height adjustment CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 603 of 659

BUMPERS 14-2

placed in the tab of each bumper bracket. Dial the

adjustment washers in the tabs as required to posi-

tion the bumper at the correct mounted height

3.

Tighten all bolts securely, connect parking lamp wir-

ing, and lower vehicle.

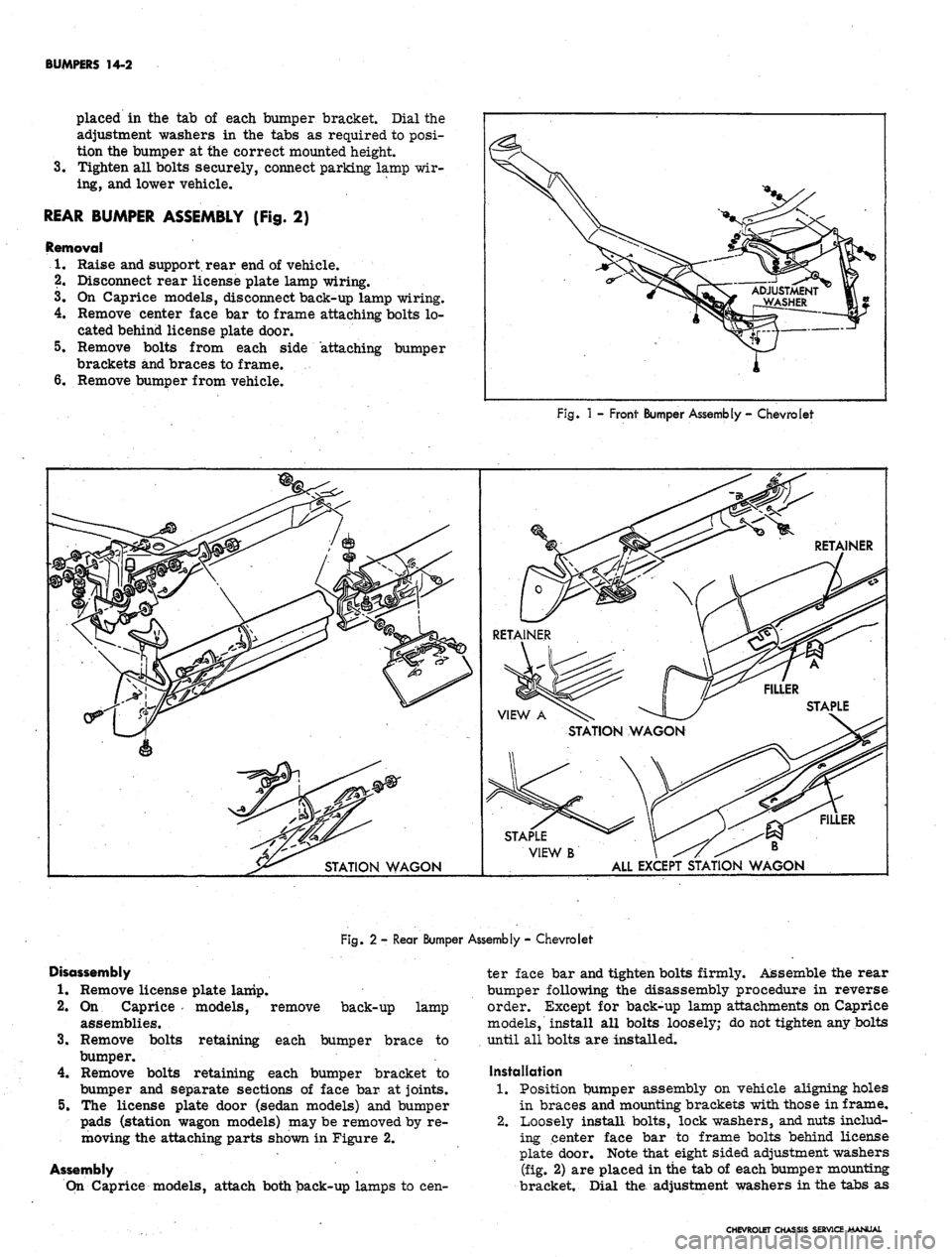

REAR BUMPER ASSEMBLY (Fig. 2)

Removal

1.

Raise and support rear end of vehicle.

2.

Disconnect rear license plate lamp wiring.

3.

On Caprice models, disconnect back-up lamp wiring.

4.

Remove center face bar to frame attaching bolts lo-

cated behind license plate door.

5. Remove bolts from each side "attaching bumper

brackets and braces to frame.

6. Remove bumper from vehicle.

Fig.

1 -

Front Bumper Assembly

-

Chevrolet

FILLER

STAPLE

VIEW

B \ ^7 ^^ B

ALL EXCEPT STATION WAGON

Fig. 2 - Rear Bumper Assembly - Chevrolet

Disassembly

1.

Remove license plate lamp.

2.

On Caprice models, remove

assemblies.

Remove bolts

3.

back-up lamp

each bumper brace to

retaining

bumper.

4.

Remove bolts retaining each bumper bracket to

bumper and separate sections of face bar at joints.

5.

The license plate door (sedan models) and bumper

pads (station wagon models) may be removed by re-

moving the attaching parts shown in Figure 2.

Assembly

On Caprice models, attach both back-up lamps to cen-

ter face bar and tighten bolts firmly. Assemble the rear

bumper following the disassembly procedure in reverse

order. Except for back-up lamp attachments on Caprice

models, install all bolts loosely; do not tighten any bolts

until all bolts are installed.

Installation

1.

Position bumper assembly on vehicle aligning holes

in braces and mounting brackets with those in frame,

2.

Loosely install bolts, lock washers, and nuts includ-

ing center face bar to frame bolts behind license

plate door. Note that eight sided adjustment washers

(fig. 2) are placed in the tab of each bumper mounting

bracket. Dial the adjustment washers in the tabs as

CHEVROLET CHASSIS SERVICE MANUAL

Page 604 of 659

BUMPERS 14-3

required to position the bumper at the correct

mounted height. ,

3.

Tighten all mounting bolts securely and connect li-

cense plate lamp wiring. On Caprice models, con-

nect back-up lamp wiring. Lower vehicle.

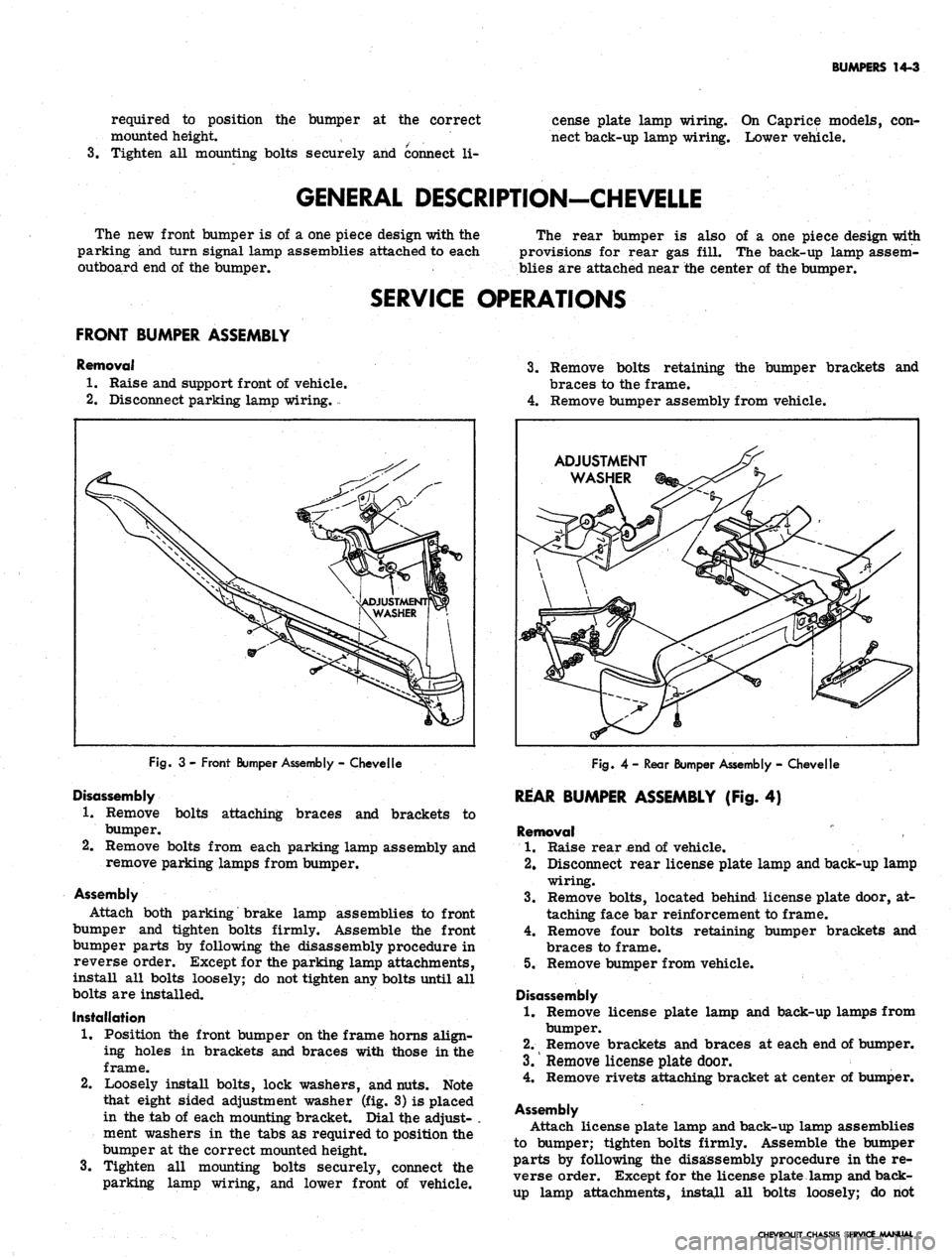

GENERAL DESCRIPTION-CHEVELLE

The new front bumper is of a one piece design with the

parking and turn signal lamp assemblies attached to each

outboard end of the bumper.

The rear bumper is also of a one piece design with

provisions for rear gas fill. The back-up lamp assem-

blies are attached near the center of the bumper.

SERVICE OPERATIONS

FRONT BUMPER ASSEMBLY

Removal

1.

Raise and support front of vehicle.

2.

Disconnect parking lamp wiring. -

Fig.

3 - Front Bumper Assembly - Chevelle

Disassembly

1.

Remove bolts attaching braces and brackets to

bumper.

2.

Remove bolts from each parking lamp assembly and

remove parking lamps from bumper.

Assembly

Attach both parking brake lamp assemblies to front

bumper and tighten bolts firmly. Assemble the front

bumper parts by following the disassembly procedure in

reverse order. Except for the parking lamp attachments,

install all bolts loosely; do not tighten any bolts until all

bolts are installed.

Installation

1.

Position the front bumper on the frame horns align-

ing holes in brackets and braces with those in the

frame.

2.

Loosely install bolts, lock washers, and nuts. Note

that eight sided adjustment washer (fig. 3) is placed

in the tab of each mounting bracket. Dial tjie adjust- .

ment washers in the tabs as required to position the

bumper at the correct mounted height.

3.

Tighten all mounting bolts securely, connect the

parking lamp wiring, and lower front of vehicle.

3.

Remove bolts retaining the bumper brackets and

braces to the frame.

4.

Remove bumper assembly from vehicle.

ADJUSTMENT

WASHER

Fig.

4-Rear Bumper Assembly - Chevelle

REAR BUMPER ASSEMBLY (Fig. 4)

Removal

1.

Raise rear end of vehicle.

2.

Disconnect rear license plate lamp and back-up lamp

wiring.

3.

Remove bolts, located behind license plate door, at-

taching face bar reinforcement to frame.

4.

Remove four bolts retaining bumper brackets and

braces to frame.

5. Remove bumper from vehicle.

Disassembly

1.

Remove license plate lamp and back-up lamps from

bumper.

2.

Remove brackets and braces at each end of bumper.

3.

Remove license plate door.

4.

Remove rivets attaching bracket at center of bumper.

Assembly

Attach license plate lamp and back-up lamp assemblies

to bumper; tighten bolts firmly. Assemble the bumper

parts by following the disassembly procedure in the re-

verse order. Except for the license plate lamp and back-

up lamp attachments, install all bolts loosely; do riot

CHEVROLET CHASSIS SERVICE MANUAL

Page 605 of 659

BUMPERS 14-4

tighten any bolts until all bolts have been installed.

Installation

1.

Position bumper bracket and brace on the frame

aligning holes in frame with those in bracket and

brace.

2.

Loosely install bolts, lock washers and nuts. Note

that eight sided adjustment washers (fig. 4) are

placed at the inside surface of each rear frame

channel. Dial washers as required to position

bumper at correct height.

Tighten all mounting bolts securely, connect back-up

lamp and license plate lamp wiring, and lower rear

of vehicle.

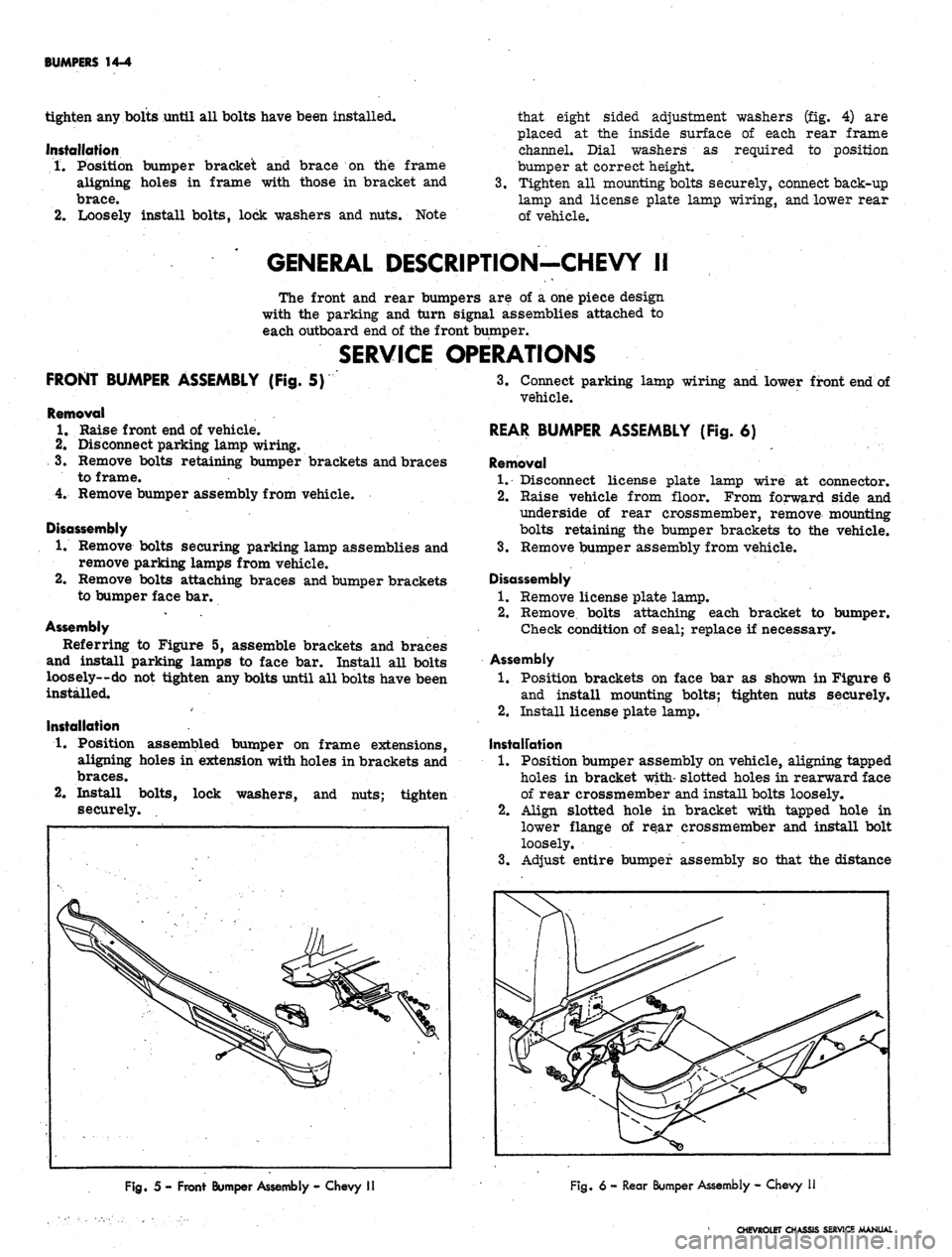

GENERAL DESCRIPTION-CHEVY II

The front and rear bumpers are of a one piece design

with the parking and turn signal assemblies attached to

each outboard end of the front bumper.

SERVICE OPERATIONS

FRONT BUMPER ASSEMBLY (Fig. 5)

Removal

1.

Raise front end of vehicle.

2.

Disconnect parking lamp wiring.

3.

Remove bolts retaining bumper brackets and braces

to frame.

4.

Remove bumper assembly from vehicle.

Disassembly

1.

Remove bolts securing parking lamp assemblies and

remove parking lamps from vehicle.

2.

Remove bolts attaching braces and bumper brackets

to bumper face bar.

Assembly

Referring to Figure 5, assemble brackets and braces

and install parking lamps to face bar. Install all bolts

loosely—do not tighten any bolts until all bolts have been

installed.

Installation

1.

Position assembled bumper on frame extensions,

aligning holes in extension with holes in brackets and

braces.

2.

Install bolts, lock washers, and nuts; tighten

securely.

3.

Connect parking lamp wiring and lower front end of

vehicle.

REAR BUMPER ASSEMBLY (Fig. 6)

Removal

1.

Disconnect license plate lamp wire at connector.

2.

Raise vehicle from floor. From forward side and

underside of rear crossmember, remove mounting

bolts retaining the bumper brackets to the vehicle.

3.

Remove bumper assembly from vehicle.

Disassembly

1.

Remove license plate lamp.

2.

Remove, bolts attaching each bracket to bumper.

Check condition of seal; replace if necessary.

Assembly

1.

Position brackets on face bar as shown in Figure 6

and install mounting bolts; tighten nuts securely.

2.

Install license plate lamp.

Instalfation

1.

Position bumper assembly on vehicle, aligning tapped

holes in bracket with- slotted holes in rearward face

of rear crossmember and install bolts loosely.

2.

Align slotted hole in bracket with tapped hole in

lower flange of rear crossmember and install bolt

loosely.

3.

Adjust entire bumper assembly so that the distance

Fig.

5 - Front Bumper Assembly - Chevy

Fig.

6 - Rear Bumper Assembly - Chevy

CHEVROLET CHASSIS SERVICE MANUAL

Page 608 of 659

BUMPERS 14-7

only and the distance between inner upper brace and

frame filled in with shims. Bolts may then be installed

to secure brace to frame.

REAR LICENSE PLATE HOUSING

The rear license plate housing may be removed from

the vehicle by removing the license plate and removing

the retaining screws as shown in Figure 9.

Fig.

9- Rear License Plate Housing

GENERAL DESCRIPTION-CAMARO

The Camaro front and rear bumpers are of a single

piece wrap around design. The front license plate bracket

functions as a bumper support between the valance panel

and bumper. Holes in the underside of bumpers, slightly

inboard of lower bumper bracket bolt, provide for new

jack load rest stud for jacking purposes.

SERVICE OPERATIONS

FRONT BUMPER ASSEMBLY (Fig. 10)

Removal

1.

Raise and support front end of vehicle.

2.

Remove bolts securing bumper support brackets to

frame.

3.

Remove bolts, one on each side at fender extension

panels, securing bumper to outer bumper bracket.

4.

Remove screws and nuts securing license plate

bracket to valance panel and remove bumper from

vehicle.

Disassembly

1.

Remove bolts attaching two support brackets to

bumper.

2.

Remove screw and nut securing license plate bracket

to bumper.

Assembly

Assemble the front bumper following the disassembly

procedure in reverse order. Install all bolts loosely; do

not tighten any bolts until all bolts are installed.

Installation

1.

Position assembled bumper on frame horns aligning

holes in bumper brackets with those in frame.

2.

Loosely install bolts, lock washers, and nuts. .Note

3.

the eight sided adjustment washers (fig. 10) are

placed in the tab of each bumper bracket. Dial the

adjustment washers in the tabs as required to posi-

tion the bumper at the correct mounted height.

Tighten all bolts securely and lower vehicle.

REAR BUMPER ASSEMBLY (Fig. 11)

Removal

1.

Raise and support rear end of vehicle.

2.

Remove bolts securing bumper brackets to frame

and rear fenders.

3.

Remove screws securing license plate bracket to

body and remove bumper from vehicle.

Disassembly

1.

Remove bolts securing four support brackets to

bumper.

2.

Remove rivets securing license plate bracket to

bumper.

Assembly

Assemble the rear bumper following the disassembly

procedure in reverse order. Install all bolts loosely; do

not tighten any bolts until all bolts are installed.

CHEVROLET CHASSIS SERVICE MANUAL

Page 620 of 659

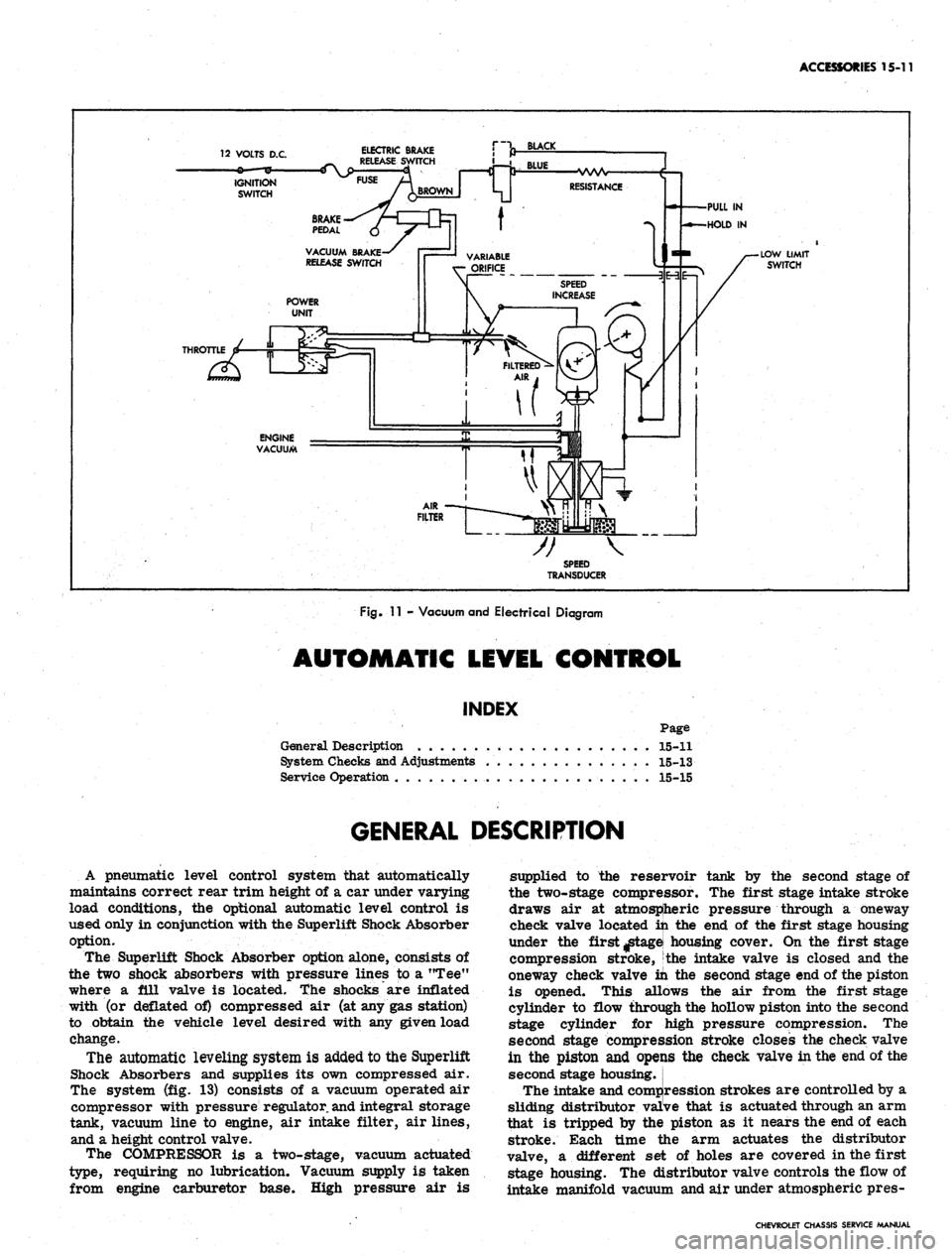

ACCESSORIES 15-11

12 VOLTS D.C.

ELECTRIC BRAKE

RELEASE

IGNITION

SWITCH

ENGINE

VACUUM

TRANSDUCER

Fig.

11 - Vacuum and Electrical Diagram

AUTOMATIC LEVEL CONTROL

INDEX

Page

General Description . . 15-11

System Checks and Adjustments 15-13

Service Operation . 15-15

GENERAL DESCRIPTION

A pneumatic level control system that automatically

maintains correct rear trim height of a car under varying

load conditions, the optional automatic level control is

used only in conjunction with the Superlift Shock Absorber

option.

The Superlift Shock Absorber option alone, consists of

the two shock absorbers with pressure lines to a "Tee"

where a ill valve is located, the shocks are inflated

with (or deflated of) compressed air (at any gas station)

to obtain the vehicle level desired with any given load

change.

The automatic leveling system is added to the Superlift

Shock Absorbers and supplies its own compressed air.

The system (fig. 13) consists of a vacuum operated air

compressor with pressure regulator,

and

integral storage

tank, vacuum line to engine, air intake filter, air lines,

and a height control valve.

The COMPRESSOR is a two-stage, vacuum actuated

type, requiring no lubrication. Vacuum supply is taken

from engine carburetor base. High pressure air is

supplied to the reservoir tank by the second stage of

the two-stage compressor. The first stage intake stroke

draws air at atmospheric pressure through a oneway

check valve located in the end of the first stage housing

under the first ^tagei housing cover. On the first stage

compression stroke, the intake valve is closed and the

oneway check valve in the second stage end of the piston

is opened. This allows the air from the first stage

cylinder to flow through the hollow piston into the second

stage cylinder for jhigh pressure compression. The

second stage compression stroke closes the check valve

in the piston and opeijis the check valve in the end of the

second stage housing.

The intake and compression strokes are controlled by a

sliding distributor valive that is actuated through an arm

that is tripped by the piston as it nears the end of each

stroke. Each time the arm actuates the distributor

valve, a different set of holes are covered in the first

stage housing. The distributor valve controls the flow of

intake manifold vacuum and air under atmospheric pres-

CHEVROLET CHASSIS SERVICE MANUAL

Page 623 of 659

ACCESSORIES 15-14

Deflate system through service valve and disconnect

line at pressure regulator valve. Install test gauge on

regulator valve high pressure fitting.

Inflate system through service valve to maximum

available pressure.

NOTE: If available pressure is less than 140

psi,

start engine to build-up reservoir to this

pressure.

Regulated pressure should build-up to and hold

steady at 100-130 psi on test gauge.

Check regulated pressure by momentarily (not more

than one second) depressing valve core on test gauge

arid observe gauge reading.

If regulated pressure now reads less than 100 psi,

replace regulator assembly.

If regulated pressure exceeds 130 psi, replace regu-

lator assembly.

Control Valve Test

Exhaust (Superlifts Inflated)

1.

Disconnect control valve lever from link.

2.

Hold lever down in exhaust position until Superlifts

deflate or for a minimum of 18 seconds.

3.

If Superlifts deflate, perform Intake Check.

4.

If Superlifts do not deflate, remove exhaust adapter

from control valve and hold lever down as in Step 2.

Replace adapter, O-ring and filter if this deflates

Superlifts.

5.

Replace control valve if none of the above steps solve

problem.

Intake (Reservoir Pressure 125 psi Minimum)

1.

Disconnect overtravel lever from link.

2.

Hold lever up in intake position until Superlifts in-

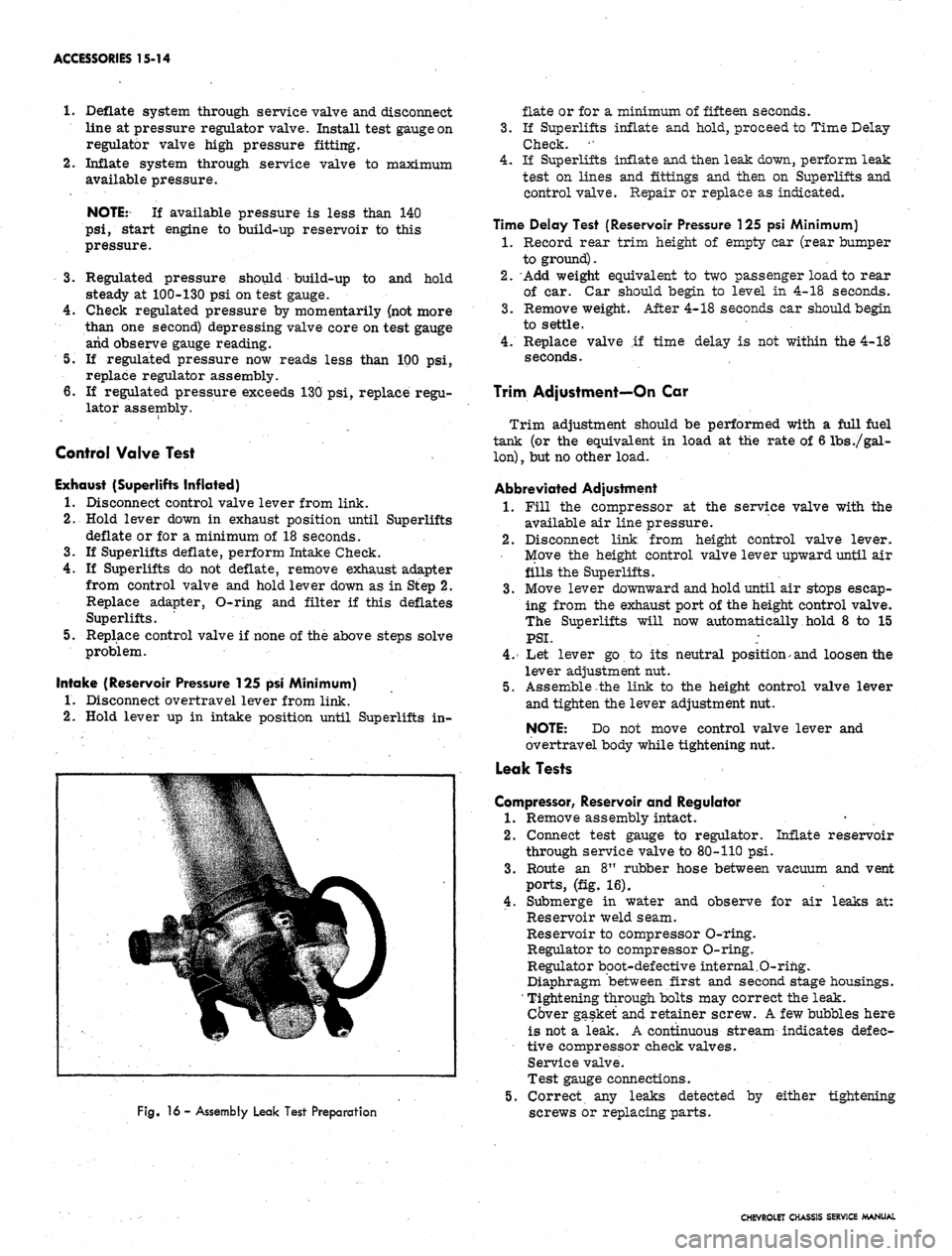

Fig.

16 - Assembly Leak Test Preparation

flate or for a minimum of fifteen seconds.

3.

If Superlifts inflate and hold, proceed to Time Delay

Check. '•

4.

If Superlifts inflate and then leak down, perform leak

test on lines and fittings and then on Superlifts and

control valve. Repair or replace as indicated.

Time Delay Test (Reservoir Pressure 125 psi Minimum)

1.

Record rear trim height of empty car (rear bumper

to ground).

2.

Add weight equivalent to two passenger load to rear

of car. Car should begin to level in 4-18 seconds.

3.

Remove weight. After 4-18 seconds car should begin

to settle.

4.

Replace valve if time delay is not within the 4-18

seconds.

Trim Adjustment—On Car

Trim adjustment should be performed with a full fuel

tank (or the equivalent in load at the rate of 6 lbs

./gal-

lon)

,

but no other load.

Abbreviated Adjustment

1.

Fill the compressor at the service valve with the

available air line pressure.

2.

Disconnect link from height control valve lever.

Move the height control valve lever upward until air

fills the Superlifts.

3.

Move lever downward and hold until air stops escap-

ing from the exhaust port of the height control valve.

The Superlifts will now automatically hold 8 to 15

PSI.

;

4.

Let lever go to its neutral position> and loosen the

lever adjustment nut.

5.

Assemble the link to the height control valve lever

and tighten the lever adjustment nut.

NOTE: Do not move control valve lever and

overtravel body while tightening nut.

Leak Tests

Compressor, Reservoir and Regulator

1.

Remove assembly intact.

2.

Connect test gauge to regulator. Inflate reservoir

through service valve to 80-110 psi.

3.

Route an 8" rubber hose between vacuum and vent

ports,

(fig. 16).

4.

Submerge in water and observe for air leaks at:

Reservoir weld seam.

Reservoir to compressor O-ring.

Regulator to compressor O-ring.

Regulator boot-defective internal.O-rihg.

Diaphragm between first and second stage housings.

' Tightening through bolts may correct the leak.

Cover gasket and retainer screw. A few bubbles here

is not a leak. A continuous stream indicates defec-

tive compressor check valves.

Service valve.

Test gauge connections.

5.

Correct any leaks detected by either tightening

screws or replacing parts.

CHEVROLET CHASSIS SERVICE MANUAL

Page 629 of 659

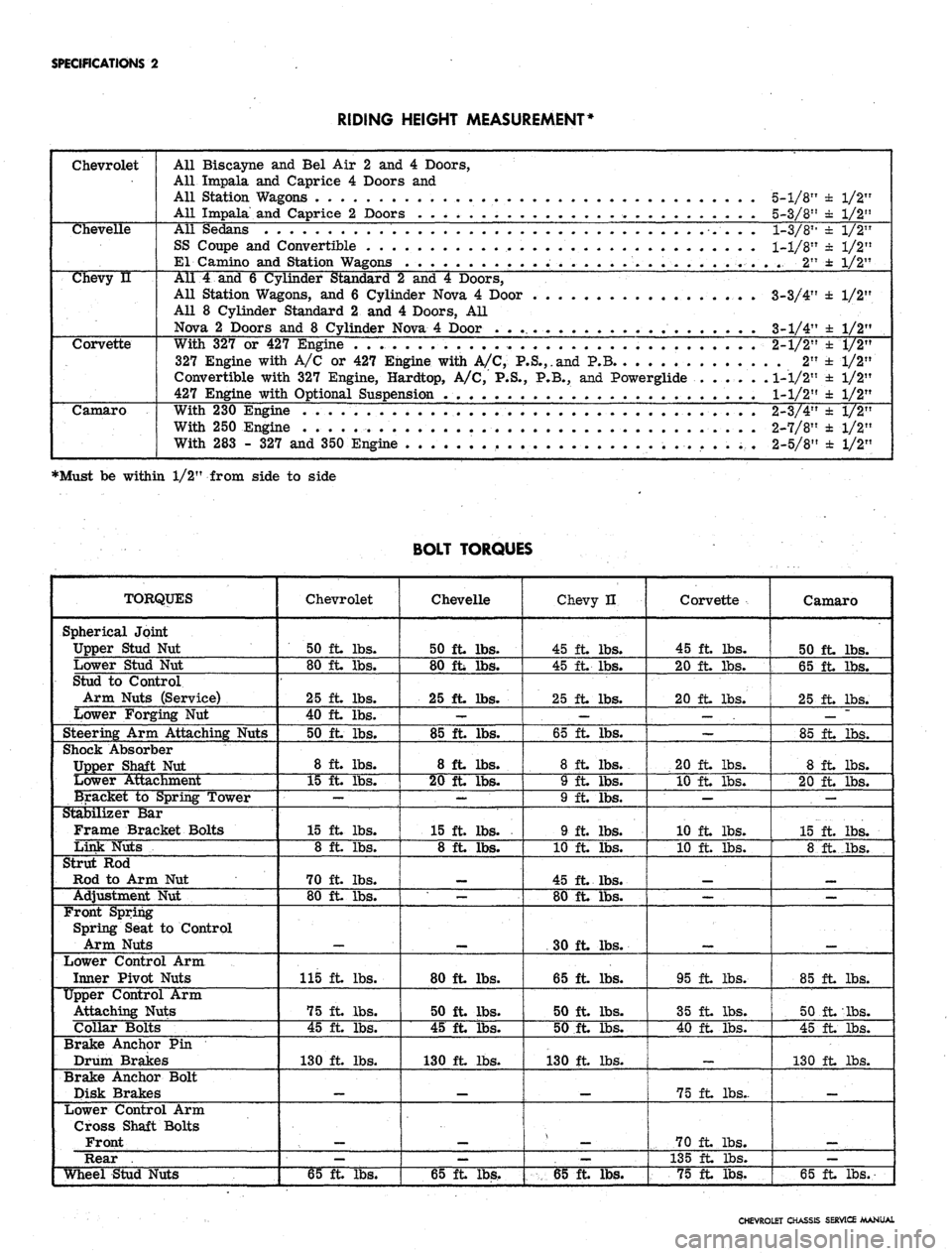

SPECIFICATIONS

2

RIDING HEIGHT MEASUREMENT*

Chevrolet

All Biscayne

and Bel Air 2 and 4

Doors,

All Impala

and

Caprice

4

Doors

and

All Station Wagons

. . . .

All Impala

and

Caprice

2

Doors

. . . . .

5-1/8"

± 1/2"

5-3/8"

± 1/2"

Chevelle

All Sedans

SS Coupe

and

Convertible

El Camino

and

Station W*

1-3/811

± 1/2"

1-1/8"

± 1/2"

..

2" ± 1/2"

Chevy

u

All

4 and 6

Cylinder Standard

2 and 4

Doors,

All Station Wagons,

and 6

Cylinder Nova

4

Door

All

8

Cylinder Standard

2 and 4

Doors,

All

Nova

2

Doors

and 8

Cylinder Nova

4

Door

. . .

3-3/4'

3-1/4'

±

1/2'

±

1/2'

Corvette

With

327 or 427

Engine

. . . .

327 Engine with

A/C or 427

Engine with

A/C,

P.S.,.and

P.B

Convertible with

327

Engine, Hardtop,

A/C, P.S., P.B., and

Powerglide

427 Engine with Optional Suspension

.

2-1/2"

.

2"

1-1/2"

1-1/2"

±

1/2"

±1/2"

±

1/2"

±

1/2"

Camaro

With

230

Engine

..... . . .

With

250

Engine

.... ...

With

283 - 327 and

350 Engine

2-3/4"

2-7/8"

2-5/8"

± 1/2"

± 1/2"

± 1/2"

•Must be within 1/2" from side to side

BOLT TORQUES

TORQUES

Spherical Joint

Upper Stud

Nut

Lower Stud

Nut

Stud

to

Control

Arm Nuts (Service)

Lower Forging

Nut

Steering

Arm

Attaching Nuts

Shock Absorber

Upper Shaft

Nut

Lower Attachment

Bracket

to

Spring Tower

Stabilizer

Bar

Frame Bracket Bolts

Link Nuts

Strut

Rod

Rod

to Arm Nut

Adjustment

Nut

Front Spring

Spring Seat

to

Control

Arm Nuts

Lower Control

Arm

Inner Pivot Nuts

Upper Control Arm

Attaching Nuts

Collar Bolts

Brake Anchor Pin

Drum Brakes

Brake Anchor Bolt

Disk Brakes

Lower Control Arm

Cross Shaft Bolts

Front

Rear .

Wheel Stud Nuts

Chevrolet

50 ft. lbs.

80 ft lbs.

25 ft. lbs.

40 ft. lbs.

50 ft. lbs.

8 ft. lbs.

15 ft. lbs.

—

15 ft lbs.

8 ft. lbs.

70 ft lbs.

80 ft lbs.

115 ft lbs.

75 ft lbs.

45 ft lbs.

130 ft lbs.

—

65 ft lbs.

Chevelle

50 ft lbs.

80 ft lbs.

25 ft. lbs.

—

85 ft lbs.

8 ft lbs.

20 ft lbs.

—

15 ft lbs.

8 ft lbs.

—

80 ft lbs.

50 ft. lbs.

45 ft. lbs.

130 ft lbs.

—

65 ft lbs.

Chevy H

45 ft lbs.

45 ft lbs.

25 ft lbs.

—

65 ft. lbs.

8 ft lbs.

9 ft lbs.

9 ft. lbs.

9 ft. lbs.

10 ft. lbs.

45 ft lbs.

80 ft lbs.

30 ft lbs.

65 ft lbs.

50 ft. lbs.

50 ft lbs.

130 ft lbs.

_

—

65 ft lbs.

Corvette

45 ft lbs.

20 ft lbs.

20 ft lbs.

—

20 ft lbs.

10 ft lbs.

—

10 ft lbs.

10 ft. lbs.

—

95 ft lbs.

35 ft lbs.

40 ft lbs.

75 ft lbs..

70 ft lbs.

135 ft lbs.

75 ft lbs.

Camaro

50 ft lbs.

65 ft lbs.

25 ft lbs.

—

85 ft lbs.

8 ft lbs.

20 ft lbs.

.

—

15 ft. lbs.

8 ft._lbs.

_

85 ft lbs.

50 ft lbs.

45 ft lbs.

130 ft lbs.

_

—

65 ft lbs.

CHEVROLET CHASSIS SERVICE MANUAL