oil filter CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 30 of 1903

Downloaded from www.Manualslib.com manuals search engine ENGINE

02

CONTENTSpage

1.6L & 1.8L Engine Mechanical ......................................................... 02-1

2.0L Engine Mechanical .............................................................. 02-76

2.4L Engine Mechanical ............................................................. 02-149

1.6L & 1.8L ENGINE MECHANICAL

GENERAL INFORMATION02-3

Description 02-3

Operation 02-3

Specifications 02-3

Special Tools 02-7

Lubrication System 02-10

DIAGNOSIS & TESTING02-13

Engine Performance Diagnostics 02-13

Engine Mechanical Diagnostics 02-14

Cylinder Compression Pressure Test 02-16

Cylinder Head Gasket Test 02-16

ON-VEHICLE SERVICE02-17

Accessory Drive Belt 02-17

Removal & Installation 02-17

Air Cleaner Element 02-18

Removal & Installation 02-18

Air Cleaner Housing 02-18

Removal & Installation 02-18

Cylinder Head Cover 02-19

Removal & Installation 02-19

Camshaft 02-20

Removal & Installation 02-20

Cylinder Head 02-23

Removal & Installation 02-23

Front Crankshaft Oil Seal 02-25

Removal & Installation 02-25 Rear Crankshaft Oil Seal

02-27

Removal & Installation 02-27

Engine Mounts 02-29

Removal & Installation - Left Mount 02-29

Removal & Installation - Right Mount 02-30

Removal & Installation - Front Mount 02-30

Removal & Installation - Rear Mount 02-31

Engine Assembly 02-31

Removal & Installation 02-31

Engine Timing Belt 02-38

Removal & Installation 02-38

Exhaust Manifold 02-41

Removal & Installation 02-41

Intake Manifold 02-43

Removal & Installation 02-43

Idler Pulley 02-45

Removal & Installation 02-45

Oil Filter 02-46

Removal & Installation 02-46

Oil Pan 02-47

Removal & Installation 02-47

Oil Pump 02-48

Removal & Installation 02-48

Oil Strainer 02-49

Removal & Installation 02-49

02

02–1Chery Automobile Co., Ltd.

Page 35 of 1903

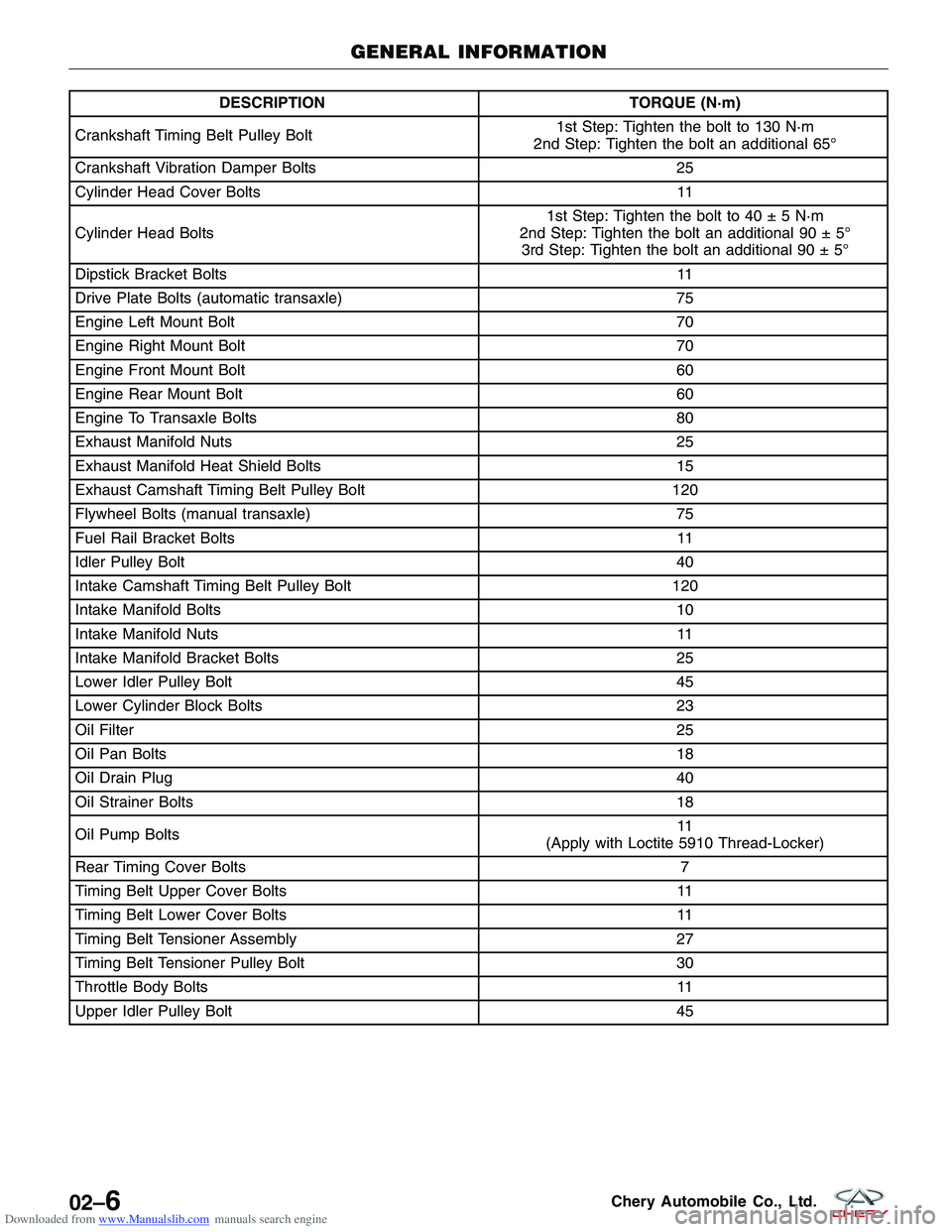

Downloaded from www.Manualslib.com manuals search engine DESCRIPTIONTORQUE (N·m)

Crankshaft Timing Belt Pulley Bolt 1st Step: Tighten the bolt to 130 N·m

2nd Step: Tighten the bolt an additional 65°

Crankshaft Vibration Damper Bolts 25

Cylinder Head Cover Bolts 11

Cylinder Head Bolts 1st Step: Tighten the bolt to 40 ± 5 N·m

2nd Step: Tighten the bolt an additional 90 ± 5° 3rd Step: Tighten the bolt an additional 90 ± 5°

Dipstick Bracket Bolts 11

Drive Plate Bolts (automatic transaxle) 75

Engine Left Mount Bolt 70

Engine Right Mount Bolt 70

Engine Front Mount Bolt 60

Engine Rear Mount Bolt 60

Engine To Transaxle Bolts 80

Exhaust Manifold Nuts 25

Exhaust Manifold Heat Shield Bolts 15

Exhaust Camshaft Timing Belt Pulley Bolt 120

Flywheel Bolts (manual transaxle) 75

Fuel Rail Bracket Bolts 11

Idler Pulley Bolt 40

Intake Camshaft Timing Belt Pulley Bolt 120

Intake Manifold Bolts 10

Intake Manifold Nuts 11

Intake Manifold Bracket Bolts 25

Lower Idler Pulley Bolt 45

Lower Cylinder Block Bolts 23

Oil Filter 25

Oil Pan Bolts 18

Oil Drain Plug 40

Oil Strainer Bolts 18

Oil Pump Bolts 11

(Apply with Loctite 5910 Thread-Locker)

Rear Timing Cover Bolts 7

Timing Belt Upper Cover Bolts 11

Timing Belt Lower Cover Bolts 11

Timing Belt Tensioner Assembly 27

Timing Belt Tensioner Pulley Bolt 30

Throttle Body Bolts 11

Upper Idler Pulley Bolt 45

GENERAL INFORMATION

02–6Chery Automobile Co., Ltd.

Page 39 of 1903

Downloaded from www.Manualslib.com manuals search engine Flywheel FixtureCH-20043

Engine Hoist

Oil Filter Remover CH-10003

Lubrication System

The engine lubrication system operates as follows:

•Oil is drawn into the oil pump through the oil pump strainer tube in the sump of the oil pan.

• Oil is pumped through the oil filter on the cylinder block.

• Oil enters the main oil gallery where it is distributed to the crankshaft main journals and to the cylinder head.

• From the main journals, the oil is routed through cross-drilled passages in the crankshaft to lubricate the con-

necting rod bearings. Controlled leakage through the crankshaft main bearings and connecting rod bearings is

slung radially outward to cool and lubricate the cylinder walls as well as the entire connecting rod, piston and

piston ring assembly.

• The engine lubrication system is a full-flow filtration, pressure feed type. The oil pump body is mounted to the

engine block. The pump inner rotor is driven by the crankshaft.

Engine Oil Pressure Specifications

Lower Idle Speed (800 ± 50 RPM) 1.2 - 1.5 bar

High Idle Speed (2000 RPM) 3.2 - 3.5 bar

High Speed (4000 RPM) 3.7 ± 0.5 bar

GENERAL INFORMATION

02–10Chery Automobile Co., Ltd.

Page 40 of 1903

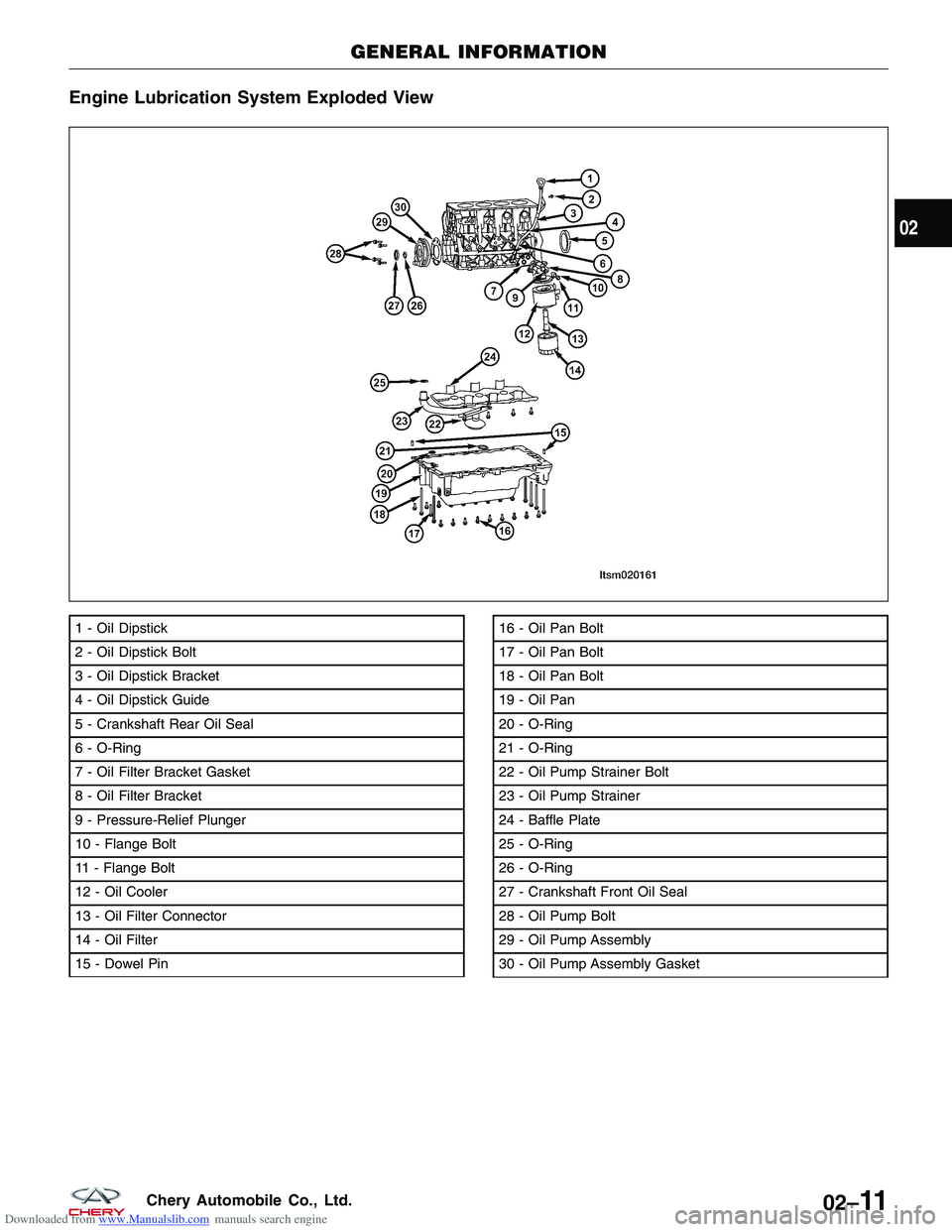

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System Exploded View

1 - Oil Dipstick

2 - Oil Dipstick Bolt

3 - Oil Dipstick Bracket

4 - Oil Dipstick Guide

5 - Crankshaft Rear Oil Seal

6 - O-Ring

7 - Oil Filter Bracket Gasket

8 - Oil Filter Bracket

9 - Pressure-Relief Plunger

10 - Flange Bolt

11 - Flange Bolt

12 - Oil Cooler

13 - Oil Filter Connector

14 - Oil Filter

15 - Dowel Pin16 - Oil Pan Bolt

17 - Oil Pan Bolt

18 - Oil Pan Bolt

19 - Oil Pan

20 - O-Ring

21 - O-Ring

22 - Oil Pump Strainer Bolt

23 - Oil Pump Strainer

24 - Baffle Plate

25 - O-Ring

26 - O-Ring

27 - Crankshaft Front Oil Seal

28 - Oil Pump Bolt

29 - Oil Pump Assembly

30 - Oil Pump Assembly Gasket

GENERAL INFORMATION

LTSM020161

02

02–11Chery Automobile Co., Ltd.

Page 41 of 1903

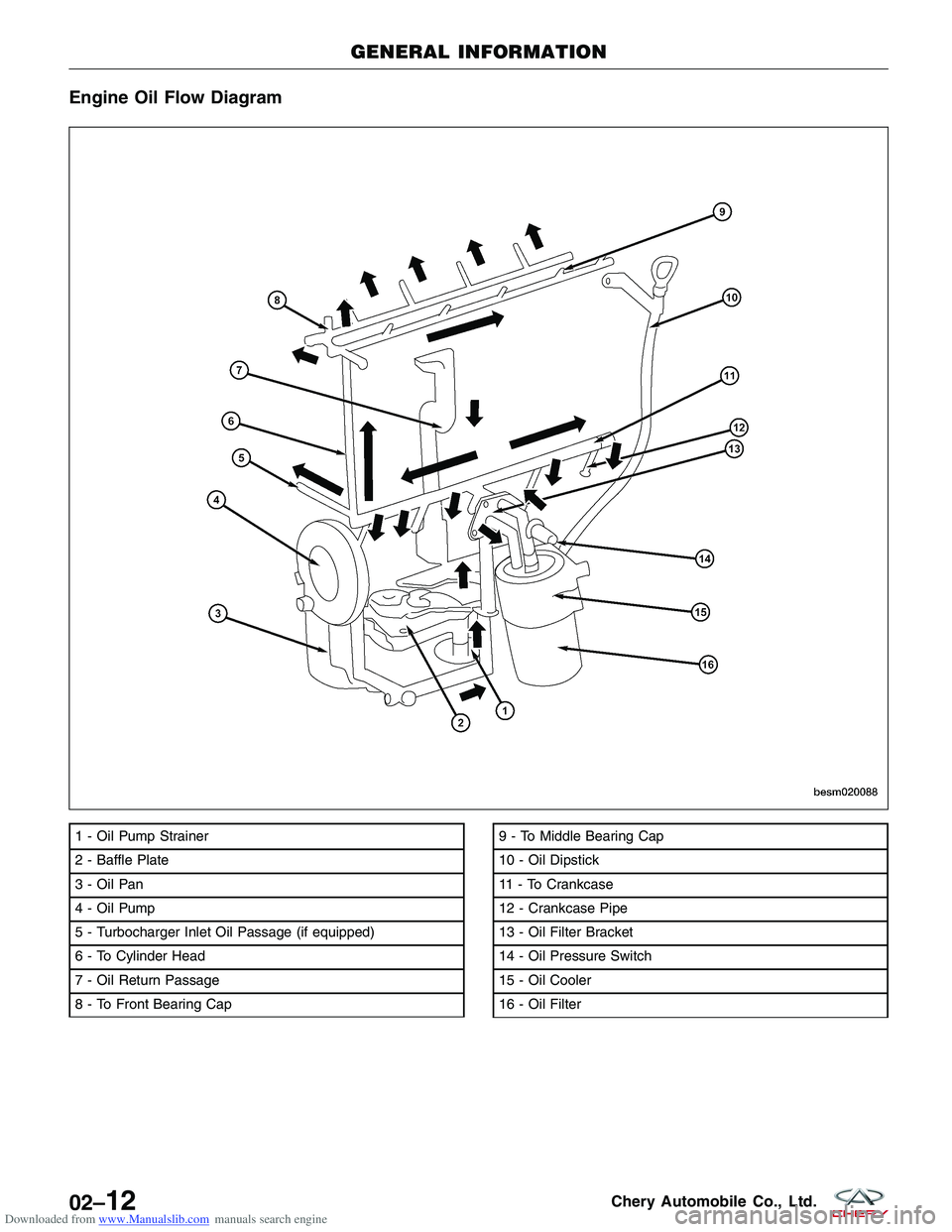

Downloaded from www.Manualslib.com manuals search engine Engine Oil Flow Diagram

1 - Oil Pump Strainer

2 - Baffle Plate

3 - Oil Pan

4 - Oil Pump

5 - Turbocharger Inlet Oil Passage (if equipped)

6 - To Cylinder Head

7 - Oil Return Passage

8 - To Front Bearing Cap9 - To Middle Bearing Cap

10 - Oil Dipstick

11 - To Crankcase

12 - Crankcase Pipe

13 - Oil Filter Bracket

14 - Oil Pressure Switch

15 - Oil Cooler

16 - Oil Filter

GENERAL INFORMATION

BESM020088

02–12Chery Automobile Co., Ltd.

Page 42 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

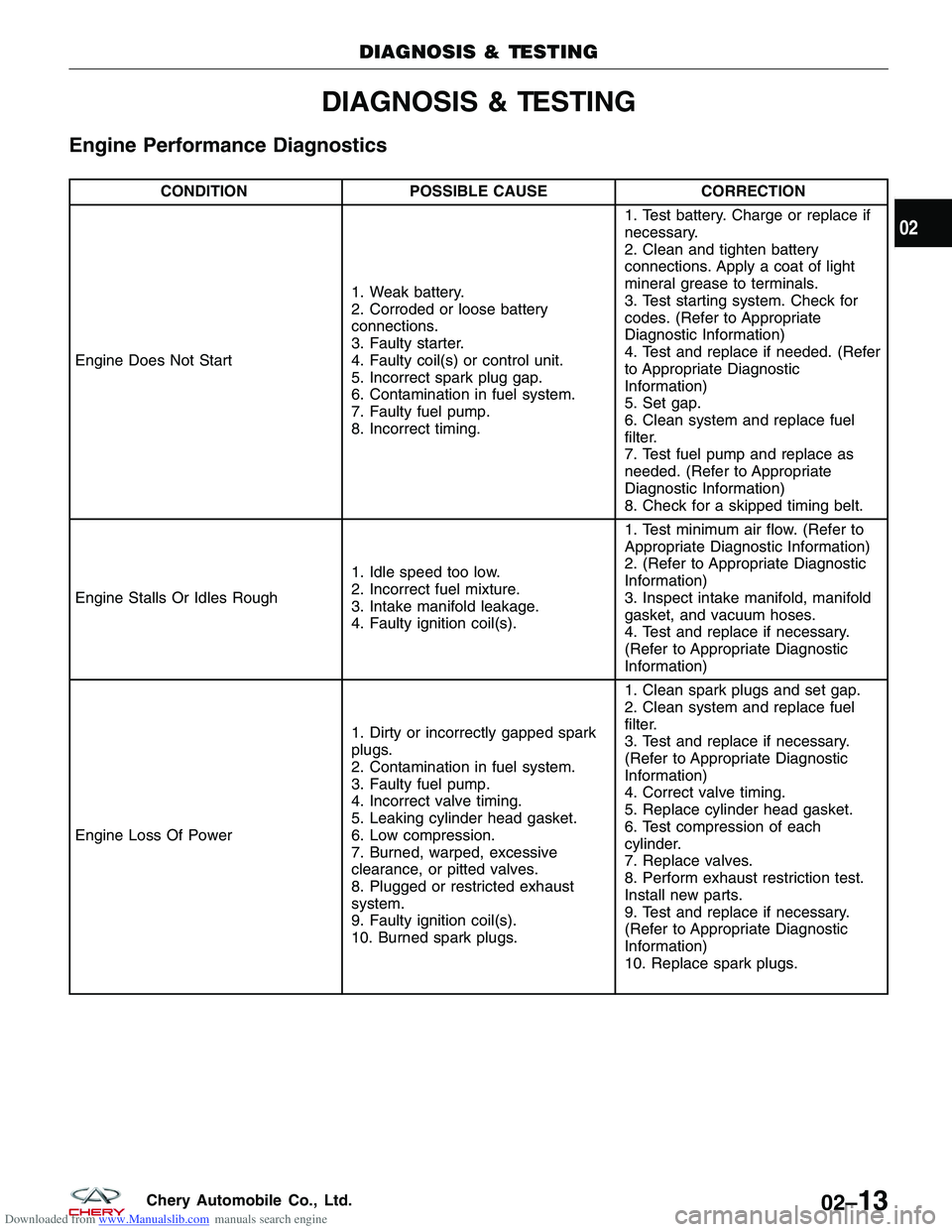

Engine Performance Diagnostics

CONDITIONPOSSIBLE CAUSE CORRECTION

Engine Does Not Start 1. Weak battery.

2. Corroded or loose battery

connections.

3. Faulty starter.

4. Faulty coil(s) or control unit.

5. Incorrect spark plug gap.

6. Contamination in fuel system.

7. Faulty fuel pump.

8. Incorrect timing.1. Test battery. Charge or replace if

necessary.

2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to terminals.

3. Test starting system. Check for

codes. (Refer to Appropriate

Diagnostic Information)

4. Test and replace if needed. (Refer

to Appropriate Diagnostic

Information)

5. Set gap.

6. Clean system and replace fuel

filter.

7. Test fuel pump and replace as

needed. (Refer to Appropriate

Diagnostic Information)

8. Check for a skipped timing belt.

Engine Stalls Or Idles Rough 1. Idle speed too low.

2. Incorrect fuel mixture.

3. Intake manifold leakage.

4. Faulty ignition coil(s).1. Test minimum air flow. (Refer to

Appropriate Diagnostic Information)

2. (Refer to Appropriate Diagnostic

Information)

3. Inspect intake manifold, manifold

gasket, and vacuum hoses.

4. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

Engine Loss Of Power 1. Dirty or incorrectly gapped spark

plugs.

2. Contamination in fuel system.

3. Faulty fuel pump.

4. Incorrect valve timing.

5. Leaking cylinder head gasket.

6. Low compression.

7. Burned, warped, excessive

clearance, or pitted valves.

8. Plugged or restricted exhaust

system.

9. Faulty ignition coil(s).

10. Burned spark plugs.1. Clean spark plugs and set gap.

2. Clean system and replace fuel

filter.

3. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

4. Correct valve timing.

5. Replace cylinder head gasket.

6. Test compression of each

cylinder.

7. Replace valves.

8. Perform exhaust restriction test.

Install new parts.

9. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

10. Replace spark plugs.

DIAGNOSIS & TESTING

02

02–13Chery Automobile Co., Ltd.

Page 43 of 1903

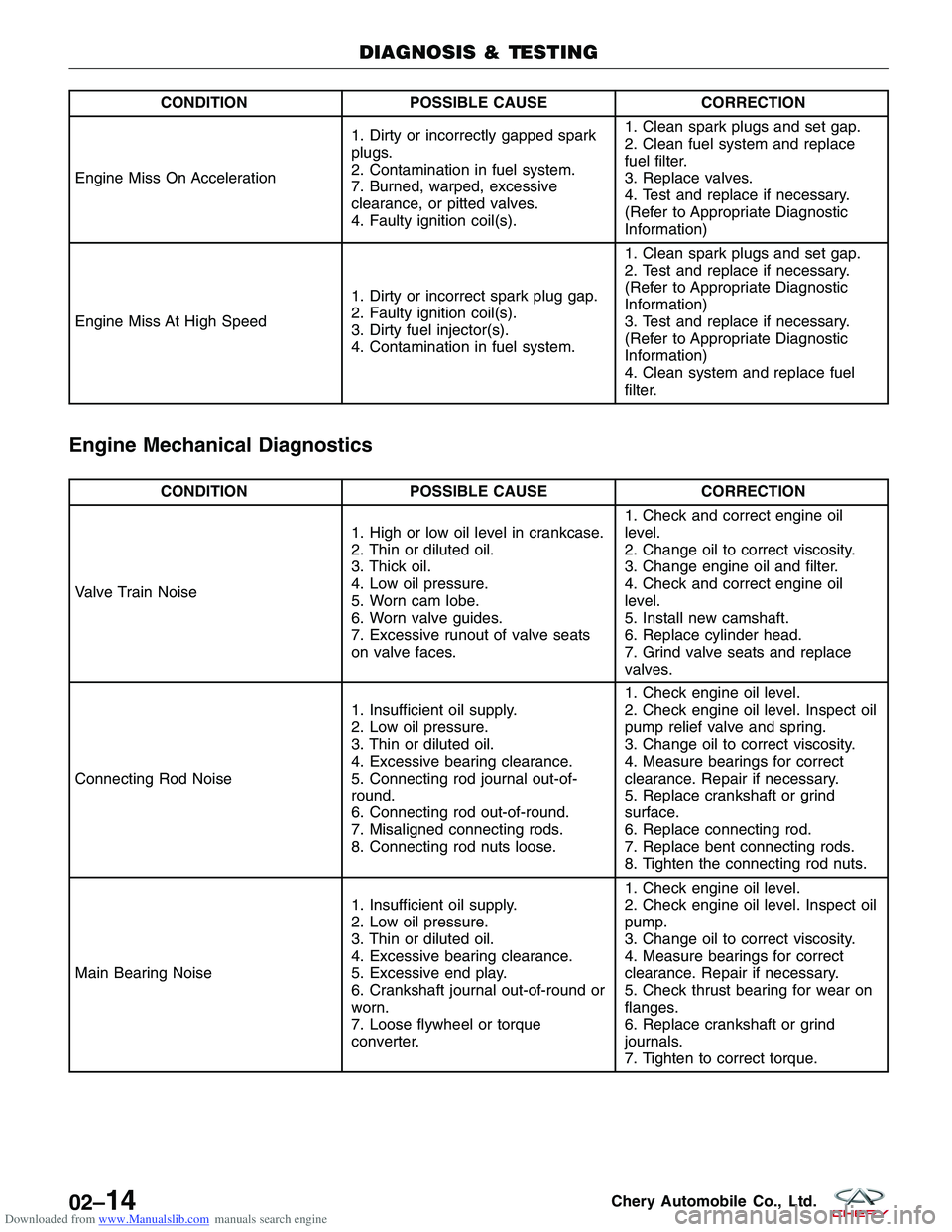

Downloaded from www.Manualslib.com manuals search engine CONDITIONPOSSIBLE CAUSE CORRECTION

Engine Miss On Acceleration 1. Dirty or incorrectly gapped spark

plugs.

2. Contamination in fuel system.

7. Burned, warped, excessive

clearance, or pitted valves.

4. Faulty ignition coil(s).1. Clean spark plugs and set gap.

2. Clean fuel system and replace

fuel filter.

3. Replace valves.

4. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

Engine Miss At High Speed 1. Dirty or incorrect spark plug gap.

2. Faulty ignition coil(s).

3. Dirty fuel injector(s).

4. Contamination in fuel system.1. Clean spark plugs and set gap.

2. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

3. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

4. Clean system and replace fuel

filter.

Engine Mechanical Diagnostics

CONDITION

POSSIBLE CAUSE CORRECTION

Valve Train Noise 1. High or low oil level in crankcase.

2. Thin or diluted oil.

3. Thick oil.

4. Low oil pressure.

5. Worn cam lobe.

6. Worn valve guides.

7. Excessive runout of valve seats

on valve faces.1. Check and correct engine oil

level.

2. Change oil to correct viscosity.

3. Change engine oil and filter.

4. Check and correct engine oil

level.

5. Install new camshaft.

6. Replace cylinder head.

7. Grind valve seats and replace

valves.

Connecting Rod Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Connecting rod journal out-of-

round.

6. Connecting rod out-of-round.

7. Misaligned connecting rods.

8. Connecting rod nuts loose.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Replace crankshaft or grind

surface.

6. Replace connecting rod.

7. Replace bent connecting rods.

8. Tighten the connecting rod nuts.

Main Bearing Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Excessive end play.

6. Crankshaft journal out-of-round or

worn.

7. Loose flywheel or torque

converter.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Check thrust bearing for wear on

flanges.

6. Replace crankshaft or grind

journals.

7. Tighten to correct torque.

DIAGNOSIS & TESTING

02–14Chery Automobile Co., Ltd.

Page 44 of 1903

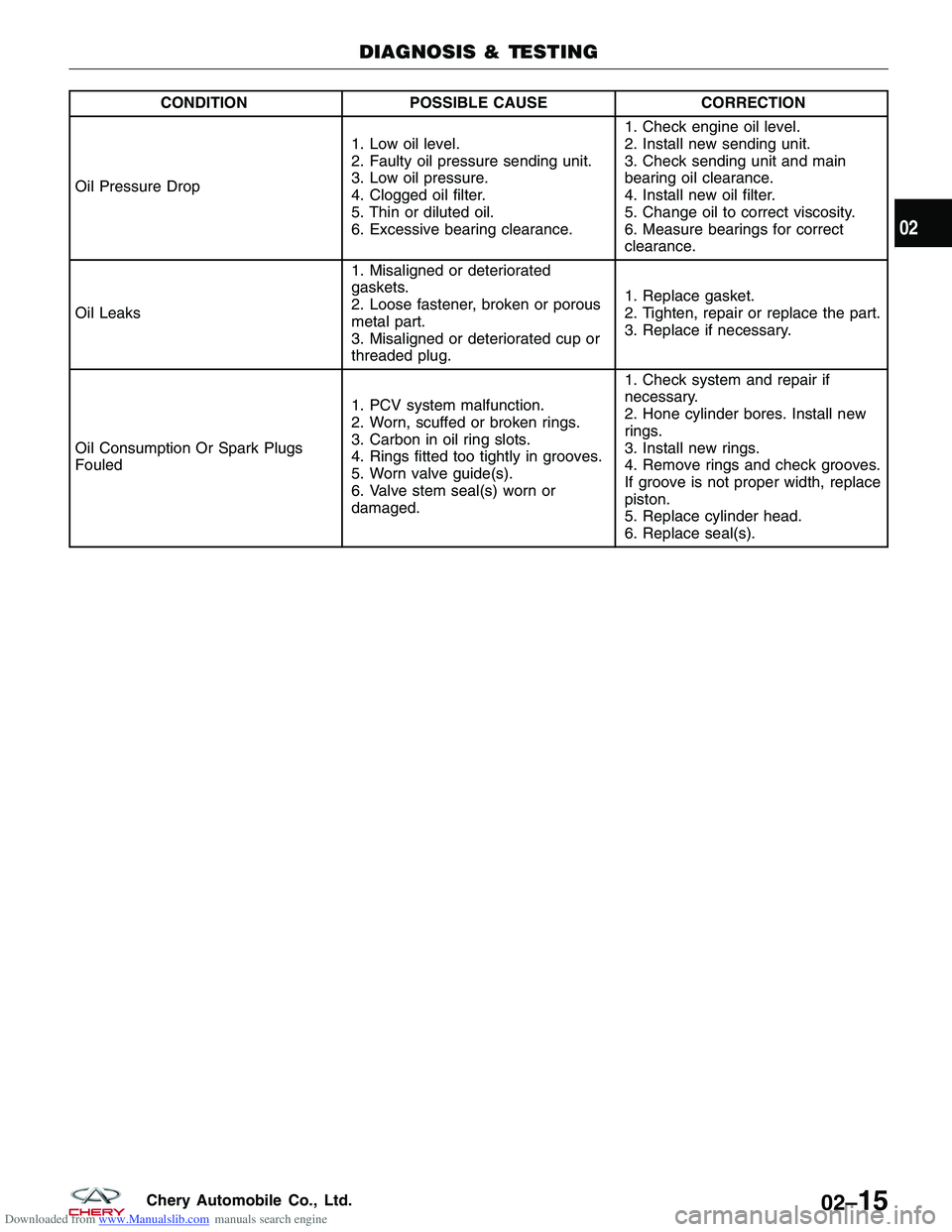

Downloaded from www.Manualslib.com manuals search engine CONDITIONPOSSIBLE CAUSE CORRECTION

Oil Pressure Drop 1. Low oil level.

2. Faulty oil pressure sending unit.

3. Low oil pressure.

4. Clogged oil filter.

5. Thin or diluted oil.

6. Excessive bearing clearance.1. Check engine oil level.

2. Install new sending unit.

3. Check sending unit and main

bearing oil clearance.

4. Install new oil filter.

5. Change oil to correct viscosity.

6. Measure bearings for correct

clearance.

Oil Leaks 1. Misaligned or deteriorated

gaskets.

2. Loose fastener, broken or porous

metal part.

3. Misaligned or deteriorated cup or

threaded plug.1. Replace gasket.

2. Tighten, repair or replace the part.

3. Replace if necessary.

Oil Consumption Or Spark Plugs

Fouled 1. PCV system malfunction.

2. Worn, scuffed or broken rings.

3. Carbon in oil ring slots.

4. Rings fitted too tightly in grooves.

5. Worn valve guide(s).

6. Valve stem seal(s) worn or

damaged.1. Check system and repair if

necessary.

2. Hone cylinder bores. Install new

rings.

3. Install new rings.

4. Remove rings and check grooves.

If groove is not proper width, replace

piston.

5. Replace cylinder head.

6. Replace seal(s).

DIAGNOSIS & TESTING

02

02–15Chery Automobile Co., Ltd.

Page 75 of 1903

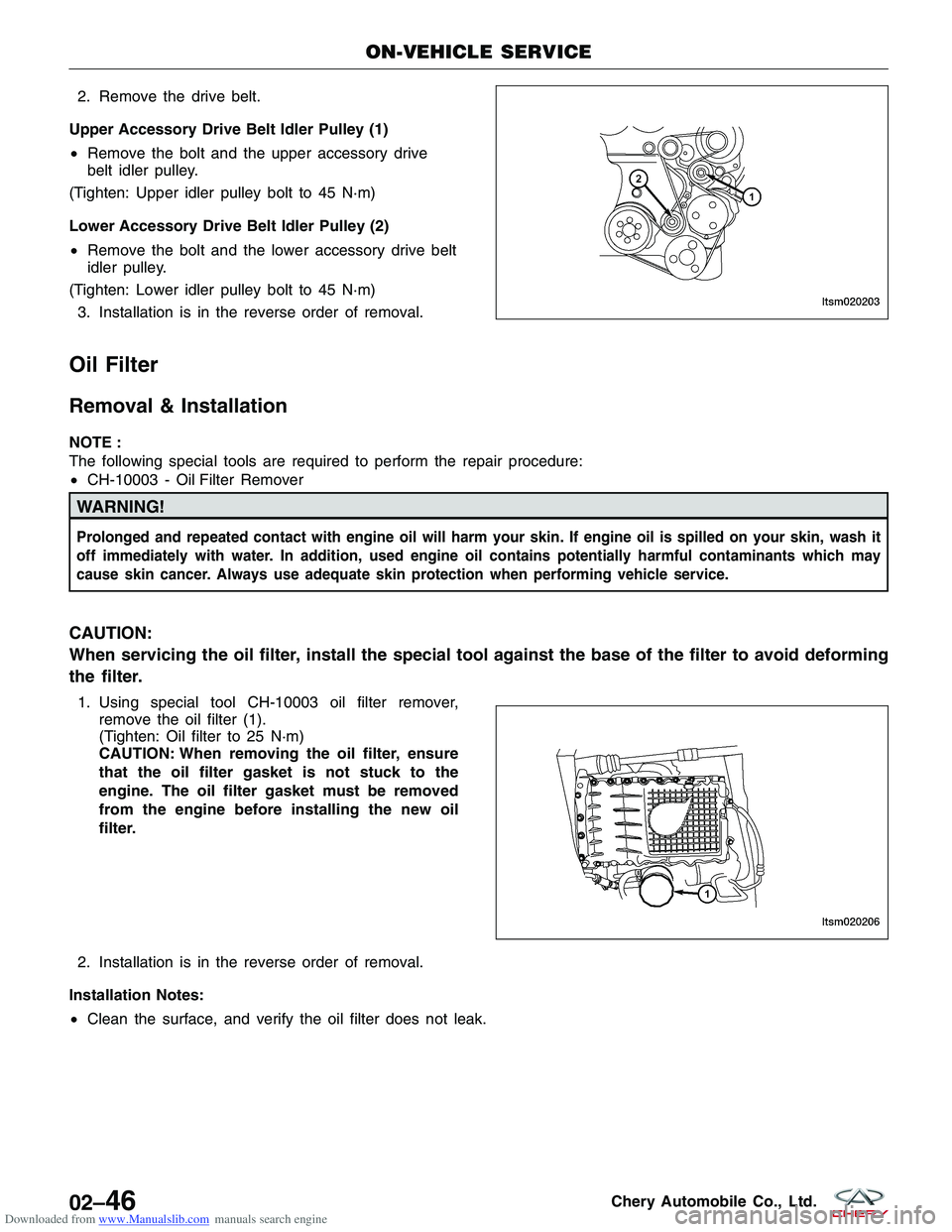

Downloaded from www.Manualslib.com manuals search engine 2. Remove the drive belt.

Upper Accessory Drive Belt Idler Pulley (1)

• Remove the bolt and the upper accessory drive

belt idler pulley.

(Tighten: Upper idler pulley bolt to 45 N·m)

Lower Accessory Drive Belt Idler Pulley (2)

• Remove the bolt and the lower accessory drive belt

idler pulley.

(Tighten: Lower idler pulley bolt to 45 N·m) 3. Installation is in the reverse order of removal.

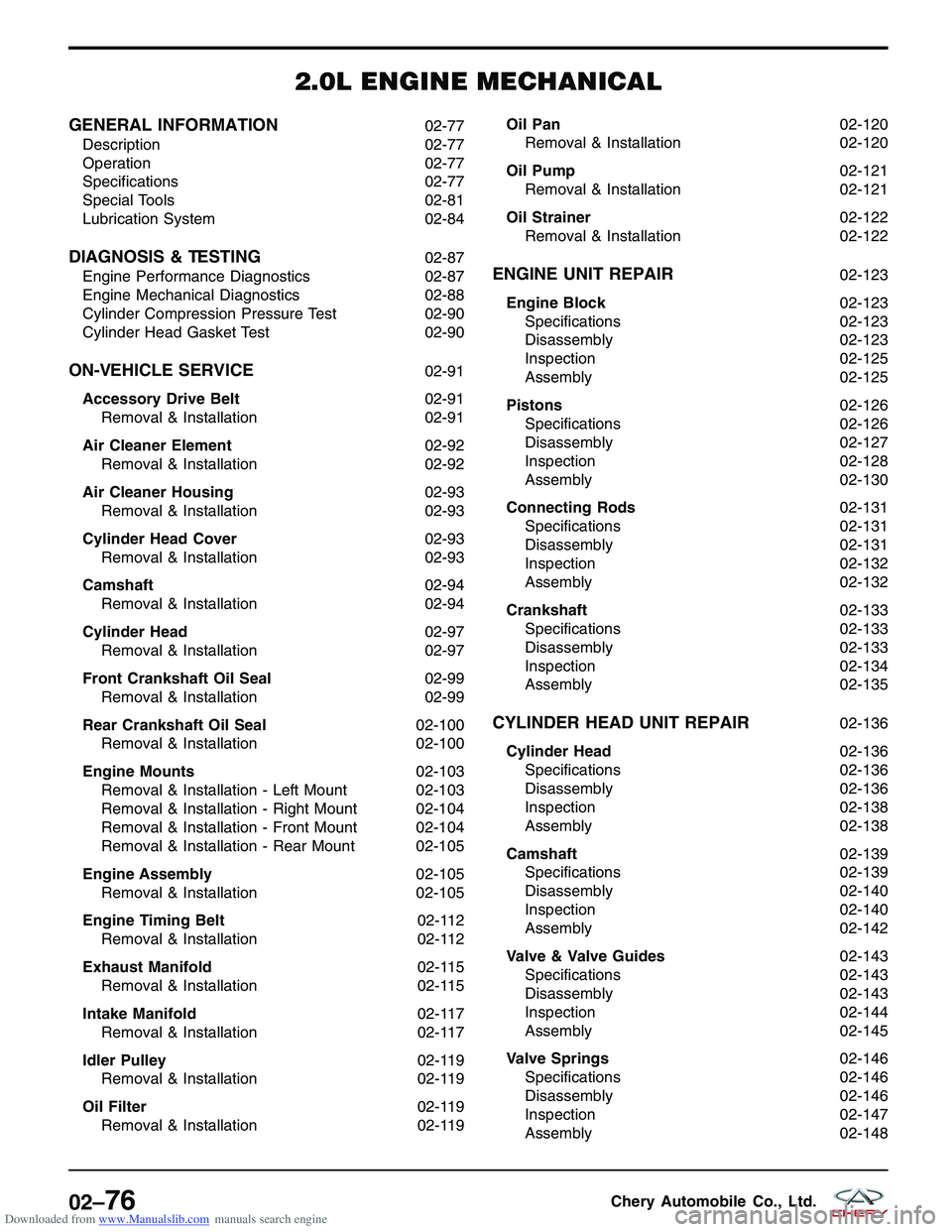

Oil Filter

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

• CH-10003 - Oil Filter Remover

WARNING!

Prolonged and repeated contact with engine oil will harm your skin. If engine oil is spilled on your skin, wash it

off immediately with water. In addition, used engine oil contains potentially harmful contaminants which may

cause skin cancer. Always use adequate skin protection when performing vehicle service.

CAUTION:

When servicing the oil filter, install the special tool against the base of the filter to avoid deforming

the filter.

1. Using special tool CH-10003 oil filter remover,

remove the oil filter (1).

(Tighten: Oil filter to 25 N·m)

CAUTION: When removing the oil filter, ensure

that the oil filter gasket is not stuck to the

engine. The oil filter gasket must be removed

from the engine before installing the new oil

filter.

2. Installation is in the reverse order of removal.

Installation Notes:

• Clean the surface, and verify the oil filter does not leak.

ON-VEHICLE SERVICE

LTSM020203

LTSM020206

02–46Chery Automobile Co., Ltd.

Page 105 of 1903

Downloaded from www.Manualslib.com manuals search engine 2.0L ENGINE MECHANICAL

GENERAL INFORMATION02-77

Description 02-77

Operation 02-77

Specifications 02-77

Special Tools 02-81

Lubrication System 02-84

DIAGNOSIS & TESTING02-87

Engine Performance Diagnostics 02-87

Engine Mechanical Diagnostics 02-88

Cylinder Compression Pressure Test 02-90

Cylinder Head Gasket Test 02-90

ON-VEHICLE SERVICE02-91

Accessory Drive Belt 02-91

Removal & Installation 02-91

Air Cleaner Element 02-92

Removal & Installation 02-92

Air Cleaner Housing 02-93

Removal & Installation 02-93

Cylinder Head Cover 02-93

Removal & Installation 02-93

Camshaft 02-94

Removal & Installation 02-94

Cylinder Head 02-97

Removal & Installation 02-97

Front Crankshaft Oil Seal 02-99

Removal & Installation 02-99

Rear Crankshaft Oil Seal 02-100

Removal & Installation 02-100

Engine Mounts 02-103

Removal & Installation - Left Mount 02-103

Removal & Installation - Right Mount 02-104

Removal & Installation - Front Mount 02-104

Removal & Installation - Rear Mount 02-105

Engine Assembly 02-105

Removal & Installation 02-105

Engine Timing Belt 02-112

Removal & Installation 02-112

Exhaust Manifold 02-115

Removal & Installation 02-115

Intake Manifold 02-117

Removal & Installation 02-117

Idler Pulley 02-119

Removal & Installation 02-119

Oil Filter 02-119

Removal & Installation 02-119Oil Pan

02-120

Removal & Installation 02-120

Oil Pump 02-121

Removal & Installation 02-121

Oil Strainer 02-122

Removal & Installation 02-122

ENGINE UNIT REPAIR02-123

Engine Block 02-123

Specifications 02-123

Disassembly 02-123

Inspection 02-125

Assembly 02-125

Pistons 02-126

Specifications 02-126

Disassembly 02-127

Inspection 02-128

Assembly 02-130

Connecting Rods 02-131

Specifications 02-131

Disassembly 02-131

Inspection 02-132

Assembly 02-132

Crankshaft 02-133

Specifications 02-133

Disassembly 02-133

Inspection 02-134

Assembly 02-135

CYLINDER HEAD UNIT REPAIR02-136

Cylinder Head 02-136

Specifications 02-136

Disassembly 02-136

Inspection 02-138

Assembly 02-138

Camshaft 02-139

Specifications 02-139

Disassembly 02-140

Inspection 02-140

Assembly 02-142

Valve & Valve Guides 02-143

Specifications 02-143

Disassembly 02-143

Inspection 02-144

Assembly 02-145

Valve Springs 02-146

Specifications 02-146

Disassembly 02-146

Inspection 02-147

Assembly 02-148

02–76Chery Automobile Co., Ltd.