coolant CHERY TIGGO 2009 Service Manual PDF

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 712 of 1903

Downloaded from www.Manualslib.com manuals search engine 6. Installation is in the reverse order of removal.

NOTE :

After installing the engine coolant temperature sensor, check the coolant level.

Knock Sensor

Description

The knock sensor is attached to the cylinder block. The knock sensor is designed to detect engine vibration that is

caused by detonation.

Operation

When the knock sensor detects a knock in one of the cylinders, it sends an input signal to the Engine Control Module

(ECM). In response, the ECM retards ignition timing for all cylinders by a specified amount.

The knock sensor contains a piezoelectric material which constantly vibrates and sends an input voltage (signal) to

the ECM while the engine operates. As the intensity of the vibration increases, the knock sensor output voltage also

increases.

The ECM ignores knock sensor input during engine idle conditions. Once the engine speed exceeds a specified

value, knock retard is allowed.

Removal & Installation

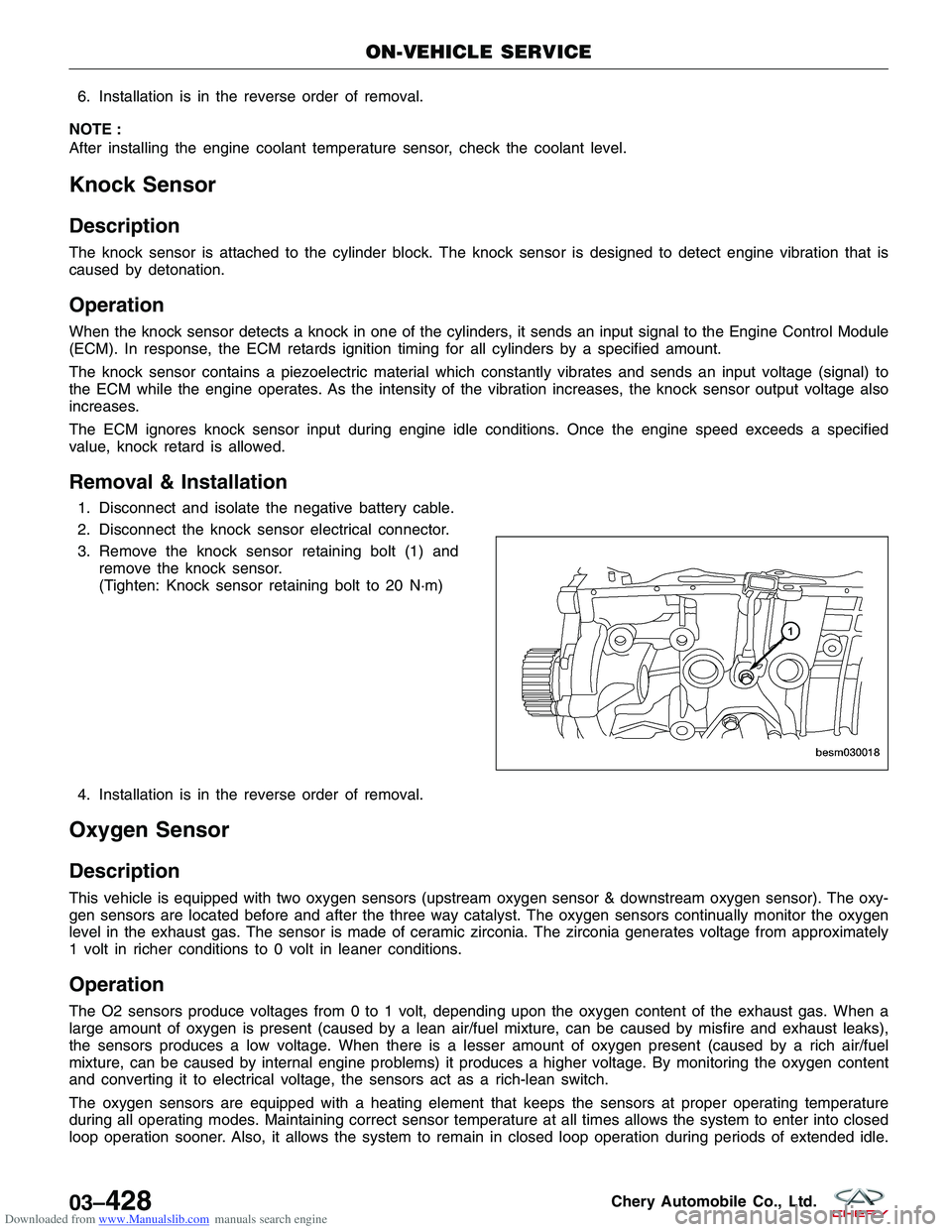

1. Disconnect and isolate the negative battery cable.

2. Disconnect the knock sensor electrical connector.

3. Remove the knock sensor retaining bolt (1) and

remove the knock sensor.

(Tighten: Knock sensor retaining bolt to 20 N·m)

4. Installation is in the reverse order of removal.

Oxygen Sensor

Description

This vehicle is equipped with two oxygen sensors (upstream oxygen sensor & downstream oxygen sensor). The oxy-

gen sensors are located before and after the three way catalyst. The oxygen sensors continually monitor the oxygen

level in the exhaust gas. The sensor is made of ceramic zirconia. The zirconia generates voltage from approximately

1 volt in richer conditions to 0 volt in leaner conditions.

Operation

The O2 sensors produce voltages from 0 to 1 volt, depending upon the oxygen content of the exhaust gas. When a

large amount of oxygen is present (caused by a lean air/fuel mixture, can be caused by misfire and exhaust leaks),

the sensors produces a low voltage. When there is a lesser amount of oxygen present (caused by a rich air/fuel

mixture, can be caused by internal engine problems) it produces a higher voltage. By monitoring the oxygen content

and converting it to electrical voltage, the sensors act as a rich-lean switch.

The oxygen sensors are equipped with a heating element that keeps the sensors at proper operating temperature

during all operating modes. Maintaining correct sensor temperature at all times allows the system to enter into closed

loop operation sooner. Also, it allows the system to remain in closed loop operation during periods of extended idle.

ON-VEHICLE SERVICE

BESM030018

03–428Chery Automobile Co., Ltd.

Page 725 of 1903

Downloaded from www.Manualslib.com manuals search engine 2.4L ENGINE CONTROLS

GENERAL INFORMATION03-442

Description 03-442

Operation 03-442

Electronic Engine Control Input & Output

Device Failure Modes 03-443

Specifications 03-444

Special Tools 03-445

Electrical Schematics 03-447

ECM Connector Pin-Out Table 03-457

DIAGNOSIS & TESTING03-458

Diagnostic Help 03-458

Diagnostic Logic 03-458

Ground Inspection 03-459

Diagnostic Tools 03-459

Diagnostic Trouble Code (DTC) List 03-461

ECM Power Supply and Ground Circuit

Test 03-462

Power Supply And Ground Circuit

Diagnostic Check 03-462

Diagnostic Trouble Code (DTC) Tests 03-469

11 - Oxygen Sensor 03-469

12- Air Flow Sensor 03-476

13 - Air Temperature Sensor 03-482

14 - Throttle Position Sensor 03-487

21 - Coolant Temperature Sensor 03-493

22 - Crankshaft Position Sensor 03-498

23 - Camshaft Position Sensor 03-504

25 - Atmosphere Pressure Sensor 03-510

31 - Knock Sensor 03-515

41 - Injector 03-519

44 - Ignition Signal 03-525

ON-VEHICLE SERVICE03-531

Engine Coolant Temperature (ECT)

Sensor 03-531

Description 03-531

Operation 03-531

Removal & Installation 03-531

Coolant Temperature Sensor (For

Instrument Cluster) 03-532

Description 03-532

Operation 03-532

Removal & Installation 03-532Knock Sensor

03-533

Description 03-533

Operation 03-533

Removal & Installation 03-533

Oxygen Sensor 03-533

Description 03-533

Operation 03-533

Upstream Oxygen Sensor 03-534

Downstream Oxygen Sensor 03-534

Removal & Installation - Upstream

Oxygen Sensor 03-534

Removal & Installation - Downstream

Oxygen Sensor 03-535

Camshaft Position (CMP) Sensor 03-536

Description 03-536

Operation 03-536

Removal & Installation 03-536

Air Flow Sensor 03-537

Description 03-537

Operation 03-537

Removal & Installation 03-537

Throttle Control Actuator 03-538

Description 03-538

Operation 03-538

Removal & Installation 03-538

Engine Control Module (ECM) 03-539

Description 03-539

Operation 03-539

Removal & Installation 03-539

Throttle Position Sensor (TPS) 03-540

Description 03-540

Operation 03-540

Removal & Installation 03-540

Idle Air Control (IAC) Motor 03-541

Description 03-541

Operation 03-541

Removal & Installation 03-541

Crankshaft Position (CKP) Sensor 03-542

Description 03-542

Operation 03-542

Removal & Installation 03-542

03

03–441Chery Automobile Co., Ltd.

Page 726 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

The Engine Control Module (ECM) consists of a microcomputer and connectors for signal input and output and for

power supply. The ECM controls the engine.

The following are the input and output components monitored by the ECM. The monitored functions include compo-

nents from the engine, ignition, transaxle, air conditioning, or any other ECM supported subsystem.

ECM Inputs

•Brake Switch Sensor

• Camshaft Position (CMP) Sensor

• Crankshaft Position (CKP) Sensor

• Engine Coolant Temperature (ECT) Sensor

• Air Flow Sensor

• Coolant Temperature Sensor (For Instrument Cluster)

• Throttle Position Sensor (Integral with Electronic Throttle Control Actuator)

• Power Steering Switch

• Knock Sensor

• Oxygen Sensor (Upstream & Downstream)

• Clutch Pedal Switch (Manual transmission only)

ECM Outputs

• Canister Control Valve

• Fuel Injectors

• Fuel Pump Relay

• Electronic Throttle Control Actuator

• Ignition Coil

• A/C Compressor

• Cooling Fan

• Oxygen Sensor heating coil (Upstream & Downstream)

Operation

The ECM monitors components and circuits and tests them in various ways depending on the hardware, function,

and type of signal. For example, analog inputs such as throttle position or engine coolant temperature are typically

checked for opens, shorts and out-of-range values. This type of monitoring is carried out continuously. Some digital

inputs like vehicle speed or crankshaft position rely on rationality checks - checking to see if the input value makes

sense at the current engine operating conditions. These types of tests may require monitoring several components

and can only be carried out under appropriate test conditions.

The ECM is a pre-programmed, microprocessor-based digital computer. It regulates ignition timing, air-fuel ratio,

emission control devices, charging system, certain transmission features, speed control, air conditioning compressor

clutch engagement and idle speed. The ECM can adapt its programming to meet changing operating conditions.

03–442Chery Automobile Co., Ltd.

Page 728 of 1903

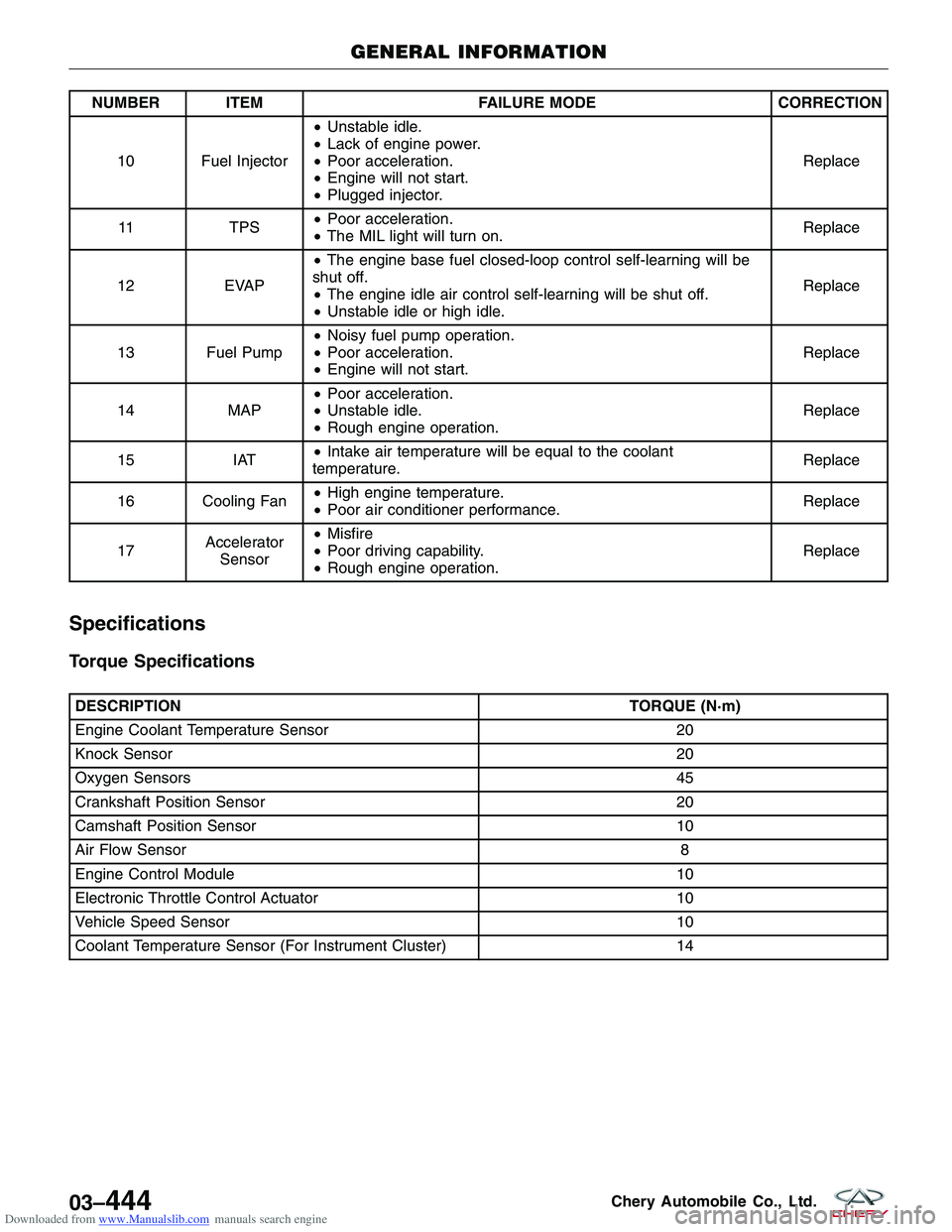

Downloaded from www.Manualslib.com manuals search engine NUMBER ITEMFAILURE MODECORRECTION

10 Fuel Injector •

Unstable idle.

• Lack of engine power.

• Poor acceleration.

• Engine will not start.

• Plugged injector. Replace

11 TPS•

Poor acceleration.

• The MIL light will turn on. Replace

12 EVAP•

The engine base fuel closed-loop control self-learning will be

shut off.

• The engine idle air control self-learning will be shut off.

• Unstable idle or high idle. Replace

13 Fuel Pump •

Noisy fuel pump operation.

• Poor acceleration.

• Engine will not start. Replace

14 MAP•

Poor acceleration.

• Unstable idle.

• Rough engine operation. Replace

15 IAT•

Intake air temperature will be equal to the coolant

temperature. Replace

16 Cooling Fan •

High engine temperature.

• Poor air conditioner performance. Replace

17 Accelerator

Sensor •

Misfire

• Poor driving capability.

• Rough engine operation. Replace

Specifications

Torque Specifications

DESCRIPTION

TORQUE (N·m)

Engine Coolant Temperature Sensor 20

Knock Sensor 20

Oxygen Sensors 45

Crankshaft Position Sensor 20

Camshaft Position Sensor 10

Air Flow Sensor 8

Engine Control Module 10

Electronic Throttle Control Actuator 10

Vehicle Speed Sensor 10

Coolant Temperature Sensor (For Instrument Cluster) 14

GENERAL INFORMATION

03–444Chery Automobile Co., Ltd.

Page 741 of 1903

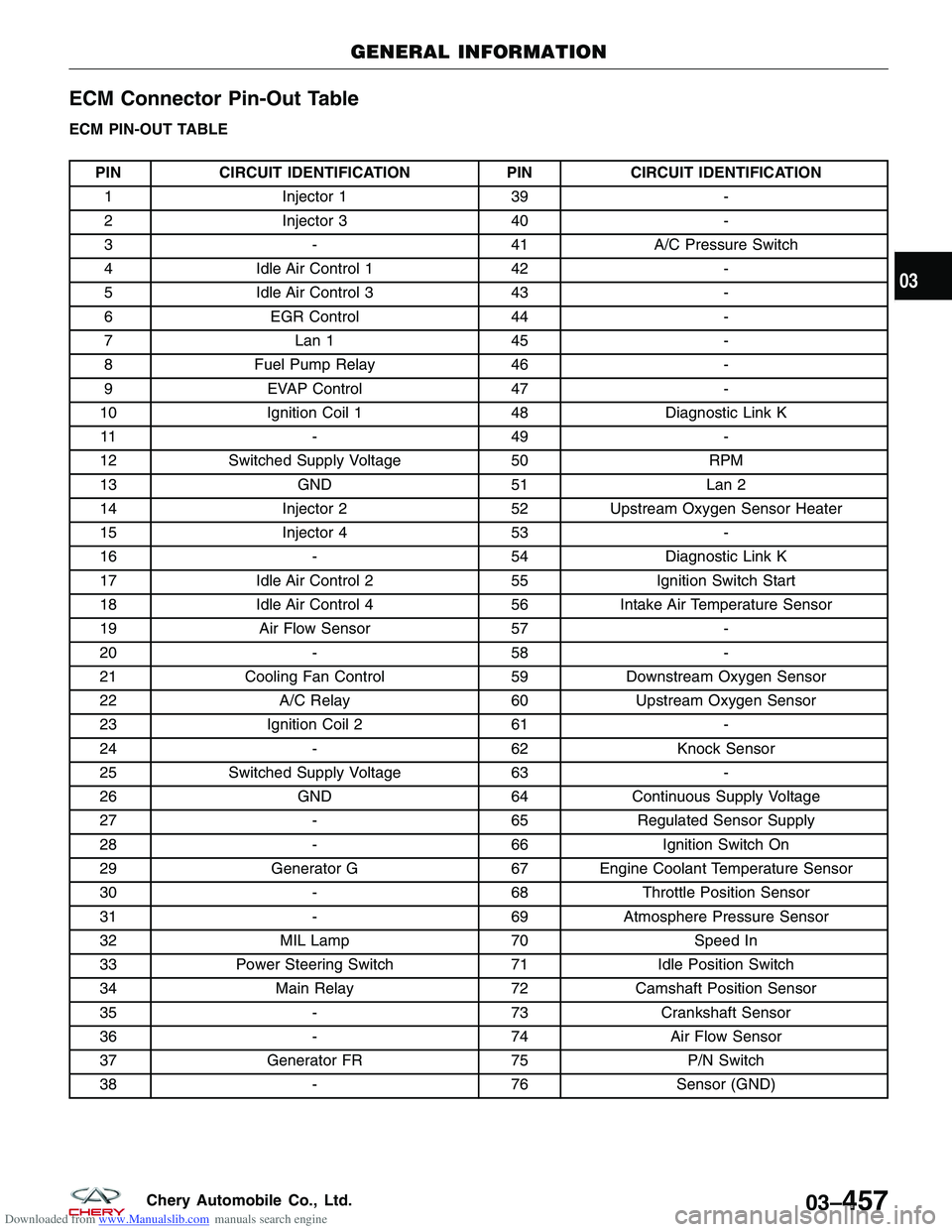

Downloaded from www.Manualslib.com manuals search engine ECM Connector Pin-Out Table

ECM PIN-OUT TABLE

PINCIRCUIT IDENTIFICATION PINCIRCUIT IDENTIFICATION

1 Injector 1 39-

2 Injector 3 40-

3 -41A/C Pressure Switch

4 Idle Air Control 1 42-

5 Idle Air Control 3 43-

6 EGR Control 44-

7 Lan 1 45-

8 Fuel Pump Relay 46-

9 EVAP Control 47-

10 Ignition Coil 1 48Diagnostic Link K

11 -4 9 -

12 Switched Supply Voltage 50RPM

13 GND 51Lan 2

14 Injector 2 52Upstream Oxygen Sensor Heater

15 Injector 4 53-

16 -54Diagnostic Link K

17 Idle Air Control 2 55Ignition Switch Start

18 Idle Air Control 4 56Intake Air Temperature Sensor

19 Air Flow Sensor 57-

20 -58 -

21 Cooling Fan Control 59Downstream Oxygen Sensor

22 A/C Relay 60Upstream Oxygen Sensor

23 Ignition Coil 2 61-

24 -62Knock Sensor

25 Switched Supply Voltage 63-

26 GND 64Continuous Supply Voltage

27 -65Regulated Sensor Supply

28 -66Ignition Switch On

29 Generator G 67 Engine Coolant Temperature Sensor

30 -68Throttle Position Sensor

31 -69Atmosphere Pressure Sensor

32 MIL Lamp 70Speed In

33 Power Steering Switch 71Idle Position Switch

34 Main Relay 72Camshaft Position Sensor

35 -73Crankshaft Sensor

36 -74Air Flow Sensor

37 Generator FR 75P/N Switch

38 -76Sensor (GND)

GENERAL INFORMATION

03

03–457Chery Automobile Co., Ltd.

Page 745 of 1903

Downloaded from www.Manualslib.com manuals search engine Diagnostic Trouble Code (DTC) List

DTCDTC DEFINITION

11 Oxygen Sensor

12 Air Flow Sensor

13 Air Temperature Sensor

14 Throttle Position Sensor

21 Coolant Temperature Sensor

22 Crankshaft Position Sensor

23 Camshaft Position Sensor

24 Speed Sensor

25 Atmosphere Pressure Sensor

31 Knock Sensor

36 Ignition Signal Terminal

41 Injector

44 Ignition Signal

54 Immobilizer Communication

61 Electronic 4AT Communication

64 ALT FR Signal

DIAGNOSIS & TESTING

03

03–461Chery Automobile Co., Ltd.

Page 763 of 1903

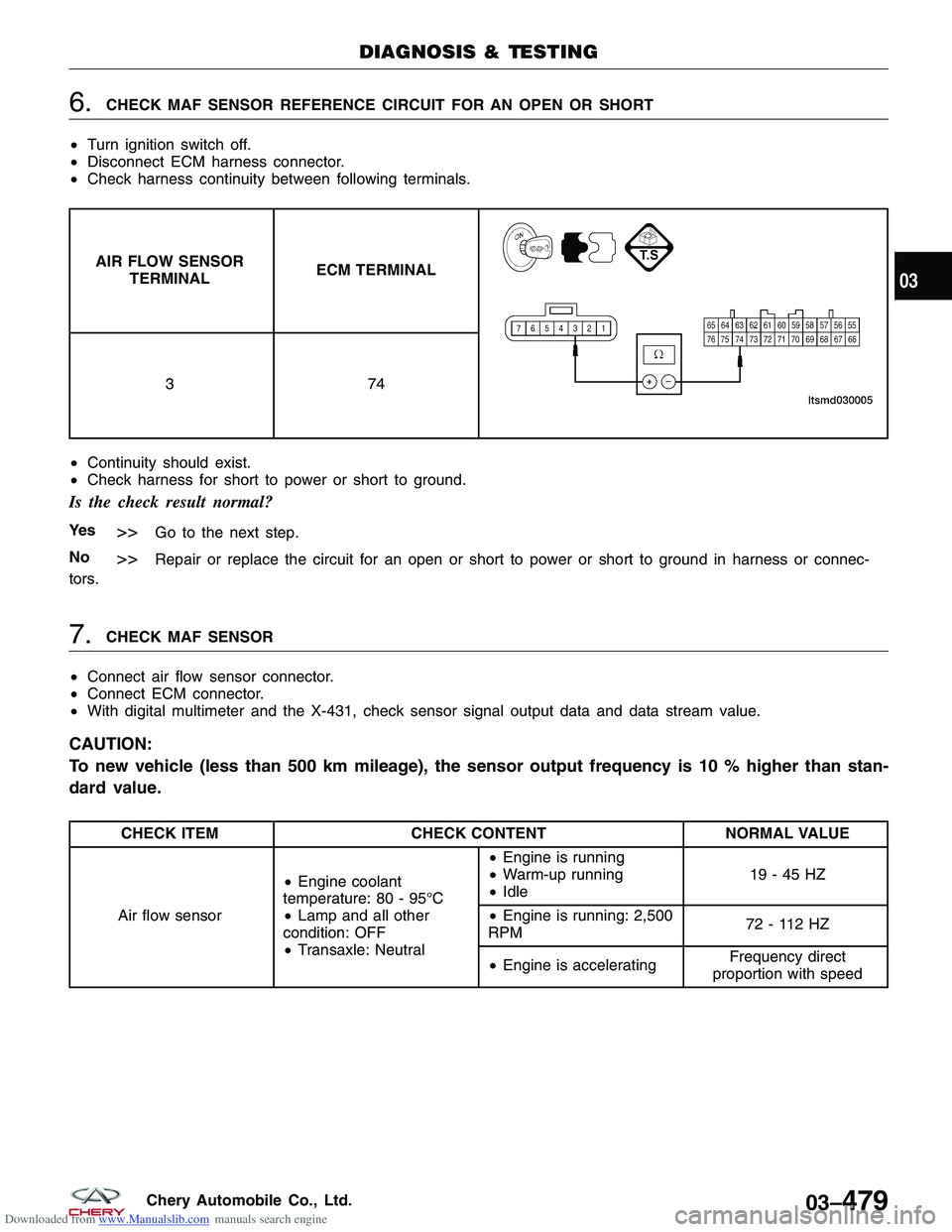

Downloaded from www.Manualslib.com manuals search engine 6.CHECK MAF SENSOR REFERENCE CIRCUIT FOR AN OPEN OR SHORT

• Turn ignition switch off.

• Disconnect ECM harness connector.

• Check harness continuity between following terminals.

AIR FLOW SENSOR

TERMINAL ECM TERMINAL

37

4

• Continuity should exist.

• Check harness for short to power or short to ground.

Is the check result normal?

Ye s>>Go to the next step.

No

>>Repair or replace the circuit for an open or short to power or short to ground in harness or connec-

tors.

7.CHECK MAF SENSOR

• Connect air flow sensor connector.

• Connect ECM connector.

• With digital multimeter and the X-431, check sensor signal output data and data stream value.

CAUTION:

To new vehicle (less than 500 km mileage), the sensor output frequency is 10 % higher than stan-

dard value.

CHECK ITEM CHECK CONTENT NORMAL VALUE

Air flow sensor •

Engine coolant

temperature: 80 - 95°C

• Lamp and all other

condition: OFF

• Transaxle: Neutral •

Engine is running

• Warm-up running

• Idle 19-45HZ

• Engine is running: 2,500

RPM 72 - 112 HZ

• Engine is accelerating Frequency direct

proportion with speed

DIAGNOSIS & TESTING

03

03–479Chery Automobile Co., Ltd.

Page 777 of 1903

Downloaded from www.Manualslib.com manuals search engine 21 - Coolant Temperature Sensor

DIAGNOSIS & TESTING

LTSMW030005T

03

03–493Chery Automobile Co., Ltd.

Page 778 of 1903

Downloaded from www.Manualslib.com manuals search engine Check reference values between ECM terminals and ground under the following conditions:

ECM TERMINALNO. ITEM

CONDITION DATA (DC

VOLTAGE)

67 Engine Coolant

Temperature (ECT) sensor Ignition switch: ON ECT: 0°C

3.2 - 3.8 V

ECT: 20°C 2.3 - 2.9 V

ECT: 40°C 1.3 - 1.9 V

ECT: 80°C 0.3 - 0.9 V

76 Sensor (GND) -Approximately 0 V

On Board Diagnostic Logic

• Self-diagnosis detection logic.

DTC NO. DTC DEFINITION DTC DETECTION

CONDITION DTC SET

CONDITION POSSIBLE CAUSE

21 Coolant temperature

sensor •

Ignition switch:

ON position for 60

seconds

• Engine: Running •

Signal output is

above 4.6 V for 4

seconds

continuously

(amount to -45°C

engine coolant

temperature).

• Signal output is

below 0.1 V for 4

seconds

continuously

(amount to 145°C

engine coolant

temperature). •

Engine Coolant

Temperature (ECT)

sensor

• Harness or

connectors

• ECM

• Ignition switch:

ON

• Engine speed is

above 500 RPM •

Signal output raise

from below 1.6 V to

above 1.6 V

(amount to 40°C

engine coolant

temperature).

• Signal output is

above 1.6 V for 5

minutes.

DTC Confirmation Procedure:

Before performing the following procedure, confirm that battery voltage is more than 12 V.

• Turn ignition switch off.

• Connect the X-431 scan tool to the Data Link Connector (DLC) - use the most current software available.

• Turn ignition switch on.

• With the scan tool, record and erase stored DTCs in the ECM.

• Start engine and warm it to normal operating temperature, then select view DTC and data stream.

• If the DTC is detected, the DTC condition is current. Go to Diagnostic Procedure - Step 1.

• If the DTC is not detected, the DTC condition is intermittent (See Diagnostic Help and Intermittent DTC Trou-

bleshooting in Section 03 Electronic Engine Controls for more information.

NOTE :

Before performing the following procedure, make sure that the ECM connection is in good condition.

NOTE :

While performing electrical diagnosis & testing, always refer to the electrical schematics for specific circuit

and component information.

DIAGNOSIS & TESTING

03–494Chery Automobile Co., Ltd.

Page 779 of 1903

Downloaded from www.Manualslib.com manuals search engine Diagnostic Procedure

1.CHECK GROUND CONNECTION

• Turn ignition switch off.

• Loosen and retighten ground screws on the body (See Ground Inspection in Section 03 Electronic Engine Con-

trols).

• Inspect the ground connection E-208 (See Vehicle Wiring Harness Layout - Engine Room Harness (With Mit-

subishi 2.4L Engine) in Section 16 Wiring).

Is the ground connections OK?

Ye s>>Go to the next step.

No

>>Repair or replace ground connection.

2.CHECK ENGINE COOLANT TEMPERATURE (ECT) SENSOR ELECTRICAL CONNECTOR

• Disconnect the ECT (1) electrical connector.

• Inspect the electrical connector for damage.

Is the electrical connector OK?

Ye s>>Go to the next step.

No

>>Repair or replace the electrical connector

as necessary.

DIAGNOSIS & TESTING

LTSM030007

03

03–495Chery Automobile Co., Ltd.