power steering CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 444 of 659

STEERING 9-4

8. Reassemble pitman arm to sector shaft, lining up

marks made during disassembly. Refer to torque

specifications at rear of manual for correct torque

value.

9. Install horn cap or ornament and connect steering

column harness at chassis connector.

NOTE:

Chevy.n models are equipped with a

shim at the frame to steering gear mounting

bolts.

Shims may be removed or installed as

required for proper steering gear alignment.

STEERING WHEEL ALIGNMENT AND

HIGH POINT CENTERING

1.

Set front wheels in straight ahead position. This can

be checked by driving vehicle a short distance on a

flat surface to determine steering wheel position at

which vehicle follows a straight path.

2.

With front wheels set straight ahead, check position

of mark on wormshaft designating steering gear high

point. This mark should be at the top side of the shaft

at 12 o'clock position and lined up with the mark in

the coupling lower clamp.

3.

If gear has been moved off high point when setting

wheels in straight ahead position, loosen adjusting

sleeve clamps on both left and right hand tie rods,

then turn both sleeves an equal number of turns in

the same direction to bring gear back on high point.

CAUTION: Turning the sleeves an unequal

number of turns or in differential directions will

disturb the toe-in setting of the wheels.

4.

Readjust toe-in as outlined in Section 3 (if necessary).

5. With wheels in a straight ahead position and the

steering gear on highpoint, check the steering wheel

alignment by measuring the distance from each hori-

zontal spoke to the horizontal centerline of the

steering wheel (fig. 5). If the horizontal spokes are

over 1-1/8 inches from the horizontal position the

wheel should be removed and centered. (See steering

wheel removal in this section.)

TOE-IN ADJUSTMENT

Adjust the steering linkage for proper toe-in setting as

outlined in Section 3.

CORVETTE STEERING RATIO (Fig. 6)

The Corvette steering ratio may be changed as follows:

CAUTION: Do not use the rearward hole in the

steering arm with power steering equipment or

interference may result.

1.

Remove tie rod ball stud nut at steering arm and

disconnect tie rod from steering arm.

2.

Move tie rod end to forward hole for 17.6:1 ratio

(fast ratio) or rear hole for 20.2:1 ratio (standard

ratio).

3.

Install tie rod stud nut and tighten securely. Repeat

operation on opposite steering arm.

COMPONENT REPLACEMENT AND REPAIRS

STEERING WHEEL

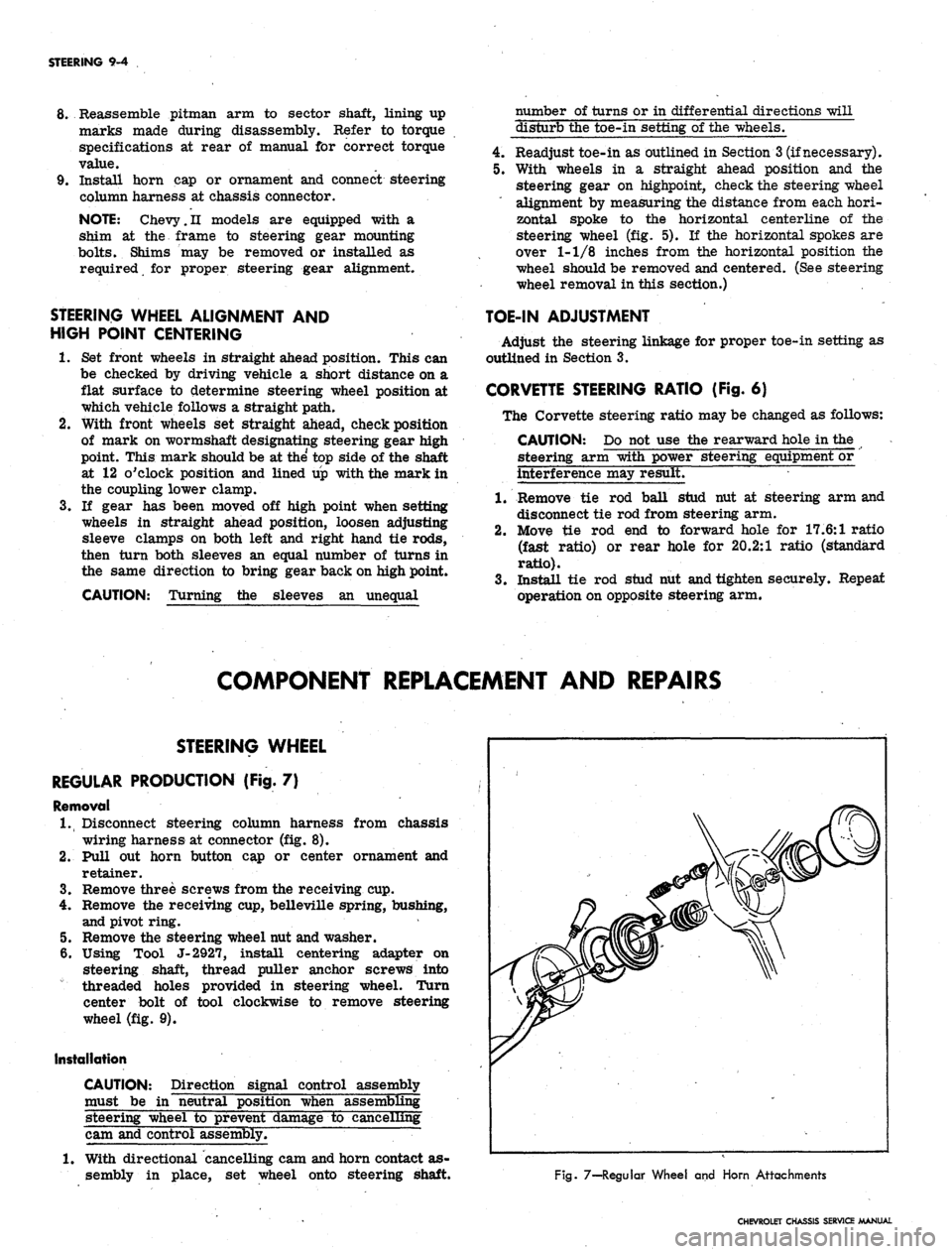

REGULAR PRODUCTION (Fig. 7)

Removal

1.

Disconnect steering column harness from chassis

wiring harness at connector (fig. 8).

2.

Pull out horn button cap or center ornament and

retainer.

3.

Remove three screws from the receiving cup.

4.

Remove the receiving cup, belleville spring, bushing,

and pivot ring.

5. Remove the steering wheel nut and washer.

6. Using Tool J-2927, install centering adapter on

steering shaft, thread puller anchor screws into

threaded holes provided in steering wheel. Turn

center bolt of tool clockwise to remove steering

wheel (fig. 9).

Installation

CAUTION: Direction signal control assembly

must be in "neutral position when assembling

steering wheel to prevent damage to cancelling

cam and control assembly.

1.

With directional cancelling cam and horn contact as-

sembly in place, set wheel onto steering shaft.

Fig. 7—-Regular Wheel and Horn Attachments

CHEVROLET CHASSIS SERVICE MANUAL

Page 448 of 659

STEERING 9-8

DIAL

UPPER COVER

FASTENER

CHEVROLET

SCREW

CHEVELLE

Fig.

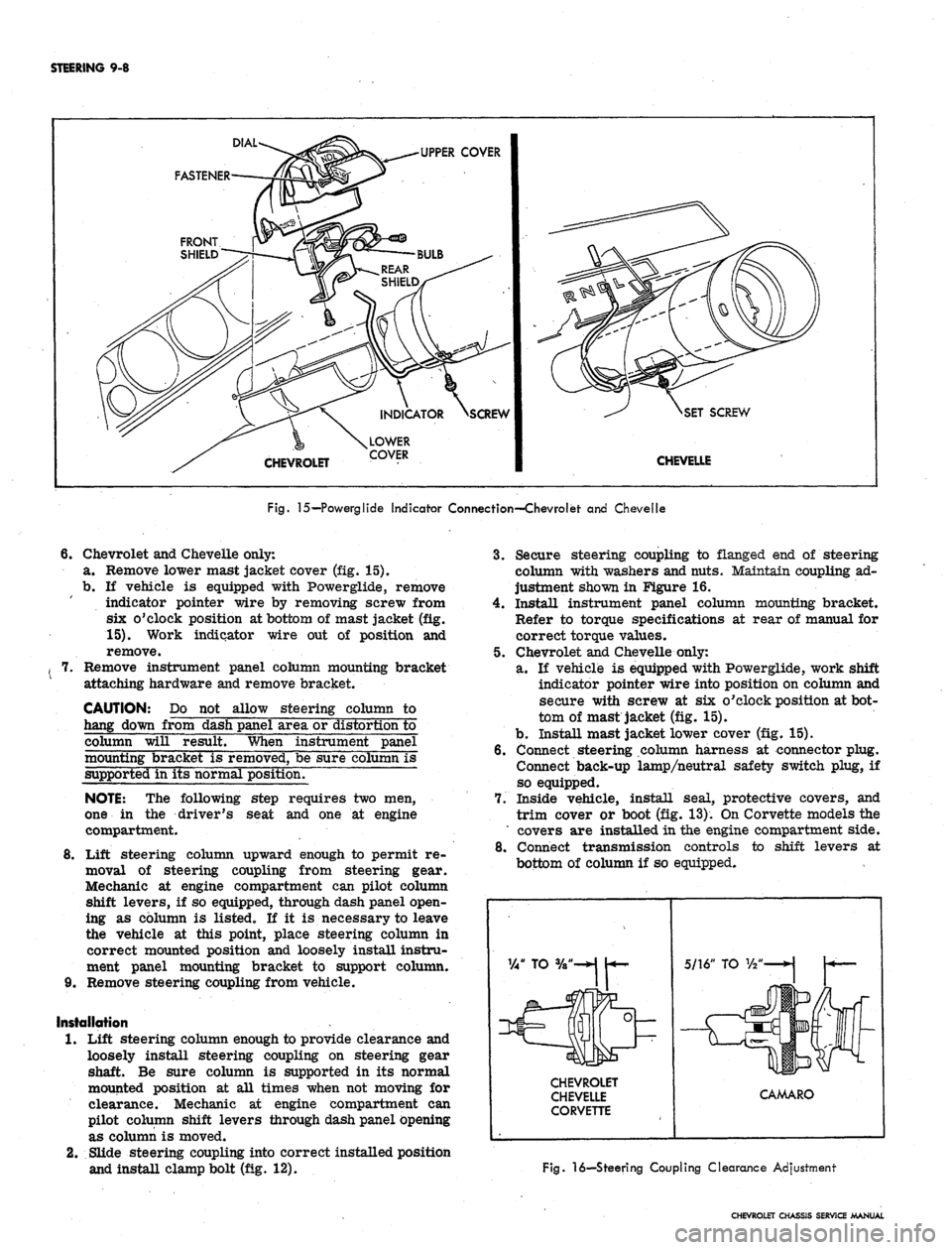

15—Powerglide Indicator Connection—Chevrolet and Chevelle

6.

Chevrolet and Chevelle only:

a. Remove lower mast jacket cover (fig. 15).

b.

If vehicle is equipped with Powerglide, remove

indicator pointer wire by removing screw from

six o'clock position at bottom of mast jacket (fig.

15).

Work indicator wire out of position and

remove.

Remove instrument panel column mounting bracket

attaching hardware and remove bracket.

CAUTION: Do not allow steering column to

hang down from dash panel area or distortion to

column will result. When instrument panel

mounting bracket is removed, be sure column is

supported in its normal position.

NOTE:

The following step requires two men,

one in the driver's seat and one at engine

compartment.

8

Lift steering column upward enough to permit re-

moval of steering coupling from steering gear.

Mechanic at engine compartment can pilot column

shift levers, if so equipped, through dash panel open-

ing as column is listed. If it is necessary to leave

the vehicle at this point, place steering column in

correct mounted position and loosely install instru-

ment panel mounting bracket to support column.

9. Remove steering coupling from vehicle.

Installation

1.

Lift steering column enough to provide clearance and

loosely install steering coupling on steering gear

shaft. Be sure column is supported in its normal

mounted position at all times when not moving for

clearance. Mechanic at engine compartment can

pilot column shift levers through dash panel opening

as column is moved.

2.

Slide steering coupling into correct installed position

and install clamp bolt (fig. 12).

3.

Secure steering coupling to flanged end of steering

column with washers and nuts. Maintain coupling ad-

justment shown in Figure 16.

4.

Install instrument panel column mounting bracket.

Refer to torque specifications at rear of manual for

correct torque values.

5. Chevrolet and Chevelle only:

a. If vehicle is equipped with Powerglide, work shift

indicator pointer wire into position on column and

secure with screw at six o'clock position at bot-

tom of mast jacket (fig. 15).

b.

Install mast jacket lower cover (fig. 15).

6. Connect steering column harness at connector plug.

Connect back-up lamp/neutral safety switch plug, if

so equipped.

7. Inside vehicle, install seal, protective covers, and

trim cover or boot (fig. 13). On Corvette models the

' covers are installed in the engine compartment side.

8. Connect transmission controls to shift levers at

bottom of column if so equipped.

CHEVROLET

CHEVELLE

CORVETTE

CAMARO

Fig.

16—Steering Coupling Clearance Adjustment

CHEVROLET CHASSIS SERVICE MANUAL

Page 450 of 659

STEERING 9-10

SECTOR SHAFT SEAL REPLACEMENT

A faulty seal may be replaced without removal of

steering gear from car by removing pitman arm as out-

lined under Maintenance and Adjustments--Steering Gear

Adjustments and proceed as follows:

1.

Loose lash adjuster lock nut and turn lash adjuster

screw several turns counterclockwise.

2.

Remove three cap screws holding side cover to gear

bushing.

3.

Pull side cover and sector shaft from gear housing

as a unit. Do not separate side cover from sector

shaft.

4.

Pull sector shaft seal from gear housing using

hooked tool or pliers.

5. Coat new seal with chassis grease and position in

sector shaft bore.

6. Place a socket or piece of pipe of suitable diameter

on top of seal and drive seal into bore by tapping

pipe or socket with soft hammer.

7. Install sector shaft side cover assembly, being care-

ful not to damage new seal with splines on end of

shaft; splines may be wrapped with a few turns of

tape to prevent this.

8. Install new side cover gasket and align side cover on

gear housing and install cap screw.

9. Perform steering gear adjustment and install pitman

arm as outlined under Maintenance and Adjustments.

STEERING COLUMN

All models are equipped with new energy absorbing

steering columns. The columns are of five basic designs

as follows:

1.

Syncromesh. The syncromesh column is used on

models with standard, column mounted, conventional

shift levers. The shift tube, within the outer mast

jacket, includes two lower shift levers for connection

to the transmission control linkage.

2.

Automatic and floor shift. This column is used on

models equipped with column mounted powerglide

shift levers, or models with floor shift. If the ve-

hicle has the column mounted powerglide shift con-

trol, the inner shift tube has a single lower shift

lever for connection to the transmission control

linkage. On floor shift models, no lower shift levers

are present on the shift tube.

3.

Tilt wheel option. The upper end and steering shaft

of this column is specially designed to accommodate

the optional tilt steering wheel.

4.

Standard Corvette Column. The standard Corvette

column is similar in design to the Automatic and

Floor Shift column used on other models, except

no shift tube is used. Other differences are pointed

out in the disassembly and assembly procedures for

Standard Corvette column.

5. Telescopic wheel option. The upper end and steering

shaft of this column is specially designed to ac-

commodate the optional telescoping steering wheel.

To perform service procedures on steering column

upper end components, it is not necessary to remove the

column from the vehicle. The steering wheel, horn com-

ponents, turn signal switch, upper housing with bearing,

shift control lever, hazard warning knob, and upper shift

bowl may all be removed with the column remaining in

the vehicle. When servicing the above components, omit

the removal procedure and proceed with the applicable

disassembly procedures. Because of the numerous dif-

ferences in steering column types, be sure to refer to the

set of instructions below which apply to the exact column

to be serviced:

CAUTION: The outer mast jacket, shift tube, _

steering shaft, and instrument panel column

mounting b

racket

are designed as energy ab-

sorbing units. Because of the design of these

components, it is absolutely necessary to handle

the column with care when performing any serv-

ice operation required. Avoid hammering, jar-

ring, dropping, or leaning on any portion of the

column.

Removal

1.

Disconnect steering column harness at connector.

Disconnect neutral safety switch and back-up lamp

switch connectors if so equipped.

Remove steering wheel as outlined in this section.

Remove nuts and washers securing flanged end of

column to steering gear. On Chevy H models, re-

move nut and clamp bolt securing lower end of steer-

ing column to steering gear.

Disconnect transmission control linkage, if so

equipped, from lower column shift tube, levers.

Chevrolet and Chevy II only: Remove screws at-

taching upper and lower mast jacket covers together.

On Chevrolet, remove screws attaching lower cover

to instrument panel (figs. 15 and 18). Remove lower

cover.

Chevelle only: Remove screws securing mast jacket

trim cover to instrument panel and remove cover

(fig. 15).

Corvette, only: Remove screws securing escutcheon

to instrument panel. Remove screws securing upper

and lower covers together and remove covers.

On Chevrolet and Chevelle columns with Powerglide

shift levers, loosen set screw at six o'clock position

at bottom of column and remove the transmission

shift indicator pointer (fig. 15).

9. Chevrolet only (fig. 19):

a. Remove screws securing cover trim to dash

panel and remove cover trim.

2.

3.

4.

5.

6.

7.

8.

Fig.

18—Mast Jacket Cover Attachments—Chevy II

CHEVROLET CHASSIS SERVICE MANUAL

Page 455 of 659

STEERING 9-15

jacket and loosely secure using the three bolts re- 8.

moved during disassembly.

Place a 0.005 maximum shim on each side of the 9.

shaft, between either one of the shift levers and the

spacer (fig. 31). 10.

Using spanner wrench J-22568 installed in spanner

holes in adapter, rotate the.adapter clockwise until

the shift levers are bottomed out (fig. 31). Bottom

the adapter against the jacket while rotating to re-

move end play. 11.

Tighten the three adapter bolts. Remove the two

0.005 shims.

Insert the steering shaft assembly into position

through the lower end of the jacket.

Attach the back-up lamp switch loosely to the jacket

using the same nuts removed during disassembly.

Install these nuts loosely, switch will be tightened to

the jacket when column is installed in vehicle and

shift levers are aligned.

If upper shift lever spring was removed, press a

10 9 8

6 5 4 3 2 1

Fig.

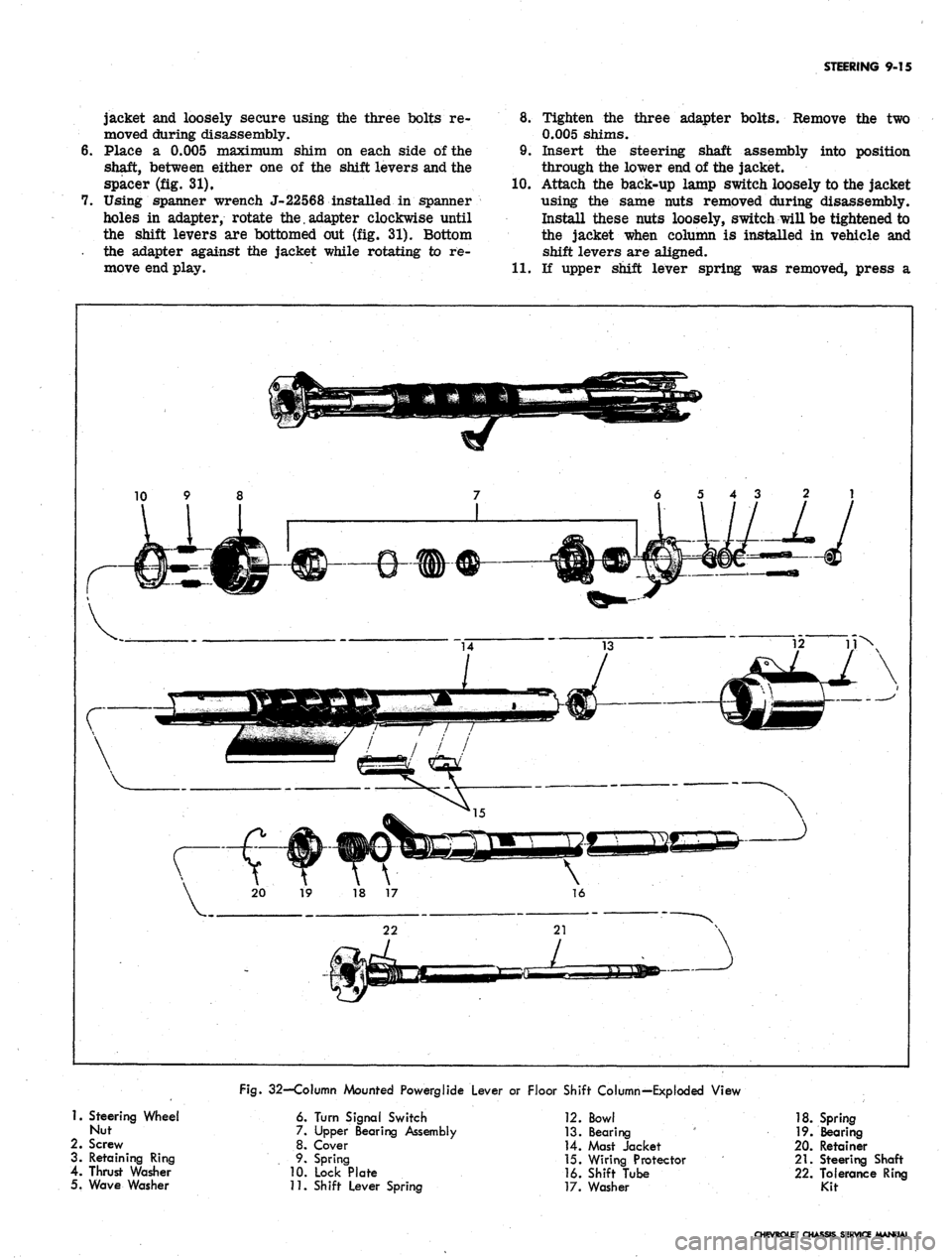

32—Column Mounted Powerglide Lever or Floor Shift Column—Exploded View

1.

Steering Wheel

Nut

2.

Screw

3. Retaining Ring

4.

Thrust Washer

5. Wave Washer

6. Turn Signal Switch

7. Upper Bearing Assembly

8. Cover

9. Spring

10.

Lock Plate

11.

Shift Lever Spring

12.

Bowl

13.

Bearing

14.

Mast Jacket

15.

Wiring Protector

16.

Shift Tube

17.

Washer

18.

Spring

19.

Bearing

20.

Retainer

21.

Steering Shaft

22.

Tolerance Ring

Kit

CHEVROLET CHASSIS SERVICE MANUAL

Page 456 of 659

STEERING 9-16

new upper shift lever spring into bowl pocket. Be

sure spring is seated in bowl pocket. Install bowl

washer (fig. 30).

12.

Insert the upper bearing housing assembly and the

turn signal switch assembly into the cover, feeding

the signal switch wires through the back of the

cover.

13.

Align the signal switch and bearing housing holes

with the holes in the cover. Install three mounting

screws through the holes.

14.

Slide three springs onto screw ends at rear of cover

and place lockplate in position over screws and

springs. Turn screws three turns into lockplate.

15.

Feed switch wire through the shift lever bowl and

place upper end assembly on top of bowl.

16.

Place the shift lever bowl and signal switch cover

assembly on top of jacket, aligning the tangs on the

I.D. of the lockplate with the slots in the top of the

jacket. Shift tube key should align in bowl keyway as

bowl is pushed ono

17.

Lock upper end assembly into position by pushing

down on the cover assembly and rotating assembly

fully clockwise. Tangs of lock plate must engage

slots in jacket.

18.

Tighten three turn signal switch mounting screws in

a gradual criss-cross sequence to avoid cocking the

lockplate.

19.

Slide wave washer and thrust washer over steering

shaft and against upper bearing housing.

20.

Start "C" retaining ring over steering shaft taper.

Complete installation of. retaining ring using snap

ring installer J-22659 as shown in Figure 28. Be

sure "C" retaining ring is completely seated into

steering shaft groove.

21.

-Place turn signal switch lever in position and secure

with screw. Screw hazard warning knob into position.

22.

Remove column from vise and pull wires flat against

jacket. Snap wire protector into place.

23.

If mesh cover was removed, wrap mesh cover around

jacket and secure with electricians or friction tape.

24.

Slide cancelling cam and upper bearing preload

spring onto end of shaft.

Disassembly—Column Mounted Power glide Lever or

Floor Shift Column (Fig. 32)

NOTE: In this procedure, automatic refers to a

column with a column mounted, Powerglide shift-

ing lever. Floor shift refers to a column taken

from a vehicle with conventional or Powerglide

floor shift controls.

1.

Unsnap and remove wiring protector and wiring clip.

CAUTION: Secure column in bench vise for

service one of two ways shown in Figure 26.

Clamping column in vise in any other manner

will damage the column. If support fixture

J^22573 is not used, frequently check position of

column in vise jaws to insure column is not

working free of jaws.

2.

Clamp column in a bench vise as shown in Figure 26.

3.

Slide upper bearing preload spring and cancelling

cam off end of shaft.

4.

On automatic columns removed from Chevy II or

Camaro, remove screws securing dial retainer to

column and remove retainer and dial (fig. 33). Slide

Fig.

33—Powerglide Dial Indicator Assembly—Chevy II

and Camaro

indicator out of shift bowl and remove indicator. Re-

move cap and bulb from turn signal switch housing.

5.

Remove turn signal lever retaining screw and re-

move lever. Push hazard warning knob in; unscrew

and remove knob.

6. On automatic columns, drive'out shift control lever

retaining pin and remove shift lever.

7.

Remove "C" retaining ring from upper steering

shaft using snap ring remover Tool J-22569 (fig. 28).

8. Slide thrust washer and wave washer off upper steer-

ing shaft (fig. 28).

9. Loosen three turn signal switch mounting screws

until the switch cover can be rotated counterclock-

wise.

It may be necessary to push on top of screws

to loosen the cover assembly. ,

NOTE: Do not remove the three turn signal

switch screws completely unless it is necessary

to replace the turn signal switch, lockplate, or

upper bearing housing and bearing.

10.

Rotate turn signal switch cover counterclockwise

and pull cover off top of jacket (fig. 29).

11.

If necessary, pry upper shift lever spring (fig. 30)

from bowl and discard spring.

12.

Remove shift lever bowl from top of jacket.

13.

If necessary to service components within the signal

switch cover, remove the three signal switch covers,

remove the three signal switch mounting screws

completely from engagement with the lockplate. Use

care to control three springs as screws are removed.

14.

Remove turn signal switch and upper bearing housing

assembly from cover.

15.

Carefully pull steering shaft assembly from bottom

of column.

16.

Remove securing back-up lamp/neutral start switch

to column, if so equipped, and remove switch. Retain

these mounting nuts.

CHEVROLET CHASSIS SERVICE MANUAL

Page 457 of 659

STEERING 9-17

STEERING SHAFT

SHIFT TUBE

Fig.

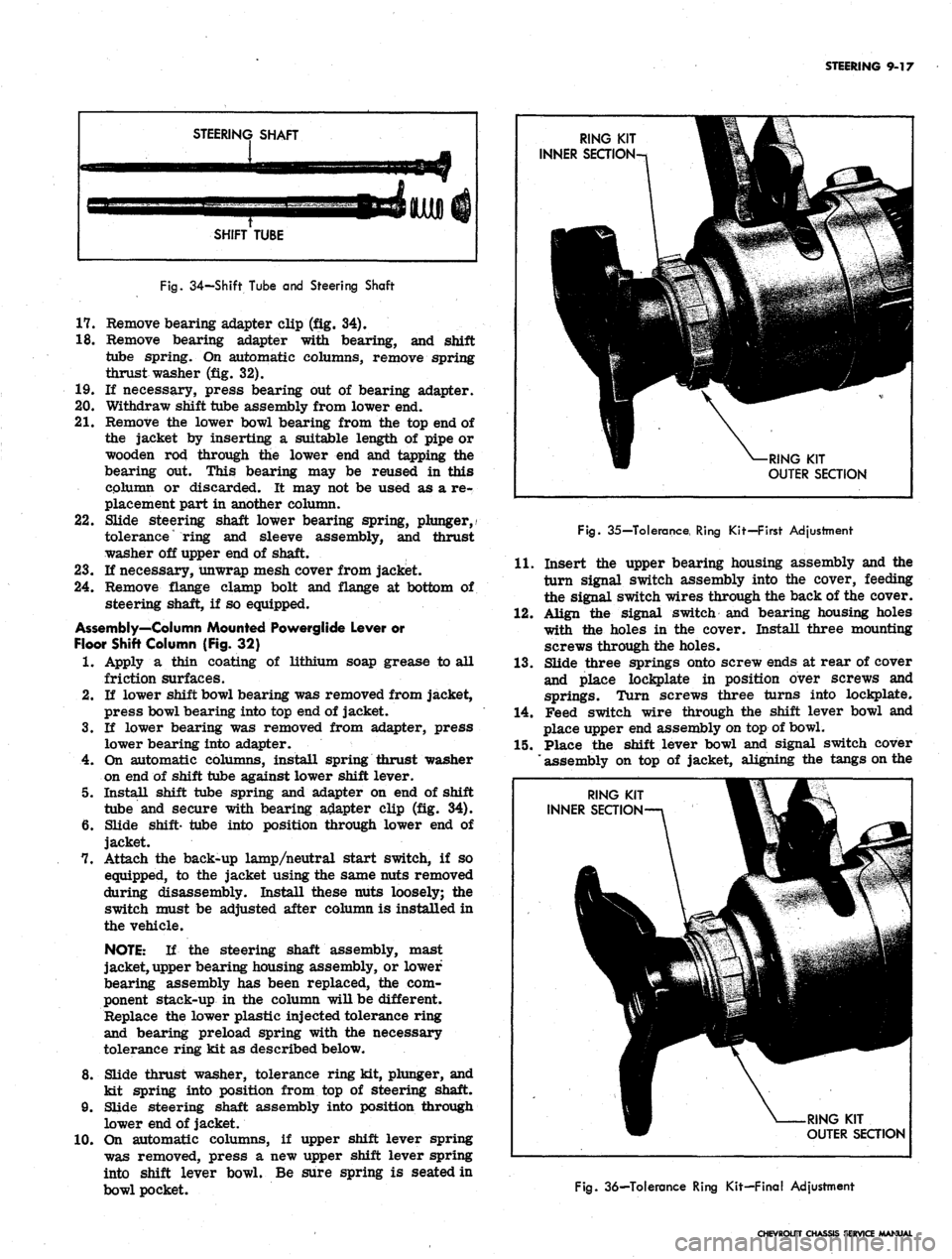

34—Shift Tube and Steering Shaft

17.

Remove bearing adapter clip (fig. 34).

18.

Remove bearing adapter with bearing, and shift

tube spring. On automatic columns, remove spring

thrust washer (fig. 32).

19.

U necessary, press bearing out of bearing adapter.

20.

Withdraw shift tube assembly from lower end.

21.

Remove the lower bowl bearing from the top end of

the jacket by inserting a suitable length of pipe or

wooden rod through the lower end and tapping the

bearing out. This bearing may be reused in this

column or discarded. It may not be used as a re-

placement part in another column.

22.

Slide steering shaft lower bearing spring, plunger,/

tolerance

*

ring and sleeve assembly, and thrust

washer off upper end of shaft.

23.

If necessary, unwrap mesh cover from jacket.

24.

Remove flange clamp bolt and flange at bottom of

steering shaft, if so equipped.

Assembly—Column Mounted Powerglide Lever or

Floor Shift Column (Fig. 32)

1.

Apply a thin coating of lithium soap grease to all

friction surfaces.

2.

If lower shift bowl bearing was removed from jacket,

press bowl bearing into top end of jacket.

3.

If lower bearing was removed from adapter, press

lower bearing into adapter.

4.

On automatic columns, install spring thrust washer

on end of shift tube against lower shift lever.

5. Install shift tube spring and adapter on end of shift

tube and secure with bearing adapter clip (fig. 34).

6. Slide shift- tube into position through lower end of

jacket.

7. Attach the back-up lamp/neutral start switch, if so

equipped, to the jacket using the same nuts removed

during disassembly. Install these nuts loosely; the

switch must be adjusted after column is installed in

the vehicle.

NOTE:

If the steering shaft assembly, mast

jacket, upper bearing housing assembly, or lower

bearing assembly has been replaced, the com-

ponent stack-up in the column will be different.

Replace the lower plastic injected tolerance ring

and bearing preload spring with the necessary

tolerance ring kit as described below.

8. Slide thrust washer, tolerance ring kit, plunger, and

kit spring into position from top of steering shaft.

9. Slide steering shaft assembly into position through

lower end of jacket.

10.

On automatic columns, if upper shift lever spring

was removed, press a new upper shift lever spring

into shift lever bowl. Be sure spring is seated in

bowl pocket.

Fig.

35—Tolerance, Ring Kit—First Adjustment

11.

Insert the upper bearing housing assembly and the

turn signal switch assembly into the cover, feeding

the signal switch wires through the back of the cover.

12.

Align the signal switch and bearing housing holes

with the holes in the cover. Install three mounting

screws through the holes.

13.

Slide three springs onto screw ends at rear of cover

and place lockplate in position over screws and

springs. Turn screws three turns into lockplate.

14.

Feed switch wire through the shift lever bowl and

place upper end assembly on top of bowl.

15.

Place the shift lever bowl and signal switch cover

assembly on top of jacket, aligning the tangs on the

RING KIT

OUTER SECTION

Fig.

36—Tolerance Ring Kit—Final Adjustment

CHEVROLET CHASSIS SERVICE MANUAL

Page 459 of 659

STEERING 9-19

20.

21.

22.

23.

24.

25.

26.

27.

28.

Start "C" retaining ring over steering shaft taper.

Complete installation of retaining ring using snap

ring installer J-22659 as shown in Figure 28. Be

sure "C" retaining ring is completely seated into

steering shaft groove.

Remove any remaining looseness from internal col-

umn stack-up by unscrewing inner tolerance kit ring

section; then screw inner kit ring section back in

1/8 to 1/4 turn (fig. 36).

Touch the outer surface of the tolerance ring kit

.at

several locations with a hot soldering iron to melt

the threads of the inner and outer ring sections

together.

Place turn signal switch lever in position and se-

cure with screw. Screw hazard warning knob into

position.

If column is automatic and to be installed in a Chevy

II or Camaro, install the bulb and cap (fig. 33). Slide

the indicator into the 'shift bowl. Install dial and re-

tainer with screws removed during disassembly.

Install flange and clamp bolt at bottom of steering

shaft, if so equipped.

Remove column from vise and pull wires flat against

bottom of jacket. Snap wire protector and clip into

place.

If mesh cover was removed, wrap mesh cover around

jacket and secure with electricians or friction tape

/**% • *t 1*1* i '% •< n

Slide cancelling cam and

spring onto end of shaft.

upper bearing preload

Disassembly-Til* Column (Fig. 37)

NOTE:

This procedure covers disassembly and

assembly instructions for all tilt columns. Auto-

matic refers to a tilt column with a column

mounted, Powerglide shifting lever. Floor shift

. refers to' a tilt column taken from a vehicle with

conventional or Powerglide floor shift controls.

1.

Unsnap and remove wiring protector.

CAUTION: Secure column in bench vise for

service one of two ways shown in Figure 26.

Clamping column in vise in any other manner

will damage the column. If support fixture

J-22573 is not used, frequently check position

of column in vise jaws to insure column is not

working free of jawsT

2.

Clamp column in a bench vise as shown in Figure 26.

3.

Slide upper bearing preload spring and cancelling

cam off end of shaft.

Fig,

38—Removing Turn Signal Cover Using Tools

J-21486 and J-6585-1

Fig.

39—Removing Steering Shaft Bearing Lock Nut

Using Lock Nut Wrench j-22599

4.

On automatic columns removed from a Camaro, re-

move screws securing dial retainer to column and

remove retainer and dial (fig. 33). Slide pointer out

of bowl and remove pointer. Remove cap and bulb

from turn signal switch housing.

5. Remove turn signal lever retaining screw and re-

move lever. Unscrew and remove tilt release lever.

Push hazard warning knob in, unscrew and remove

knob.

6. On Automatic columns, drive out shift control lever

retaining pin and remove shift lever.

7. Assemble slide hammer Tool J-6585-1 to turn signal

cover remover Tool J-21486. Place cover remover

over turn signal cover, tighten clamp, and pull

cover from end of column with slide hammer (fig.

38).

8. Remove three turn signal switch mounting screws.

Note short length of secure removed from top

position.

9. Lift signal switch assembly off bearing housing and

allow to hang by the wires. On some columns, the

switch and wires can be removed at this time; re-

move switch and wires if possible. If switch and

wires cannot be removed, allow assembly to hang

by wires.

10.

Install tilt release lever and place column in full up

position. Remove tilt spring retainer using screw-

driver blade that just fits into slot opening. Insert

screwdriver in slot, press in approximately 3/16-

inch;

rotate retainer approximately 1/8 turn clock-

wise until ears align with grooves in housing, and

remove retainer and spring. Use care when remov-

ing spring, it is tightly compressed.

11.

Remove steering shaft bearing lock nut using lock nut

wrench Tool J-22599 (fig. 39). Remove inner race

•seat and inner "race.

12.

Remove two pivot pins from bearing housing using

pivot pin remover Tool J-21854 (fig. 40).

CHEVROLET CHASSIS SERVICE MANUAL

Page 469 of 659

STEERING 9-29

column mounting bracket, and place bracket in cor-

rect position on underside of instrument panel.

Loosely install bracket using bracket to column

mounting screws and bracket to instrument panel

washers and bolts.

NOTE: Steering shaft to gear clamp must be

tightened before column attaching bolts are

torqued. Refer to "Steering Gear-Chevy n",

installation procedure, for correct Chevy II

steering column alignment procedure.

5.

Camaro only (fig. 60):

Lay wedge shim in position on instrument panel

column mounting bracket and place bracket in cor-

rect position on underside of instrument panel.

Loosely install bracket using bracket to column

mounting screws, nuts, and washer and bolt as shown

in Figure 60.

6. Corvette only (fig. 61):

Loosely secure column mounting bracket to sup-

port plate and instrument panel with washers and

bolts.

7.

Secure flanged end of column to steering coupling

with lockwashers and nuts. On Chevy n, connect col-

umn to steering gear with clamp, clamp bolt, and

nut. On Corvette, slide steering shaft flange into

lower coupling

half,

and install upper clamp bolt

loosely; also secure support, seal and clamp loosely

at dash on engine side.

8. Tighten instrument panel mounting bracket bolts and

nuts.

Refer to torque specifications at rear of manual

for correct torque values.

9. Chevrolet only (fig. 15):

Place upper and lower mast jacket covers in po-

sition and secure covers together and to instrument

panel using nuts and screws as shown in Figure 15.

10.

Chevy H only (fig. 18):

Place lower mast jacket cover in position under

mast jacket and secure to upper cover with screws.

11.

CheveUe only (fig. 15):

Place mast jacket trim cover in position over col-

Fig.

61—Instrument Panel Mounting Bracket and

Support Plqte—Corvette

umn on underside of instrument panel and secure

with screws.

12.

Corvette only (fig. 14):

Slide escutcheon into position at instrument panel

and secure with screws. Place upper end lower

covers in position and secure with screws.

13.

On Chevrolet and CheveUe models with column

mounted powerglide controls, secure transmission

shift indicator pointer into position with set screw

(fig. 15). ,

14.

Chevrolet only (fig. 19):

a. Secure seal and cover to dash panel with screws.

b.

Place clamp assembly in position and install

clamp screw.

c. Install dash panel trim cover with mounting

screws.

15.

Chevelle only (fig. 20):

a. Secure seal and inner and outer covers to dash

panel with screws.

b.

Secure inner and outer covers together with

screws.

c. Install trim cover to dash panel with two

retainers.

16.

Chevy H only (fig. 21):

a. Secure seal, retainer, and clamp to dash panel

with screws.

b.

Install clamp screw.

c. Slide collar into position. Pinch and staple upper

tabs together.

17.

Camaro only (fig. 22):

a. Secure seal, upper cover, and lower cover to

dash panel with screws.

b.

Secure upper and lower cover together with

screws.

c. Fold rubber boot over securely against dash panel

to conceal covers.

18.

Corvette only (fig. 23):

a. Secure seal and support assembly to dash panel

on engine compartment side.

b.

Tighten clamp, washer, and clamp bolt on engine

compartment side.

19.

Connect transmission linkage to lower shift tube

levers in engine compartment, if column is so

equipped. Adjust levers as outlined in Section 7.

20.

Install steering wheel as outlined in this section.

21.

Connect directional signal, horn, back-up lamp, and

neutral start switch at wiring harness plugs. Adjust

back-up lamp, neutral start switch as outlined in

Section 12.

22.

Adjust steering gear and align and center steering

wheel as outlined in this section.

STEERING LINKAGE (Fig. 62)

TIE RODS

There are two tie rod assemblies used on all models.

Each assembly is of three piece construction, consisting

of a sleeve and two tie rod ends. The ends are threaded

into the sleeve and locked with clamps. Right and left

hand threads are provided to facilitate toe-in adjustment

and steering gear centering.

The tie rod ends are self-adjusting for wear and re-

quire no attention in service other than periodic lubrica-

tion and occasional inspection to see that ball studs are

tight. Replacement of tie rod ends should be made when

CHEVROLET CHASSIS SERVICE MANUAL

Page 472 of 659

STEERING

9-32

arm on frame and install mounting bolts, washers

and nuts. No washer is used on Corvette.

Install relay rod to idler arm, ^making certain seal

is on stud. Install and tighten nut.

Install cotter pin.

Refer to torque specifications at rear of manual for'

correct torque values.

Chevy II (Fig. 62}

Removal

1.

Remove cotter pin, nut and washer securing idler

arm to relay rod.

2.

Remove relay rod from idler arm.

3.

If equipped with power steering disconnect power

cylinder shaft from idler arm bracket.

4.

Remove three idler bracket to frame bolts and nuts

and remove bracket and idler arm assembly.

5.

Remove cotter pin, nut, washer and bolt securing the

idler arm to the bracket.

6. Press out the idler arm bushing for replacement.

Installation

NOTE: Installation must be done with front

wheels straight ahead or the car will lead to one

side.

1.

Install idler arm bushing, if previously removed.

NOTE: Make certain the outer sleeve of the

bushing does not protrude above surface of idler

arm.

2.

Reverse removal procedure and torque all nuts ac-

cording to specifications.

PITMAN ARM

Removal

1.

Remove cotter pin from pitman arm ball stud and

remove nut.

2.

Remove relay rod from pitman arm by tapping on

side of rod or arm in which the stud mounts with a

hammer while using a heavy hammer or similar tool

as a backing. Pull down on relay rod to remove

from stud.

3.

Remove pitman arm nut from sector shaft and mark

relation of arm position to shaft.

4.

Remove pitman arm with Tool J-6632 as shown in

Figure 2.

Installation

1.

Install pitman arm on sector shaft, lining up the

• marks made upon removal.

2.

Install sector shaft nut.

3.

Position relay rod on to pitman arm. Install nut.

Continue to tighten arm enough to align castellation

with hole in stud and install cotter pin.

STEERING ARM

If, through collision or other damage, it becomes nec-

essary to remove and replace either steering arm, pro-

ceed as follows:

Removal

1.

Remove tie rod from steering arm as outlined in this

section.

2.

Remove front wheel, hub and brake drum as a unit

by removing hub cap and dust cap, cotter pin from

spindle nut and the spindle nut. Pull assembly to-

ward outside of vehicle. If removal is difficult, it

may be necessary to back off brake adjustment to

increase brake shoe-to-drum clearance; see Hy-

draulic Brake Adjustment, Section 5. On models

with disc brakes, remove caliper and disc.

3.

With wheel and drum assembly or caliper and disc

removed, steering arm retaining bolt heads are ac-

cessible and removal of steering arm from vehicle

may be accomplished by removing retaining nuts.

Installation

1.

Place steering arm in position on vehicle and install

retaining bolts*

2.

Install nuts. Use only the special locknut listed for

this use in the Chevrolet Parts Catalog.

3.

Pack wheel bearings using a high quality wheel

bearing lubricant. Install bearings and wheel-hub-

brake drum assembly removed previously. On disc

brake models, install disc and caliper.

4.

Install keyed washer and spindle nut. Proceed as out-

lined under t{ Front Wheel Bearing Adjustment" in

Section 3.

5.

Install tie rod ball stud in steering arm. Be sure that

the dust cover is in place on ball stud.

6. Install castellated nut on ball stud, tighten securely

and install cotter pin.

7.

Following directions given in Section 3 to check cor-

nering wheel relationship and toe-in; correct as

required.

STEERING DAMPER-CORVETTE

Removal

1.

Remove bolt from damper pivot bracket at relay rod.

2.

Remove nut from damper pivot at frame bracket and

withdraw damper assembly.

Damper is serviced as a unit. Replace damper if

3.

damaged or excessively worn.

Installation

1.

Place piston rod end into frame bracket and install

retainers, bushings, and nut.

2.

Insert cylinder end pivot into relay rod bracket and

install through bolt.

CHEVROLET CHASSIS SERVICE MANUAL

Page 473 of 659

STEERING

9-33

POWER STEERING

INDEX

Page

General Description

. 9-33

Maintenance

and

Adjustments

9-33

Bleeding Hydraulic System

9-33

Fluid Level

. 9-33

Adjustments

. 9-34

Power Steering Gear

. . 9-34

Pump Belt Tension

9-34

Hydraulic System Checks

9-34

Component Replacement

and

Repairs

. 9-35

Power Steering Pump.

. 9-35

Power Steering Gear

9-36

Control Valve

and

Adapter Assembly

9.35

Power Cylinder

9.37

Power Steering Hoses

9.39

GENERAL DESCRIPTION

Two types

of

power steering

are

used

for 1967.

One

is

the conventional linkage type

for

Chevy

n and

Corvette

vehicles

and the

other

is the

integral gear type

for

Chevrolet, Chevelle,

and

Camaro.

For

both types

the

hydraulic pressure

is

provided

by an

engine-driven vane-

type pump.

On

the

Chevy

n and

Corvette linkage type power steer-

ing, hydraulic pressure

is

delivered through

a

hose from

the pump

to a

valve which senses

the

requirement

for

power assistance

and

supplies

the

power cylinder

ac-

cordingly.

The

steering gear used with this power steer-

ing

is the

same basic unit used

on

manually steered

vehicles;

it is

serviced

as

outlined

in the

manual steering

part

of

this section except

for

adjustment, which

is

covered

in the

following pages.

The

steering linkage also

is serviced the same

as

manual counterparts.

The Chevrolet, Chevelle

and

Camaro integral gear type

power steering

has the

hydraulic pressure delivered

from

the

pump through two hoses

to the

steering gear.

In

the power steering gear

the

steering shaft, hydraulic

valve, worm, and rack-piston

nut are all in

line making

a

compact

and

space saving assembly.

All oil

passages

are

internal within

the

gear except

the

pressure

and

return

hoses.

The steering gear

is a

recirculating ball system

in

which steel balls

act as a

rolling thread between

the

steering worm

and

rack-piston

nut. The

rack-piston

nut

is

all one

piece

and is

geared

to the

sector

of

the piston

shaft.

The

valve

is

contained

in the

gear housing elimi-

nating

the

need

of

bolts

or

seals

to

attach

a

separate

valve housing.

The valve

is an

open-center, rotary-type three

way

valve.

The

spool

is

held

in

neutral position by means

of a

torsion

bar. The

spool

is

attached

by

means

of

the stub

shaft

to one end of the

torsion

bar

and

to the

valve body

on

the

other

end.

Twisting

of the

torsion bar allows

the

spool

to

move

in

relation

to the

valve body thereby oper-

ating

the

valve.

MAINTENANCE

AND

ADJUSTMENTS

BLEEDING HYDRAULIC SYSTEM

1.

Fill

oil

reservoir

to

proper level and

let oil

remain

undistrubed

for at

least two minutes.

2.

Start engine

and run

only

for

about

two

seconds.

3.

Add

oil if

necessary.

4.

Repeat above procedure until

oil

level remains

con-

stant after running engine.

5. Raise front

end of

vehicle

so

that wheels

are off

the

ground.

6. Increase engine speed

to

approximately

1500 rpm.

7. Turn

the

wheels

(off

ground) right

and

left, lightly

contacting

the

wheel stops.

8. Add

oil if

necessary.

9. Lower

the car and

turn wheels right and left

on the

ground.

10.

Check

oil

level and refill

as

required.

11.

If oil is

extremely foamy, allow vehicle

to

stand

a

few minutes with engine

off and

repeat above

procedure.

,

a.

Check belt tightness

and

check

for a

bent

or

loose

pulley. (Pulley should

not

wobble with engine

running.)

b.

Check

to

make sure hoses

are not

touching

any

other parts

of the car,

particularly sheet metal.

c. Check

oil

level, filling

to

proper level

if

neces-

sary, following operations

1

through

10.

This

step

and

Step

"D" are

extremely important

as

low

oil

level and/or

air in the oil are the

most

frequent causes

of

objectionable pump noise.

d. Check

the

presence

of air in the oil. If air is

present, attempt

to

bleed system

as

described

in

operations

1

through

10. If it

becomes obvious

that

the

pump will

not

bleed after

a few

trials,

proceed

as

outlined under Hydraulic System

Checks.

FLUID

LEVEL

1.

Check

oil

level

in the

reservoir

by

checking

the dip

stick when

oil is at

operating temperature.

On

Chevelle models equipped with remote reservoir,

the reservoir should

be

maintained approximately

3/4 full when

oil is at

operating temperature.

2.

Fill,

if

necessary,

to

proper level with

GM

Power

Steering Fluid

or, if

this

is not

available, automatic

CHEVROLET CHASSIS SERVICE MANUAL