check engine CHEVROLET CAMARO 1971 2.G User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1971, Model line: CAMARO, Model: CHEVROLET CAMARO 1971 2.GPages: 88, PDF Size: 34.8 MB

Page 38 of 88

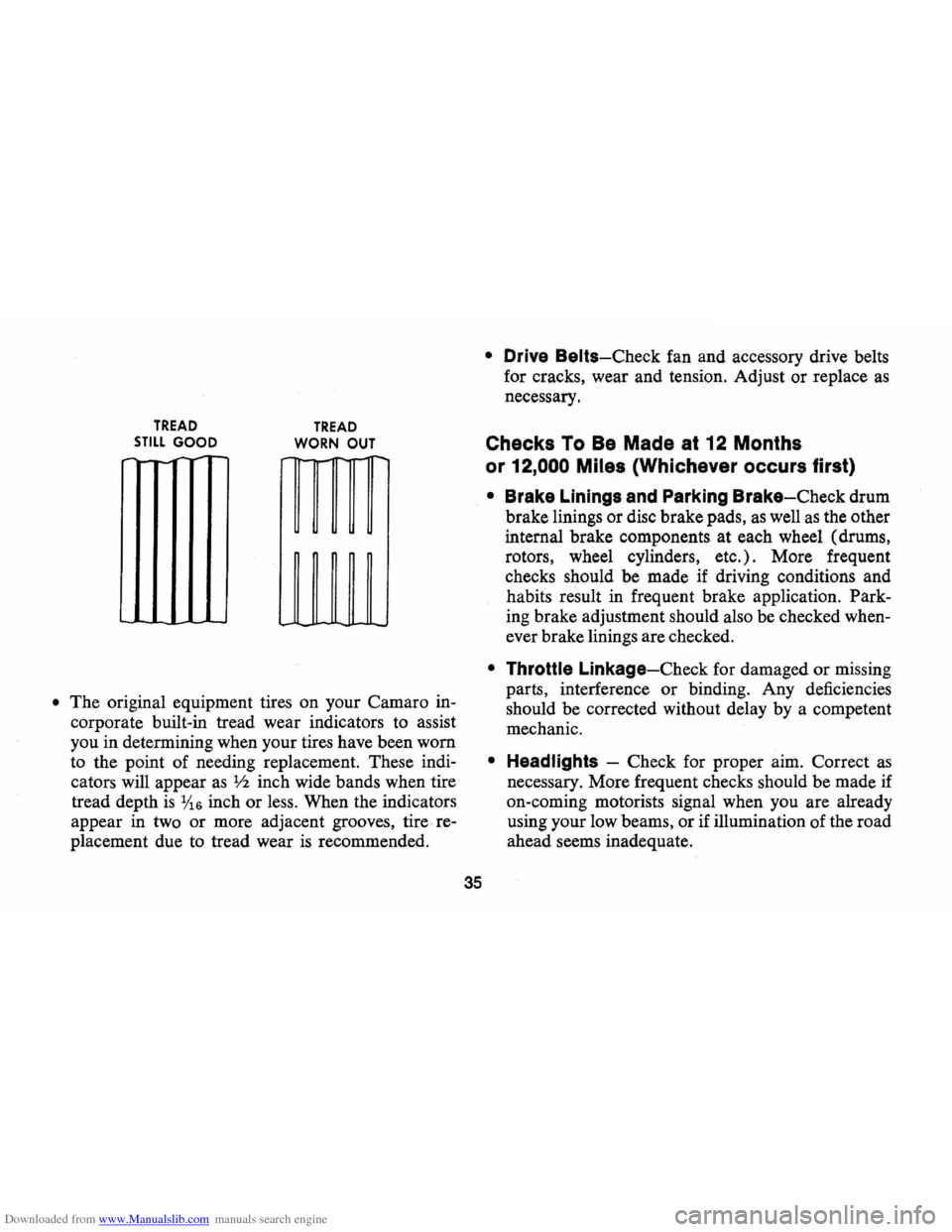

Downloaded from www.Manualslib.com manuals search engine TREAD STILL GOOD

-

TREAD

WORN OUT

• The original equipment tires on your Camaro in

corporate built-in tread wear indicators to assist

you in detennining when your tires have been worn

to the point of needing replacement. These indi

cators will appear

as V2 inch wide bands when tire

tread depth

is 1;16 inch or less. When the indicators

appear in two or more adjacent grooves, tire re

placement due to tread wear

is recommended.

35

• Drive Belts-Check fan and accessory drive belts

for cracks, wear and tension. Adjust or replace

as

necessary.

Checks To Be Made at 12 Months

or

12,000 Miles (Whichever occurs first)

• Brake Linings and Parking Brake-Check drum

brake linings or disc brake pads,

as well as the other

internal brake components at each wheel (drums,

rotors, wheel cylinders, etc.) . More frequent

checks should be made if driving conditions and

habits result in frequent brake application. Park

ing brake adjustment should also be checked when

ever brake linings are checked.

• Throttle Linkage-Check for damaged or missing

parts, interference or binding. Any deficiencies

should be corrected without delay by a competent

mechanic.

• Headlights -Check for proper aim. Correct as

necessary. More frequent checks should be made if

on-coming motorists signal when you are already

using your low beams, or if illumination of the road

ahead seems inadequate.

Page 39 of 88

Downloaded from www.Manualslib.com manuals search engine For further details on the engine and transmission

items listed on the

"Vehicle Safety Maintenance

Schedule," and for other recommended maintenance,

refer

to the "Service and Maintenance" and "Air

Pollution. Control" Sections of this manual.

CHECKS lOBE PERFORMED

BY OWNER

Listed below are the safety checks that should be

made by the owner . These checks should be made at

least every 4 months or

6,000 miles, whichever occurs

first , or more often when so indicated . Any

deficien

cies should be brought to the attention of your dealer

or service station, so the advice of a qualified mech

anic is available regarding the need for repairs or

replacements.

• Anti-Theft Lock-Check for proper operation by

attempting to turn key to

LOCK position in the

various transmission gears with

car stationary. Key

should

tum to LOCK position only when trans

mission control is in PARK on automatic trans

mission models or in REVERSE on manual trans

mission models.

• Seat Belts-Check lap and shoulder belts as well

as buckles, retractors and anchors for loose con-

36

nections, damage and positive latching action.

• Windshield Wipers and Washers-Check con

dition and alignment of wiper blades. Check

amount and direction of fluid sprayed by washers

during use.

• Defrosters-Check performance by turning con

trols to "de-ice" and "Hi" fan speed and noting

amount of air directed against the windshield.

• Wheel Alignment and Balance-In addition to

abnormal tire wear the need for wheel alignment

service may be indicated by a pull to the right or

left when driving on a straight level road. The need

for wheel balancing may be indicated by a

vibra

tion at the steering wheel while driving.

• Parking Brake and "Park" Mechanism-Check

parking brake holding ability by parking on a fairly

steep hill and restraining the vehicle with the

parking brake only.

On cars with automatic trans

missions, check the holding ability of the "Park"

mechanism by releasing all brakes after the trans

mission selector lever has been placed in the "P"

position.

• Lights -Check license plate lights, side marker

lights , headlamps, parking lamps, tail lamps , brake

Page 40 of 88

Downloaded from www.Manualslib.com manuals search engine lights, turn signals, backup lamps, and hazard

warning flashers. Have someone observe operation

of each light while you activate the controls.

• Starter Safety Switch (Automatic Transmis

sion Cars)

CAUTION: Before making the following check, be sure to have a clear distance ahead and behind the car, set the parking brake and firmly apply the foot brake. Do not depress accelerator pedal. Be prepared to turn ott ignition switch immediately if engine should start.

Check starter safety switch by placing the transmis

sion in each of the driving gears while attempting to

start the engine. The starter should operate only in the

Park ("P") or Neutral ("N") positions.

• Starter Interlock (Manual Transmission Cars)

-To check a manual transmission equipped car,

depress the clutch halfway, place the transmission

in neutral, and attempt to start.

The starter should

operate only when clutch

is fully depressed.

• Transmission Shift Indicator-Check to be sure

shift indicator accurately indicates the shift posi

tion selected.

• Horn-Blow the horn occasionally to be sure that

it works.

37

• Seat Back LatcheS-Check to see that seat bac k

latches are holding by pulling forward on the seat

back top.

• Rearview Mirrors and Sun Visors-Check that

friction joints are properly adjusted so mirrors and

sun visors stay in the selected position.

• Door LatcheS-Check for positive closing, la tch

ing and locking.

• Hood Latches-Check to make sure hood closes

firmly . Check also for broken , d amaged or missing

parts which might prevent secure latching.

• Fluid LeakS-Check for fuel, water, oil or other

fluid leaks by observing the ground beneath the

vehicle after it has been parked for a while . (Water

dripping from air conditioning system after use

is

normal). If gasoline fumes are noticed at any time,

the cause should be determined

and corrected with

out delay because of the possibility of fire.

• Exhaust System-See engine exhaust gas caution

at beginning of starting and operating section of

this manual for suggested driver observations and

checks.

Page 42 of 88

Downloaded from www.Manualslib.com manuals search engine • To. start the car when the Ener

gizer (battery)

is discharged,

use a single auxiliary battery

Qr

Energizer Qf the same vQltage as

the discharged battery, with suit

able jumper cables.

• Make cQnnectiQns detailed as

fQllQws:

Jump Starting with

Auxiliary (Booster) Battery

If booster battery is part Qf an

Qther vehicle's electrical system,

bQQster shQuld be treated carefully

when using jumper cables.

FQllQW

exactly the prQcedure Qutlined be

IQw, being careful nQt to. cause

sparks:

1. Set parking brake and place

autQmatic transmissiQn in

"PARK" ("NEUTRAL" fQr

manual transmissiQn).

2. Attach

Qne end of Qne jumper

cable

to. the PQsitive terminal Qf

the booster battery (identified by

"+" or "P" Qn the battery case,

PQst Qr clamp) and the Qther end

Qf same cable to. PQsitive ter

minal

Qf discharged battery.

3. Attach ene end ef the remain

ing cable

to. negative terminal

("-" er "N") ef booster battery,

and finally to. negative terminal

ef discharged battery -taking

i;cAufICsN}R.4btAl0W,CAP '!":;',';"S"!<"" .

···.···.T~·p,.v~ttt.,0 •• ot~~()l.nf.·#rii·j~6Itl t"~

'd.nger of being '. bu'n.d,~oo/.ntl.v.' .houldb.'ch.cked,.ndcoo/.nt .dd.4. only wh.n the .nglne/. cool.

'.Donot r.IJJov.radl.tbic.p whlj."'gln~ .ndradl.to,are.tlll hot, b.c.u ••. the

. cooling sVst.", will blow 'out .c.,dlng , fluid .nd st"m und.r pr.ssur ••

,

tol.mov. b"pWh.riengln./s

39

care that jumper clamps do. nQt

CQntact each ether,

Reverse this sequence exactly

when remeving the jumper cables.

CAUTION: Any proc~ur.~th.rt".n the'

.bove could r •• ult In person.' In/ury c.us.d by electrolyte .qulrtlng out .th. b.tt.ryvent., d.m.g. or In/ury due to b.tt.ry .xplo./on .ndlor d.m.g. to the charging sy.t.m of the boost., v.hlc/,'; or Immoblllz.d . v.hlcl.'. chargIng 'Y'tem. Do not .ttempt to lump .tart a c.r havIng • frozen battery b.cau •• the bit

t.ry mlY .xplod.. It • froz.n b.ttery I. su.pect.d, op.n .nd .x.mln •• 11 fill v.nt. , on the b.ttery. If Ie. c.n b •.. en, or the .,.ctrolyt. fluid c.nnotb •••• n, do not

att.mpt to .tart with /um".r c.bl ...

.'. $Iow~y ,otat • . c.p . count.rC/ockwl'~ .iQ ; d.terit(DO NOT PRESS DOWN WHILE

ROTATING).

•. Walt unt/f.ny ,e.ldu.' pressure I.re' lI.v.d-•• Indlc.t.d by • hissIng .ound.

• p,.ss down on c.p whll. continuing to rot.te counterclockwise.

Radl.tor pre.,ure cap. should b. check.d by • quallfl.d m.chanlc p.rlodlcally for proper op.ratlon and replaced .s r .. qulr.d with the .pplicabl.AC typ •.

Page 43 of 88

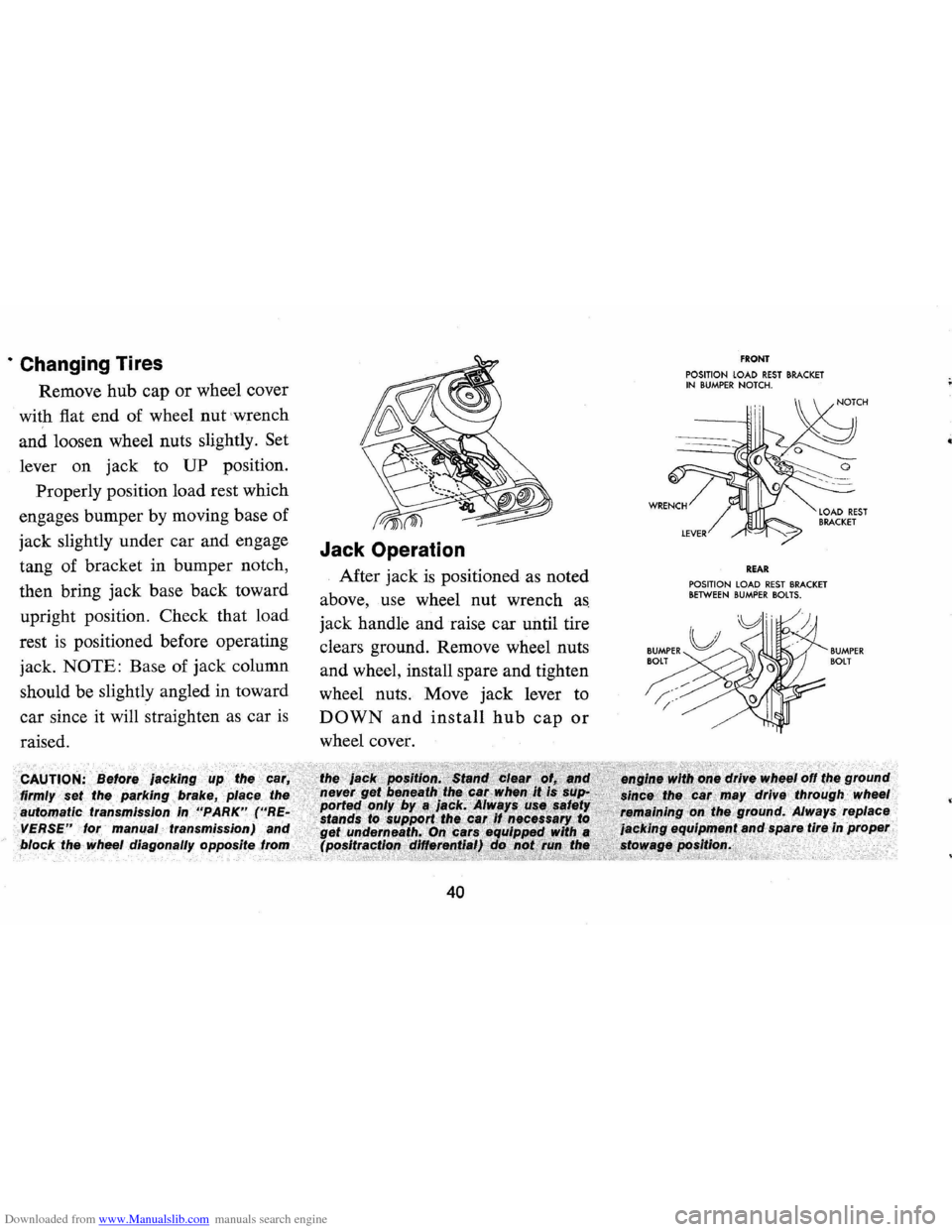

Downloaded from www.Manualslib.com manuals search engine · Changing Tires

Remove hub cap or wheel cover

with fiat end of wheel

nut wrench

and loosen wheel nuts slightly.

Set

lever on jack to UP position.

Properly position load rest which

engages bumper by moving base of

jack slightly under car and engage

tang of bracket in bumper notch,

then bring jack base back toward

upright position. Check that load

rest is positioned before operating

jack.

NOTE: Base of jack column

should be slightly angled in toward

car since it will straighten as car

is

raised.

firmly

automatic rralrlSOIlSSlon

VERSE" lor manual transmission)

Jack Operation

After jack is positioned as noted

above, use wheel nut wrench

as

jack handle and raise car until tire

clears ground. Remove wheel nuts

and wheel, install spare and tighten

wheel nuts. Move jack lever to

DOWN and install hub cap or

wheel cover.

block the wheel diagonally opposite .. _.... .,.. __

40

FRONT POSITION LOAD REST BRACKET IN BUMPER NOTCH.

REAR POSITION LOAD REST BRACKET BETWEEN BUMPER BOLTS.

BUMPER BOlT

Page 47 of 88

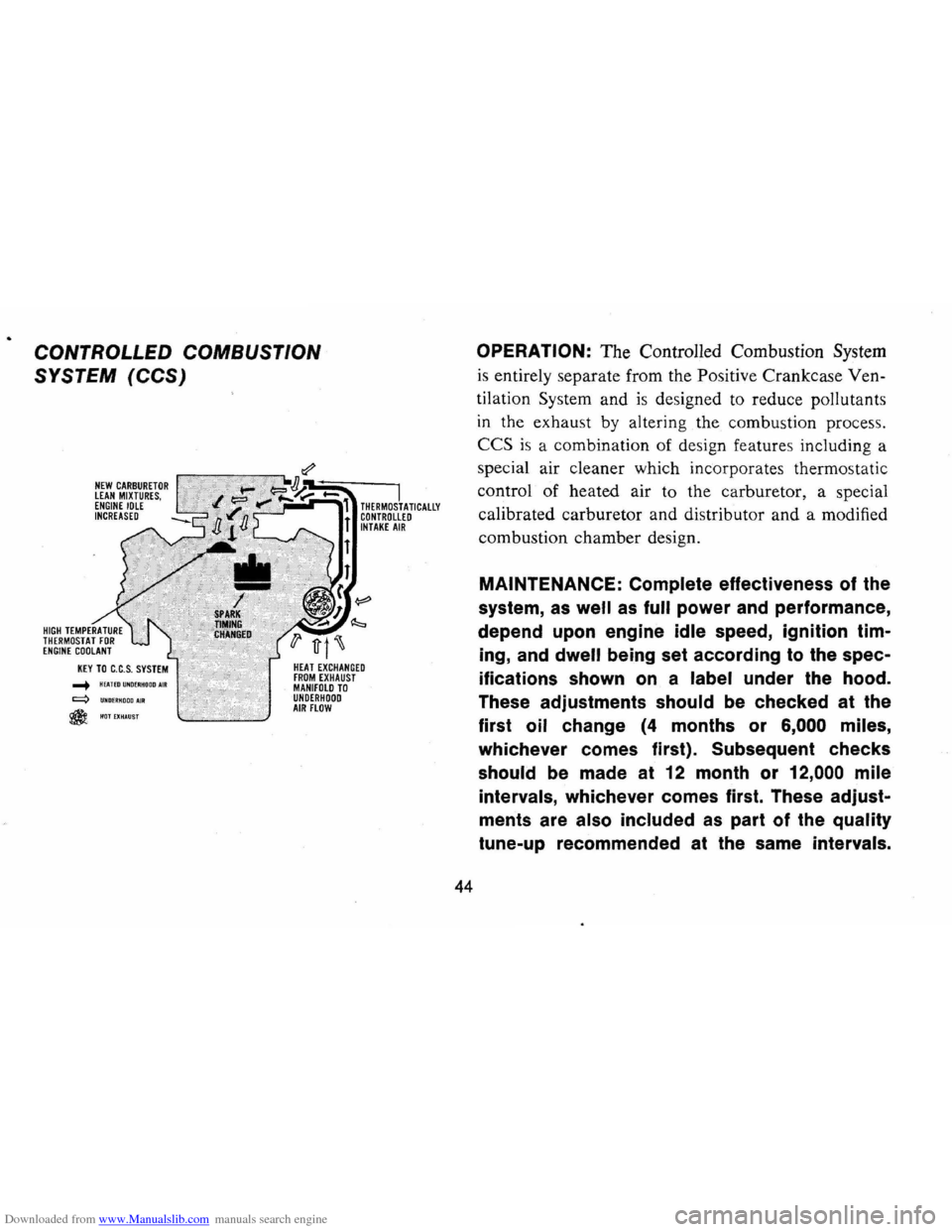

Downloaded from www.Manualslib.com manuals search engine CONTROLLED COMBUSTION

SYSTEM

(CCS)

NEW CARBURETOR LEAN MIXTURES, ENGINE IDLE INCREASED

..... HEAlEDUNDEIiHODDAIR q UND£RHOODAJR

@HOTEXHAUST

I THERMOSTATICALLY CONTROLLED INTAKE AIR

HEAT EXCHANGED FROM EXHAUST MANIFOLD TO UNDERHOOD AIR FLOW

44

OPERATION: The Controlled Combustion System

is entirely separate from the Positive Crankcase Ven

tilation

Sys tem and is designed to reduce pollutants

in the exhau st by altering the combustion process,

CCS is a combination of design features including a

special air cleaner which incorporates thermostatic

control of heated air to the carburetor, a special

calibrated carburetor and distributor and a modified

combustion chamber design,

MAINTENANCE: Complete effectiveness of the

system,

as well as full power and performance,

depend

upon engine idle speed, ignition tim

ing,

and dwell being set according to the spec

ifications

shown on a label under the hood.

These adjustments should be checked at the

first oil change

(4 months or 6,000 miles,

whichever comes first). Subsequent checks

should be made at

12 month or 12,000 mile

intervals, whichever comes first. These adjust

ments are also included

as part of the quality

tune-up recommended at

the same intervals.

Page 48 of 88

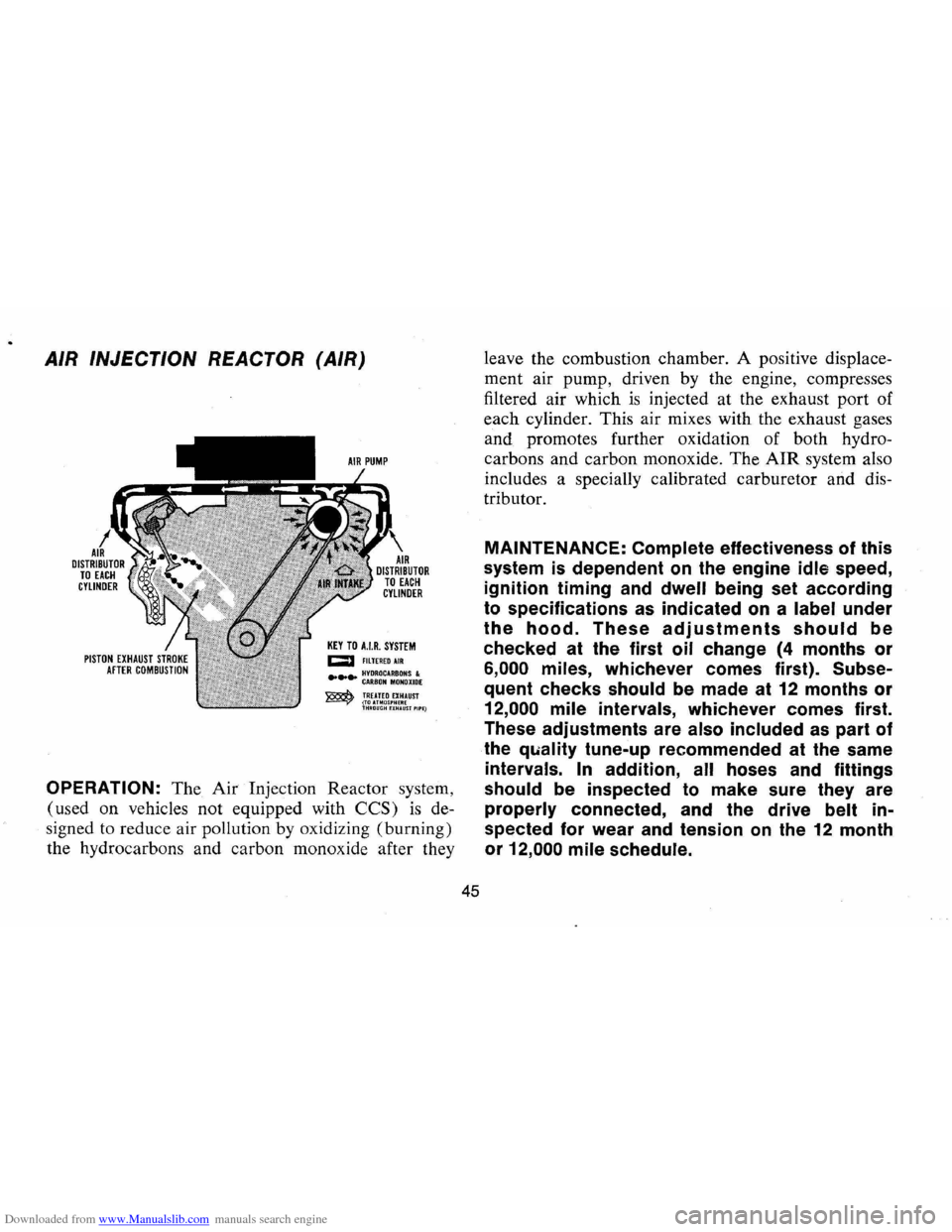

Downloaded from www.Manualslib.com manuals search engine AIR INJECTION REACTOR (AIR)

KEY TO HR. SYSTEM CJ F1LTEREDAIR

.... ~!~:~~A:~~~~I:E ~ TREATED EXHAUST ~(TOUMOS'HERE THMOUGHHHAlIST'II'E)

OPERATION: The Air Injection Reactor system,

(used on vehicles not equipped with

CCS) is de

signed to reduce air pollution by oxidizing (burning)

the hydrocarbons and carbon monoxide after they

45

leave the combustion chamber. A positive displace

ment air pump, driven by the engine, compresses

filtered air which

is injected at the exhaust port of

each cylinder. This air mixes with the exhaust gases

and promotes further oxidation of both hydro

carbons and carbon monoxide. The

AIR system also

includes a specially calibrated carburetor and dis

tributor.

MAINTENANCE: Complete effectiveness of this

system

is dependent on the engine idle speed,

ignition timing and

dwell being set according

to specifications as indicated on a label under

the hood. These adjustments should be

checked at the first oil change (4 months or

6,000 miles, whichever comes first). Subse

quent checks should be made at 12 months or

12,000 mile intervals, whichever comes first.

These adjustments are

also included as part of

the

quality tune-up recommended at the same

intervals. In addition, all hoses and fittings

should be inspected to make sure they are

properly connected, and the drive belt in

spected for wear

and tension on the 12 month

or

12,000 mile schedule.

Page 55 of 88

Downloaded from www.Manualslib.com manuals search engine NOTE: If this cap requires a re

placement, only· a cap with these

same features should be used. Fail

ure to use the correct cap can re

sult in a serious malfunction of the

system. Correct replacement caps

may

be obtained from your Au

thorized Chevrolet Dealer.

Engine Oil

Recommendations

Use only engine oil which meets

oil quality standard GM 6041-M.

High quality oils which are in

tended for service

MS and pass car

makers' tests are

of this quality.

The oil change interval (see para

graph entitled

"Engine Oil Change

Interval") and the new vehicle

warranty are based on the use of

oils that meet these requirements.

NOTE: Non-detergent and other

low quality oils are specifically not

recommended. The use of proper

engine oils and oil change intervals are

your best assurance of contin

ued reliability and performance

from your Camaro engine.

Checking Oil Level

The engine oil should be main

tained at proper level. The best

time to check it

is before operating

the engine or as

the last step in a

fuel stop. This will allow the oil ac

cumulation in the engine to drain

back in the crankcase .

To check

the evel, remove the oil gauge rod

(dip stick), wipe it clean and rein

sert it firmly for an accurate read

ing. The oil gauge rod

is marked

"FULL" and "ADD." The oil level

should be maintained in the safety

margin, neither going above the

"FULL" line nor below the "ADD"

line. Reseat the gauge firmly after

taking the reading.

NOTE: The oil gauge rod is also

marked

"Use GM 6041-M Quality

MS Oil" as a reminder to use only

52

high quality oils as prescribed

under "Engine Oil Recommenda

tions."

Supplemental Engine Oil

Additives

The regular use of supplemental

additives

is specifically not recom

mended and will increase operat

ing costs. However, in cases of spe

cific problems which may arise

under certain conditions, additive

supplements are available that can

effectively and economically solve

these problems without causing

other difficulties.

For example, if

higher detergency

is required to re

duce varnish and sludge deposits

resulting from some unusual opera

tional difficulty, a thoroughly tested

and approved concentrate -

"En

gine Oil Supplement"-is available

at your Chevrolet dealer.

It is sug

gested that, in the event of

an oper

ational problem, you consult your

dealer for advice.

Page 56 of 88

Downloaded from www.Manualslib.com manuals search engine Engine Oil Change Interval

Change oil each 4 months. If

more than 6,000 miles are driven

in a 4-month period, change oil

each

6,000 miles.

In certain types of service in

cluding:

• operation under dusty condi

tions,

• trailer pulling,

• extensive idling, or

• short trip operation at freezing

temperatures (engine not

thor

oughly warmed up),

the oil change interval should not

exceed 2 months, or

3,000 miles,

whichever occurs

first. Operation

in dust storms may require an im

mediate change of oil. See your

Chevrolet dealer for advice on the

frequency of oil and filter changes under

unusual driving conditions.

The above recommendations

apply to the first change

as well as

subsequent oil changes. The oil

change interval for your Camaro

engine

is based on the use of oils

that

meet. the requirements indi

cated in the section on "Engine Oil

Recommendations." Oil change in

tervals longer than those listed

above will result in serious

reduc

tion in engine life and may affect

Chevrolet's obligation under the

provisions of the

New Vehicle War

ranty.

A high quality

MS oil meeting

General Motors Standard GM

6041-M was installed in your en

gine at the factory. It is not neces

sary to change this factory-installed

oil prior to the recommended

nor

mal change period. However, the

oil level should

be checked more

frequently during the break-in pe

riod since somewhat higher oil con-

53

sumption is normal until the piston

rings become seated.

Manifold Heat

Control Valve

Every 6,000 miles or 4 months,

check heat control valve for free

dom of operation.

If shaft is stick

ing free it up with GM Manifold

Heat Control Solvent or its equiva

lent.

Engine

Oil Filter

Replacement

The engine oil filter should be

replaced at the first oil change and

every second oil change thereafter.

This recommendation

is based on

the use of engine oils that meet the

requirements indicated in the

sec

tion on "Engine Oil Recommenda

tions," and the use of a quality oil

filter. AC

Oil Filters provide maxi

mum engine protection.

Page 57 of 88

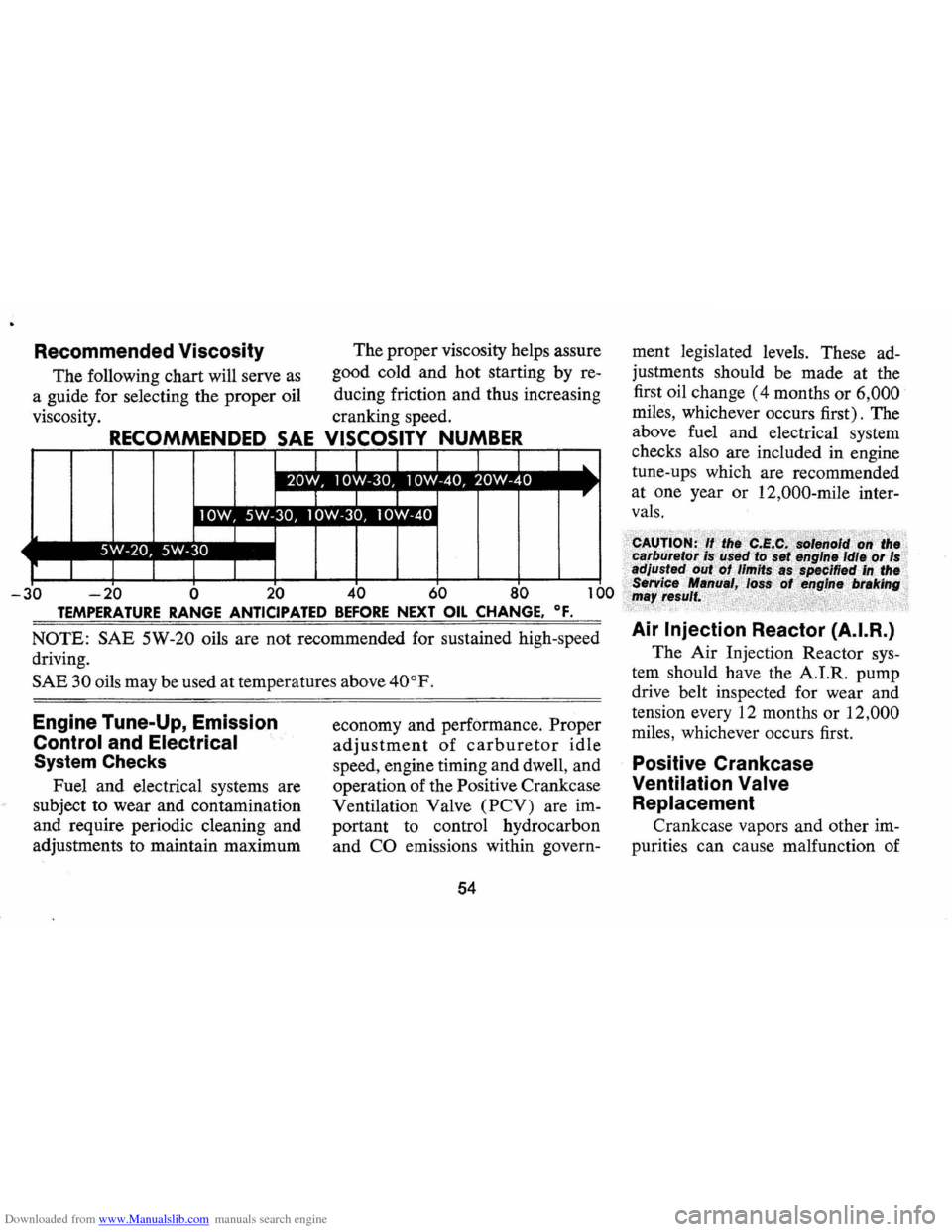

Downloaded from www.Manualslib.com manuals search engine Recommended Viscosity

The following chart will serve as

a guide for selecting the proper oil

viscosity. The

proper viscosity helps assure

good cold and hot starting by re

ducing friction and thus increasing

cranking speed.

OSITY NUMBER

-20 0 20 60 0

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE. OF.

NOTE: SAE 5W-20 oils are not recommended for sustained high-speed

driving.

SAE 30 oils may be used at temperatures above 40°F.

Engine Tune-Up, Emission

Control and Electrical

System Checks

Fuel and electrical systems are

subject to wear and contamination

and require periodic cleaning and

adjustments to maintain maximum economy

and performance. Proper

adjustment of carburetor idle

speed, engine timing and dwell, and

operation of the Positive Crankcase

Ventilation Valve

(PCV) are im

portant to control hydrocarbon

and

CO emissions within govern-

54

ment legislated levels. These ad

justments should be made at the

first oil change

(4 months or 6,000

miles, whichever occurs first). The

above fuel and electrical system

checks also are included in engine

tune-ups which are recommended

at one year or 12,000-mile inter

vals.

Air Injection Reactor (A.I.R.)

The Air Injection Reactor sys

tem should have the A.I.R. pump

drive belt inspected for wear and

tension every 12 months or

12,000

miles, whichever occurs first.

Positive Crankcase

Ventilation

Valve

Replacement

Crankcase vapors and other im

purities can cause malfunction of