air conditioning CHEVROLET ASTRO 2004 Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2004, Model line: ASTRO, Model: CHEVROLET ASTRO 2004Pages: 382, PDF Size: 2.73 MB

Page 121 of 382

Instrument Panel Overview...............................3-2

Hazard Warning Flashers................................3-4

Other Warning Devices...................................3-5

Horn.............................................................3-5

Tilt Wheel.....................................................3-5

Turn Signal/Multifunction Lever.........................3-6

Exterior Lamps.............................................3-12

Interior Lamps..............................................3-15

Accessory Power Outlets...............................3-16

Ashtrays and Cigarette Lighter........................3-17

Climate Controls............................................3-18

Climate Control System.................................3-18

Outlet Adjustment.........................................3-20

Rear Heating System....................................3-21

Rear Air Conditioning System.........................3-21

Warning Lights, Gages and Indicators.............3-23

Warning Lights, Gages, and Indicators.............3-23

Instrument Panel Cluster................................3-24

Speedometer and Odometer...........................3-25

Safety Belt Reminder Light.............................3-26

Air Bag Readiness Light................................3-26

Charging System Light..................................3-27

Voltmeter Gage............................................3-28

Brake System Warning Light..........................3-28Anti-Lock Brake System Warning Light.............3-29

Engine Coolant Temperature Gage..................3-30

Malfunction Indicator Lamp.............................3-30

Oil Pressure Gage........................................3-34

Security Light...............................................3-35

Service All-Wheel Drive Light.........................3-35

Tow/Haul Mode Light....................................3-36

Check Gages Warning Light...........................3-36

Fuel Gage...................................................3-36

Low Fuel Warning Light.................................3-37

Audio System(s).............................................3-38

Setting the Time for Radios with the

Set Button................................................3-38

Setting the Time for Radios with HR

and MN Buttons........................................3-38

AM-FM Radio...............................................3-39

Radio with CD..............................................3-41

Rear Seat Audio (RSA).................................3-46

Theft-Deterrent Feature..................................3-47

Radio Reception...........................................3-50

Care of Your CDs.........................................3-50

Care of Your CD Player................................3-50

Fixed Mast Antenna......................................3-50

Section 3 Instrument Panel

3-1

Page 138 of 382

Climate Controls

Climate Control System

With this system you can control the heating, cooling

and ventilation for your vehicle.

Turn the right knob clockwise or counterclockwise to

direct the air¯ow inside of your vehicle.To change the current mode, select one of the following:

)(Bi-Level):This mode directs approximately half

of the air to the instrument panel outlets and directs

most of the remaining air to the ¯oor outlets. Some air

may be directed toward the windshield.

H(Vent):This mode directs air to the instrument

panel outlets.

6(Floor):This mode directs most of the air to the

¯oor outlets with some air directed to the outboard

outlets (for the side windows) and some air directed to

the windshield.

A/C (Air Conditioning):This setting brings in outside

air, cools and dehumidi®es it.

MAX A/C (Maximum Air Conditioning):This setting

cools the air the fastest, by recirculating the inside air.

The right knob can also be used to select the defrost

mode. Information on defogging and defrosting can be

found later in this section.

9(Fan):Turn the left knob clockwise or

counterclockwise to increase or decrease the fan speed.

Temperature Control:Turn the center knob clockwise

or counterclockwise to increase or decrease the

temperature inside your vehicle.

3-18

Page 139 of 382

Defogging and Defrosting

Turn the right knob to select the defog or defrost mode.

-(Blend):With this setting, the outside air comes

out of both the ¯oor and defroster outlets. Adjust

the temperature knob for warmer or cooler air. The air

conditioning compressor may operate in this setting

to dehumidfy the air.

1(Defrost):This setting operates the defroster. Most

of the air comes out near the windshield, with some

going to the ¯oor outlets and front side windows. The air

conditioning compressor may operate in this setting to

dehumidify the air.

The bi-level setting is useful for cold weather with a

large number of passengers or very humid conditions to

help keep the windshield clear. Use defrost to remove

fog or ice from the windshield quickly in extremely

cold conditions. The temperature knob should be in the

red area and the fan control toward high.

Rear Window Defogger

The rear window defogger uses a warming grid to

remove fog or frost from the rear window.

The rear window defogger will only work when the

ignition is in RUN.Press this button to turn

the rear window defogger

on or off. Be sure to

clear as much snow from

the window as possible.

The rear window defogger will turn off several minutes

after the button is pressed. If turned on again, the

defogger will run for several more minutes before turning

off. The defogger can also be turned off by pressing

the button again or by turning off the engine.

Notice:Using a razor blade or sharp object to clear

the inside rear window may damage the rear

window defogger. Repairs would not be covered by

your warranty. Do not clear the inside of the rear

window with sharp objects.

3-19

Page 141 of 382

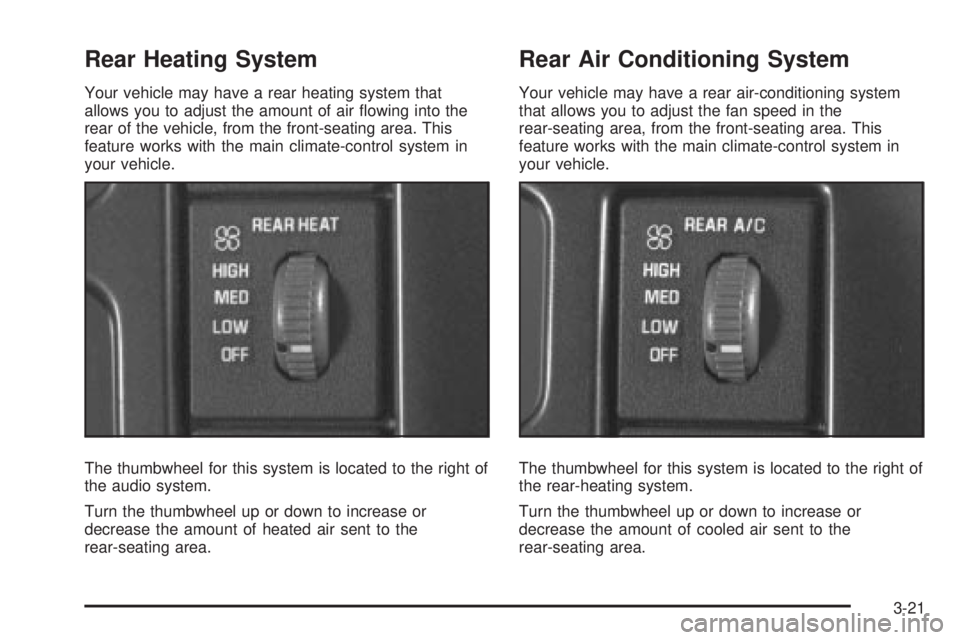

Rear Heating System

Your vehicle may have a rear heating system that

allows you to adjust the amount of air ¯owing into the

rear of the vehicle, from the front-seating area. This

feature works with the main climate-control system in

your vehicle.

The thumbwheel for this system is located to the right of

the audio system.

Turn the thumbwheel up or down to increase or

decrease the amount of heated air sent to the

rear-seating area.

Rear Air Conditioning System

Your vehicle may have a rear air-conditioning system

that allows you to adjust the fan speed in the

rear-seating area, from the front-seating area. This

feature works with the main climate-control system in

your vehicle.

The thumbwheel for this system is located to the right of

the rear-heating system.

Turn the thumbwheel up or down to increase or

decrease the amount of cooled air sent to the

rear-seating area.

3-21

Page 142 of 382

Directing the Air¯ow

To direct the air¯ow to the rear-seating area, use the

right knob located on the main climate-control panel.

Generally the upper outlets are used for air conditioning

and the ¯oor outlets are used for heating.

Selecting the Fan Speed

Rear Heat and Rear A/C

9(Fan):Move either thumbwheel on either climate

control panel up or down to HIGH, MED (Medium)

or LOW to increase or decrease the fan speed in the

rear-seating area. Move the thumbwheel to OFF to turn

off the fan.

Setting the Temperature

To increase or decrease the temperature for the entire

vehicle use the center knob located on the main

climate-control panel.

The air-conditioning system on the main climate-control

panel must be turned on to direct cooled air to the

rear of the vehicle. If it is not on, then the temperature

in the rear of the vehicle will remain at cabin

temperature.

Be sure to keep the area under the front seats clear of

any objects so that the air inside of your vehicle can

circulate effectively.

For information on how to use the main climate-control

system. For information on ventilation, see ªOutlet

Adjustmentº earlier in this section.

3-22

Page 277 of 382

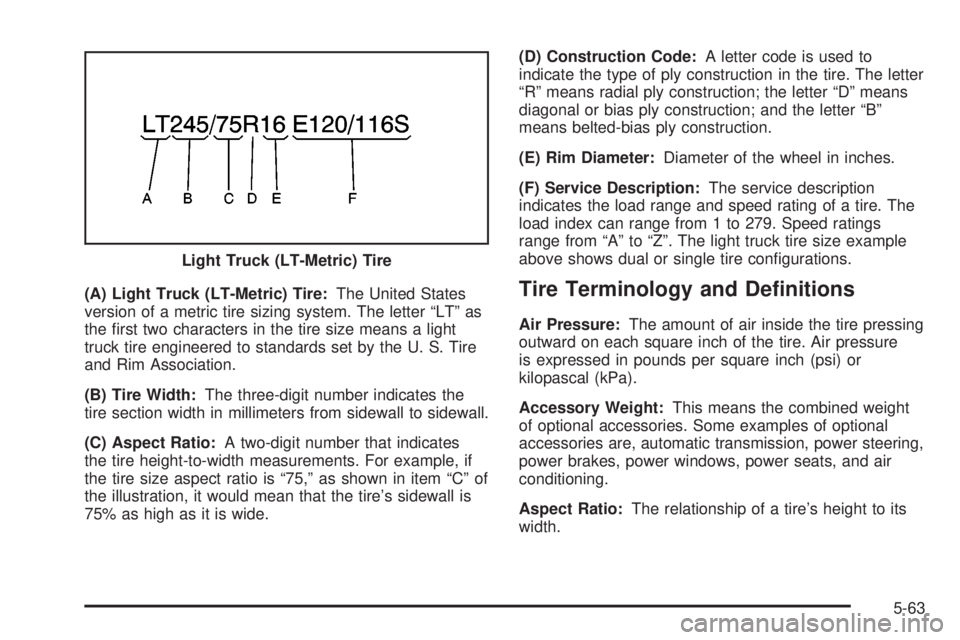

(A) Light Truck (LT-Metric) Tire:The United States

version of a metric tire sizing system. The letter ªLTº as

the ®rst two characters in the tire size means a light

truck tire engineered to standards set by the U. S. Tire

and Rim Association.

(B) Tire Width:The three-digit number indicates the

tire section width in millimeters from sidewall to sidewall.

(C) Aspect Ratio:A two-digit number that indicates

the tire height-to-width measurements. For example, if

the tire size aspect ratio is ª75,º as shown in item ªCº of

the illustration, it would mean that the tire's sidewall is

75% as high as it is wide.(D) Construction Code:A letter code is used to

indicate the type of ply construction in the tire. The letter

ªRº means radial ply construction; the letter ªDº means

diagonal or bias ply construction; and the letter ªBº

means belted-bias ply construction.

(E) Rim Diameter:Diameter of the wheel in inches.

(F) Service Description:The service description

indicates the load range and speed rating of a tire. The

load index can range from 1 to 279. Speed ratings

range from ªAº to ªZº. The light truck tire size example

above shows dual or single tire con®gurations.Tire Terminology and De®nitions

Air Pressure:The amount of air inside the tire pressing

outward on each square inch of the tire. Air pressure

is expressed in pounds per square inch (psi) or

kilopascal (kPa).

Accessory Weight:This means the combined weight

of optional accessories. Some examples of optional

accessories are, automatic transmission, power steering,

power brakes, power windows, power seats, and air

conditioning.

Aspect Ratio:The relationship of a tire's height to its

width. Light Truck (LT-Metric) Tire

5-63

Page 312 of 382

Fuse/Circuit

Breaker Usage

3 Courtesy Lamps, Glove Box Lamp,

Dome Reading Lamps, Vanity Mirror

Lamps, Courtesy Lamps

4 Daytime Running Lamps Relay,

Instrument Panel Cluster

5 Rear Defogger

6 Cruise Module, Truck Body Control

Module, Instrument Panel Cluster,

Cruise Control Switch,

Electrochromic Mirror

7 Power Outlets, Subwoofer Ampli®er

8 Crank Circuit Fuse, Park/Neutral

Switch, Starter Enabler Relay

9 License Plate Lamp, Tailamps,

Parking Lamps, Ashtray Lamp,

Panel Lights, Trailer Taillamps, Front

and Rear Sidemarker Lamps, Door

Switch Illumination, Headlamp

Switch Illumination, Rear Seat Audio

Illumination, Truck Body Control

Module

10 Air Bag System

11 Not UsedFuse/Circuit

Breaker Usage

12 Blower Motor, Rear Air Conditioning

Relay Coil, Front Cont. Temp. Door

Motor, HI Blower Relay, Defogger

Timer Coil

13 Cigarette Lighter, Door Lock

Switches, Dutch Door Release

Module

14 Cluster Illumination, Climate

Controls, Chime Module, Radio

Illumination, Rear Heat Switch

Illumination, Rear Wiper/Washer

Switch Illumination, Rear Liftgate

Switch Illumination, Remote

Cassette Illumination, Overhead

Console, Truck Body Control

Illumination

15 Truck Body Module, Headlamp

Relay

16 Front Turn Signals, Rear Turn

Signals, Trailer Turn Signals,

Back-Up Lamps, Brake

Transmission Shift Interlock Solenoid

17 Front Wipers, Front Washer Pump

5-98

Page 314 of 382

Feed Usage

AUX B Up®tter Battery Feed

AUX A Up®tter Accessory Feed

Relays Usage

A/C Relay

(Rear Heat

and A/C)Rear/Heat and Air ConditioningRelays Usage

Up®tter-ACCY

RelayUp®tter Accessory

Starter Enable

RelayStarter

A/C Enable

RelayAir Conditioning

Headlamps

RelayHeadlamps

Fuel Pump

RelayFuel Pump

Fuse/Circuit

BreakerUsage

UPFITTER-

BATTUp®tter Battery Power Stud, Trailer

Wiring Harness

UPFITTER-

ACCYUp®tter Accessory Relay

Spare Not used

Spare Not used

Spare Not used

ECM-1BFuel Pump Relay and Motor, VCM,

Oil Pressure Switch/Sender

HORN Horn Relay and Horn

5-100

Page 315 of 382

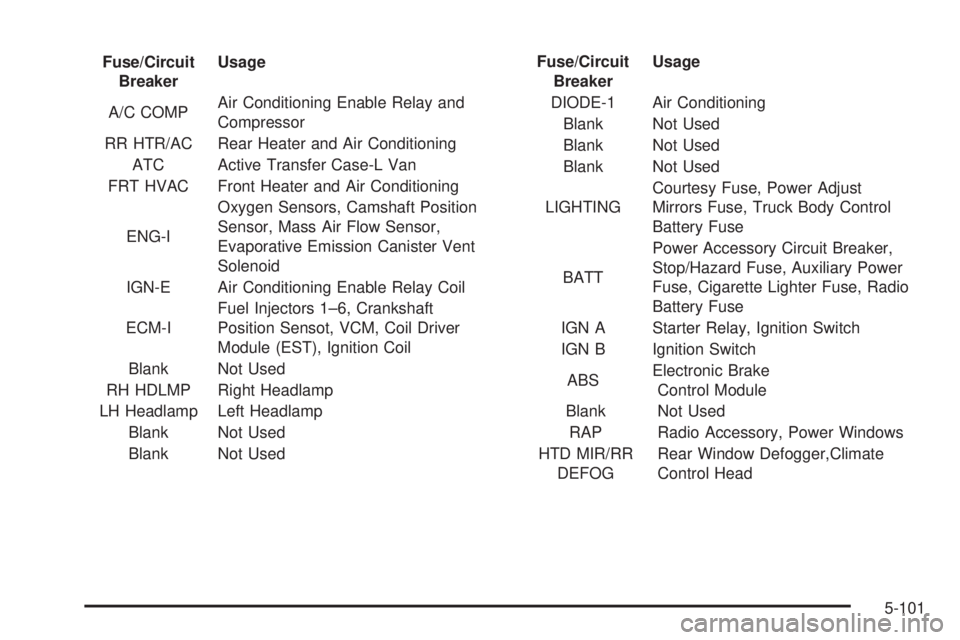

Fuse/Circuit

BreakerUsage

A/C COMPAir Conditioning Enable Relay and

Compressor

RR HTR/AC Rear Heater and Air Conditioning

ATC Active Transfer Case-L Van

FRT HVAC Front Heater and Air Conditioning

ENG-IOxygen Sensors, Camshaft Position

Sensor, Mass Air Flow Sensor,

Evaporative Emission Canister Vent

Solenoid

IGN-E Air Conditioning Enable Relay Coil

ECM-IFuel Injectors 1±6, Crankshaft

Position Sensot, VCM, Coil Driver

Module (EST), Ignition Coil

Blank Not Used

RH HDLMP Right Headlamp

LH Headlamp Left Headlamp

Blank Not Used

Blank Not UsedFuse/Circuit

BreakerUsage

DIODE-1 Air Conditioning

Blank Not Used

Blank Not Used

Blank Not Used

LIGHTINGCourtesy Fuse, Power Adjust

Mirrors Fuse, Truck Body Control

Battery Fuse

BATTPower Accessory Circuit Breaker,

Stop/Hazard Fuse, Auxiliary Power

Fuse, Cigarette Lighter Fuse, Radio

Battery Fuse

IGN A Starter Relay, Ignition Switch

IGN B Ignition Switch

ABSElectronic Brake

Control Module

Blank Not Used

RAP Radio Accessory, Power Windows

HTD MIR/RR

DEFOGRear Window Defogger,Climate

Control Head

5-101

Page 348 of 382

Part C: Periodic Maintenance

Inspections

Listed in this part are inspections and services which

should be performed at least twice a year (for instance,

each spring and fall).

You should let your dealer's

service department do these jobs. Make sure any

necessary repairs are completed at once.

Proper procedures to perform these services may be

found in a service manual. SeeService Publications

Ordering Information on page 7-11.

Steering, Suspension and Front

Drive Axle Boot and Seal Inspection

Inspect the front and rear suspension and steering

system for damaged, loose or missing parts, signs of

wear or lack of lubrication. Inspect the power steering

lines and hoses for proper hook-up, binding, leaks,

cracks, cha®ng, etc. Clean and then inspect the drive

axle boot seals for damage, tears or leakage. Replace

seals if necessary.

Exhaust System Inspection

Inspect the complete exhaust system. Inspect the body

near the exhaust system. Look for broken, damaged,

missing or out-of-position parts as well as open seams,

holes, loose connections or other conditions which

could cause a heat build-up in the ¯oor pan or could let

exhaust fumes into the vehicle. See

Engine Exhaust

on page 2-28.

Fuel System Inspection

Inspect the complete fuel system for damage or leaks.

Engine Cooling System Inspection

Inspect the hoses and have them replaced if they

are cracked, swollen or deteriorated. Inspect all pipes,

®ttings and clamps; replace as needed. Clean the

outside of the radiator and air conditioning condenser.

To help ensure proper operation, a pressure test of

the cooling system and pressure cap is recommended

at least once a year.

6-28