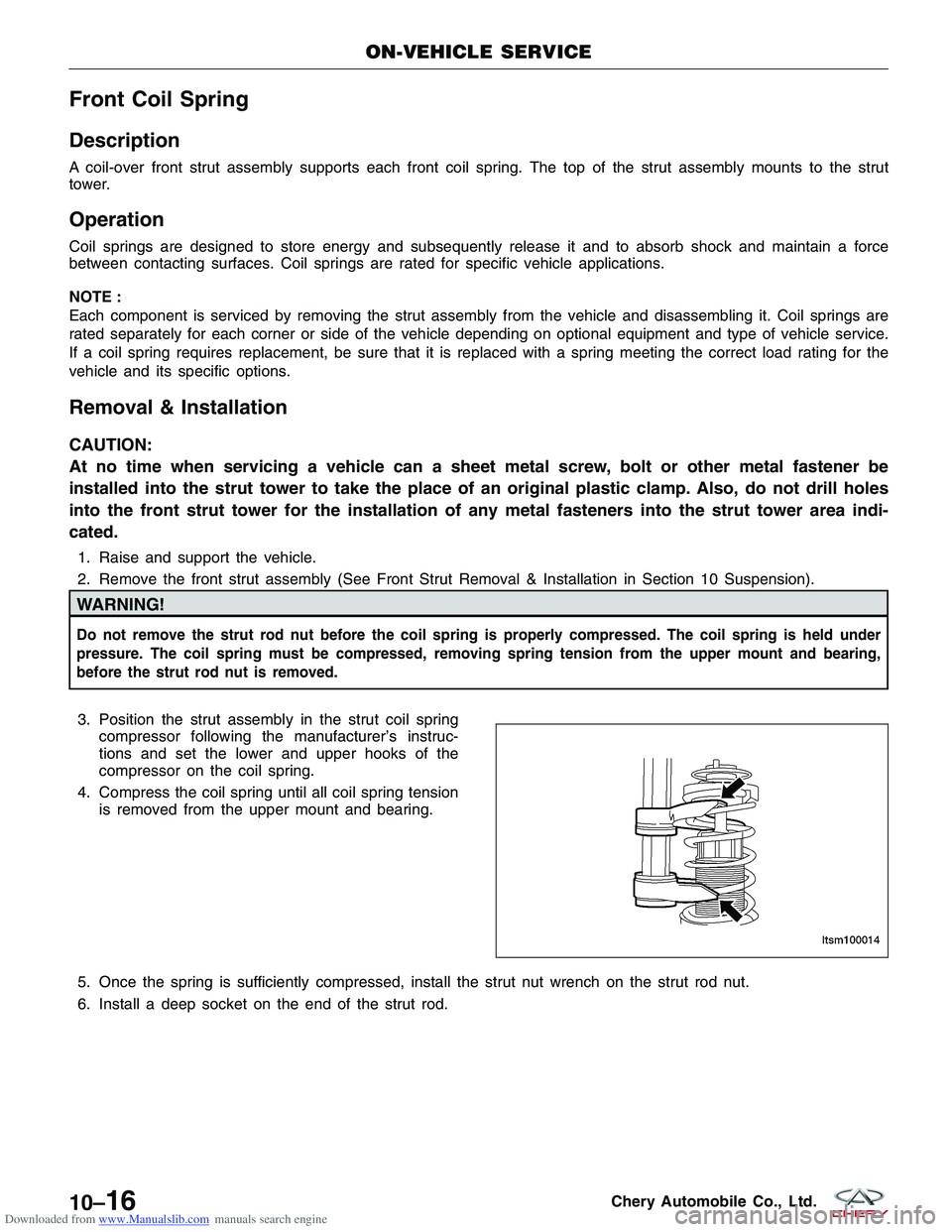

WARNING!

Do not remove the strut rod nut before the coil spring is properly compressed. The coil spring is held under

pressure. The coil spring must be compressed, removing spring tension from the upper mount and bearing,

before the strut rod nut is removed.

3. Position the strut assembly in the strut coil springcompressor following the manufacturer’s instruc-

tions and set the lower and upper hooks of the

compressor on the coil spring.

4. Compress the coil spring until all coil spring tension is removed from the upper mount and bearing.

5. Once the spring is sufficiently compressed, install the strut nut wrench on the strut rod nut.

6. Install a deep socket on the end of the strut rod.

ON-VEHICLE SERVICE

LTSM100014

10–16Chery Automobile Co., Ltd.

Page 1423 of 1903

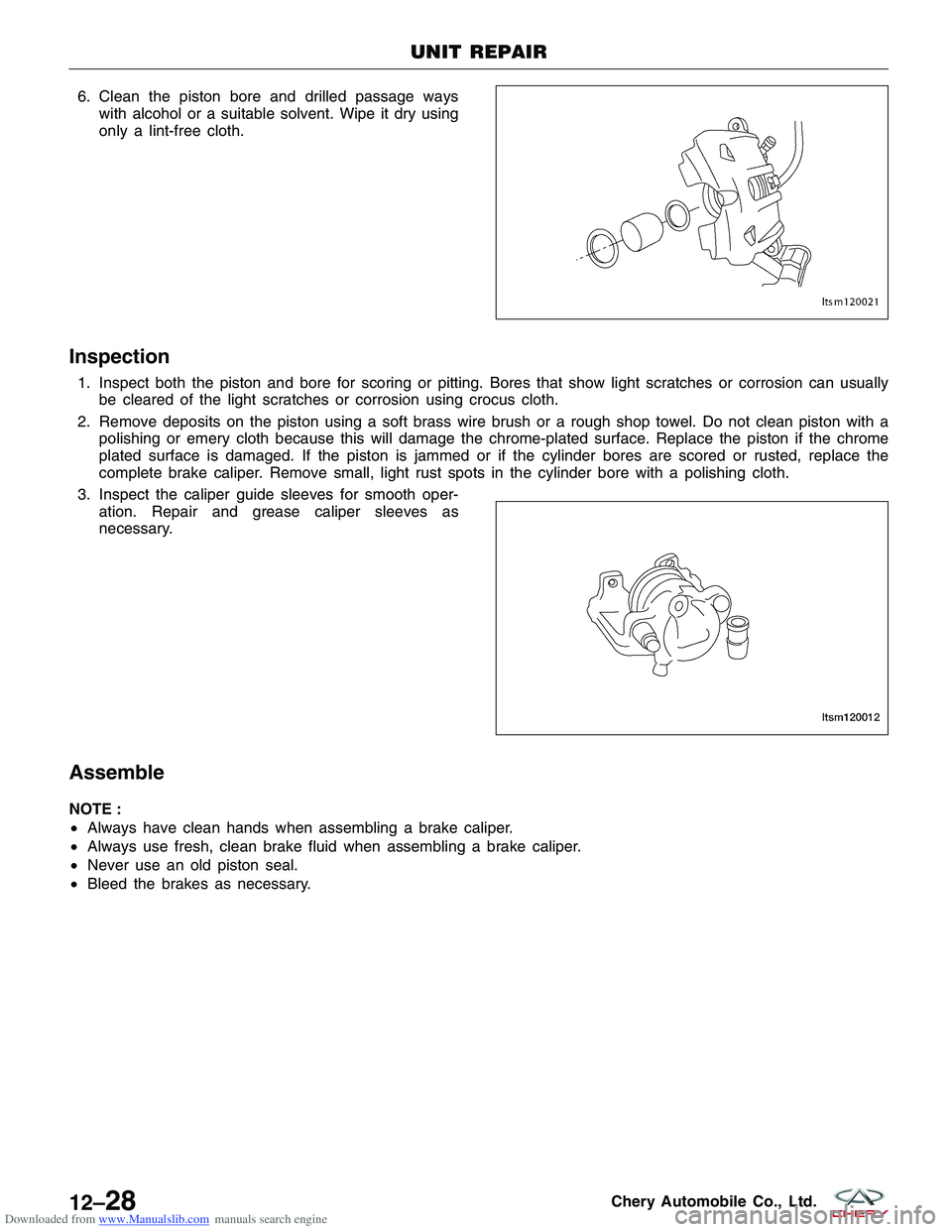

Downloaded from www.Manualslib.com manuals search engine 6. Clean the piston bore and drilled passage wayswith alcohol or a suitable solvent. Wipe it dry using

only a lint-free cloth.

Inspection

1. Inspect both the piston and bore for scoring or pitting. Bores that show light scratches or corrosion can usuallybe cleared of the light scratches or corrosion using crocus cloth.

2. Remove deposits on the piston using a soft brass wire brush or a rough shop towel. Do not clean piston with a polishing or emery cloth because this will damage the chrome-plated surface. Replace the piston if the chrome

plated surface is damaged. If the piston is jammed or if the cylinder bores are scored or rusted, replace the

complete brake caliper. Remove small, light rust spots in the cylinder bore with a polishing cloth.

3. Inspect the caliper guide sleeves for smooth oper- ation. Repair and grease caliper sleeves as

necessary.

Assemble

NOTE :

•Always have clean hands when assembling a brake caliper.

• Always use fresh, clean brake fluid when assembling a brake caliper.

• Never use an old piston seal.

• Bleed the brakes as necessary.

UNIT REPAIR

LTSM120021

LTSM120012

12–28Chery Automobile Co., Ltd.

Page 1426 of 1903

Downloaded from www.Manualslib.com manuals search engine CAUTION:

Do not use a screwdriver or other metal tool for seal removal. Using such tools can scratch the

bore or leave burrs on the seal groove edges.

5. Using a soft tool such as a plastic trim stick (1),work the piston seal (2) out of its groove in caliper

piston bore. Discard the used seal.

6. Clean the piston bore and drilled passage ways with alcohol or a suitable solvent. Wipe it dry using

only a lint-free cloth.

Inspection

1. Inspect both the piston and bore for scoring or pitting. Bores that show light scratches or corrosion can usuallybe cleared of the light scratches or corrosion using crocus cloth.

2. Remove deposits on the piston using a soft brass wire brush or a rough shop towel. Do not clean piston with a polishing or emery cloth because this will damage the chrome-plated surface. Replace the piston if the chrome

plated surface is damaged. If the piston is jammed or if the cylinder bores are scored or rusted, replace the

complete brake caliper. Remove small, light rust spots in the cylinder bore with a polishing cloth. Remove heavy

rust spots in front of the groove for the piston seal using fine-grit emery paper (grit size 380 to 500).

3. Inspect the caliper seal rings. Repair the seal rings as necessary.

UNIT REPAIR

BESM120003

LTSM120021

LTSM120012

12

12–31Chery Automobile Co., Ltd.