ESP CHEVROLET CAMARO 1967 1.G Chassis Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 426 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-20

4.

Attach the retaining straps with strap guide attached

to the fuel tank support, and secure with-the nut and

lockwasher assembly.

5. Connect the filler neck boot to the drain hose of the

tank and install boot around filler neck,

6. Connect the fuel pickup line, ground wire and make

certain that the fuel drain line is flush to 1/2" in-

board of the rear bumper opening.

7. Attach tank metering unit wires (fig. 25).

8. Replace fuel in tank. Replace gas cap.

9. Check for possible leaks.

10.

Reconnect the exhaust system by reversing the above

removal procedures (see "Exhaust System").

11.

Install spare tire carrier by securing the bolt

attachment.

12.

Install the spare tire in the tire carrier.

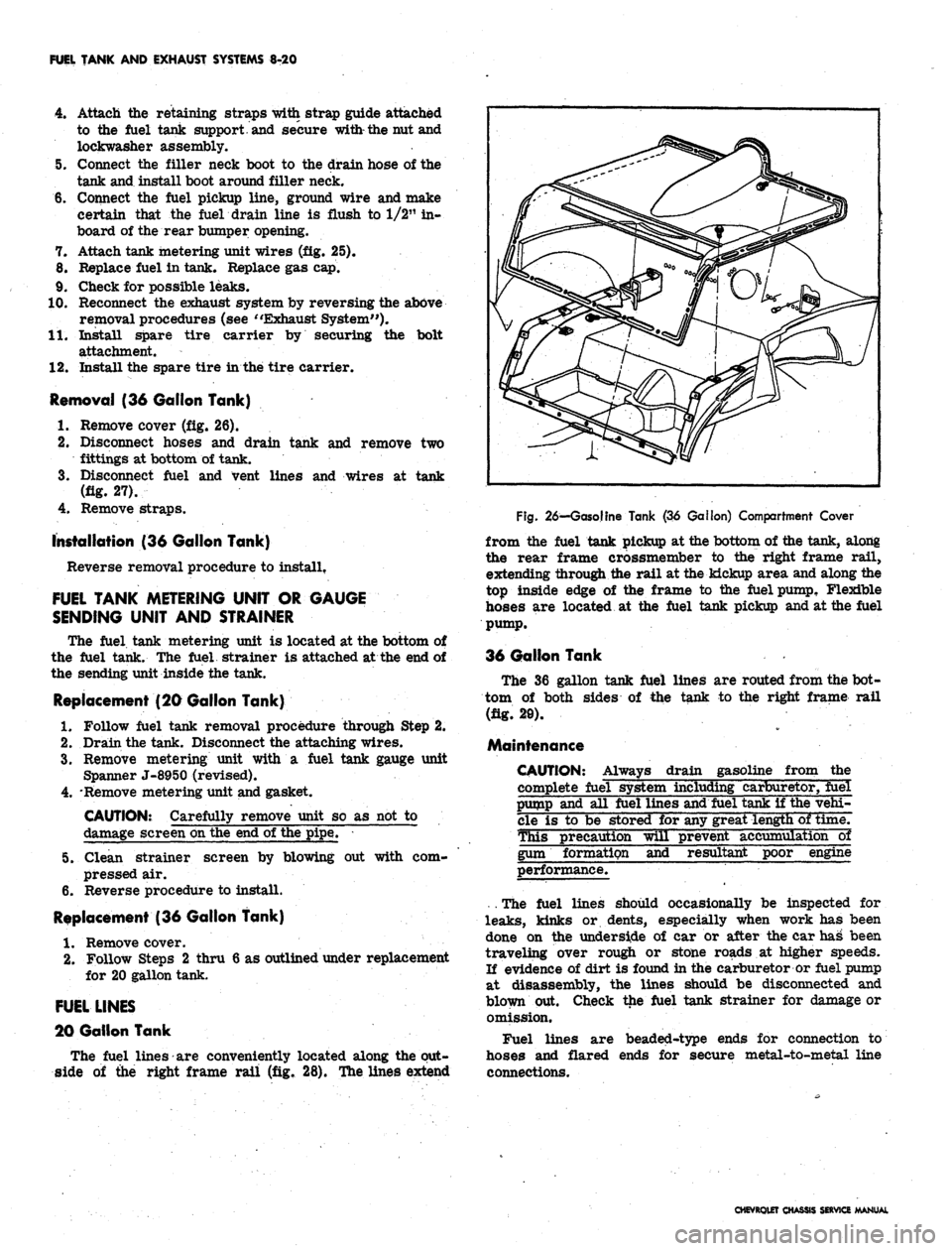

Removal (36 Gallon Tank)

1.

Remove cover (fig. 26).

2.

Disconnect hoses and drain tank and remove two

fittings at bottom of tank.

3.

Disconnect fuel and vent lines and wires at tank

(fig. 27).

4.

Remove straps.

installation (36 Gallon Tank)

Reverse removal procedure to install.

FUEL TANK METERING UNIT OR GAUGE

SENDING UNIT AND STRAINER

The fuel tank metering unit is located at the bottom of

the fuel tank. The fuel strainer is attached at the end of

the sending unit inside the tank.

Replacement (20 Gallon Tank)

1.

Follow fuel tank removal procedure through Step 2.

2.

Drain the tank. Disconnect the attaching wires.

3.

Remove metering unit with a fuel tank gauge unit

Spanner J-8950 (revised).

4.

'Remove metering unit and gasket.

CAUTION: Carefully remove unit so as not to

damage screen on the end of the pipe.

5. Clean strainer screen by blowing out with com-

pressed air.

6. Reverse procedure to install.

Replacement (36 Gallon Tank)

1.

Remove cover.

2.

Follow Steps 2 thru 6 as outlined under replacement

for 20 gallon tank.

FUEL LINES

20 Gallon Tank

The fuel lines are conveniently located along the out-

side of the right frame rail (fig. 28). The lines extend

Fig.

26—Gasoline Tank (36 Gallon) Compartment Cover

from the fuel tank pickup at the bottom of the tank, along

the rear frame crossmember to the right frame rail,

extending through the rail at the kickup area and along the

top inside edge of the frame to the fuel pump, Flexible

hoses are located at the fuel tank pickup and at the fuel

pump.

36 Gallon Tank

The 36 gallon tank fuel lines are routed from the bot-

tom of both sides of the tank to the right frame rail

(fig. 20).

Maintenance

CAUTION: Always drain gasoline from the

complete fuel system including carburetor, fuel

pump and all fuel lines and fuel tank if the vehi-

cle is to be stored for any great length of time.

This precaution will prevent accumulation~ol

gum formation and resultant poor engine

performance.

. The fuel lines should occasionally be inspected for

leaks,

kinks or dents, especially when work has been

done on the underside of car or after the car has been

traveling over rough or stone roads at higher speeds.

If evidence of dirt is found in the carburetor or fuel pump

at disassembly, the lines should be disconnected and

blown put. Check the fuel tank strainer for damage or

omission.

Fuel lines are beaded-type ends for connection to

hoses and flared ends for secure metal-to-metal line

connections.

CHEVROLET CHASSIS SERVICE MANUAL

Page 481 of 659

SECTION 10

WHEELS AND TIRES

INDEX

Page

General Description

10-1

Maintenance

and

Adjustments

.............. 10—1

Tires

10-1

Pressures . 10-1

Inspection 10-1

Wear 10-1

Rotation 10-4

Noise 10-4

Cleaning 10-4

Change (W/Wheels) 10-4

Wheels 10-5

Static Balancing (w/Tire) 10-5

Page

Dynamic Balancing (w/Tire) . 10-5

Run Out (w/o Tire) 10-5

Cleaning 10-5

Service Operations 10-5

Tires 10-5

Removal 10-5

Installation 10-5

Repair 10^6

Wheels . 10-6

Valve Assembly 10-6

Repair (Rim) 10-7

GENERAL DESCRIPTION

WHEELS

Chevrolet, Chevelle, Camaro, Chevy n, and Corvette

are base equipped with welded steel wheels. Five studs

with nuts fasten each wheel to the front hub or rear axle

flange. Disc brake equipped vehicles (except Chevrolet

and Corvette) require special 14 inch diameter wheels

with a revised design for clearance, Chevrolet disc brake

equipped vehicles have 15 in. diameter wheels as do all

Corvettes.

Chevrolet station wagons, Chevelle Super Sport 396,

Corvette and Camaro Super Sport 350 are base equipped

with 6 in. width wheels. All other vehicles have 5 in.

width wheels, except Chevy n 100, 300 and 500 Series

Sedans, which have 4 in. width wheels.

Do not install 6 inch width wheels or snow chains on

Chevrolets equipped with rear fender skirts.

TIRES

The factory installed tires on Chevrolet passenger

cars are selected to provide the best all around tire

performance for all normal operation. They are de-

signed to operate satisfactorily with loads up to and in-

cluding the specified full rated load capacity of the

automobile when inflated as recommended in the Vehicle

Capacity Rating and Recommended Tire Inflation Pres-

sures Table (see Specifications).

Optional Oversize and 8-Ply Rating Tires

{Chevrolet and Chevelle Only)

Oversize or 8-ply rating tires are not necessary on

passenger cars for normal requirements. However, an

extra margin of tire service is available when these

options are used at loads up to and including full rated

load.

Optional oversize 4-ply rating and/or 8-ply rating

tires are available on models as indicated in the Tire

Usage Chart (see Specifications). On some models (ex-

ample—Station Wagon), space limitations do not permit

the use of a larger size tire; hence, the 8-ply rating

tire is an available option.

In either case, these tires are applicable to extended

operation at or near full rated load or for trailer towing

when an extra margin of tire service is desired. How-

ever, use of a larger tire or an 8-ply rating tire should

not be construed as permitting an increase in the full

rated vehicle load (see Specifications).

MAINTENANCE AND ADJUSTMENTS

TIRES

Inflation Pressures

To ensure the proper tire inflation pressure for the

owners particular requirements follow the recommenda-

tions in the Vehicle Capacity Rating and Recommended

Tire Inflation Pressures Table (seeSpecifications). Keep

tires properly inflated, and check inflation pressures

periodically. This will ensure the best tire life and riding

comfort, over the full range of driving conditions.

Inspection

Every few thousand miles and at each lubrication, tires

should be checked for sharp objects or stones in the

tread. H tire is punctured, it should be repaired using

one of several repair kits available through tire manu-

facturers1 outlets.

Wear

Misalignment

This is wear due to excessive toe-in or toe-out. In

CHEVROLET CHASSIS SERVICE MANUAL

Page 485 of 659

WHEELS AND TIRES 10-5

WHEELS

The wheel and tire assembly should be removed from

vehicles equipped with disc brakes to properly perform

balancing operations. This is necessary due to drag of

the spring loaded brake shoes on the disc.

Static Balancing (W/Tire)

Static Balance (still balance) is the equal distribution

of weight of the wheel and tire assembly about the axis

of rotation so that the assembly has no tendency to rotate

by

itself.

Static unbalance causes the pounding action of

the front wheels that is called "tramp".

To correct static unbalance (front and rear): The

quickest and best methods to correct static unbalance

are through the use of wheel balancers which are com-

mercially available. Refer to the Information and in-

structions included with these balaricers.

Dynamic Balancing (W/Tire)

Dynamic Balance (running balance) requires the wheel

to be not only in static balance, but balanced and running

smoothly while turning on an axis which runs through the

centerline of the wheel and tire perpendicular to the axis

of rotation.

The quickest and best methods of testing and correcting

dynamic unbalance are by the use of dynamic wheel

balancers which are commercially available. These bal-

ancers include all necessary information on where and

how the balancing weights should be placed. The follow-

ing information, however, will help in the correction of

dynamic balance.

NOTE:

Before attempting to balance the

wheels, check to be certain that no foreign

matter has been trapped in the wheel ventila-

tion slots or in the accessory wheel discs. This

is especially important if the vehicle has been

run in soft mud and then parked in freezing

weather.

When a wheel that is statically unbalanced is dynam-

ically in balance the dynamic balance can be retained

while correcting "the static balance by installing the cor-

rective weights so that half of the weight required is

placed on the inner edge of the rim and the other half

on the outer edge of the rim.

Dynamic unbalance can be corrected without destroying

static balance by installing weights so half of weight

required for dynamic balance is placed on the rim op-

posite the heavy point, while the other half is placed 180°

away and on the opposite side of the rim.

NOTE:

Vehicles with wire wheel covers should

have the wheels balanced with the wire wheel

covers installed on the wheels.

Run Out (W/OTire)

The wheels should not run out (wobble) more than

1/16" as measured on the side of the rim at the base

of the tire. Excessive run-out is the result of a bent

wheel, an improperly mounted wheel, worn knuckle bear-

ings or steering connections. These parts should be

checked for correct adjustment, proper alignment and

wear whenever excessive run-out is encountered.

The wheels should also run concentric with the steering

knuckle spindle within 1/16 inch as measured on the tire

bead seat of the rim with the tire removed.

Wheel run-out, eccentricity and balance are closely

associated with steering and front wheel alignment.

Further information on these subjects will be found under

"Suspension".

Cleaning Aluminum Wheels

Do not use wire brush or abrasive cleaners when

cleaning wheels. Use only cleaners that will not react

with aluminum.

SERVICE OPERATIONS

TIRES

Removal

Dismounting tubeless tires presents no problems if the

correct procedures are used and the following precau-

tions observed.

1.

Remove the valve cap and valve core. Let out all the

air.

2.

Press the inner side of the tire into the rim well.

Use bead loosening tool or if regular tire irons are

used, take particular care not to injure or tear the

sealing ribs on the bead.

CAUTION: Never use tire irons with sharp

edges or corners.

3.

Using tire irons on the opposite side, remove bead,

taking small "bites" around the rim.

4.

Turn the tire over, and use two tire irons, one be-

tween the rim flange and the bead to pry the rim

upward, the other iron to pry outward between the

bead seat and the bead.

Installation

Extreme care must be exercised to prevent injury to

the sealing bead and circumferential bead when forcing

tire over rim.

1.

Apply a light film of Ruglyde or other suitable rubber

lubricant to sealing bead of tire.

NOTE:

The use of excessive lubrication may

lead to rim slippage and subsequent breaking of

air seal.

2.

Carefully mount the outer bead in usual manner by

using tire irons, taking small "bites" around rim,

being careful not to injure the tire bead.

CAUTION: DO NOT use a hammer, as damage

to the bead will result.

3.

Install the inner bead in the same manner.

NOTE:

If a seal cannot be effected in the fore-

going manner with the rush of air it can be

, accomplished by applying to the circumference

of the tire a tire mounting band or heavy sash

cord and tightening with the use of a tire iron.

On tire mounting machines, bouncing the tire

assembly is not required. The tire should be

CHEVROLET CHASSIS SERVICE MANUAL

Page 486 of 659

WHEELS AND TIRES

10-6

lifted on the rim to force the top tire bead

against the top rim flange. The weight of the

tire will seat the bottom bead.

Repair

When a tire loses all or most of its air pressure,

particularly when driving at high legal speeds on today1 s

super-highways, recommended procedure is to remove it

from the wheel for complete inspection to be sure no

tire damage has occurred. Punctured tires should be

removed from the wheel and permanently repaired from

the inside.

Externally applied plug type repairs should be con-?

sidered temporary and the tire should be permanently

repaired as soon as possible.

Hot Patch Method

It is essential to thoroughly clean and remove all

foreign matter from the hole left by the puncturing-object

without enlarging the injury and then follow the manu-

facturer's instructions for vulcanizing the patch.

Rubber Plug Methods

There are several types of rubber plugs--some are

inserted from the inside of the tire; others are inserted

from the outside of the tire without demounting the tire

from the rim.

When using the plug method be sure to clean and

lubricate the hole with repair cement before inserting

the plug. Your tire supplier has available complete kits

containing materials, tools and detailed instructions for

making repairs with plugs. Follow instructions in the kit

you use.

Cold Patch Method

(Self Vulcanizing Type)

In this method it is essential to thoroughly clean and

remove all foreign matter from the hole left by the

puncturing object without enlarging the injury; also on

the inside of the tire, buff an area large enough for the

patch. Follow the manufacturer1 s instructions for appli-

cation of the special cement and self-vulcanizing cold

patch.

Pressure Gun Method

Several types of pressure guns are available. Consult

your tire supplier for materials and instructions.

Tire Installation Safety Precautions

When tires are mounted on dirty or corroded rims, or

when they are not properly centered on rims, the tire

bead may "bind" on the rim, and refuse to seat. Allowing

pressure to continue to build up within the assembly in

an attempt to seat the tire bead is a DANGEROUS PRAC-

TICE which can result in a broken tire bead, and serious

injury to the serviceman.

1.

Make sure that rim flanges and bead ledge (espe-

cially hump and radius) areas are smooth and clean.

Remove any oxidized rubber, dried soap solution,

rust, heavy paint, etc. with a wire brush, or, in ex-

treme cases, a file.

2.

Lubricate tire beads, rim flanges, and bead ledge

areas with a liberal amount of thin vegetable oil

soap solution, or approved rubber lubricant,

3.

Insure that air pressure build-up during the bead

seating process is not allowed to exceed 40 pounds

pressure. If beads have not seated by the time pres-

sure reaches 40 pounds, assembly should be deflated,

re-positioned on rim, re-lubricated and re-inflated.

4.

Make sure valve core is inserted in valve stem

prior to inflating.

5.

Use an extension gauge with clip on chuck so air

pressure build-up can be closely watched and so

that you can stand well back from the assembly

during the bead seating process.

WHEELS

Valve Assembly

Replace

NOTE: Always use new valve assembly when

replacing.

1.

Cut or drive old valve assembly out of rim.

2.

Clean valve hole and surrounding area on inside of

flange with steel wool.

Fig. 6 - Installing Valve

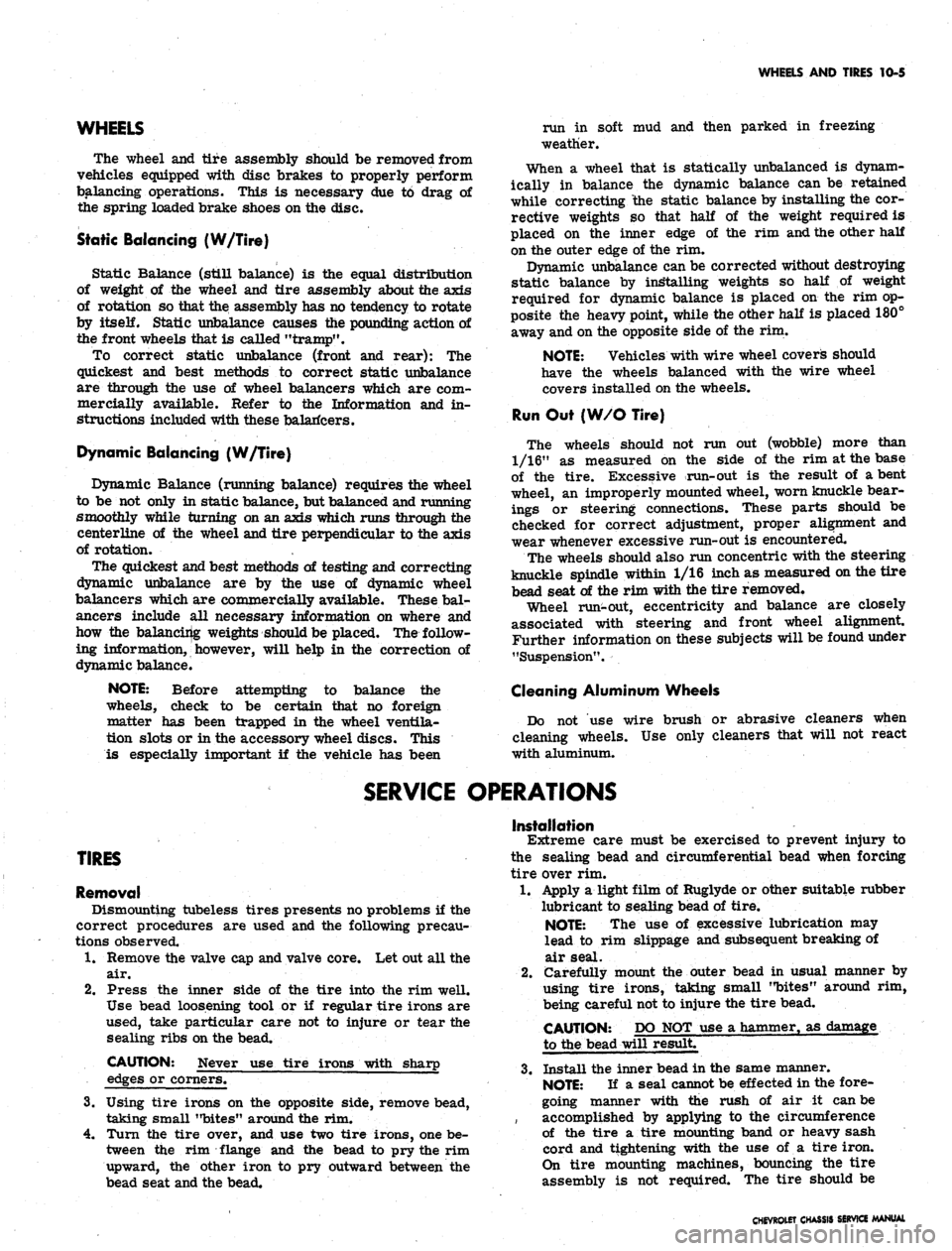

Fig. 7 - Rim Inspection

CHEVROLET CHASSIS SERVICE MANUAL

Page 564 of 659

ELECTRICAL-BODY AND CHASSIS 12-52

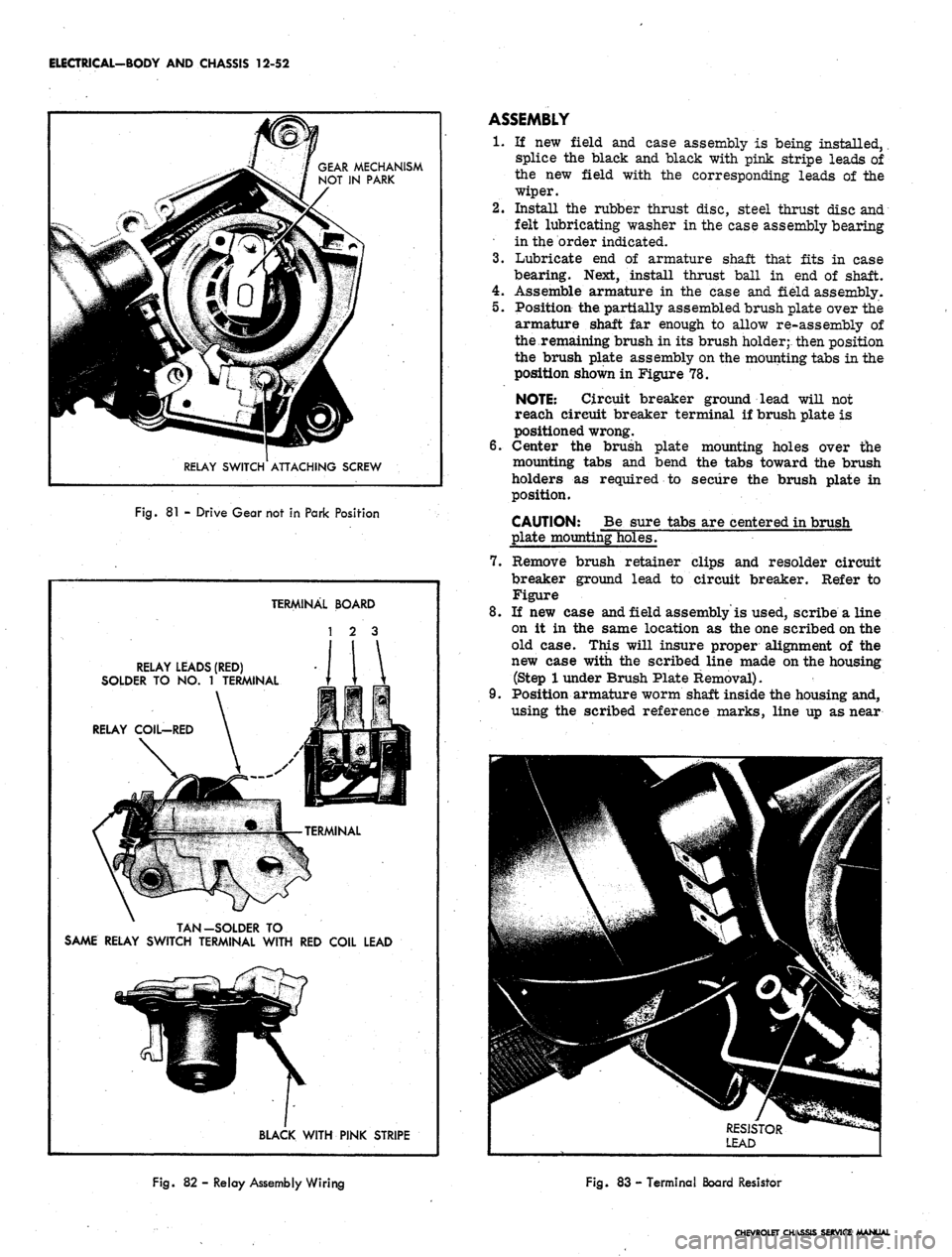

GEAR MECHANISM

NOT IN PARK

RELAY SWITCH ATTACHING SCREW

Fig.

81 -

Drive Gear not

in

Park Position

TERMINAL BOARD

1 2 3

RELAY LEADS (RED)

SOLDER TO NO. 1 TERMINAL

RELAY

COIL-RED

TAN-SOLDER TO

SAME RELAY SWITCH TERMINAL WITH RED COIL LEAD

BLACK WITH PINK STRIPE

ASSEMBLY

1.

If new field and case assembly is being installed,

splice the black and black with pink stripe leads of

the new field with the corresponding leads of the

wiper.

2.

Install the rubber thrust disc, steel thrust disc and

felt lubricating washer in the case assembly bearing

in the order indicated.

3.

Lubricate end of armature shaft that fits in case

bearing. Next, install thrust ball in end of shaft.

4.

Assemble armature in the case and field assembly.

5.

Position the partially assembled brush plate over the

armature shaft far enough to allow re-assembly of

the remaining brush in its brush holder;- then position

the brush plate assembly on the mounting tabs in the

position shown in Figure 78.

NOTE: Circuit breaker ground lead will not

reach circuit breaker terminal if brush plate is

positioned wrong.

6. Center the brush plate mounting holes over the

mounting tabs and bend the tabs toward the brush

holders as required to secure the brush plate in

position.

CAUTION: Be sure tabs are centered in brush

plate mounting holes.

7.

Remove brush retainer clips and resolder circuit

breaker ground lead to circuit breaker. Refer to

Figure

8. If new case and field assembly'is used, scribe a line

on it in the same location as the one scribed on the

old case. This will insure proper alignment of the

new case with the scribed line made on the housing

(Step

1

under Brush Plate Removal).

9. Position armature worm shaft inside the housing and,

using the scribed reference marks, line up as near

Fig.

82 - Relay Assembly Wiring

Fig.

83 -

Terminal Board Resistor

CHEVROLET CHASSIS SERVICE MANUAL

Page 567 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-55

COVER RELAY COIL

ASSEMBLY

PAWL SPRING

a=-

VALVE ASSEMBLY

RATCHET DOG AND _/_ f1

LATCHOUT SPRING ^—-»*

PAWL

RATCHET WHEEL

J

Fig.

SO

-

Exploded View

of

Pump

Relay Switch—Latch and Terminal Board Assembly

1.

Resolder leads

to

wiper terminal board as required

(fig. 82).

2.

Slide terminal board into wiper housing being careful

to position the terminal board resistor lead as shown

in Figure 83.

3.

Resolder leads

to

relay switch assembly

as

required

(fig. 82).

4.

Position relay-switch assembly

in

housing.

CAUTION:

Be

very careful

to

route leads

in

such

a

manner

as to

avoid having them pinched

between relay and wiper housing.

5. Install relay-switch mounting screw.

6. Assemble gear box cover and washer pump assembly

to wiper being careful that the ground strap

is

prop-

erly connected. Refer

to

Figure 75 for assembly

of

washer pump

to

gear housing.

B-Drive Gear Disassembly (Fig.

84)

1.

Remove washer pump assembly.

2.

Remove crank

arm

retaining nut, crank arm, rubber

seal

cap,

retaining ring, shim washers, shield

and

spacer washer in the order indicated.

3.

Slide gear assembly out

of

housing (fig. 85).

4.

Slide drive plate and shaft out

of

gear and remove the

drive pawl, lock pawl

and

coil spring

as

required.

Drive Gear—Assembly

1.

Position drive pawl

on

drive plate

as

shown

in

Fig.

ure 86.

2.

Assemble lock pawl over drive pawl

as

shown

in

Figure

86.

3.

Slide gear

and

tube over

the

drive shaft (fig. 87).

(Move drive and lock pawls

as

required to allow their

respective pins

to fit in the

gear guide channel,

fig.

88).

4.

Holding

the

gear, manually rotate

the

drive plate

until

the

drive

and

lock pawl guide pins snap into

their respective pockets in the gear (fig. 88).

5. Reinstall coil spring between lock

and

drive pawls

(fig. 88).

IMPORTANT: Be very careful

to

maintain lock

and drive pawl guide pins

in

their respective

pockets during Step

6.

6. Assemble inner spacer washer over gear shaft

and

assemble gear mechanism

in

housing

so

that

it is

positioned with respect to the housing in the approxi-

mate location shown

in

Figure 85.

7. Reassemble

the

outer spacer washer, shield, shim

washers

as

required

to

obtain .005"

max.

end play,

snap ring and rubber seal cap in the order indicated.

Refer to Figure 84.

8. Operate wiper

to

"park"

or

"off" position and install

crank arm.

9. Reassemble washer pump

to

wiper (fig. 75).

WASHER PUMP UNIT

The washer pump and/or valve assembly

may be re-

moved from the wiper assembly

as a

unit; therefore,

it is

not necessary

to

remove

the

wiper assembly irom

the

vehicle

if

only

the

washer pump and/or valve assembly

required service.

When

the

pump

is

removed from

the

wiper assembly,

all working parts

are

readily accessible and may easily

be serviced

as

necessary

(fig. 89).

An exploded view

of

the washer pump

is

shown in Figure 90.

Removal and Installation

1.

Raise vehicle hood.

2.

Disconnect washer hoses

and

electrical connections

from assembly.

3.

Remove

3

screws securing washer pump

and

cover

to wiper assembly. Remove pump from wiper gear

box.

4.

Position pump

and

cover assembly

to

the wiper and

install retaining screws.

5. Connect washer hoses

to

valve assembly and wiring

leads

to

pump and wiper terminals.

6. Check operation

of

unit.

CHEVROLET CHASSIS SERVICE MANUAL

Page 611 of 659

ACCESSORIES 15-2

GENERAL DESCRIPTION

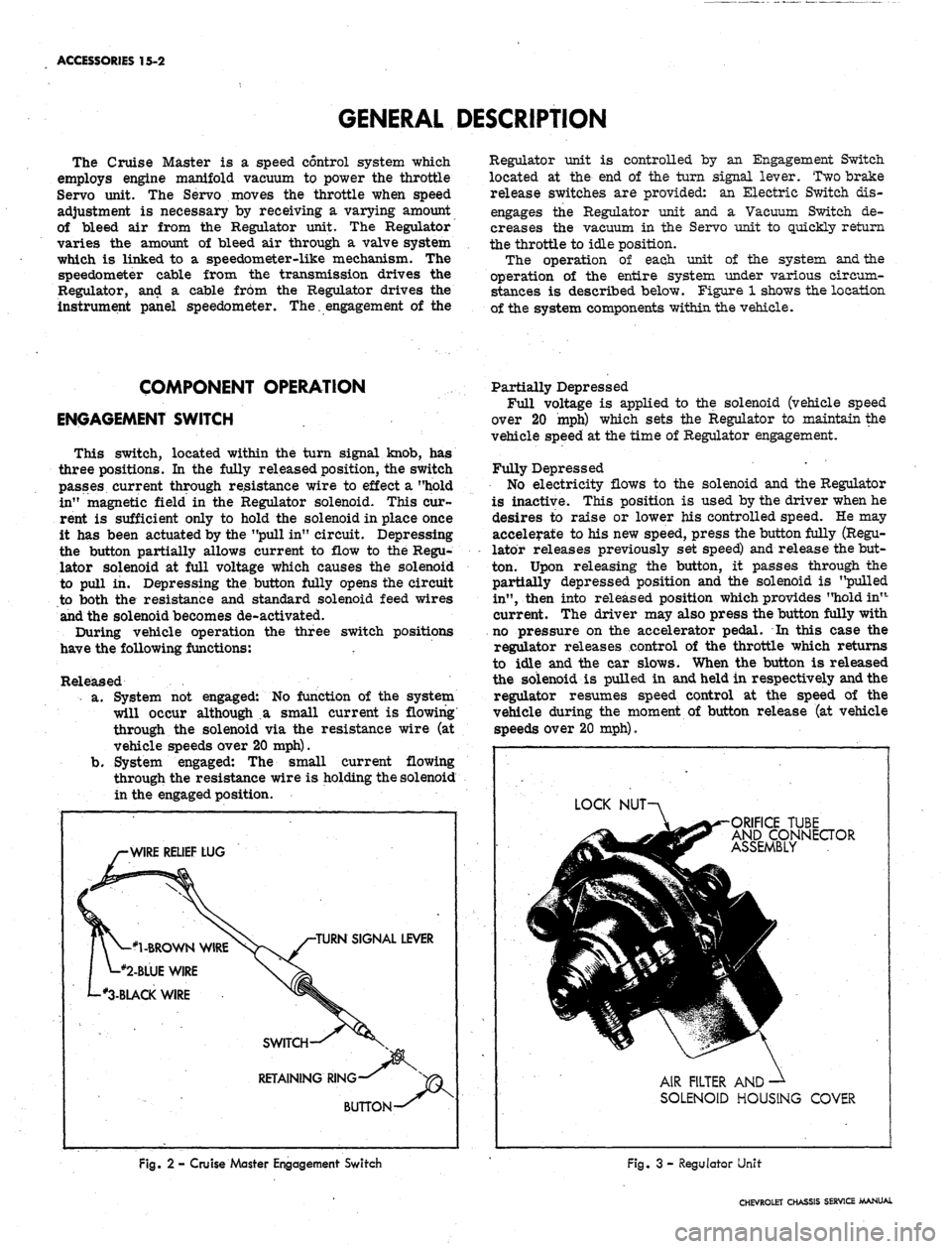

The Cruise Master is a speed control system which

employs engine manifold vacuum to power the throttle

Servo unit. The Servo moves the throttle when speed

adjustment is necessary by receiving a varying amount

of bleed air from the Regulator unit. The Regulator

varies the amount of bleed air through a valve system

which is linked to a speedometer-like mechanism. The

speedometer cable from the transmission drives the

Regulator, and a cable from the Regulator drives the

instrument panel speedometer. The. engagement of the

Regulator unit is controlled by an Engagement Switch

located at the end of the turn signal lever. Two brake

release switches are provided: an Electric Switch dis-

engages the Regulator unit and a Vacuum Switch de-

creases the vacuum in the Servo unit to quickly return

the throttle to idle position.

The operation of each unit of the system and the

operation of the entire system under various circum-

stances is described below. Figure 1 shows the location

of the system components within the vehicle-

COMPONENT OPERATION

ENGAGEMENT SWITCH

This switch, located within the turn signal knob, has

three positions. In the fully released position, the switch

passes current through resistance wire to effect a "hold

in" magnetic field in the Regulator solenoid. This cur-

rent is sufficient only to hold the solenoid in place once

it has been actuated by the "pull in" circuit. Depressing

the button partially allows current to flow to the Regu-

lator solenoid at full voltage which causes the solenoid

to pull in. Depressing the button fully opens the circuit

to both the resistance and standard solenoid feed wires

and the solenoid becomes de-activated.

During vehicle operation the three switch positions

have the following functions:

Released

a. System not engaged: No function of the system

will occur although a small current is flowing

through the solenoid via the resistance wire (at

vehicle speeds over 20 mph).

b.

System engaged: The small current flowing

through the resistance wire is holding the solenoid

in the engaged position.

^r-WIRE RELIEF LUG

1 ^-#2-BLUE WIRE

L'3.BLACK WIRE

X /-TURN SIGNAL LEVER

SWITCH—^

^SN

RETAINING RING-^ %^

BUTTON -^

Fig.

2 - Cruise Master Engagement Switch

Partially Depressed

Full voltage is applied to the solenoid (vehicle speed

over 20 mph) which sets the Regulator to maintain the

vehicle speed at the time of Regulator engagement.

Fully Depressed

No electricity flows to the solenoid and the Regulator

is inactive. This position is used by the driver when he

desires to raise or lower his controlled speed. He may

accelerate to his new speed, press the button fully (Regu-

lator releases previously set speed) and release the but-

ton. Upon releasing the button, it passes through the

partially depressed position and the solenoid is "pulled

in", then into released position which provides "hold in"-

current. The driver may also press the button fully with

no pressure on the accelerator pedal. In this case the

regulator releases control of the throttle which returns

to idle and the car slows. When the button is released

the solenoid is pulled in and held in respectively and the

regulator resumes speed control at the speed of the

vehicle during the moment of button release (at vehicle

speeds over 20 mph).

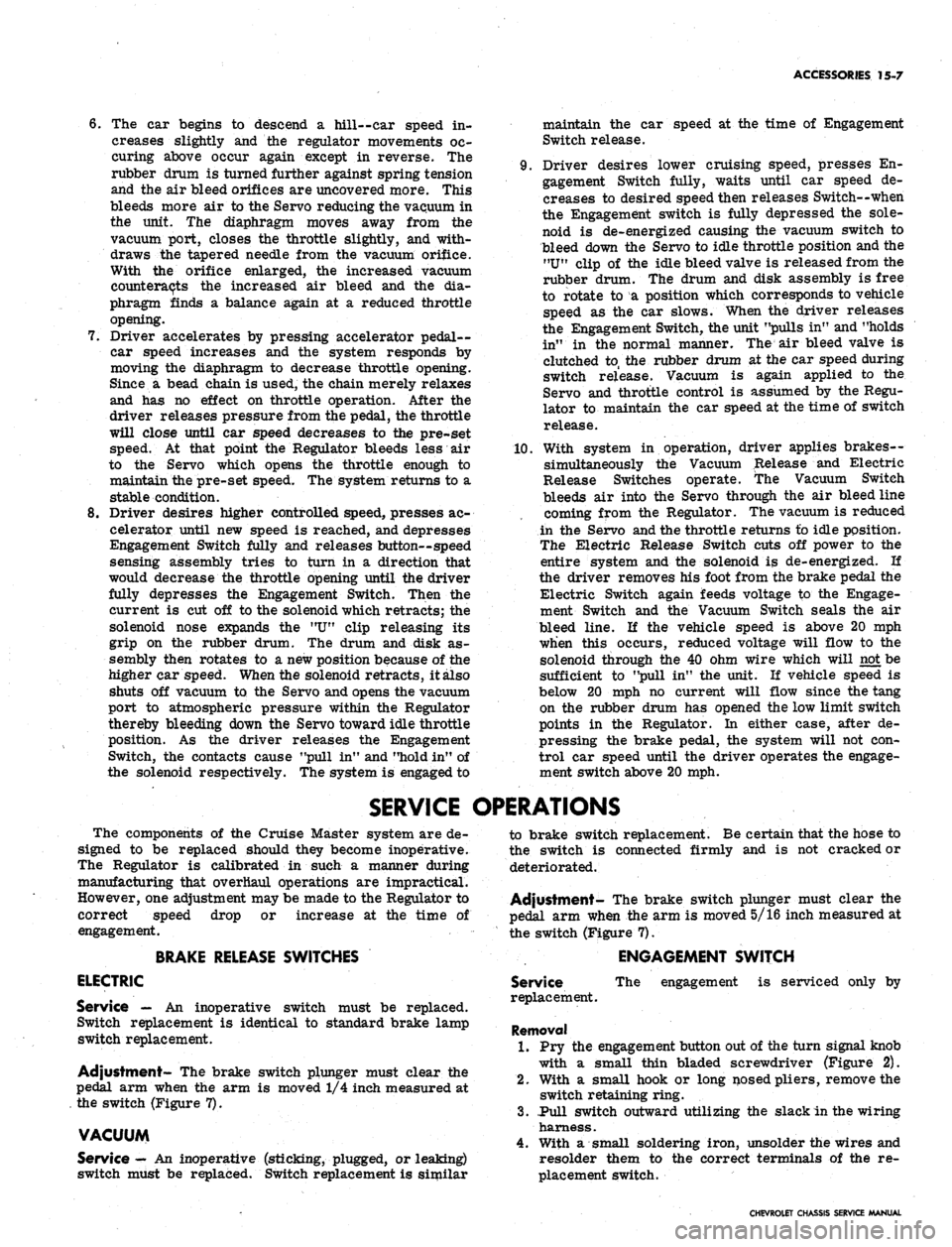

LOCK

NUT

ORIFICE

TUBE

AND

CONNECTOR

ASSEMBLY

AIR FILTER AND

SOLENOID HOUSING COVER

Fig. 3 - Regulator Unit

CHEVROLET CHASSIS SERVICE MANUAL

Page 616 of 659

ACCESSORIES 15-7

6. The car begins to descend a hill--car speed in-

creases slightly and the regulator movements oc-

curing above occur again except in reverse. The

rubber drum is turned further against spring tension

and the air bleed orifices are uncovered more. This

bleeds more air to the Servo reducing the vacuum in

the unit. The diaphragm moves away from the

vacuum port, closes the throttle slightly, and with-

draws the tapered needle from the vacuum orifice.

With the orifice enlarged, the increased vacuum

counteracts the increased air bleed and the dia-

phragm finds a balance again at a reduced throttle

opening.

7.

Driver accelerates by pressing accelerator pedal-

car speed increases and the system responds by

moving the diaphragm to decrease throttle opening.

Since a bead chain is used, the chain merely relaxes

and has no effect on throttle operation. After the

driver releases pressure from the pedal, the throttle

will close until car speed decreases to the pre-set

speed. At that point the Regulator bleeds less air

to the Servo which opens the throttle enough to

maintain the pre-set speed. The system returns to a

stable condition.

8. Driver desires higher controlled speed, presses ac-

celerator until new speed is reached, and depresses

Engagement Switch fully and releases button--speed

sensing assembly tries to turn in a direction that

would decrease the throttle opening until the driver

fully depresses the Engagement Switch. Then the

current is cut off to the solenoid which retracts; the

solenoid nose expands the "U" clip releasing its

grip on the rubber drum. The drum and disk as-

sembly then rotates to a new position because of the

higher car speed. When the solenoid retracts, it also

shuts off vacuum to the Servo and opens the vacuum

port to atmospheric pressure within the Regulator

thereby bleeding down the Servo toward idle throttle

position. As the driver releases the Engagement

Switch, the contacts cause "pull in" and "hold in" of

the solenoid respectively. The system is engaged to

maintain the car speed at the time of Engagement

Switch release.

9. Driver desires lower cruising speed, presses En-

gagement Switch fully, waits until car speed de-

creases to desired speed then releases Switch--when

the Engagement switch is fully depressed the sole-

noid is de-energized causing the vacuum switch to

bleed down the Servo to idle throttle position and the

"U"

clip of the idle bleed valve is released from the

rubber drum. The drum and disk assembly is free

to rotate to a position which corresponds to vehicle

speed as the car slows. When the driver releases

the Engagement Switch, the unit "pulls in" and "holds

in" in the normal manner. The air bleed valve is

clutched to, the rubber drum at the car speed during

switch release. Vacuum is again applied to the

Servo and throttle control is assumed by the Regu-

lator to maintain the car speed at the time of switch

release.

10.

With system in operation, driver applies brakes--

simultaneously the Vacuum Release and Electric

Release Switches operate. The Vacuum Switch

bleeds air into the Servo through the air bleed line

coming from the Regulator. The vacuum is reduced

in the Servo and the throttle returns to idle position.

The Electric Release Switch cuts off power to the

entire system and the solenoid is de-energized. If

the driver removes his foot from the brake pedal the

Electric Switch again feeds voltage to the Engage-

ment Switch and the Vacuum Switch seals the air

bleed line. If the vehicle speed is above 20 mph

when this occurs, reduced voltage will flow to the

solenoid through the 40 ohm wire which will not be

sufficient to "pull in" the unit. If vehicle speed is

below 20 mph no current will flow since the tang

on the rubber drum has opened the low limit switch

points in the Regulator. In either case, after de-

pressing the brake pedal, the system will not con-

trol car speed until the driver operates the engage-

ment switch above 20 mph.

SERVICE OPERATIONS

The components of the Cruise Master system are de-

signed to be replaced should they become inoperative.

The Regulator is calibrated in such a manner during

manufacturing that overhaul operations are impractical.

However, one adjustment may be made to the Regulator to

correct speed drop or increase at the time of

engagement.

BRAKE RELEASE SWITCHES

ELECTRIC

Service — An inoperative switch must be replaced.

Switch replacement is identical to standard brake lamp

switch replacement.

Adjustment- The brake switch plunger must clear the

pedal arm when the arm is moved 1/4 inch measured at

the switch (Figure 7).

VACUUM

Service

—

An inoperative (sticking, plugged, or leaking)

switch must be replaced. Switch replacement is similar

to brake switch replacement. Be certain that the hose to

the switch is connected firmly and is not cracked or

deteriorated.

Adjustment- The brake switch plunger must clear the

pedal arm when the arm is moved 5/16 inch measured at

the switch (Figure 7).

ENGAGEMENT SWITCH

Service

replacement.

The engagement is serviced only by

Removal

1.

Pry the engagement button out of the turn signal knob

with a small thin bladed screwdriver (Figure 2).

2.

With a small hook or long nosed pliers, remove the

switch retaining ring.

3.

.Pull switch outward utilizing the slack in the wiring

harness.

4.

With a small soldering iron, unsolder the wires and

resolder them to the correct terminals of the re-

placement switch.

CHEVROLET CHASSIS SERVICE MANUAL